display RENAULT SCENIC 2006 J84 / 2.G Tyre Pressure Monitoring Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2006, Model line: SCENIC, Model: RENAULT SCENIC 2006 J84 / 2.GPages: 37, PDF Size: 0.15 MB

Page 4 of 37

TYRE PRESSURE MONITOR

Fault finding - Introduction

35B

35B-3

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50

To cut off + after ignition, proceed as follows:

–Disconnect the diagnostic tool.

–Press the Start button twice briefly (less than 3 seconds),

–See that the + after ignition feed has been cut off by checking that the computer warning lights on the

instrument panel have gone out.

Faults

The current status of faults must be considered when the diagnostic tool is used following switching to + after

ignition (with no action on the system components).

For a present fault, handle the fault according to the procedure listed in the section on Interpretation of faults in

Workshop Repair Manual 372 Section 87B Passenger compartment connection unit.

There is no stored fault on the tyre pressure monitor.

Conformity check

The aim of the conformity check is to check statuses and parameters that do not produce a fault display on the

diagnostic tool when they are inconsistent. Therefore, this stage is used to:

–carry out fault finding on faults that do not have a fault display, and which may correspond to a customer

complaint.

–check that the system is operating correctly and that there is no risk of a fault recurring after repairs.

This section features the fault finding procedure for statuses and parameters, and the conditions for checking them.

If a status is not operating normally or a parameter is outside permitted tolerance values, you should consult the

corresponding fault finding page.

Customer complaints - Fault finding chart

If the check using the diagnostic tool is satisfactory but the customer complaint is still present, the fault should be

treated as a customer complaint.

A summary of the overall procedure to follow is provided on the following page

in the form of a flow chart.

