relay RENAULT SCENIC 2000 J64 / 1.G Technical Note 3426A Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2000, Model line: SCENIC, Model: RENAULT SCENIC 2000 J64 / 1.GPages: 118, PDF Size: 1.5 MB

Page 21 of 118

Downloaded from www.Manualslib.com manuals search engine ENGINE AND PERIPHERALS

Engine and transmission assembly

10

10-5

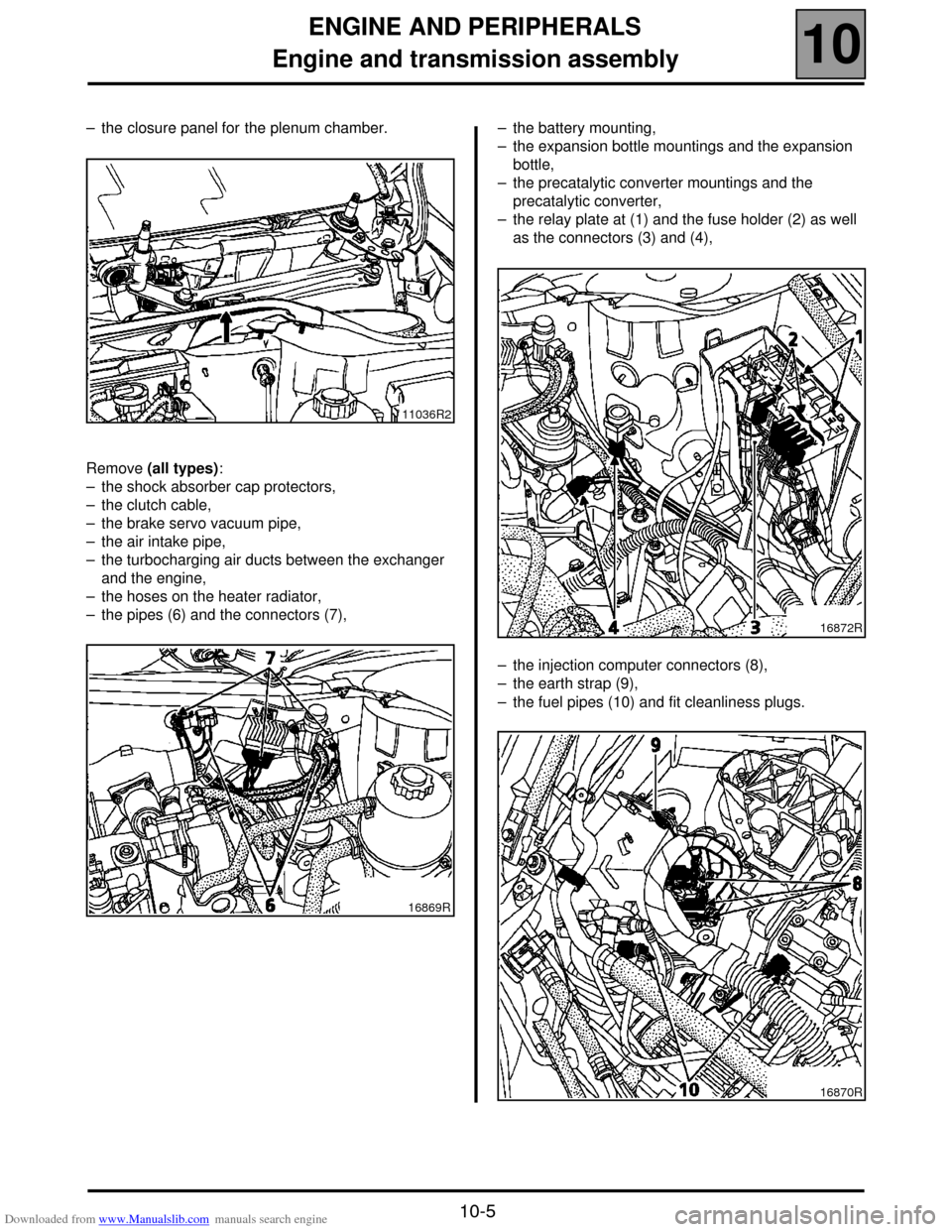

– the closure panel for the plenum chamber.

