display RENAULT SCENIC 2006 J84 / 2.G Power Assisted Steering Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2006, Model line: SCENIC, Model: RENAULT SCENIC 2006 J84 / 2.GPages: 56, PDF Size: 0.18 MB

Page 3 of 56

POWER ASSISTED STEERING

Fault finding - Introduction

36B

36B - 3V6 MR-366-X84-36B000$066_eng.mif

PAS

Vdiag No.: 04, 06, 08, 0C

and 12

To cut off the + after ignition feed, proceed as follows:

–disconnect the diagnostic tool,

–press the start button briefly 2 times (less than 3 seconds),

–confirm that the forced + after ignition feed has been cut off by checking that the computer indicator lights on the

instrument panel have gone out.

Faults

Faults are declared as either present or stored (depending on whether they appeared in a certain context and have

disappeared since, or whether they remain present but have not been diagnosed within the current context).

The present or stored status of faults should be taken into consideration when the diagnostic tool is used following

the + after ignition supply being switched on (without acting on the system components).

For a present fault, apply the procedure described in the Interpretation of faults section.

For a stored fault, note the faults displayed and apply the notes section.

If the fault is confirmed when the instructions in the Notes section are applied, the fault is present. Deal with the fault

If the fault is not confirmed, check:

–the electrical lines which correspond to the fault,

–the connectors on these lines (corrosion, bent pins, etc.),

–the resistance of the component detected as faulty,

–the condition of the wires (melted or cut insulation, wear).

Conformity check

The aim of the conformity check is to check data that does not produce a fault on the diagnostic tool when

inconsistent. Therefore, this stage is used to:

–carry out fault finding on faults that do not have a fault display, and which may correspond to a customer

complaint.

–check that the system is operating correctly and that there is no risk of a fault recurring after repairs.

This section gives the fault finding procedures for statuses and parameters and the conditions for checking them.

If a status is not behaving normally or a parameter is outside the permitted tolerance values, consult the

corresponding fault finding page.

Customer complaints - Fault finding chart

If the test with the diagnostic tool is OK but the customer complaint is still present, the fault should be processed by

customer complaint.

A summary of the overall procedure to follow is provided on the following page in the form of a flow chart.

Page 8 of 56

POWER ASSISTED STEERING

Fault finding - System operation

36B

36B - 8V6 MR-366-X84-36B000$132_eng.mif

PAS

Vdiag No.: 04, 06, 08, 0C

and 12

SYSTEM OPERATION

On this vehicle, the steering system is power-assisted by an electric motor (mounted on the steering column). The

driver's actions are translated by a torque sensor, which measures the force applied to the steering wheel by the

driver, and by an angle measuring sensor. The steering wheel angle signal is used by the electronic stability program

computer for the trajectory control programming.

Assistance is provided by means of an electric motor which applies an appropriate torque to the steering column, in

one direction or the other.

A computer controls this assistance according to several vehicle environment parameters, including the vehicle

speed.

NOTE

Depending on the operating conditions and the operations performed on the vehicle before switching on the ignition,

the assistance system may take a certain time to be activated after engine starting; this also applies after battery cut-

off or switching off the ignition.

Fault finding warning lights illumination programming:

Slow flashing of the Service warning light at 2 Hz: the electric power steering system is in fault finding mode.

Rapid flashing of the Service warning light at 8 Hz accompanied by the Check steering message: the steering

wheel angle sensor is not calibrated and not indexed.

Service warning light continuously lit with Check steering displayed on instrument panel: signal received by the

EPAS computer.

–assistance equal to that provided at a speed of 24 mph (40 km/h) if vehicle speed signal is absent or incorrect,

–angle sensor signal invalid: steering wheel angle sensor not calibrated (no active recall).

STOP warning light continuously lit with steering defective displayed on the instrument panel: fault in the EPAS

system.

If the fault is still present after repair, contact the Techline.