Edition 4

Page 8 of 37

List of monitored parts: Computer, valves, receivers

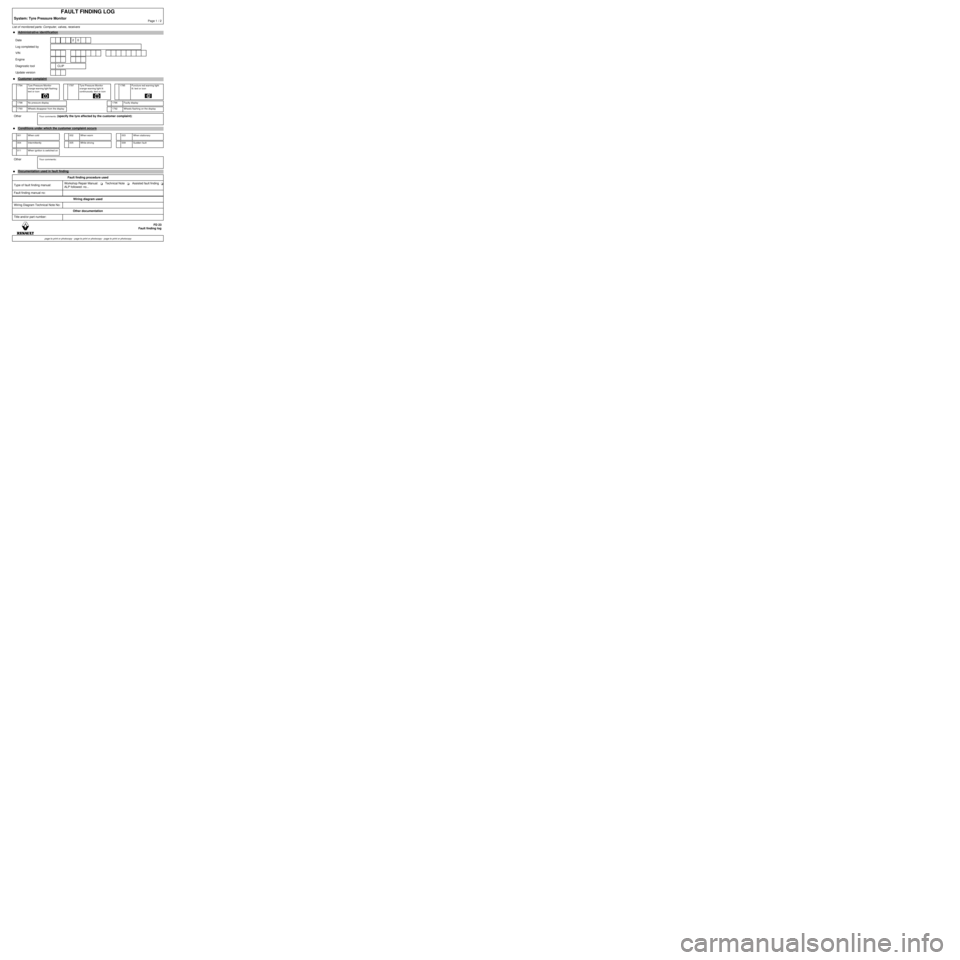

FAULT FINDING LOG

System: Tyre Pressure MonitorPage 1 / 2

●Administrative identification

Date 2 0

Log completed by

VIN

Engine

Diagnostic tool CLIP

Update version

●Customer complaint

1794 Tyre Pressure Monitor

orange warning light flashing:

text or icon

1797 Tyre Pressure Monitor

orange warning light lit

continuously: text or icon

1795 Puncture red warning light

lit: text or icon

1798 No pressure display 1796 Faulty display

1793 Wheels disappear from the display 1792 Wheels flashing on the display

OtherYour comments: (specify the tyre affected by the customer complaint):

●Conditions under which the customer complaint occurs

001 When cold 002 When warm 003 When stationary

004 Intermittently 005 While driving 009 Sudden fault

011 When ignition is switched on

OtherYour comments:

●

Documentation used in fault finding

Fault finding procedure used

Type of fault finding manual:Workshop Repair Manual: Technical Note Assisted fault finding

ALP followed: no...

Fault finding manual no:

Wiring diagram used

Wiring Diagram Technical Note No:

Other documentation

Title and/or part number:

FD 23

Fault finding log

page to print or photocopy - page to print or photocopy - page to print or photocopy

Page 10 of 37

TYRE PRESSURE MONITOR

Fault finding - System operation

35B

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50TYRE PRESSURE MONITOR

Fault finding - System operation

SYSTEM COMPOSITION

The tyre pressure monitor system consists of the following components:

–four sensors (one on each wheel but not on the emergency spare wheel)

–a computer (UCH)

–a receiver aerial (17-cm bare wire connected to the UCH)

–an instrument panel display for the driver

In addition to these components, the PAX system is comprised of four special tyres with a support ring to allow flat

tyre driving following a puncture over a maximum distance of 120 miles (200 km), at a maximum speed of 48 mph

(80 km/h).

WARNING

It is forbidden to install PAX System tyres on a vehicle without PAX System tyres as standard.

Edition 435B-9

Page 11 of 37

TYRE PRESSURE MONITOR

Fault finding - System operation

35B

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50

System operation:

–The valves are activated after driving at a speed greater than 12 mph (20 km/h).

–During driving, the valves emit signals every minute.

–The valves remain active for 15 minutes after the vehicle stops, then switch to standby mode.

–In standby mode, the valves emit signals only if they detect a pressure difference between two successive

measurements greater than 68 mbar or if the pressure difference since last emitting is greater than 68 mbar (due

to tyre cooling).

–The tyres are considered to be cold when the vehicle speed has been zero for 1h 45 min.

–The minimum time for detection of a leak is approximately 15 minutes.

–The message Pressure unsuitable for the speed is activated only if the vehicle travels at more than 102 mph

(170 km/h) (as an indication) for 3 minutes and the pressure on at least one of the tyres is 400 mbar less than the

recommended pressure at low speed. This message is inactive if the tyres are inflated to motorway pressure,

irrespective of the vehicle speed.

–Alert thresholds:

–over-inflated while cold =recommended pressure + 700 mbar

–over-inflated while warm = recommended pressure + 850 mbar

–under-inflated = recommended pressure - 400 mbar

–very under-inflated = recommended pressure - 600 mbar

–imbalance = difference in pressure between the left-hand and right-hand wheels on the same axle greater

than 500 mbar

–Tyre pressure monitor information messages for the driver:

–"PUNCTURE: CHANGE TYRE" + STOP warning light + highlighting of the wheel concerned on the

instrument panel display + buzzer.

–"ADJUST TYRE PRESSURE" + highlighting of the wheel concerned on the instrument panel.

