ignition RENAULT SCENIC 2006 J84 / 2.G Tyre Pressure Monitoring User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2006, Model line: SCENIC, Model: RENAULT SCENIC 2006 J84 / 2.GPages: 37, PDF Size: 0.15 MB

Page 23 of 37

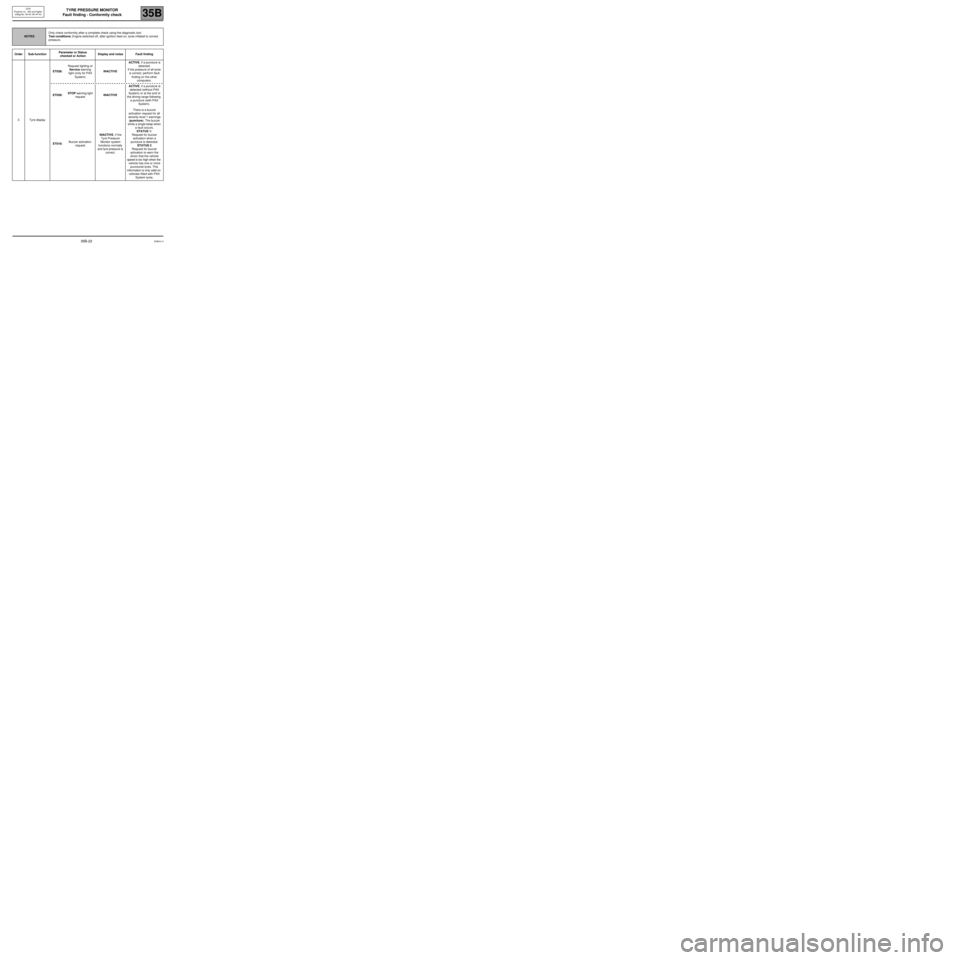

TYRE PRESSURE MONITOR

Fault finding - Conformity check

35B

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50

NOTESOnly check conformity after a complete check using the diagnostic tool.

Test conditions: Engine switched off, after ignition feed on, tyres inflated to correct

pressure.

Order Sub-functionParameter or Status

checked or Action Display and notes Fault finding

3Tyre displayET038:Request lighting of

Service warning

light (only for PAX

System)INACTIVEACTIVE, if a puncture is

detected.

If the pressure of all tyres

is correct, perform fault

finding on the other

computers.

ET039: STOP warning light

requestINACTIVEACTIVE, if a puncture is

detected (without PAX

System) or at the end of

the driving range following

a puncture (with PAX

System).