Angle sensor programming (initialisation)

The steering wheel angle sensor is initialised after the ignition is switched on. The sensor is not initialised until the

steering wheel has gone through a quarter turn left or right. If this turn is not carried out, the steering wheel angle

value reading will be 1.2 degrees higher or lower than the actual value.

Check consistency of ET020 Steering wheel angle sensor programming. Note:

If the computer detects a fault, the level of assistance can be modified depending on how serious the fault is.

An incorrect or absent vehicle speed signal results in fixed, unsatisfactory assistance.

Page 11 of 56

POWER ASSISTED STEERING

Fault finding - Configurations and programming36B

36B - 11V6 MR-366-X84-36B000$330_eng.mif

PAS

Vdiag No.: 04, 06, 08, 0C

and 12POWER ASSISTED STEERING

Fault finding - Configurations and programming

VP004: STEERING WHEEL ANGLE SENSOR PROGRAMMING

NOTESThis programming procedure is performed after replacing the EPAS computer.

WARNING

Programming the steering wheel angle sensor means programming the 0 angle (wheels straight ahead position).

It must be done for any blank computer, and every time it is requested in this note.

The absence of or incorrect programming of this sensor will illuminate the Service warning light and create an

Electronic Stability Program fault.

OPERATIONS TO PERFORM BEFORE PROGRAMMING

–With the ignition on or engine running (to obtain maximum steering assistance), turn the steering wheel to full

left lock and then to full right lock,

–position the vehicle with the wheels straight ahead and the steering at the centre point (driving in a straight line),

–run the command by pressing the CONFIRM button,

–while the COMMAND IN PROGRESS message is displayed, turn the steering wheel a quarter of a turn from left

to right.

–Once the COMMAND COMPLETE message is displayed, exit fault finding mode (close dialogue with the

computer without switching off the tool) and then switch off the vehicle's ignition for 15 seconds minimum for

the programming to be registered.

Note:

To obtain a precise position with the wheels set straight ahead (driving in a straight line), this operation must be

performed on a front axle adjustment bench (especially for vehicles fitted with ESP).

OPERATIONS TO PERFORM AFTER PROGRAMMING

–Switch on the ignition and establish dialogue with the EPAS computer,

–turn the steering wheel to full left lock and then to full right lock,

–check that the programming has been properly registered: ET020 Steering wheel angle sensor programming

should be STATUS 4,

–check the conformity of the angle value by consulting parameter PR121 Steering wheel angle,

–check that there are no faults,

–carry out the necessary repairs, consulting the fault finding manual.

IMPORTANT

If the vehicle is fitted with ESP, establish dialogue with the ABS/ESP computer after the operation; if the function

is available (depending on computer version) clear the ESP sensor programming using command RZ003.

Make sure there are no ESP faults: make the necessary repairs, consulting the fault finding manual.