Remove (all types):

– the shock absorber cap protectors,

– the clutch cable,

– the brake servo vacuum pipe,

– the air intake pipe,

– the turbocharging air ducts between the exchanger

and the engine,

– the hoses on the heater radiator,

– the pipes (6) and the connectors (7),– the battery mounting,

– the expansion bottle mountings and the expansion

bottle,

– the precatalytic converter mountings and the

precatalytic converter,

– the relay plate at (1) and the fuse holder (2) as well

as the connectors (3) and (4),

– the injection computer connectors (8),

– the earth strap (9),

– the fuel pipes (10) and fit cleanliness plugs.

11036R2

16869R

16872R

16870R

Page 63 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Injection warning light

13

13-12

Injection warning light

Vehicles using the high pressure diesel system are fitted with two injection warning lights used during the preheating

phase and in case of an injection fault (or engine overheating).

WARNING LIGHT PRINCIPLE

!When ignition is switched on, the preheating light is lit during the preheating phase and then goes out (see section

13 "Pre-postheating control").

!When there is a fault on the injection system the "fault" warning light lights up. These faults are:

– internal computer fault,

– engine speed fault (the vehicle doesn't start),

– main relay or low pressure fault (the vehicle doesn't start),

– injector fault,

–TDC sensor coherence fault and camshaft sensor,

– rail pressure sensor fault,

– rail pressure regulator fault,

– accelerator potentiometer fault,

– engine immobiliser fault,

– computer supply voltage fault,

– engine overheating.

NOTE: the OBD warning light (symbolised by an engine), visible when the ignition is switched on, is never visible

when the engine is running.

Page 70 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Thermal plunger

13

13-19

Thermal plunger

The three thermal plungers are located on a water unit

fixed under the manifold at the engine - gearbox joint.

The objective of the system is to reheat the coolant.

The thermal plungers are supplied with 12 volts by

two relays. One relay controls two thermal plungers,

and the other relay controls one thermal plunger. This

enables control of one, two or three thermal plungers

as required.

The resistance of the thermal plungers is:

