heating RENAULT SCENIC 2009 J84 / 2.G Air Conditioning Manual Conditioning Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: SCENIC, Model: RENAULT SCENIC 2009 J84 / 2.GPages: 23

Page 2 of 23

62C - 2

MANUAL AIR CONDITIONING

62C

V2 MR-372-J84-62C000$010.mif

162CMANUAL AIR CONDITIONING

Fault finding – Introduction

1. SCOPE OF THIS DOCUMENT

This document describes the fault finding procedures applicable to all manual heating and ventilation systems with

the following specifications:

2. PREREQUISITES FOR FAULT FINDING

Standard documentation:

Fault finding procedures (this manual):

–Paper (Workshop Repair Manual or Technical Note), Dialogys.

Wiring Diagrams:

–Visu-Diagram (CD-ROM), paper.

Special tooling required:

Vehicle(s): SCENIC

Function affected: heating and ventilation system

SPECIAL TOOLING REQUIRED

Multimeter and oscilloscope

Page 6 of 23

62C - 6

MANUAL AIR CONDITIONING

62C

V2 MR-372-J84-62C000$020.mif

MANUAL AIR CONDITIONING

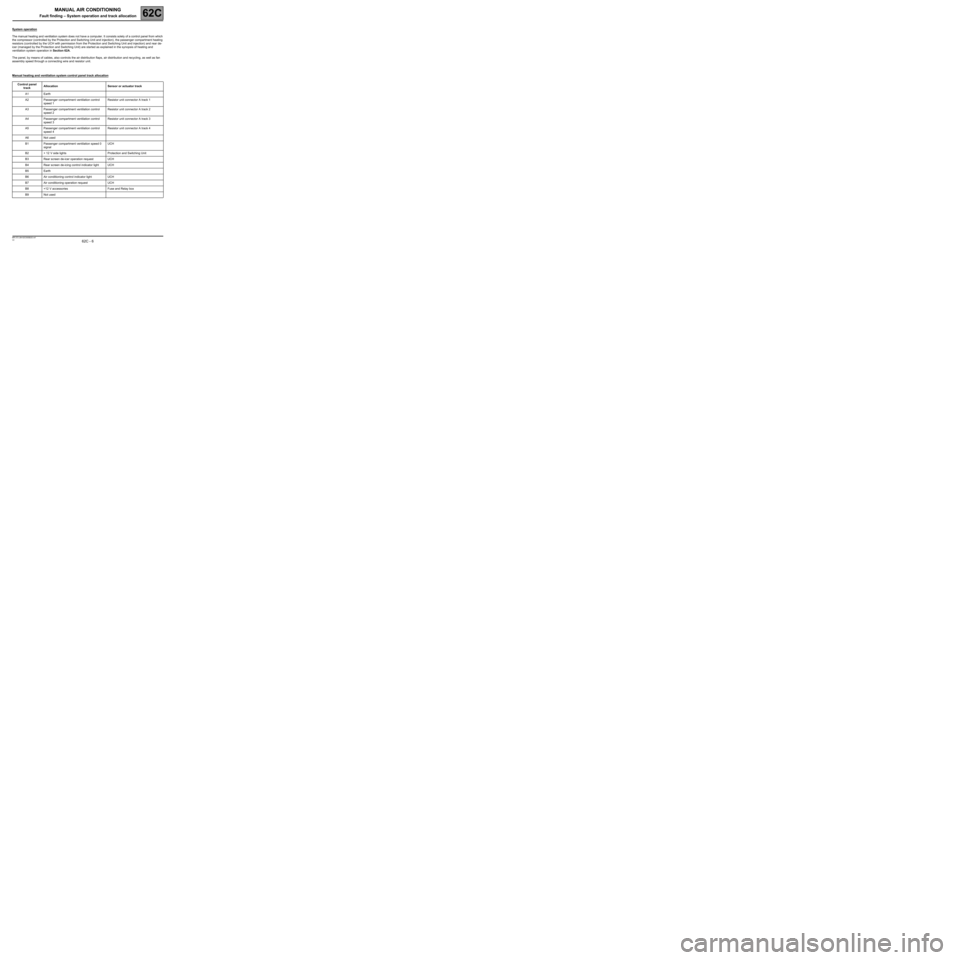

Fault finding – System operation and track allocation

System operation

The manual heating and ventilation system does not have a computer. It consists solely of a control panel from which