–"INFLATE TYRES MOTORWAY" + highlighting of all four wheels on the instrument panel.

–"TYRE SENSOR INOPERATIVE" + clearing of the wheel concerned.

–"ELECTRONIC FAULT" + "Service" warning light + the wheels concerned disappear from the

instrument panel.

–Tyre pressure monitor information messages for a puncture with the PAX System:

–"PUNCTURE: REPAIR TYRE" + highlighting of the wheel concerned on the instrument panel.

–"PUNCTURE: SLOW DOWN" + buzzer (if vehicle speed > 48 mph (80 km/h)).

–"DRIVING WITH FLAT: X MILES REMAINING" (X decreases from 120 miles (200 km) to 0) + STOP

warning light when X = 0 + highlighting of the wheel concerned on the instrument panel.

⇒

No instrument panel display of tyre pressure on the SCENIC II.

Edition 435B-10

Page 15 of 37

TYRE PRESSURE MONITOR

Fault finding - Configurations and programming

35B

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50TYRE PRESSURE MONITOR

Fault finding - Configurations and programming

SC002:

PROGRAMMING THE FOUR VALVE CODES

IMPORTANT

Any repairs that involve replacement of a wheel sensor require knowledge of the recommendations

defined in Workshop Repair Manual 371 section 35.

–Inflate the four tyres to 3.8 bar.

–Using the diagnostic tool, establish dialogue with the UCH.

–Select the Repair mode menu

–Select the Programming menu

–Select line SC002 Programming the four valve codes under the Tyres function.

Display of stored codes and recognised valve set.

–Select the Valve set selection menu, then Summer or Winter.

–Confirm to obtain the table "valve programming conditions".

–Confirm by selecting next, which brings up the search for valve code menu.

–Excite each valve by holding the valve exciter on the tyre, just under the valve in question.

–Start with the front left-hand wheel.

–Wait for the new code to appear on the screen before moving on to the next valve.

–Program the codes in the following order:

Front left-hand Front right-hand Rear right-hand Rear left-hand

–Click on the "Confirm" button to transmit the codes to the UCH.

–Inflate the tyres to the recommended pressures.

–Carry out a road test: speed > 12 mph (20 km/h) for 10 minutes.

–Make sure no message appears on the instrument panel.

IMPORTANT

When swapping wheels over, reprogram the UCH for the new valve positions using the diagnostic tool and

programming the valve codes.

Then replace the colour rings in the locations noted on the label on the driver's door.