MR-366-X84-36B000$330_eng.mif

Page 25 of 56

POWER ASSISTED STEERING

Fault finding - Conformity check

36B

36B - 25V6 MR-366-X84-36B000$528_eng.mif

PAS

Vdiag No.: 04, 06, 08, 0C

and 12POWER ASSISTED STEERING

Fault finding - Conformity check

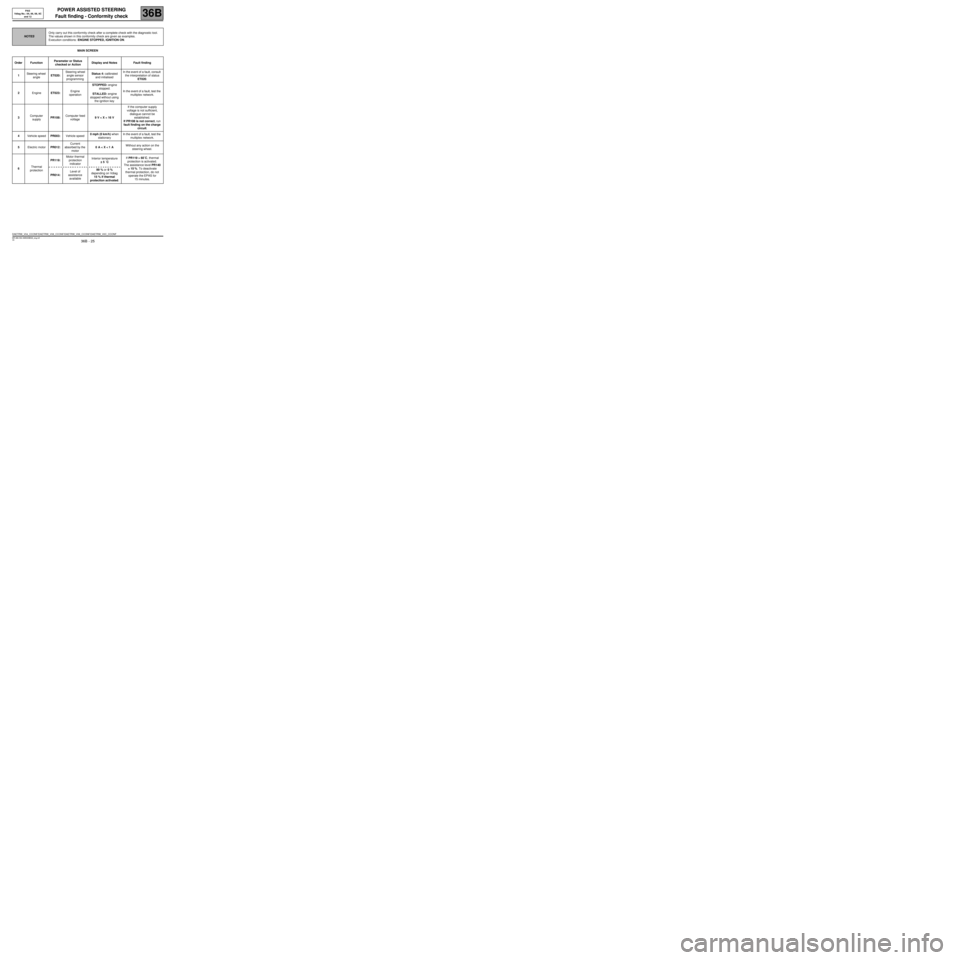

MAIN SCREEN

NOTESOnly carry out this conformity check after a complete check with the diagnostic tool.

The values shown in this conformity check are given as examples.

Execution conditions: ENGINE STOPPED, IGNITION ON.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

1Steering wheel

angleET020:Steering wheel

angle sensor

programmingStatus 4: calibrated

and initialisedIn the event of a fault, consult

the interpretation of status

ET020.

2EngineET023:Engine

operationSTOPPED: engine

stopped.

STALLED: engine

stopped without using

the ignition keyIn the event of a fault, test the

multiplex network.

3Computer

supplyPR108:Computer feed

voltage9 V < X < 16 VIf the computer supply

voltage is not sufficient,

dialogue cannot be

established.

If PR108 is not correct, run

fault finding on the charge

circuit.

4Vehicle speedPR003:Vehicle speed0 mph (0 km/h) when

stationaryIn the event of a fault, test the

multiplex network.

5Electric motorPR012:Current

absorbed by the

motor0 A < X < 1 AWithout any action on the

steering wheel.

6Thermal

protectionPR119:Motor thermal

protection

indicatorInterior temperature

± 5 ˚CIf PR119 > 60˚C, thermal

protection is activated.

The assistance level PR140

= 15 %. To deactivate

thermal protection, do not

operate the EPAS for

15 minutes. PR014:Level of

assistance

available99 % or 0 %

depending on Vdiag

15 % if thermal

protection activated.