the compressor (controlled by the Protection and Switching Unit and injection), the passenger compartment heating

resistors (controlled by the UCH with permission from the Protection and Switching Unit and injection) and rear de-

icer (managed by the Protection and Switching Unit) are started as explained in the synopsis of heating and

ventilation system operation in Section 62A.

The panel, by means of cables, also controls the air distribution flaps, air distribution and recycling, as well as fan

assembly speed through a connecting wire and resistor unit.

Manual heating and ventilation system control panel track allocation

Control panel

track Allocation Sensor or actuator track

A1 Earth

A2 Passenger compartment ventilation control

speed 1Resistor unit connector A track 1

A3 Passenger compartment ventilation control

speed 2Resistor unit connector A track 2

A4 Passenger compartment ventilation control

speed 3Resistor unit connector A track 3

A5 Passenger compartment ventilation control

speed 4Resistor unit connector A track 4

A6 Not used

B1 Passenger compartment ventilation speed 0

signal UCH

B2 + 12 V side lights Protection and Switching Unit

B3 Rear screen de-icer operation request UCH

B4 Rear screen de-icing control indicator light UCH

B5 Earth

B6 Air conditioning control indicator light UCH

B7 Air conditioning operation request UCH

B8 +12 V accessories Fuse and Relay box

B9 Not used

Page 7 of 23

62C - 7

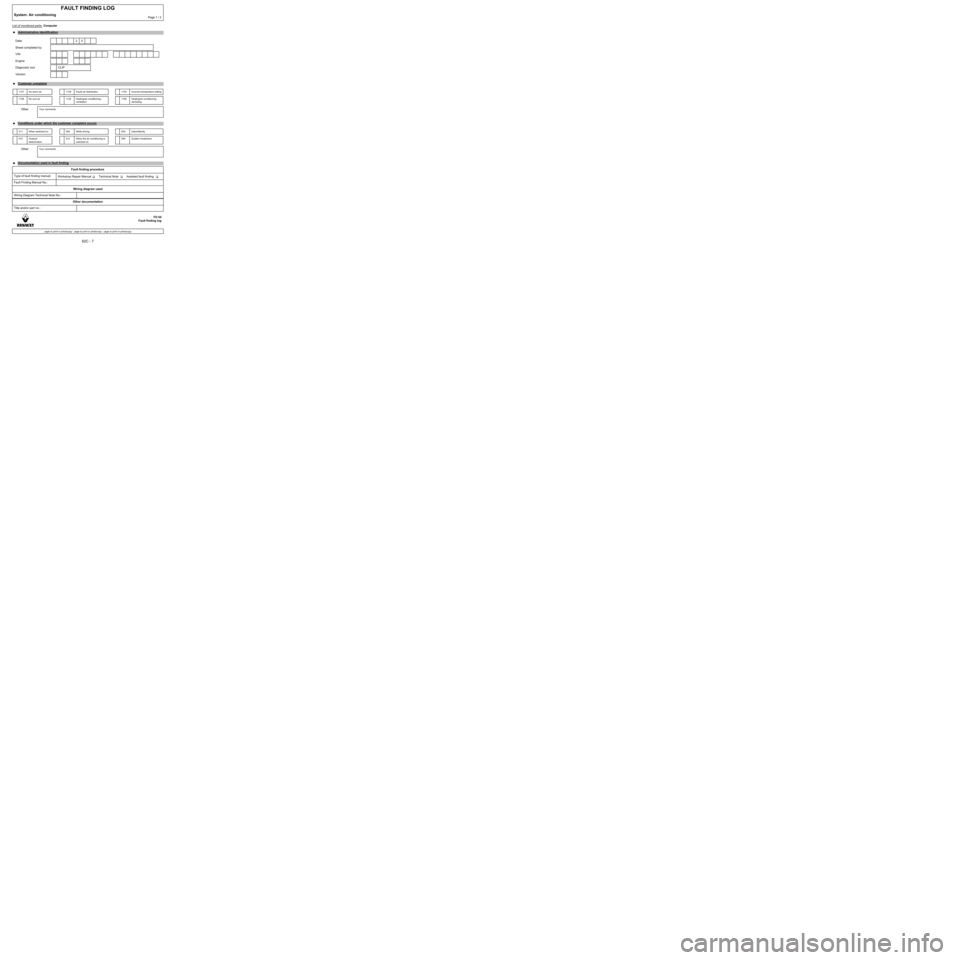

List of monitored parts: Computer

FAULT FINDING LOG

System: Air conditioningPage 1 / 2

●Administrative identification

Date: 2 0

Sheet completed by

VIN

Engine

Diagnostic tool CLIP

Version

●Customer complaint

1127 No warm air 1129 Faulty air distribution 1130 Incorrect temperature setting

1128 No cool air 1125 Heating/air conditioning:

ventilation1182 Heating/air conditioning:

demisting

OtherYour comments

●

Conditions under which the customer complaint occurs

011 When switched on 005 While driving 004 Intermittently

010 Gradual

deterioration012 When the air conditioning is

switched on009 Sudden breakdown

OtherYour comments

●

Documentation used in fault finding

Fault finding procedure

Type of fault finding manual:

Workshop Repair Manual Technical Note Assisted fault finding

Fault Finding Manual No.:

Wiring diagram used

Wiring Diagram Technical Note No.:

Other documentation

Title and/or part no.:

FD 04

Fault finding log

page to print or photocopy - page to print or photocopy - page to print or photocopy