Edition 435B-14

Page 16 of 37

TYRE PRESSURE MONITOR

Fault finding - Configurations and programming

35B

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50

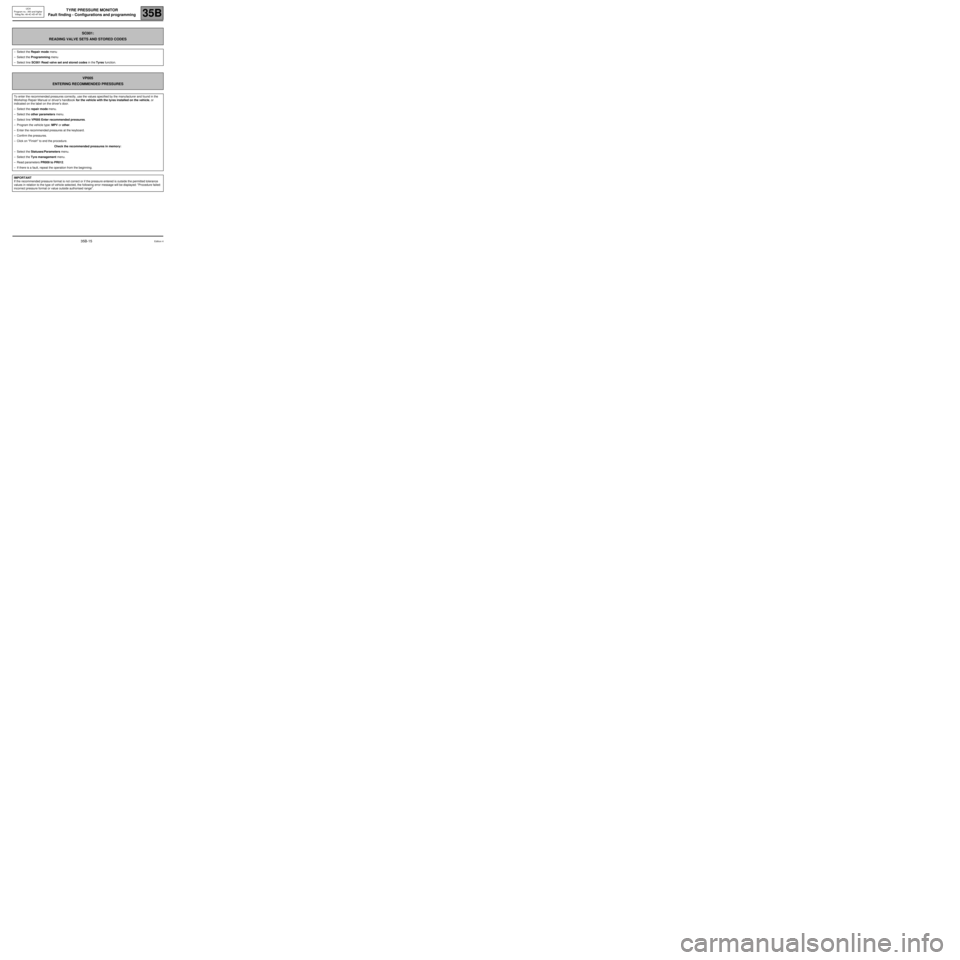

SC001:

READING VALVE SETS AND STORED CODES

–Select the Repair mode menu

–Select the Programming menu

–Select line SC001 Read valve set and stored codes in the Tyres function.

VP005

ENTERING RECOMMENDED PRESSURES

To enter the recommended pressures correctly, use the values specified by the manufacturer and found in the

Workshop Repair Manual or driver's handbook for the vehicle with the tyres installed on the vehicle, or

indicated on the label on the driver's door.

–Select the repair mode menu.

–Select the other parameters menu.

–Select line VP005 Enter recommended pressures.

–Program the vehicle type: MPV or other.

–Enter the recommended pressures at the keyboard.

–Confirm the pressures.

–Click on "Finish" to end the procedure.

Check the recommended pressures in memory:

–Select the Statuses/Parameters menu.

–Select the Tyre management menu.

–Read parameters PR009 to PR012.

–If there is a fault, repeat the operation from the beginning.

IMPORTANT

If the recommended pressure format is not correct or if the pressure entered is outside the permitted tolerance

values in relation to the type of vehicle selected, the following error message will be displayed: "Procedure failed:

incorrect pressure format or value outside authorised range".