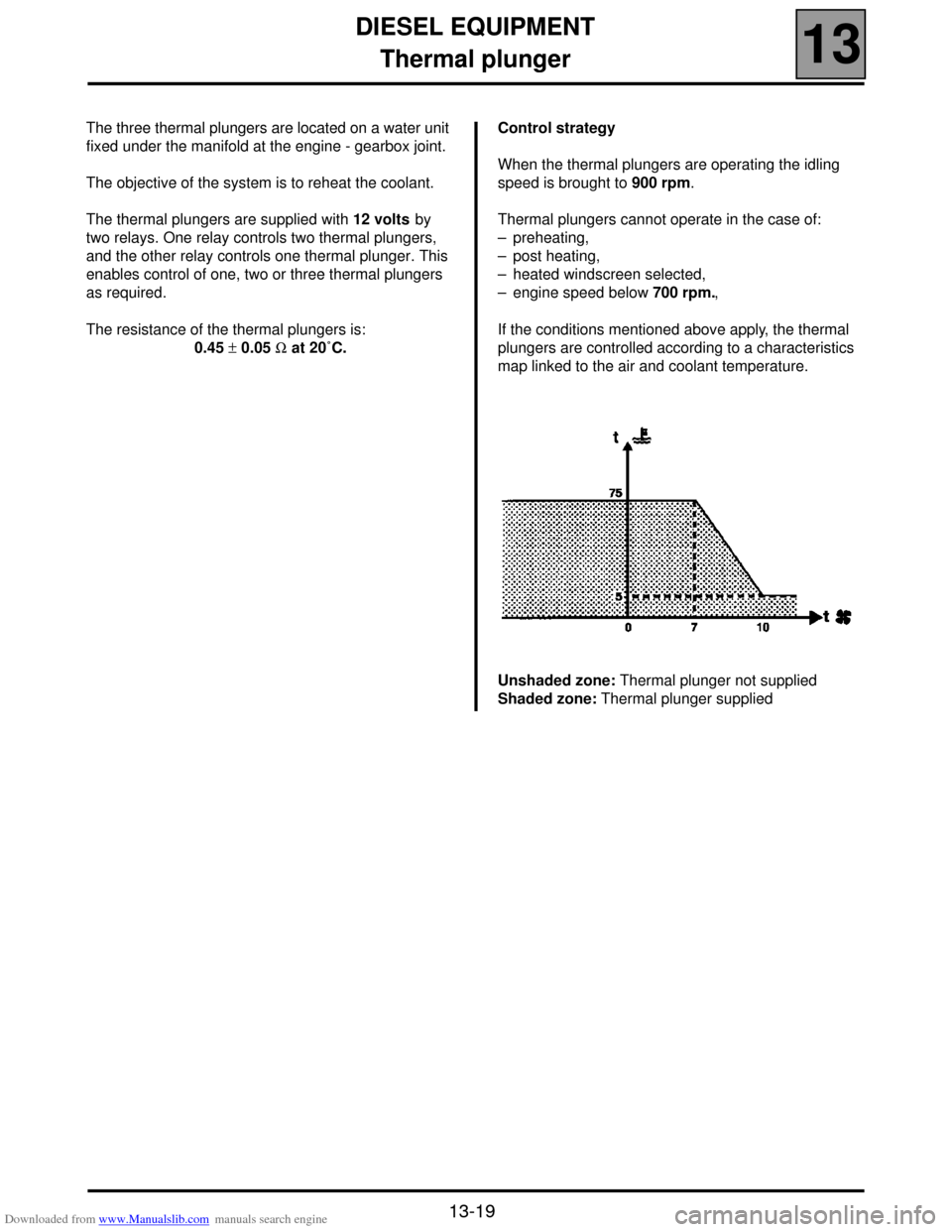

0.45 ± 0.05 Ω at 20˚C. Control strategy

When the thermal plungers are operating the idling

speed is brought to 900 rpm.

Thermal plungers cannot operate in the case of:

– preheating,

– post heating,

– heated windscreen selected,

– engine speed below 700 rpm.,

If the conditions mentioned above apply, the thermal

plungers are controlled according to a characteristics

map linked to the air and coolant temperature.

Unshaded zone: Thermal plunger not supplied

Shaded zone: Thermal plunger supplied

Page 92 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Coolant temperature management