Page 9 of 23

62C-9

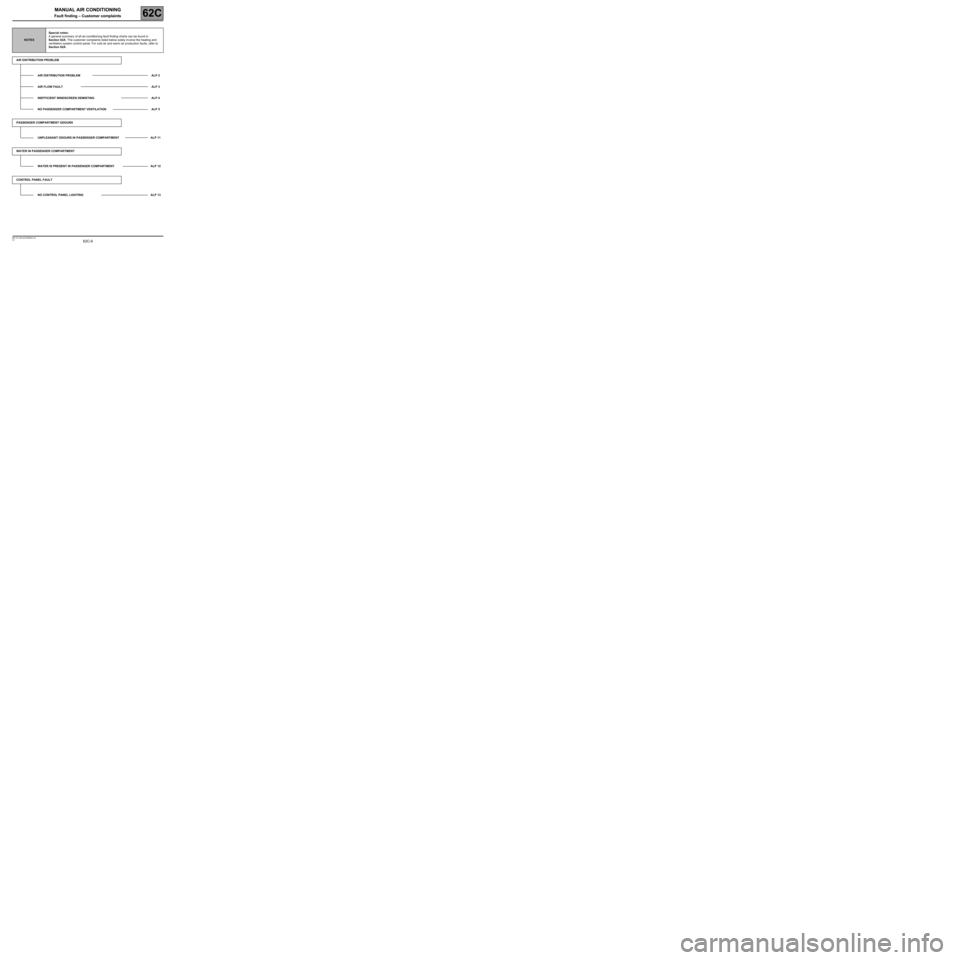

MANUAL AIR CONDITIONING

Fault finding – Customer complaints62C

V2 MR-372-J84-62C000$030.mif

MANUAL AIR CONDITIONING

Fault finding – Customer complaints

NOTESSpecial notes:

A general summary of all air-conditioning fault finding charts can be found in

Section 62A. The customer complaints listed below solely involve the heating and

ventilation system control panel. For cold air and warm air production faults, refer to

Section 62A.

AIR DISTRIBUTION PROBLEM

AIR DISTRIBUTION PROBLEM ALP 2

AIR FLOW FAULT ALP 3

INEFFICIENT WINDSCREEN DEMISTING ALP 4

NO PASSENGER COMPARTMENT VENTILATION ALP 5

PASSENGER COMPARTMENT ODOURS

UNPLEASANT ODOURS IN PASSENGER COMPARTMENT ALP 11

WATER IN PASSENGER COMPARTMENT

WATER IS PRESENT IN PASSENGER COMPARTMENT ALP 12

CONTROL PANEL FAULT

NO CONTROL PANEL LIGHTING ALP 13

Page 10 of 23

62C-10

MANUAL AIR CONDITIONING

Fault finding – Customer complaints62C

V2 MR-372-J84-62C000$030.mif

NOTESSpecial notes:

A general summary of all air-conditioning fault finding charts can be found in

Section 62A. The customer complaints listed below solely involve the heating and

ventilation system control panel. For cold air and warm air production faults, refer to

Section 62A.