Edition 435B-15

Page 17 of 37

TYRE PRESSURE MONITOR

Fault finding - Configurations and programming

35B

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50

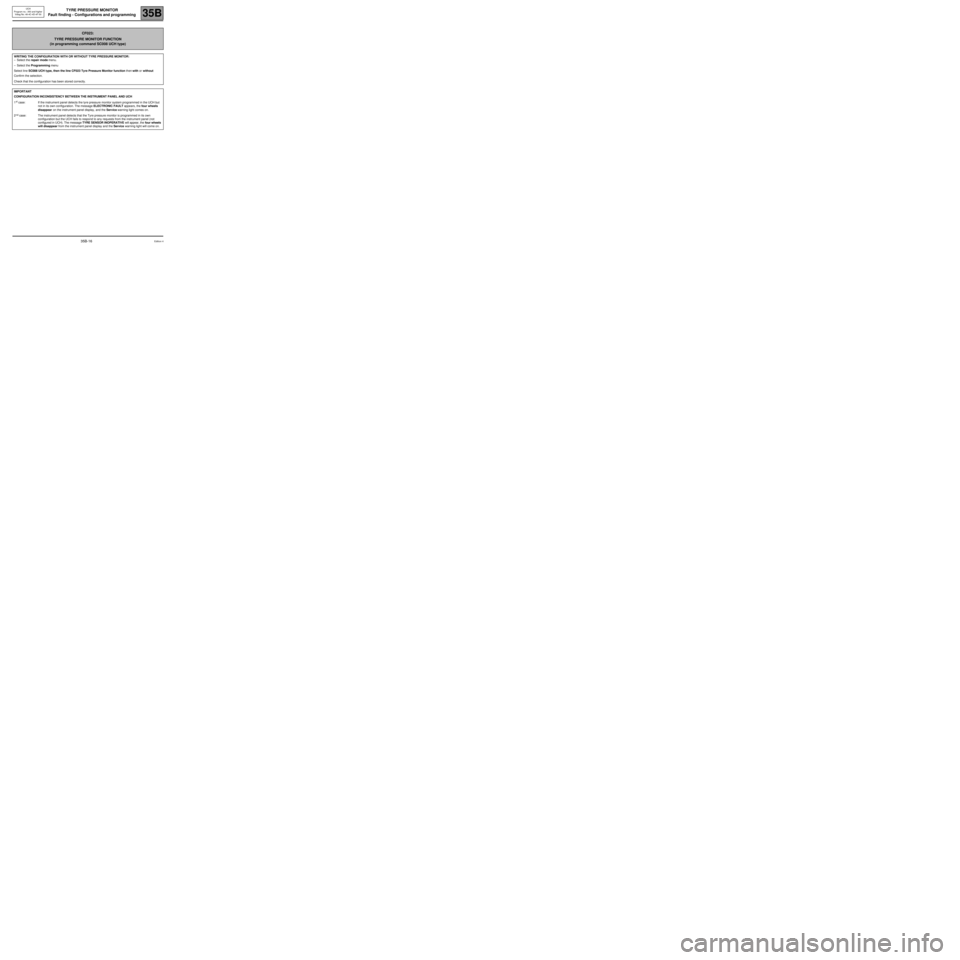

CF023:

TYRE PRESSURE MONITOR FUNCTION

(in programming command SC008 UCH type)

WRITING THE CONFIGURATION WITH OR WITHOUT TYRE PRESSURE MONITOR:

–Select the repair mode menu.

–Select the Programming menu

Select line SC008 UCH type, then the line CF023 Tyre Pressure Monitor function then with or without

Confirm the selection.

Check that the configuration has been stored correctly.

IMPORTANT

CONFIGURATION INCONSISTENCY BETWEEN THE INSTRUMENT PANEL AND UCH

1

st case: If the instrument panel detects the tyre pressure monitor system programmed in the UCH but

not in its own configuration. The message ELECTRONIC FAULT appears, the four wheels

disappear on the instrument panel display, and the Service warning light comes on.

2

nd case: The instrument panel detects that the Tyre pressure monitor is programmed in its own

configuration but the UCH fails to respond to any requests from the instrument panel (not

configured in UCH). The message TYRE SENSOR INOPERATIVE will appear, the four wheels

will disappear from the instrument panel display and the Service warning light will come on.