13

13-41

Coolant temperature management

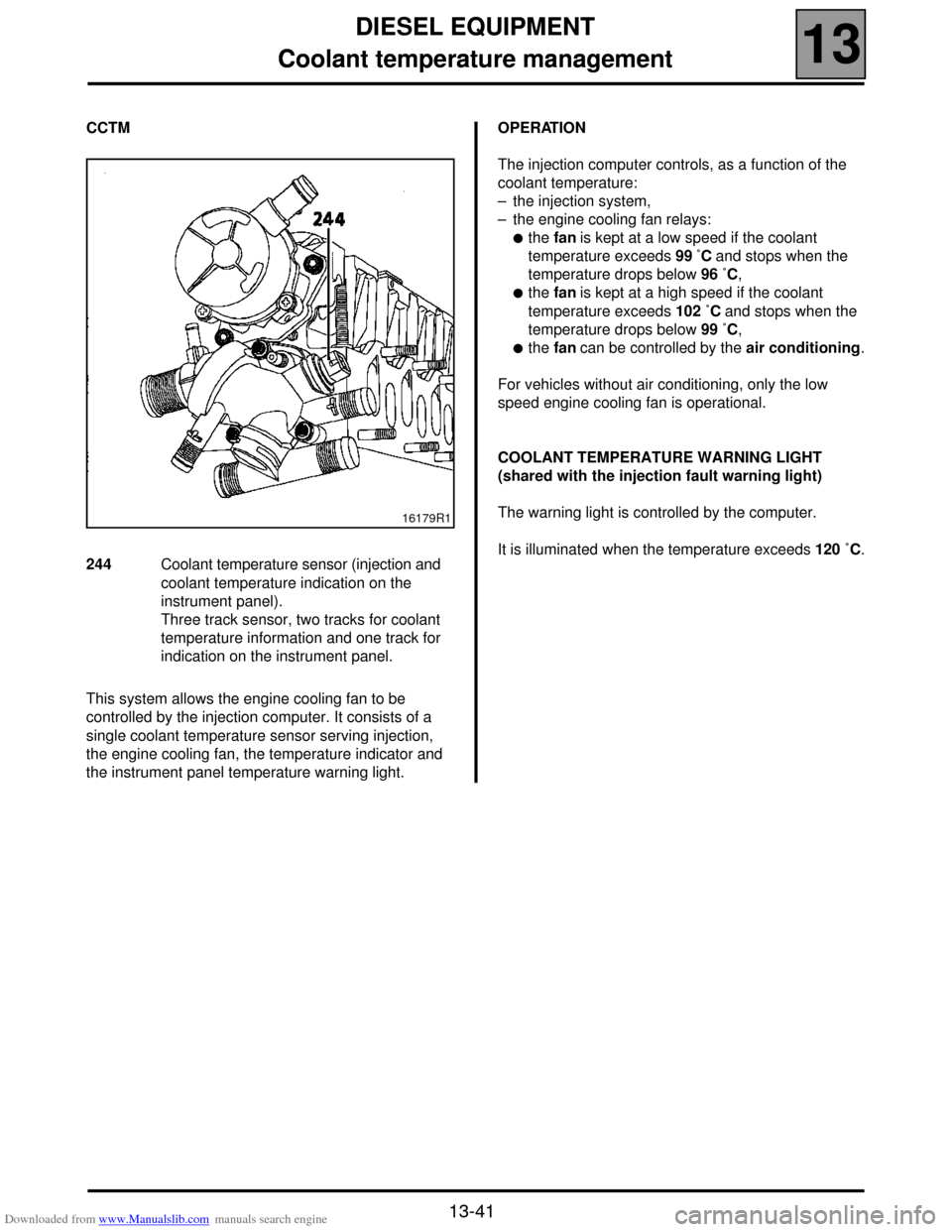

CCTM

This system allows the engine cooling fan to be

controlled by the injection computer. It consists of a

single coolant temperature sensor serving injection,

the engine cooling fan, the temperature indicator and

the instrument panel temperature warning light.OPERATION

The injection computer controls, as a function of the

coolant temperature:

– the injection system,

– the engine cooling fan relays:

!the fan is kept at a low speed if the coolant

temperature exceeds 99 ˚C and stops when the

temperature drops below 96 ˚C,

!the fan is kept at a high speed if the coolant

temperature exceeds 102 ˚C and stops when the

temperature drops below 99 ˚C,

!the fan can be controlled by the air conditioning.

For vehicles without air conditioning, only the low

speed engine cooling fan is operational.

COOLANT TEMPERATURE WARNING LIGHT

(shared with the injection fault warning light)

The warning light is controlled by the computer.

It is illuminated when the temperature exceeds 120 ˚C.

16179R1

244 Coolant temperature sensor (injection and

coolant temperature indication on the

instrument panel).

Three track sensor, two tracks for coolant

temperature information and one track for

indication on the instrument panel.