COMPRESSOR NOISES

AIR CONDITIONING NOISES DURING OPERATION ALP 14

PASSENGER COMPARTMENT VENTILATION NOISES ALP 15

Page 11 of 23

62C-11

MANUAL AIR CONDITIONING

Fault finding – Fault Finding Chart62C

V2 MR-372-J84-62C000$040.mif

MANUAL AIR CONDITIONING

Fault finding – Fault Finding Chart

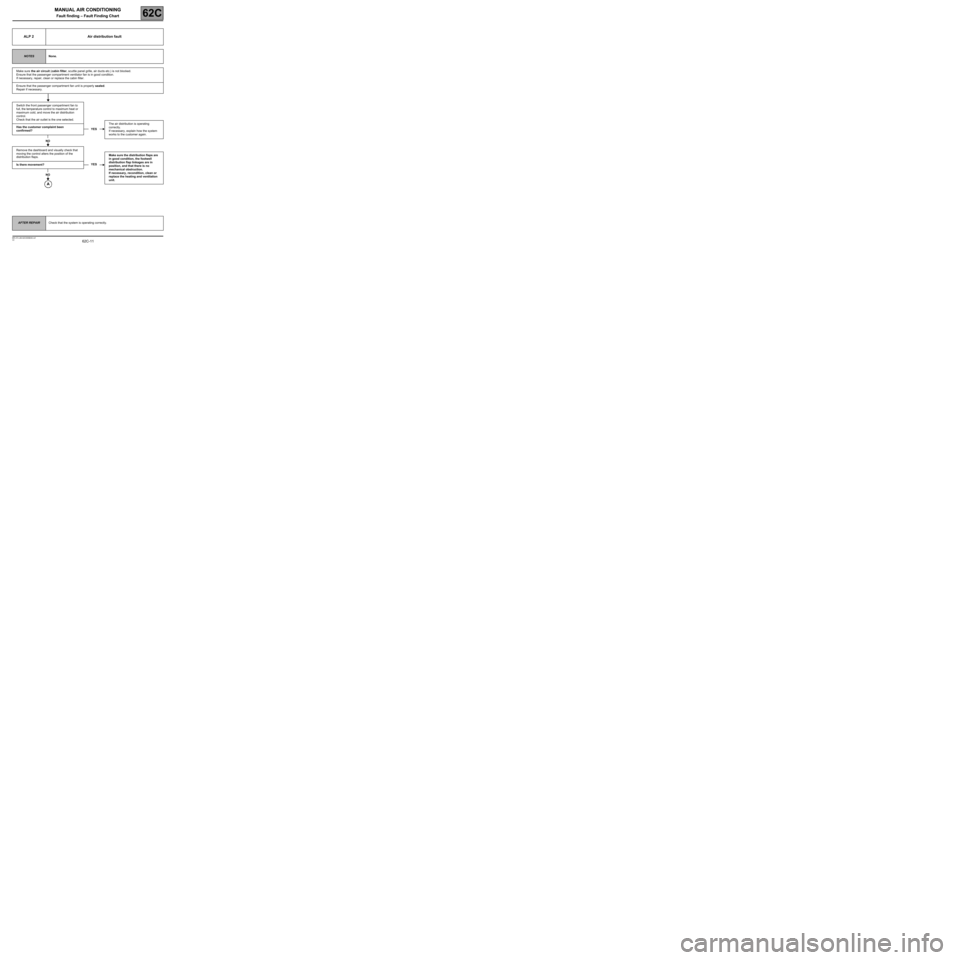

ALP 2 Air distribution fault

NOTESNone.

Make sure the air circuit (cabin filter, scuttle panel grille, air ducts etc.) is not blocked.

Ensure that the passenger compartment ventilator fan is in good condition.

If necessary, repair, clean or replace the cabin filter.

Ensure that the passenger compartment fan unit is properly sealed.

Repair if necessary.

Switch the front passenger compartment fan to

full, the temperature control to maximum heat or

maximum cold, and move the air distribution

control.

Check that the air outlet is the one selected.

Has the customer complaint been

confirmed?

NO

Remove the dashboard and visually check that

moving the control alters the position of the

distribution flaps.

Is there movement?

NO

The air distribution is operating

correctly.

If necessary, explain how the system

works to the customer again.

Make sure the distribution flaps are

in good condition, the footwell

distribution flap linkages are in

position, and that there is no

mechanical obstruction.

If necessary, recondition, clean or

replace the heating and ventilation

unit.

YES

YES

AFTER REPAIRCheck that the system is operating correctly.

Page 19 of 23

62C-19

MANUAL AIR CONDITIONING

Fault finding – Fault Finding Chart62C

V2 MR-372-J84-62C000$040.mif

AFTER REPAIRCheck that the system is operating correctly.