DAETRW_V04_CCONF/DAETRW_V08_CCONF/DAETRW_V06_CCONF/DAETRW_V0C_CCONF

MR-366-X84-36B000$528_eng.mif

Page 26 of 56

POWER ASSISTED STEERING

Fault finding - Conformity check

36B

36B - 26V6 MR-366-X84-36B000$528_eng.mif

PAS

Vdiag No.: 04, 06, 08, 0C

and 12

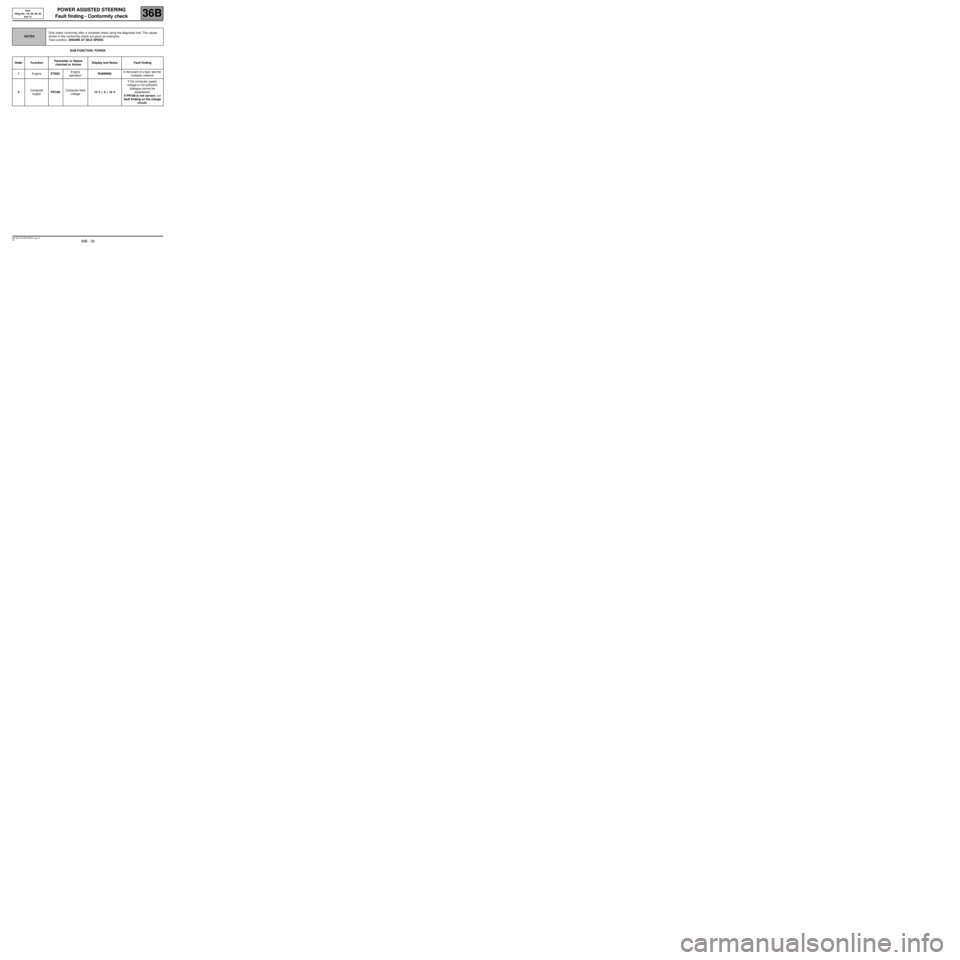

SUB-FUNCTION: POWER

NOTESOnly carry out this conformity check after a complete check with the diagnostic tool.

The values shown in this conformity check are given as examples.

Execution conditions: ENGINE STOPPED, IGNITION ON.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

1EngineET023:Engine

operationSTOPPED or

STALLEDIn the event of a fault, test the

multiplex network.

2Computer

supplyPR108:Computer feed

voltage9 V < X < 16 VIf the computer supply

voltage is not sufficient,

dialogue cannot be

established.

If PR108 is not correct, run

fault finding on the charge

circuit.