Page 93 of 118

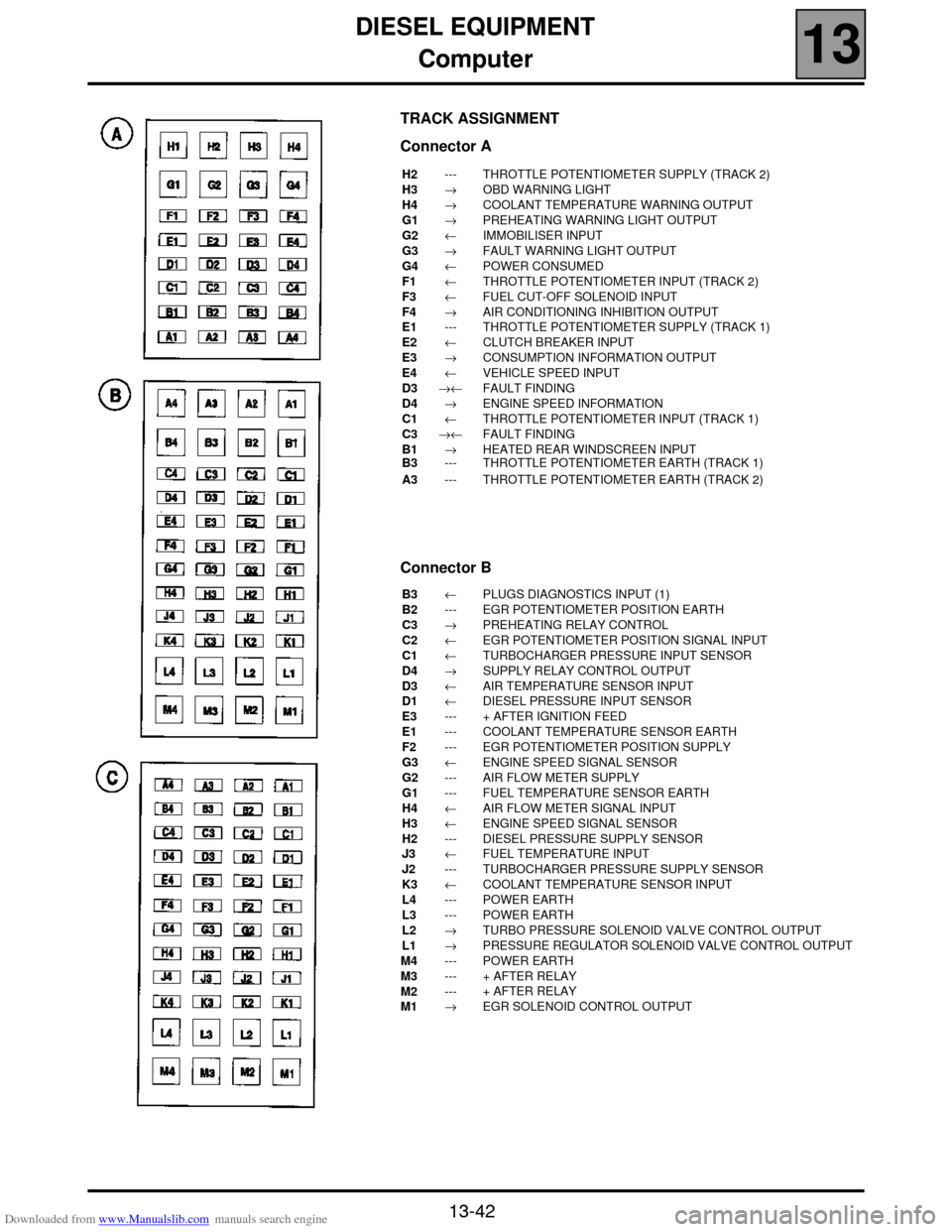

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Computer

13

13-42

Computer

TRACK ASSIGNMENT

Connector A

H2

H3

H4

G1

G2

G3

G4

F1

F3

F4

E1

E2

E3

E4

D3

D4

C1

C3

B1

B3

A3---

→

→

→

←

→

←

←

←

→

---

←

→

←

→←

→

←

→←

→

---

---THROTTLE POTENTIOMETER SUPPLY (TRACK 2)