ET016:Buzzer activation

requestINACTIVE, if the

Tyre Pressure

Monitor system

functions normally

and tyre pressure is

correct.There is a buzzer

activation request for all

severity level 1 warnings

(puncture). The buzzer

emits a single beep when

a fault occurs.

STATUS 1:

Request for buzzer

activation when a

puncture is detected.

STATUS 2

Request for buzzer

activation to warn the

driver that the vehicle

speed is too high when the

vehicle has one or more

punctured tyres. This

information is only valid on

vehicles fitted with PAX

System tyres.

Edition 435B-22

Page 24 of 37

TYRE PRESSURE MONITOR

Fault finding - Interpretation of statuses

35B

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50TYRE PRESSURE MONITOR

Fault finding - Interpretation of statuses

ET032

ET033

ET034

ET035FRONT LEFT-HAND WHEEL VALVE SIGNAL

FRONT RIGHT-HAND WHEEL VALVE SIGNAL

REAR RIGHT-HAND WHEEL VALVE SIGNAL

REAR LEFT-HAND WHEEL VALVE SIGNAL

NOTESBefore carrying out any operation, apply the fault finding procedure (see Introduction).

Special notes: If a tyre pressure sensor is present in the wheel, precautions must

be taken when removing/refitting tyres. Failure to take the precautions specified

in Section 35 of the Workshop Repair Manual could result in the sensor being

damaged, and potential operating faults in the tyre pressure monitor.

OK:

Absent:

Over-inflated:

Punctured:

Under-inflated: The sensor is operating correctly and the pressure is correct.

The sensor does not transmit or is not present on the vehicle.

The sensor sends a "tyre over-inflated" signal.

The sensor sends a "tyre very under-inflated" signal (recommended pressure 0.6 bar) or a

rapid pressure loss signal.

The sensor sends a "tyre under-inflated" signal.

Make sure the signal sent by the sensor corresponds to the pressure measured with the pressure gauge.

If it does not, inflate or deflate the tyres and check that they change status.

IMPORTANT

Wait 90 seconds before checking the change of status.

Original status = over-inflated

Original status = punctured or under-

inflatedDeflate

InflateFinal status = OK or punctured or under-

inflated

Final status = OK or over-inflated

If the status still displays an incorrect signal as compared to the tyre inflation level, refer to the fault finding chart.

–If the original status is: over-inflated or under-inflated

See ALP 2 and 3 Pressure adjustment.

–If the original status is: Punctured

See ALP 7 Puncture: change the tyre.

–If the original status is: Absent

See ALP 4, 5 and 6 Sensor out of order.

–If the status does not change, replace the sensor on the wheel concerned by following the instructions and

programming procedure for the four valve codes, SC002 Program four valve codes (see Configuration and

programming).

AFTER REPAIRDeal with any other possible faults.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

SSPP_V48_ET032/SSPP_V4C_ET032 /SSPP_V4D_ET032/SSPP_V4F_ET032 /SSPP_V50_ET032/

SSPP_V48_ET033/SSPP_V4C_ET033 /SSPP_V4D_ET033/SSPP_V4F_ET033 /SSPP_V50_ET033/

SSPP_V48_ET034/SSPP_V4C_ET034 /SSPP_V4D_ET034/SSPP_V4F_ET034 /SSPP_V50_ET034/

SSPP_V48_ET035/SSPP_V4C_ET035 /SSPP_V4D_ET035/SSPP_V4F_ET035 /SSPP_V50_ET035

Edition 4

35B-23

Page 25 of 37

TYRE PRESSURE MONITOR

Fault finding - Interpretation of statuses

35B

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50

ET036

TYRE PRESSURE IMBALANCE

NOTESBefore carrying out any operation, apply the fault finding procedure (see Introduction).

None

Note:

The threshold of imbalance between the left-hand and right-hand wheels on the same axle is 500 mbar.