Edition 435B-16

Page 19 of 37

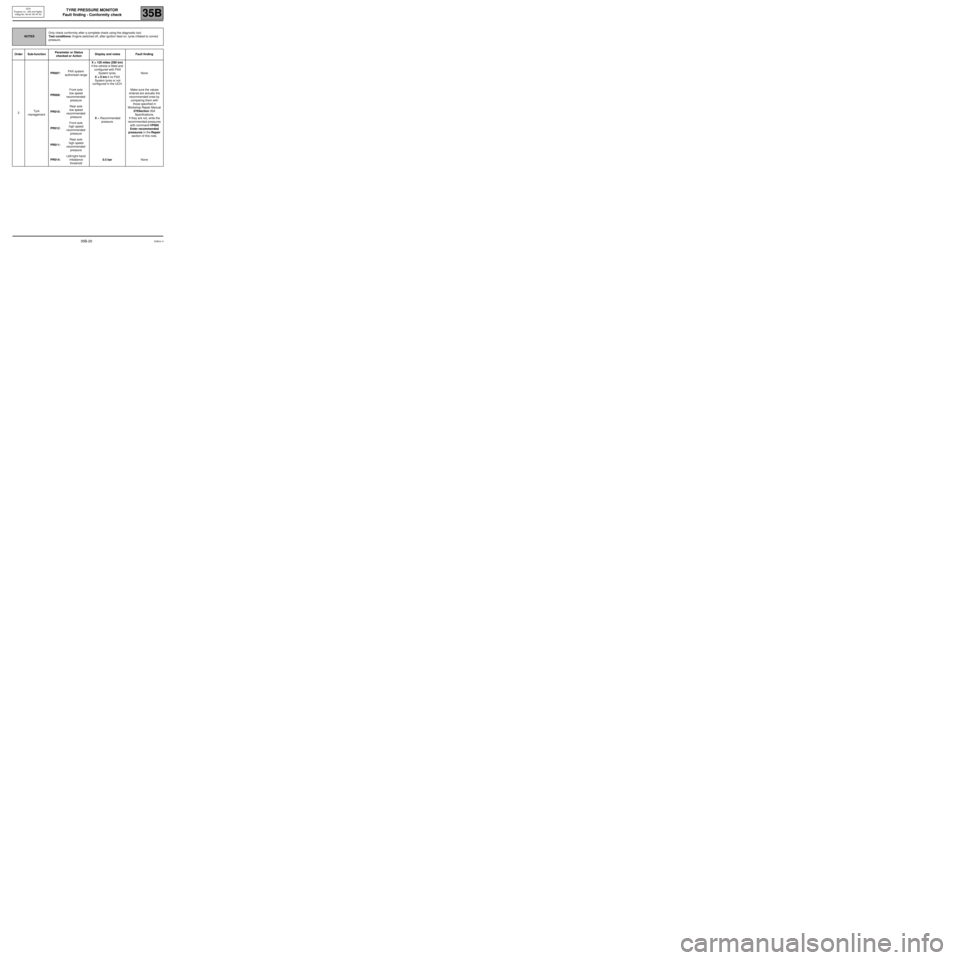

TYRE PRESSURE MONITOR

Fault finding - Conformity check

35B

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50TYRE PRESSURE MONITOR

Fault finding - Conformity check

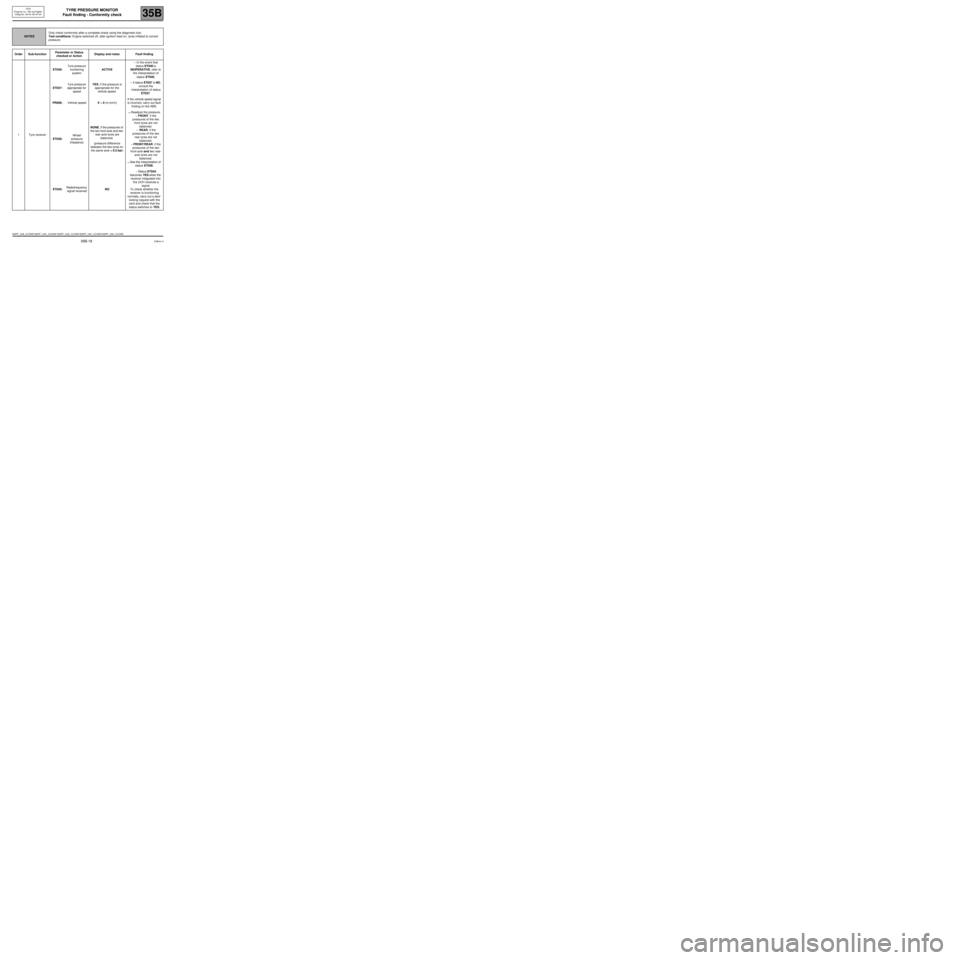

NOTESOnly check conformity after a complete check using the diagnostic tool.

Test conditions: Engine switched off, after ignition feed on, tyres inflated to correct

pressure.

Order Sub-functionParameter or Status

checked or ActionDisplay and notes Fault finding

1Tyre receiverET040:Tyre pressure

monitoring

systemACTIVE– In the event that

status ET040 is

INOPERATIVE, refer to

the interpretation of

status ET040.

ET037:Tyre pressure

appropriate for

speedYES, if the pressure is

appropriate for the

vehicle speed.– If status ET037 is NO,

consult the

interpretation of status

ET037.

PR008:Vehicle speedX = 0 (in km/h)If the vehicle speed signal

is incorrect, carry out fault

finding on the ABS.

ET036:Wheel

pressure

imbalanceNONE, if the pressures of

the two front-axle and two

rear-axle tyres are

balanced.

(pressure difference

between the two tyres on

the same axle < 0.5 bar)

⇒ Readjust the pressure.

– FRONT, if the

pressures of the two

front tyres are not

balanced.

– REAR, if the

pressures of the two

rear tyres are not

balanced.

– FRONT/REAR, if the

pressures of the two

front-axle and two rear-

axle tyres are not

balanced.

⇒ See the interpretation of

status ET036.

ET045:Radiofrequency

signal receivedNO– Status ET045

becomes YES when the

receiver integrated into

the UCH receives a

signal.

To check whether the

receiver is functioning

normally, carry out a door

locking request with the

card and check that the

status switches to YES.