OBD WARNING LIGHT

COOLANT TEMPERATURE WARNING OUTPUT

PREHEATING WARNING LIGHT OUTPUT

IMMOBILISER INPUT

FAULT WARNING LIGHT OUTPUT

POWER CONSUMED

THROTTLE POTENTIOMETER INPUT (TRACK 2)

FUEL CUT-OFF SOLENOID INPUT

AIR CONDITIONING INHIBITION OUTPUT

THROTTLE POTENTIOMETER SUPPLY (TRACK 1)

CLUTCH BREAKER INPUT

CONSUMPTION INFORMATION OUTPUT

VEHICLE SPEED INPUT

FAULT FINDING

ENGINE SPEED INFORMATION

THROTTLE POTENTIOMETER INPUT (TRACK 1)

FAULT FINDING

HEATED REAR WINDSCREEN INPUT

THROTTLE POTENTIOMETER EARTH (TRACK 1)

THROTTLE POTENTIOMETER EARTH (TRACK 2)

Connector B

B3

B2

C3

C2

C1

D4

D3

D1

E3

E1

F2

G3

G2

G1

H4

H3

H2

J3

J2

K3

L4

L3

L2

L1

M4

M3

M2

M1←

---

→

←

←

→

←

←

---

---

---

←

---

---

←

←

---

←

---

←

---

---

→

→

---

---

---

→PLUGS DIAGNOSTICS INPUT (1)