Page 27 of 56

POWER ASSISTED STEERING

Fault finding - Conformity check

36B

36B - 27V6 MR-366-X84-36B000$528_eng.mif

PAS

Vdiag No.: 04, 06, 08, 0C

and 12

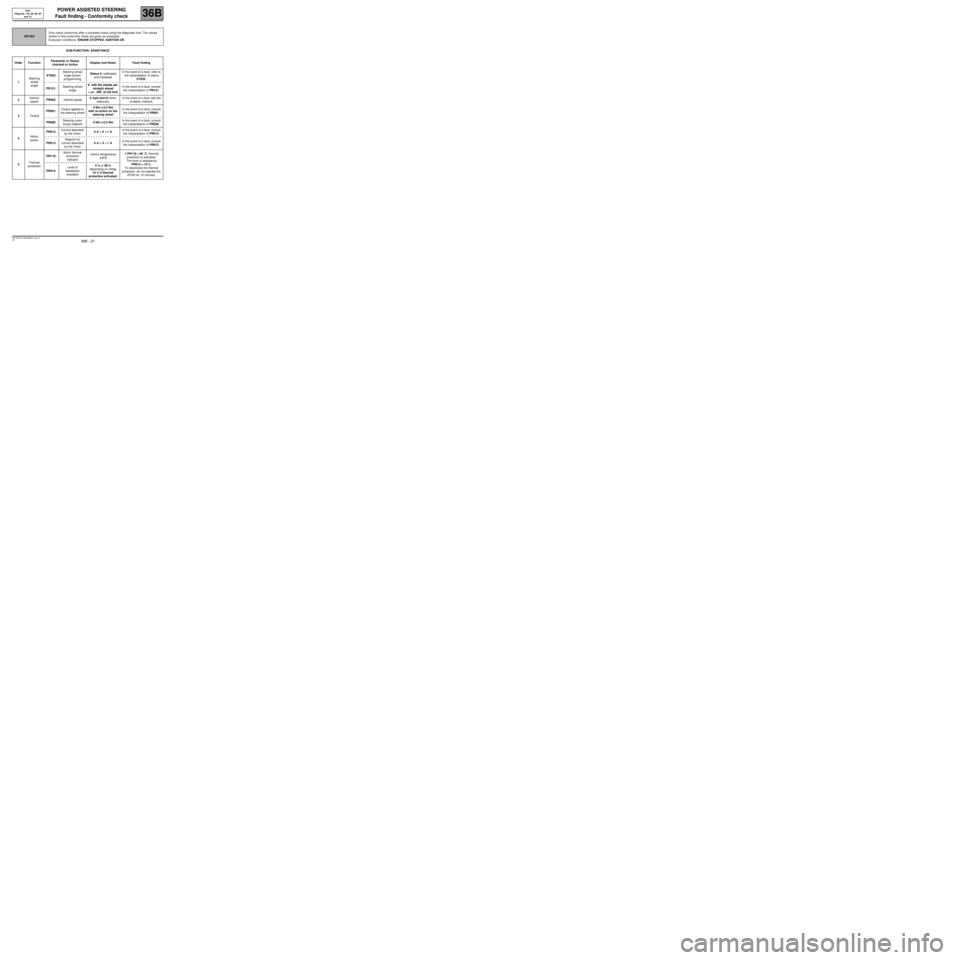

SUB-FUNCTION: ASSISTANCE

NOTESOnly check conformity after a complete check using the diagnostic tool. The values

shown in this conformity check are given as examples.

Execution conditions: ENGINE STOPPED, IGNITION ON.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

1Steering

wheel

angleET020:Steering wheel

angle sensor

programmingStatus 4: calibrated

and initialisedIn the event of a fault, refer to

the interpretation of status

ET020.

PR121:Steering wheel

angle0˚ with the wheels set

straight ahead

+ or - 580˚ at full lockIn the event of a fault, consult

the interpretation of PR121.

2Vehicle

speedPR003:Vehicle speed0 mph (km/h) when

stationaryIn the event of a fault, test the

multiplex network.

3TorquePR001:Torque applied to

the steering wheel0 Nm ± 0.2 Nm

with no action on the

steering wheelIn the event of a fault, consult

the interpretation of PR001.

