check engine RENAULT SCENIC 2009 J84 / 2.G Air Conditioning Manual Conditioning Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: SCENIC, Model: RENAULT SCENIC 2009 J84 / 2.GPages: 23

Page 18 of 23

MANUAL AIR CONDITIONING

Fault finding – Fault Finding Chart62C

62C-18V2 MR-372-J84-62C000$040.mif

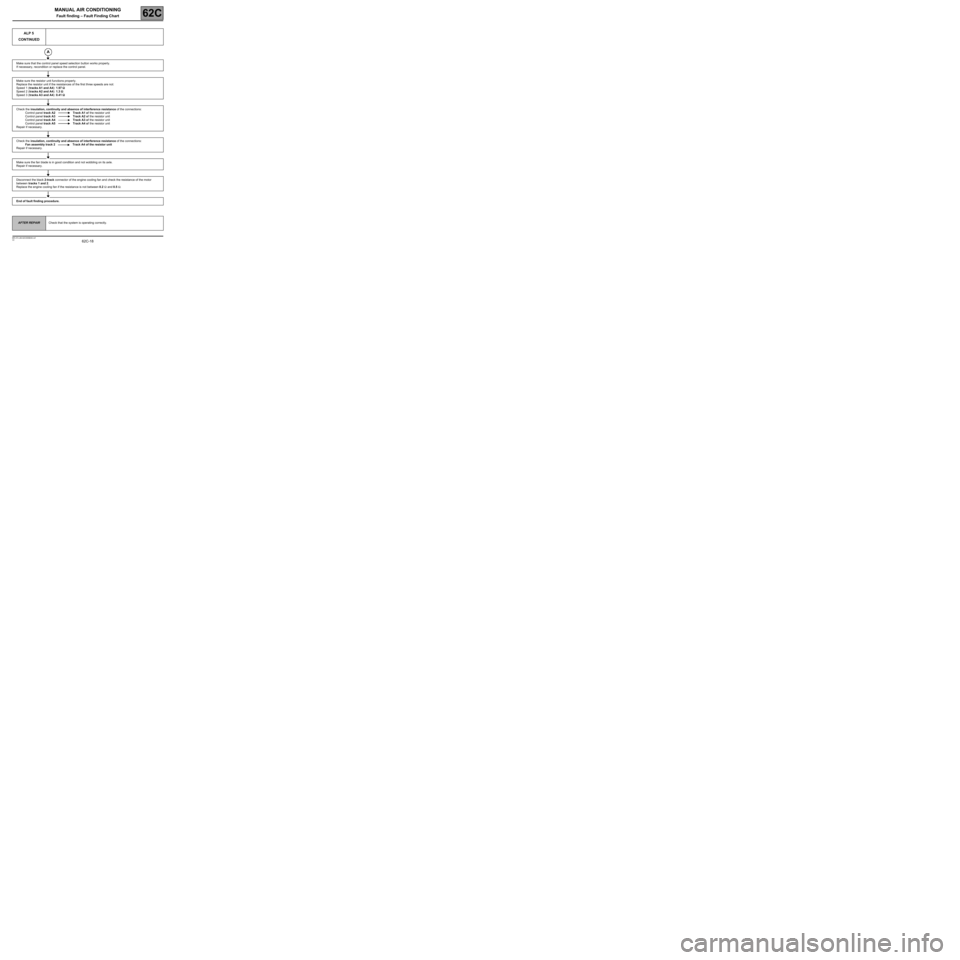

ALP 5

CONTINUED

Make sure that the control panel speed selection button works properly.

If necessary, recondition or replace the control panel.

Make sure the resistor unit functions properly.

Replace the resistor unit if the resistances of the first three speeds are not:

Speed 1 (tracks A1 and A4): 1.97 ΩΩ Ω Ω

Speed 2 (tracks A2 and A4): 1.3 ΩΩ Ω Ω

Speed 3 (tracks A3 and A4): 0.41 ΩΩ Ω Ω

Check the insulation, continuity and absence of interference resistance of the connections:

Control panel track A2 Track A1 of the resistor unit

Control panel track A3 Track A2 of the resistor unit

Control panel track A4 Track A3 of the resistor unit

Control panel track A5 Track A4 of the resistor unit

Repair if necessary.

Check the insulation, continuity and absence of interference resistance of the connections:

Fan assembly track 2 Track A4 of the resistor unit

Repair if necessary.

Make sure the fan blade is in good condition and not wobbling on its axle.

Repair if necessary.

Disconnect the black 2-track connector of the engine cooling fan and check the resistance of the motor

between tracks 1 and 2.

Replace the engine cooling fan if the resistance is not between 0.2 Ω and 0.5 Ω.

End of fault finding procedure.

AFTER REPAIRCheck that the system is operating correctly.