EGR POTENTIOMETER POSITION EARTH

PREHEATING RELAY CONTROL

EGR POTENTIOMETER POSITION SIGNAL INPUT

TURBOCHARGER PRESSURE INPUT SENSOR

SUPPLY RELAY CONTROL OUTPUT

AIR TEMPERATURE SENSOR INPUT

DIESEL PRESSURE INPUT SENSOR

+ AFTER IGNITION FEED

COOLANT TEMPERATURE SENSOR EARTH

EGR POTENTIOMETER POSITION SUPPLY

ENGINE SPEED SIGNAL SENSOR

AIR FLOW METER SUPPLY

FUEL TEMPERATURE SENSOR EARTH

AIR FLOW METER SIGNAL INPUT

ENGINE SPEED SIGNAL SENSOR

DIESEL PRESSURE SUPPLY SENSOR

FUEL TEMPERATURE INPUT

TURBOCHARGER PRESSURE SUPPLY SENSOR

COOLANT TEMPERATURE SENSOR INPUT

POWER EARTH

POWER EARTH

TURBO PRESSURE SOLENOID VALVE CONTROL OUTPUT

PRESSURE REGULATOR SOLENOID VALVE CONTROL OUTPUT

POWER EARTH

+ AFTER RELAY

+ AFTER RELAY

EGR SOLENOID CONTROL OUTPUT

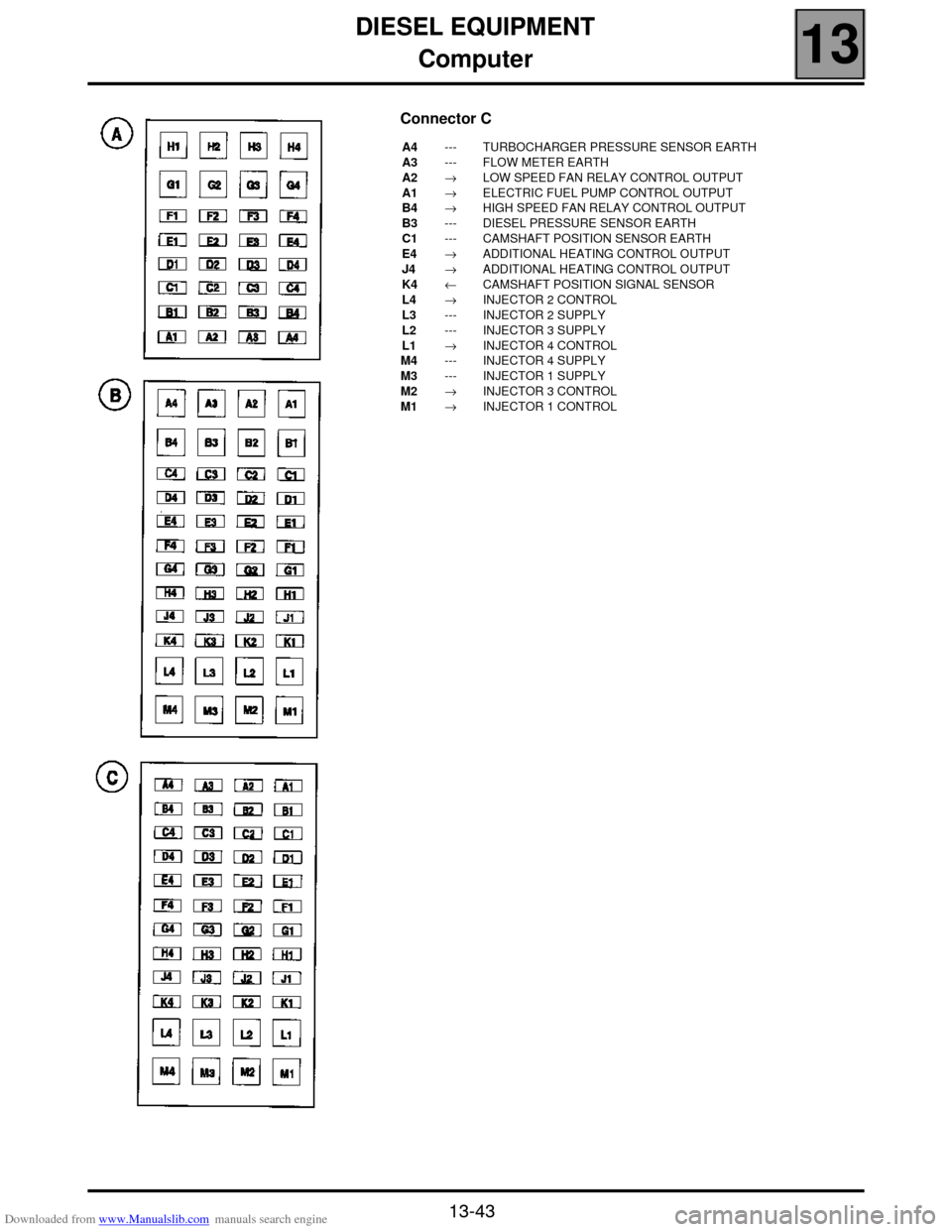

Page 94 of 118

Downloaded from www.Manualslib.com manuals search engine DIESEL EQUIPMENT

Computer

13

13-43

Connector C

A4

A3

A2

A1

B4

B3

C1

E4

J4

K4

L4

L3

L2

L1

M4

M3

M2

M1---

---

→

→

→

---

---

→

→

←

→

---

---

→

---

---

→

→TURBOCHARGER PRESSURE SENSOR EARTH

FLOW METER EARTH

LOW SPEED FAN RELAY CONTROL OUTPUT

ELECTRIC FUEL PUMP CONTROL OUTPUT

HIGH SPEED FAN RELAY CONTROL OUTPUT

DIESEL PRESSURE SENSOR EARTH

CAMSHAFT POSITION SENSOR EARTH

ADDITIONAL HEATING CONTROL OUTPUT

ADDITIONAL HEATING CONTROL OUTPUT

CAMSHAFT POSITION SIGNAL SENSOR

INJECTOR 2 CONTROL

INJECTOR 2 SUPPLY

INJECTOR 3 SUPPLY

INJECTOR 4 CONTROL

INJECTOR 4 SUPPLY

INJECTOR 1 SUPPLY

INJECTOR 3 CONTROL

INJECTOR 1 CONTROL