PR006:Steering motor

torque setpoint0 Nm ± 0.2 NmIn the event of a fault, consult

the interpretation of PR006.

4Motor

powerPR012:Current absorbed

by the motor0 A < X < 1 AIn the event of a fault, consult

the interpretation of PR012.

PR013:Setpoint for

current absorbed

by the motor0 A < X < 1 AIn the event of a fault, consult

the interpretation of PR013.

5Thermal

protectionPR119:Motor thermal

protection

indicatorInterior temperature

± 5˚CIf PR119 > 60 ˚C, thermal

protection is activated.

The level of assistance

PR014 = 15 %.

To deactivate the thermal

protection, do not operate the

EPAS for 15 minutes. PR014:Level of

assistance

available0 % or 99 %

depending on Vdiag

15 % if thermal

protection activated.

Page 28 of 56

POWER ASSISTED STEERING

Fault finding - Conformity check

36B

36B - 28V6 MR-366-X84-36B000$528_eng.mif

PAS

Vdiag No.: 04, 06, 08, 0C

and 12

SUB-FUNCTION: ASSISTANCE (CONTINUED)

NOTESOnly carry out this conformity check after a complete check with the diagnostic tool.

The values shown in this conformity check are given as examples.

Execution conditions: ENGINE STOPPED, IGNITION ON.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

6Computer

calibrationET026:Computer

calibrationConfiguration 1 to 5

according to

equipment and vehicle

type.Redefine the vehicle

specifications using

command SC001 Computer

calibration.