Check, using a pressure gauge, that the inflation pressure of the tyres fitted on the vehicle indeed corresponds

to the pressures noted on the door, in the Driver’s Handbook or in MR 370, 35A, and if not readjust the

pressures. Ensure the correct balance of the pressures or axle(s) concerned.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any other possible faults.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

SSPP_V48_ET036/SSPP_V4C_ET036 /SSPP_V4D_ET036/SSPP_V4F_ET036 /SSPP_V50_ET036

Edition 4

35B-24

Page 26 of 37

TYRE PRESSURE MONITOR

Fault finding - Interpretation of statuses

35B

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50

ET037

TYRE PRESSURE APPROPRIATE FOR SPEED

NOTESBefore carrying out any operation, apply the fault finding procedure (see 35B

Introduction).

NO: If the vehicle speed is above 102 mph (170 km/h) (as an indication) for more than

3 minutes and the pressure on at least one of the tyres is 400 mbar or more below

"motorway" pressure.

YES: if the vehicle speed is below 102 mph (170 km/h) (as an indication) or if the

pressure of the four tyres corresponds to the pressure of parameters PR011 and

PR012 High speed recommended pressure, whatever the speed.

Make sure that the tyre pressures are at the recommended "motorway" pressure (see MR 370, 35A or Driver's

Handbook), and reinflate the tyres if necessary.

Check that the pressures entered (PR009 to PR012) match the manufacturer's specifications.

If the pressures entered do not correspond to the manufacturer's values, write the recommended pressures

using procedure VP005 "Write recommended pressures (see Configuration and programming.

If status ET037 remains NO, contact the Techline.

AFTER REPAIRDeal with any other possible faults.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

SSPP_V48_ET037/SSPP_V4C_ET037 /SSPP_V4D_ET037/SSPP_V4F_ET037 /SSPP_V50_ET037

Edition 4

35B-25

Page 27 of 37

TYRE PRESSURE MONITOR

Fault finding - Interpretation of statuses

35B

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50

In the event that status ET040 is inoperative: ET040

TYRE PRESSURE MONITOR SYSTEM

NOTESBefore carrying out any operation, apply the fault finding procedure (see Introduction).

Check that no fault is present.

ACTIVE: If the four wheel valves transmit their signal and the signal is correctly received by the UCH.

INOPERATIVE: If a component is faulty or incorrectly configured.

Check in the configuration reading menu to ensure that configuration LC017 tyre pressure monitor has been

properly entered in the UCH. If this is not the case, start configuration in the "Programming" menu with

command CF023 Tyre pressure monitor, under SC008 UCH type.

Check that there is no ABS fault.

Use status ET045 RF signal received to check that the receiving aerial works correctly by trying central door

locking with the card at 4 to 5 metres to the rear right-hand of the vehicle.

If central door locking does not work, check aerial presence and positioning on the UCH.

If, after performing all these checks, no fault has been found and status ET040 is still Inoperative, contact

Techline.

AFTER REPAIRDeal with any other possible faults.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