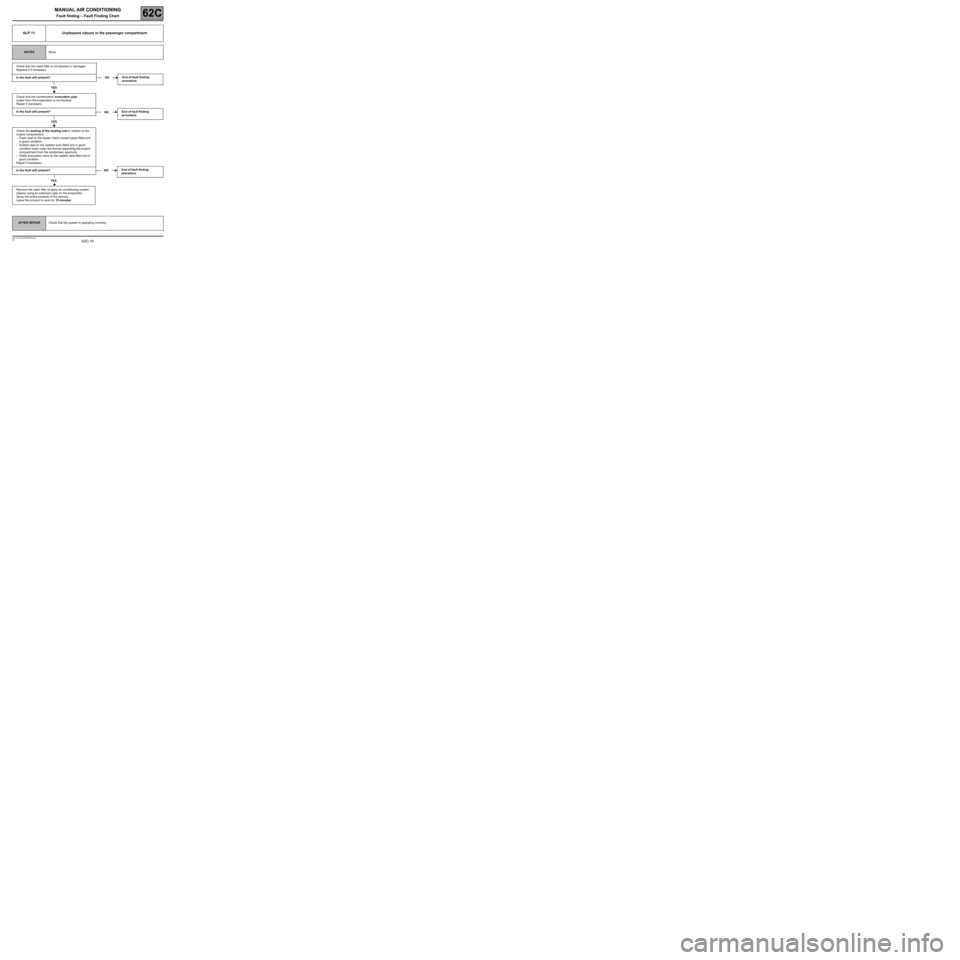

ALP 11 Unpleasant odours in the passenger compartment

NOTESNone.

Check that the cabin filter is not blocked or damaged.

Replace it if necessary.

Is the fault still present?

YES

Check that the condensation evacuation pipe

(water from the evaporator) is not blocked.

Repair if necessary.

Is the fault still present?

YES

Check the sealing of the heating unit in relation to the

engine compartment:

–Foam seal on the heater matrix coolant pipes fitted and

in good condition.

–Rubber seal on the radiator tank fitted and in good

condition (seal under the bonnet separating the engine

compartment from the windscreen aperture).

–Water evacuation valve on the radiator tank fitted and in

good condition.

Repair if necessary.

Is the fault still present?

YES

Remove the cabin filter to apply air conditioning system

cleaner using an extension pipe on the evaporator.

Spray the entire contents of the aerosol.

Leave the product to work for 15 minutes.

End of fault finding

procedure.

End of fault finding

procedure.

End of fault finding

procedure.