Page 29 of 56

POWER ASSISTED STEERING

Fault finding - Conformity check

36B

36B - 29V6 MR-366-X84-36B000$528_eng.mif

PAS

Vdiag No.: 04, 06, 08, 0C

and 12

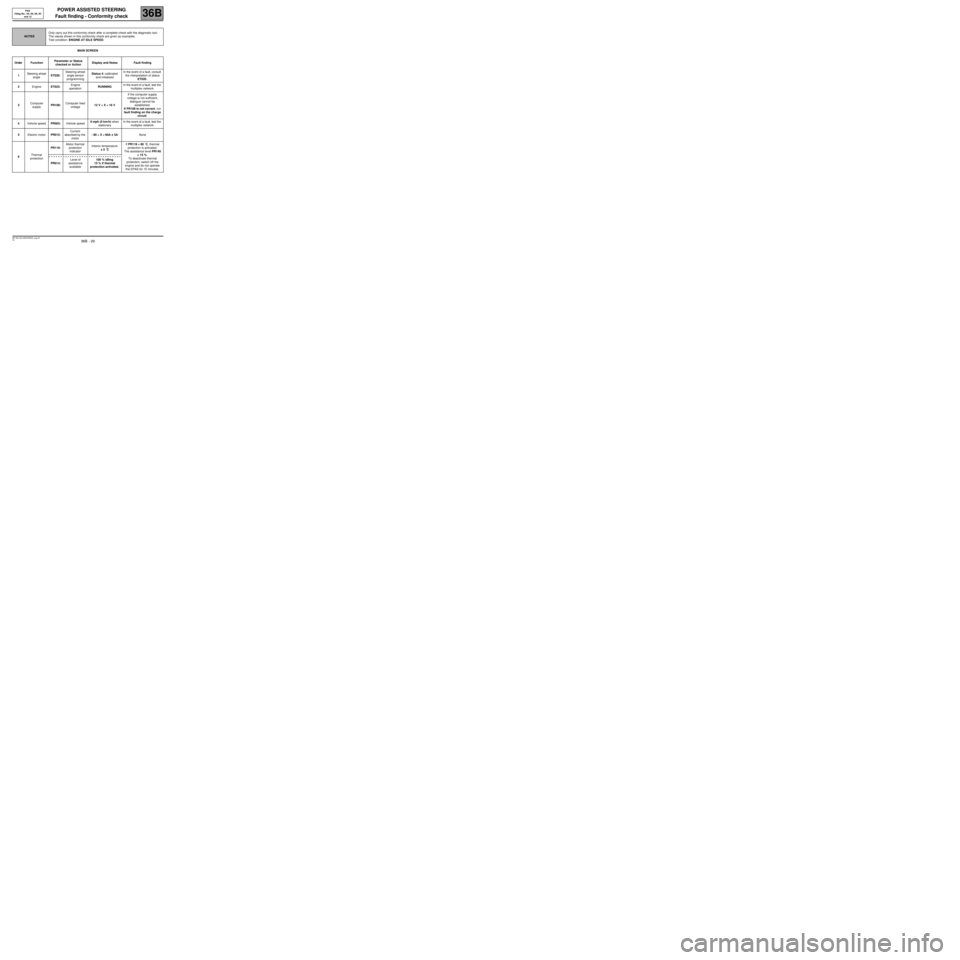

MAIN SCREEN

NOTESOnly carry out this conformity check after a complete check with the diagnostic tool.

The values shown in this conformity check are given as examples.

Test condition: ENGINE AT IDLE SPEED.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

1Steering wheel

angleET020:Steering wheel

angle sensor

programmingStatus 4: calibrated

and initialisedIn the event of a fault, consult

the interpretation of status

ET020.

2EngineET023:Engine

operationRUNNINGIn the event of a fault, test the

multiplex network.

3Computer

supplyPR108:Computer feed

voltage12 V < X < 16 VIf the computer supply

voltage is not sufficient,

dialogue cannot be

established.

If PR108 is not correct, run

fault finding on the charge

circuit.

4Vehicle speedPR003:Vehicle speed0 mph (0 km/h) when

stationaryIn the event of a fault, test the

multiplex network.

5Electric motorPR012:Current

absorbed by the

motor- 90 < X < 90A ± 5ANone

6Thermal

protectionPR119:Motor thermal

protection

indicatorInterior temperature

± 5 ˚CIf PR119 > 60 ˚C, thermal

protection is activated.

The assistance level PR140

= 15 %.

To deactivate thermal

protection, switch off the

engine and do not operate

the EPAS for 15 minutes. PR014:Level of

assistance

available100 % idling

15 % if thermal

protection activated.

Page 30 of 56

POWER ASSISTED STEERING

Fault finding - Conformity check

36B

36B - 30V6 MR-366-X84-36B000$528_eng.mif

PAS

Vdiag No.: 04, 06, 08, 0C

and 12

SUB-FUNCTION: POWER

NOTESOnly check conformity after a complete check using the diagnostic tool. The values

shown in this conformity check are given as examples.

Test condition: ENGINE AT IDLE SPEED.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

1EngineET023:Engine

operationRUNNINGIn the event of a fault, test the

multiplex network.

2Computer

supplyPR108:Computer feed

voltage12 V < X < 16 VIf the computer supply

voltage is not sufficient,

dialogue cannot be

established.

If PR108 is not correct, run

fault finding on the charge

circuit.