SSPP_V48_ET040/SSPP_V4C_ET040 /SSPP_V4D_ET040/SSPP_V4F_ET040 /SSPP_V50_ET040

Edition 4

35B-26

Page 31 of 37

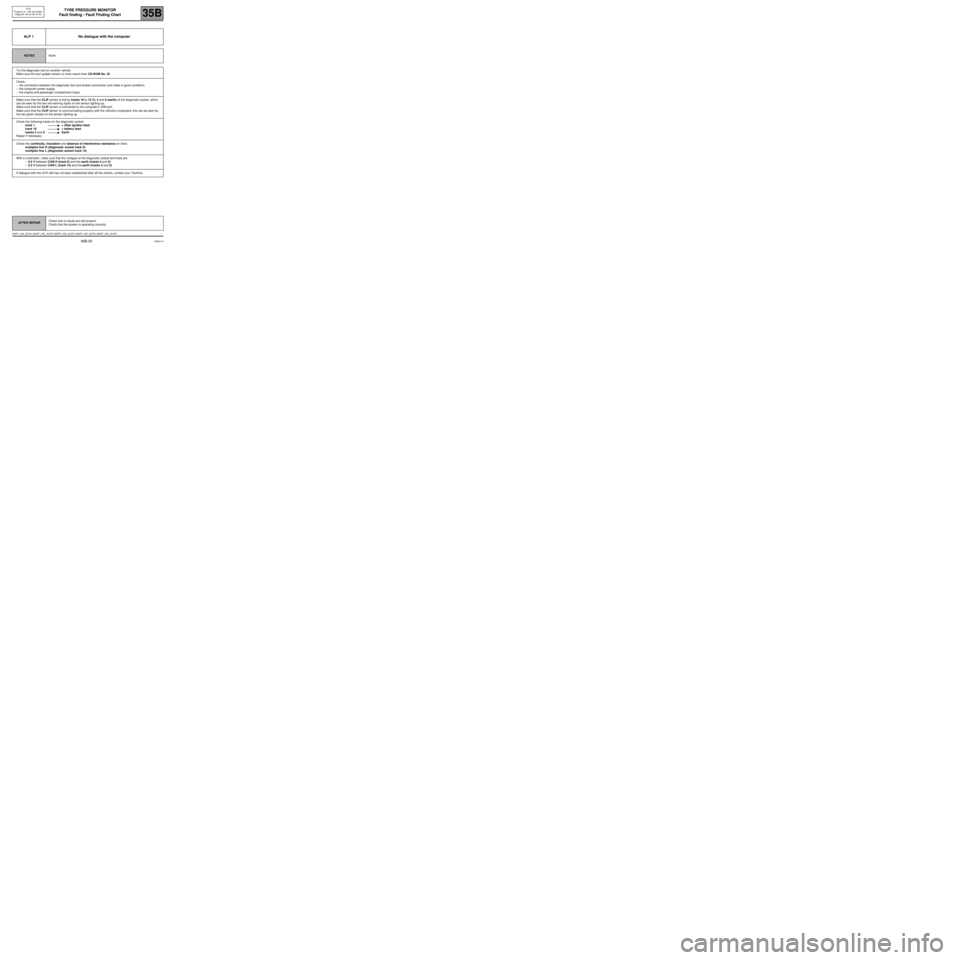

TYRE PRESSURE MONITOR

Fault finding - Fault Finding Chart

35B

UCH

Program no.: 350 and higher

Vdiag No: 48-4C-4D-4F-50TYRE PRESSURE MONITOR

Fault finding - Fault Finding Chart

ALP 1 No dialogue with the computer

NOTESNone

Try the diagnostic tool on another vehicle.

Make sure the tool update version is more recent than CD-ROM No. 32.

Check:

–the connection between the diagnostic tool and socket (connection and cable in good condition).

–the computer power supply

–the engine and passenger compartment fuses.

Make sure that the CLIP sensor is fed by tracks 16 (+ 12 V), 4 and 5 (earth) of the diagnostic socket, which

can be seen by the two red warning lights on the sensor lighting up.

Make sure that the CLIP sensor is connected to the computer's USB port.

Make sure that the CLIP sensor is communicating properly with the vehicle's computers; this can be seen by

the two green diodes on the sensor lighting up.

Check the following tracks on the diagnostic socket:

track 1 + After ignition feed

track 16 + battery feed

tracks 4 and 5 Earth

Repair if necessary.

Check the continuity, insulation and absence of interference resistance on lines:

multiplex line H (diagnostic socket track 6)

multiplex line L (diagnostic socket track 14)

With a multimeter, make sure that the voltages at the diagnostic socket terminals are:

–2.5 V between CAN H (track 6) and the earth (tracks 4 and 5)

–2.5 V between CAN L (track 14) and the earth (tracks 4 and 5)

If dialogue with the UCH still has not been established after all the checks, contact your Techline.

AFTER REPAIRCheck that no faults are still present.

Check that the system is operating correctly.

SSPP_V48_ALP01 /SSPP_V4C_ALP01/SSPP_V4D_ALP01/SSPP_V4F_ALP01/SSPP_V50_ALP01

Edition 4

35B-30