SSPP_V48_CCONF/SSPP_V4C_CCONF/ SSPP_V4D_CCONF/SSPP_V4F_CCONF/SSPP_V50_CCONF

Edition 4

35B-18

Page 20 of 37

TYRE PRESSURE MONITOR

Fault finding - Conformity check

35B

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50

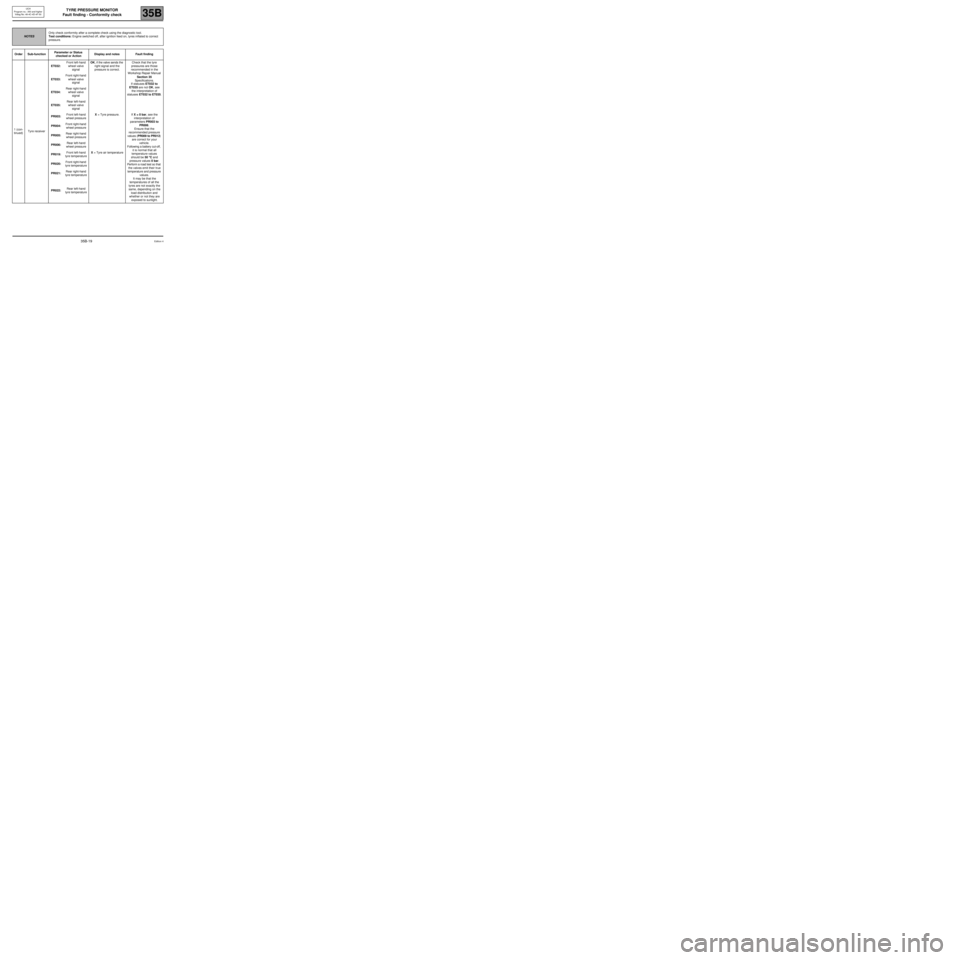

NOTESOnly check conformity after a complete check using the diagnostic tool.

Test conditions: Engine switched off, after ignition feed on, tyres inflated to correct

pressure.

Order Sub-functionParameter or Status

checked or ActionDisplay and notes Fault finding

1 (con-

tinued)Tyre receiverET032:Front left-hand

wheel valve

signalOK, if the valve sends the

right signal and the

pressure is correct.Check that the tyre

pressures are those

recommended in the

Workshop Repair Manual

Section 35

Specifications.

If statuses ET032 to

ET035 are not OK, see

the interpretation of

statuses ET032 to ET035. ET033:Front right-hand

wheel valve

signal

ET034:Rear right-hand

wheel valve

signal

ET035:Rear left-hand

wheel valve

signal

PR003:Front left-hand

wheel pressureX = Tyre pressure. If X = 0 bar, see the

interpretation of

parameters PR003 to

PR006.

Ensure that the

recommended pressure

values (PR009 to PR012)

are correct for your

vehicle.

Following a battery cut-off,

it is normal that all

temperature values

should be 50 °° ° °

C and

pressure values 0 bar.

Perform a road test so that

the valves emit their true

temperature and pressure

values.

It may be that the

temperatures of all the

tyres are not exactly the

same, depending on the

load distribution and

whether or not they are

exposed to sunlight. PR004:Front right-hand

wheel pressure

PR005:Rear right-hand

wheel pressure

PR006:Rear left-hand

wheel pressure

PR019:Front left-hand

tyre temperatureX = Tyre air temperature

PR020:Front right-hand

tyre temperature

PR021:Rear right-hand

tyre temperature

PR022:Rear left-hand

tyre temperature

Edition 435B-19

Page 21 of 37

TYRE PRESSURE MONITOR

Fault finding - Conformity check

35B

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50

NOTESOnly check conformity after a complete check using the diagnostic tool.

Test conditions: Engine switched off, after ignition feed on, tyres inflated to correct

pressure.

Order Sub-functionParameter or Status

checked or ActionDisplay and notes Fault finding

2Tyre

managementPR007:PAX system

authorised rangeX = 120 miles (200 km)

if the vehicle is fitted and

configured with PAX

System tyres.

X = 0 km if no PAX

System tyres or not

configured in the UCH.None

PR009:Front axle

low speed

recommended

pressure

X = Recommended

pressure.Make sure the values

entered are actually the

recommended ones by

comparing them with

those specified in

Workshop Repair Manual

370Section 35A

Specifications.

If they are not, write the

recommended pressures

with command VP005

Enter recommended

pressures in the Repair

section of this note. PR010:Rear axle

low speed

recommended

pressure

PR012:Front axle

high speed

recommended

pressure

PR011:Rear axle

high speed

recommended

pressure

PR014:Left/right-hand

imbalance

threshold0.5 barNone

Edition 435B-20