Page 19 of 23

62C-19

MANUAL AIR CONDITIONING

Fault finding – Fault Finding Chart62C

V2 MR-372-J84-62C000$040.mif

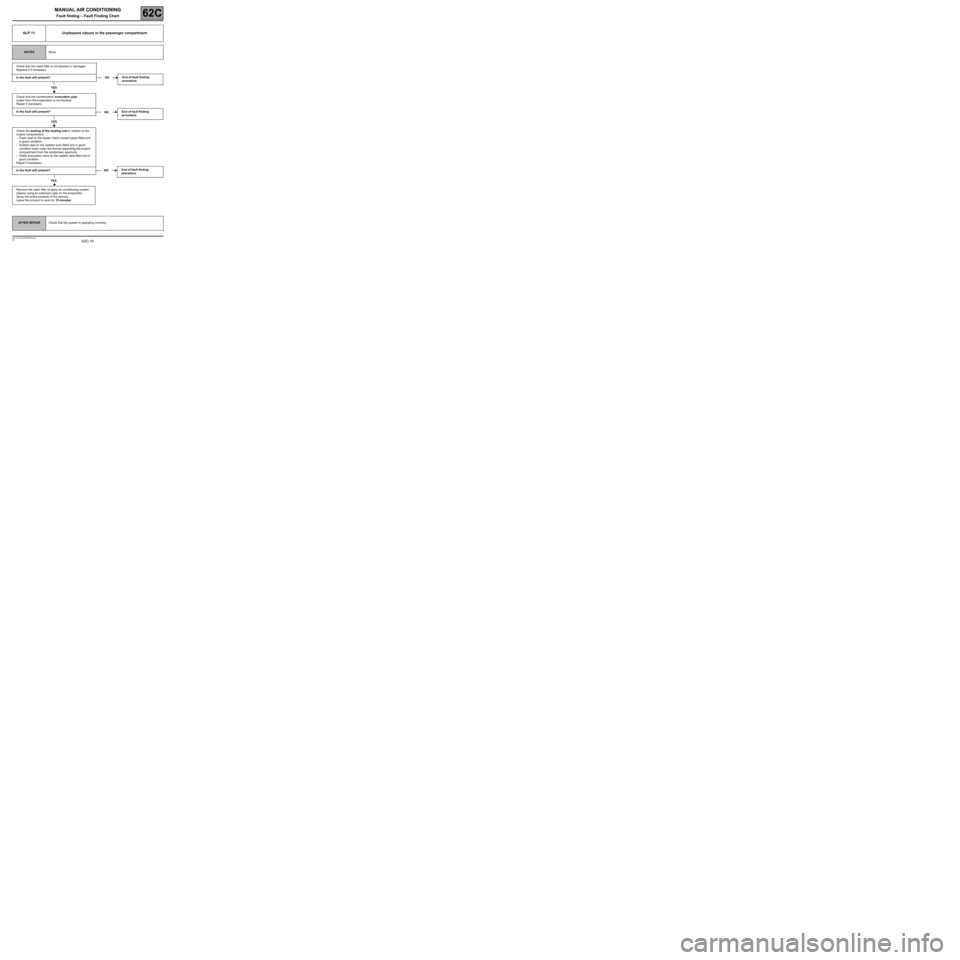

AFTER REPAIRCheck that the system is operating correctly.

ALP 11 Unpleasant odours in the passenger compartment

NOTESNone.

Check that the cabin filter is not blocked or damaged.

Replace it if necessary.

Is the fault still present?

YES

Check that the condensation evacuation pipe

(water from the evaporator) is not blocked.

Repair if necessary.

Is the fault still present?

YES

Check the sealing of the heating unit in relation to the

engine compartment:

–Foam seal on the heater matrix coolant pipes fitted and

in good condition.

–Rubber seal on the radiator tank fitted and in good

condition (seal under the bonnet separating the engine

compartment from the windscreen aperture).

–Water evacuation valve on the radiator tank fitted and in

good condition.

Repair if necessary.

Is the fault still present?

YES

Remove the cabin filter to apply air conditioning system

cleaner using an extension pipe on the evaporator.

Spray the entire contents of the aerosol.

Leave the product to work for 15 minutes.

End of fault finding

procedure.

End of fault finding

procedure.

End of fault finding

procedure.

NO

NO

NO

Page 22 of 23

MANUAL AIR CONDITIONING

Fault finding – Fault Finding Chart62C

62C-22V2 MR-372-J84-62C000$040.mif

ALP 14 Air conditioning noises during operation

NOTESOnly deal with this customer complaint after a full check with the diagnostic tool

(fault reading and configuration checks).

Check that the computers involved in the air conditioning function (Injection, Protection and Switching Unit,

UCH and Air conditioning control panel) are correctly configured.

Reconfigure if necessary (see 62A, Air conditioning, Configurations and Configuration reading).

Check that:

–the compressor fitted to the vehicle corresponds correctly to the engine (see MR 370 Mechanical, 62A, Air

conditioning, Air conditioning: Parts and consumables for the repair).

Replace the compressor if necessary (see MR 370, Mechanical, 62A, Air conditioning, Compressor:

Removal - Refitting).

–the compressor is correctly fixed (see MR 370 Mechanical, 62A, Air conditioning, Compressor: Removal -

Refitting).

Check the condition of the compressor belt and check its tension. Replace the belt if necessary (see MR 370

Mechanical, 11A, Top and front of engine, Accessories belt: Removal - Refitting).

Check that the intermediate pipes, condenser and dehydrator reservoir are correctly fitted.

–Check the mountings and brackets of the components.

–Check the contact between and proximity of the components.

(see MR 370 Mechanical, 62A, Air conditioning, Air conditioning: List and location of components).

Check the correct operation of the cooling fan assembly or passenger compartment fan assembly and

condenser:

–check the electrical supply of the fan using parameters ET007 High speed fan assembly control, AC009 Low

speed fan assembly and AC010 High speed fan assembly (see 62A, Air conditioning, Conformity check,

Cold loop sub-function).

Check the quantity of refrigerant (see MR 370 Mechanical, 62A, Air conditioning, Air conditioning: Parts

and consumables for the repair).

If the quantity of refrigerant is:

–Greater than the manufacturer's information, recharge according to the manufacturer's values (see MR 370

Mechanical, 62A, Air conditioning: Draining - Filling).

–Less than the manufacturer's information, check for leaks (see MR 370 Mechanical, 62A, Air conditioning,

Refrigerant circuit: Check).

If the fault is still present, replace the compressor (see MR 370, Mechanical, 62A, Air conditioning,

Compressor: Removal - Refitting).

AFTER REPAIRCarry out a complete check using the diagnostic tool.