NO

NO

NO

Page 23 of 23

MANUAL AIR CONDITIONING

Fault finding – Fault Finding Chart62C

62C-23V2 MR-372-J84-62C000$040.mif

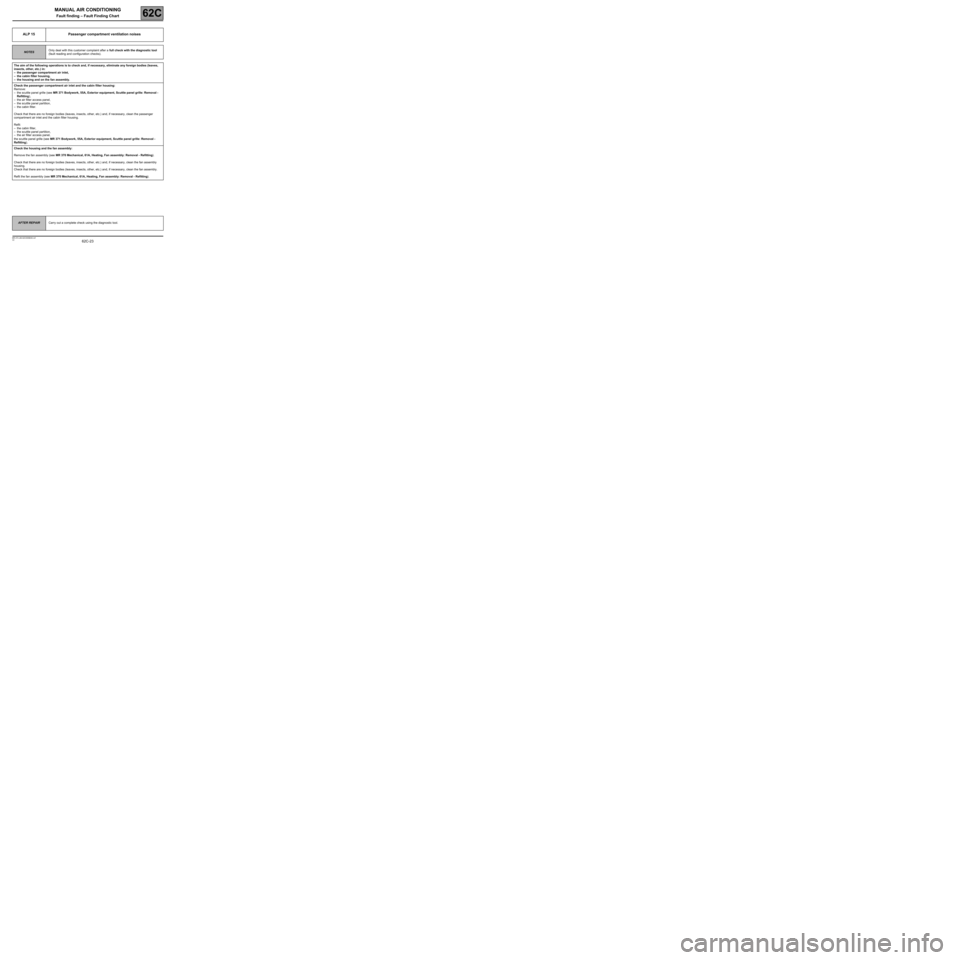

ALP 15 Passenger compartment ventilation noises

NOTESOnly deal with this customer complaint after a full check with the diagnostic tool

(fault reading and configuration checks).

The aim of the following operations is to check and, if necessary, eliminate any foreign bodies (leaves,

insects, other, etc.) in:

–the passenger compartment air inlet,

–the cabin filter housing,

–the housing and on the fan assembly.

Check the passenger compartment air inlet and the cabin filter housing:

Remove:

–the scuttle panel grille (see MR 371 Bodywork, 55A, Exterior equipment, Scuttle panel grille: Removal -

Refitting),

–the air filter access panel,

–the scuttle panel partition,

–the cabin filter.

Check that there are no foreign bodies (leaves, insects, other, etc.) and, if necessary, clean the passenger

compartment air inlet and the cabin filter housing.

Refit:

–the cabin filter,

–the scuttle panel partition,

–the air filter access panel,

the scuttle panel grille (see MR 371 Bodywork, 55A, Exterior equipment, Scuttle panel grille: Removal -

Refitting).

Check the housing and the fan assembly:

Remove the fan assembly (see MR 370 Mechanical, 61A, Heating, Fan assembly: Removal - Refitting).

Check that there are no foreign bodies (leaves, insects, other, etc.) and, if necessary, clean the fan assembly

housing.

Check that there are no foreign bodies (leaves, insects, other, etc.) and, if necessary, clean the fan assembly.

Refit the fan assembly (see MR 370 Mechanical, 61A, Heating, Fan assembly: Removal - Refitting).

AFTER REPAIRCarry out a complete check using the diagnostic tool.