Page 31 of 56

POWER ASSISTED STEERING

Fault finding - Conformity check

36B

36B - 31V6 MR-366-X84-36B000$528_eng.mif

PAS

Vdiag No.: 04, 06, 08, 0C

and 12

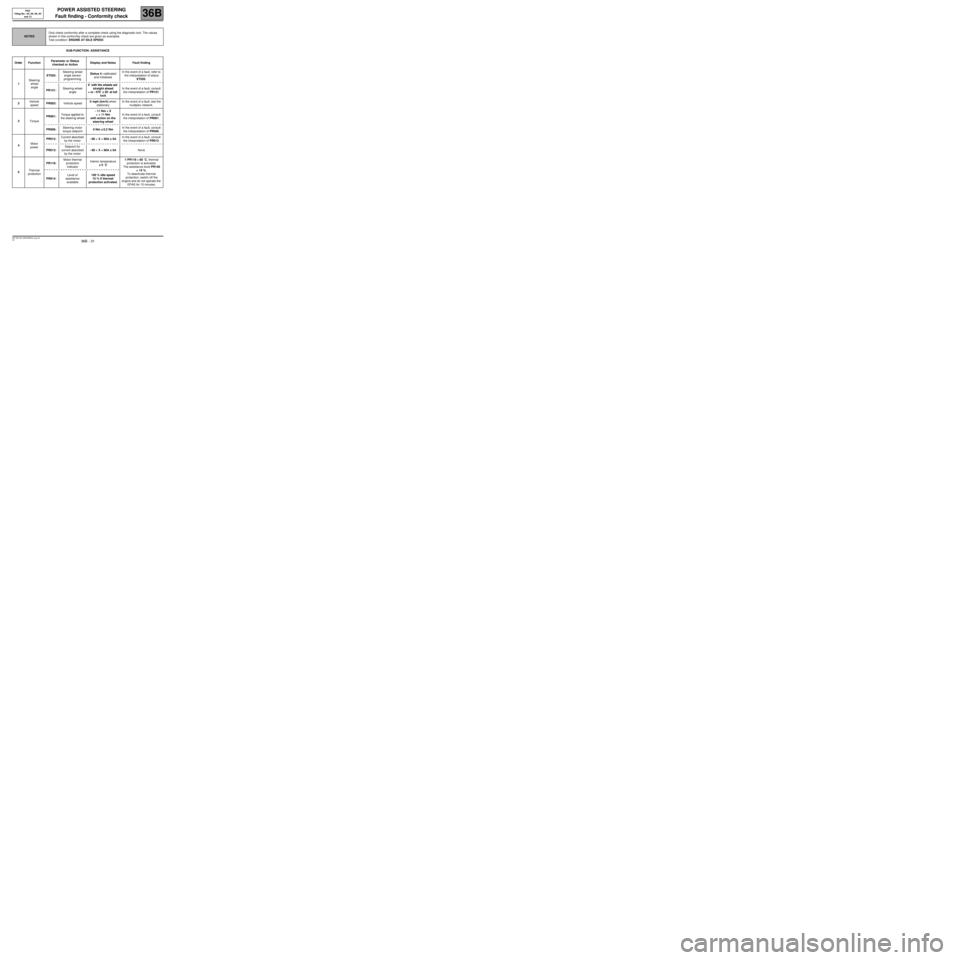

SUB-FUNCTION: ASSISTANCE

NOTESOnly check conformity after a complete check using the diagnostic tool. The values

shown in this conformity check are given as examples.

Test condition: ENGINE AT IDLE SPEED.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

1Steering

wheel

angleET020:Steering wheel

angle sensor

programmingStatus 4: calibrated

and initialisedIn the event of a fault, refer to

the interpretation of status

ET020.

PR121:Steering wheel

angle0˚ with the wheels set

straight ahead

+ or - 570˚ ± 20˚ at full

lockIn the event of a fault, consult

the interpretation of PR121.

2Vehicle

speedPR003:Vehicle speed0 mph (km/h) when

stationaryIn the event of a fault, test the

multiplex network.

3TorquePR001:Torque applied to

the steering wheel- 11 Nm < X

< + 11 Nm

with action on the

steering wheelIn the event of a fault, consult

the interpretation of PR001.

PR006:Steering motor

torque setpoint0 Nm ± 0.2 NmIn the event of a fault, consult

the interpretation of PR006.

4Motor

powerPR012:Current absorbed

by the motor- 90 < X < 90A ± 5AIn the event of a fault, consult

the interpretation of PR012.

PR013:Setpoint for

current absorbed

by the motor- 90 < X < 90A ± 5ANone

5Thermal

protectionPR119:Motor thermal

protection

indicatorInterior temperature

± 5 ˚CIf PR119 > 60 ˚C, thermal

protection is activated.

The assistance level PR140

= 15 %.

To deactivate thermal

protection, switch off the

engine and do not operate the

EPAS for 15 minutes. PR014:Level of

assistance

available100 % idle speed

15 % if thermal

protection activated.