fuel pressure RENAULT SCENIC 2009 J84 / 2.G Engine And Peripherals EDC16 User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: SCENIC, Model: RENAULT SCENIC 2009 J84 / 2.GPages: 273

Page 81 of 273

DIESEL INJECTION

Fault finding – Interpretation of faults13B

13B-81V3 MR-372-J84-13B250$360.mif

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16

PROGRAM No.: C1

Vdiag No.: 51

*Opening cyclic ratioDF053

CONTINUED 3

●Or usingavoltmeter:

With the regulator connected, connect the negative terminal of the voltmeter totrack 2of the rail pressure regulator

and thepositive terminal totrack 1.Clear any fuel pressure solenoid valve faults, then run commandAC011 Rail

pressure re gulator:

Thevoltmeter should display two successive voltage readings:

~3.15voltsfor an opening cycle ratio of 25% then~9.45Vfor an opening cycle ratio of 75% (ten cycles).

●Or using an oscillos cope(at 5 V range/division a nd 1 ms/div tim e base):

With the regulator connected, connect the negative terminal of the oscill oscope to the battery earth and the positive

terminal totrack 2of the fuel pressure solenoid valve, clear any r ail pressure regulator faults, and r un command

AC0 11 R ail pressure regulator:

theoscillo sco pe sh ould disp lay a square pulse signal with an a mplitude o f 1 2.5 V at a frequency of 1 85 Hz (with a n

OCR* alternating successively from 25 to 75%).

if the measurement does not show any control or continuous voltage, contact the techline.

Page 82 of 273

DIESEL INJECTION

Fault finding – Interpretation of faults13B

13B-82V3 MR-372-J84-13B250$360.mif

DF053

CONTINUED 4

2.DEF to

8.DEF

NOTESNone

Check the rail pressure regulator connectors.

Check the injection computer connections.

Check the low pressure circuit by running test 2 Low pressure circuit check.

Check the conformity of the fuel used by applying test 10 Diesel fuel conformity check.

Check the injector return flow, run test 8 Poor injector operation.

Check the operation of the overpressure valve if fitted to the vehicle, run test 11 Incorrect operation of the

overpressure valve.

Repair if necessary.

Measure the resistance of the pressure regulator between its tracks 1 and 2.

If the resistance is not 3 ± 1 Ω at 20˚C, replace the injection pump.

Check the continuity and for the absence of interference resistance on the following connections:

Injection computer brown 48-track

connector B, track M4Track 2 of the rail pressure regulator

Injection supply relay mounting track 5 track 1 of the rail pressure regulator

Repair if necessary.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16

PROGRAM No.: C1

Vdiag No.: 51

Page 83 of 273

DIESEL INJECTION

Fault finding – Interpretation of faults13B

13B-83V3 MR-372-J84-13B250$360.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

DF053

CONTINUED 5

In the event of rail overpressure:

Check the operation of the injectors: refer to test 8 Poor injector operation.

Check that the rail pressure sensor is operating correctly using command AC011 Rail pressure regulator. Display

parameter PR038 Rail pressure, and refer to the conformity check to check the operating values.

If these checks do not reveal any faults, and if the fault is still present, replace the injection pump.

in the event of rail underpressure:

Check that the rail pressure sensor is operating correctly using command AC011 Rail pressure regulator. Display

parameter PR038 Rail pressure, and refer to the conformity check to check the operating values.

Check the low pressure diesel circuit priming.

Check the conformity of the diesel filter connections.

Check the condition of the filter (clogging and water saturation).

Check that there are no air bubbles between the filter and the high pressure pump.

Check the low and high pressure diesel fuel circuit sealing (visual inspections, odour, etc.): pump housing,

pressure relief valve, pipes, rail and injector unions, injector wells, etc.

Check the operation of the injectors: refer to test 8 Poor injector operation.

Carry out the necessary operations.

If the fault is still present, replace the injection pump.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

Page 94 of 273

DIESEL INJECTION

Fault finding – Interpretation of faults13B

13B-94V3 MR-372-J84-13B250$405.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

DF057

PRESENT

OR

STOREDWATER IN DIESEL FUEL DETECTOR CIRCUIT

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after the engine is started or following a road test.

Check the conformity of the fuel used by applying test 10 Diesel fuel conformity check.

Check the sealing of the tank and low pressure circuit by applying test 2 Low pressure circuit check.

A) Make sure the water in diesel fuel detection sensor is properly connected.

–If not, clear the fault,

–Carry out a road test (speed > 12 mph (20 km/h) and engine speed > 1200 rpm) for more than 30 seconds.

–If the fault does not recur, end the fault finding procedure.

–If the fault does recur, go to step C.

B) If the water detection sensor is absent:

–Insulate the electrical connector not connected to the vehicle (risk of dampness, oxidation, and erratic

appearance of faults).

Check that the configuration reading LC065 Water detected in the diesel is NONE.

If LC065 is WITH, run command RZ005 Programming to reinitialise the vehicle configurations.

–Clear the faults.

–Carry out a road test (speed > 12 mph (20 km/h) and engine speed > 1200 rpm) for more than 30 seconds.

–If the fault does not recur, end the fault finding procedure.

C) If the sensor is properly connected:

–Bleed the diesel filter unit (see MR 364, Mechanics, 13A, Fuel supply).

–Clear the fault.

–Carry out a road test (speed > 12 mph (20 km/h) and engine speed > 1200 rpm) for more than 30 seconds.

–If the fault does not recur, end the fault finding procedure.

D) If the fault recurs:

–Check for continuity and the absence of interference resistance on the connection between:

Injection computer 32-track grey connector track A2 Track 3 of the water detection sensor

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16_V51_DF057

Page 137 of 273

DIESEL INJECTION

Fault finding – Conformity check13B

13B - 137V3 MR-372-J84-13B250$450.mif

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

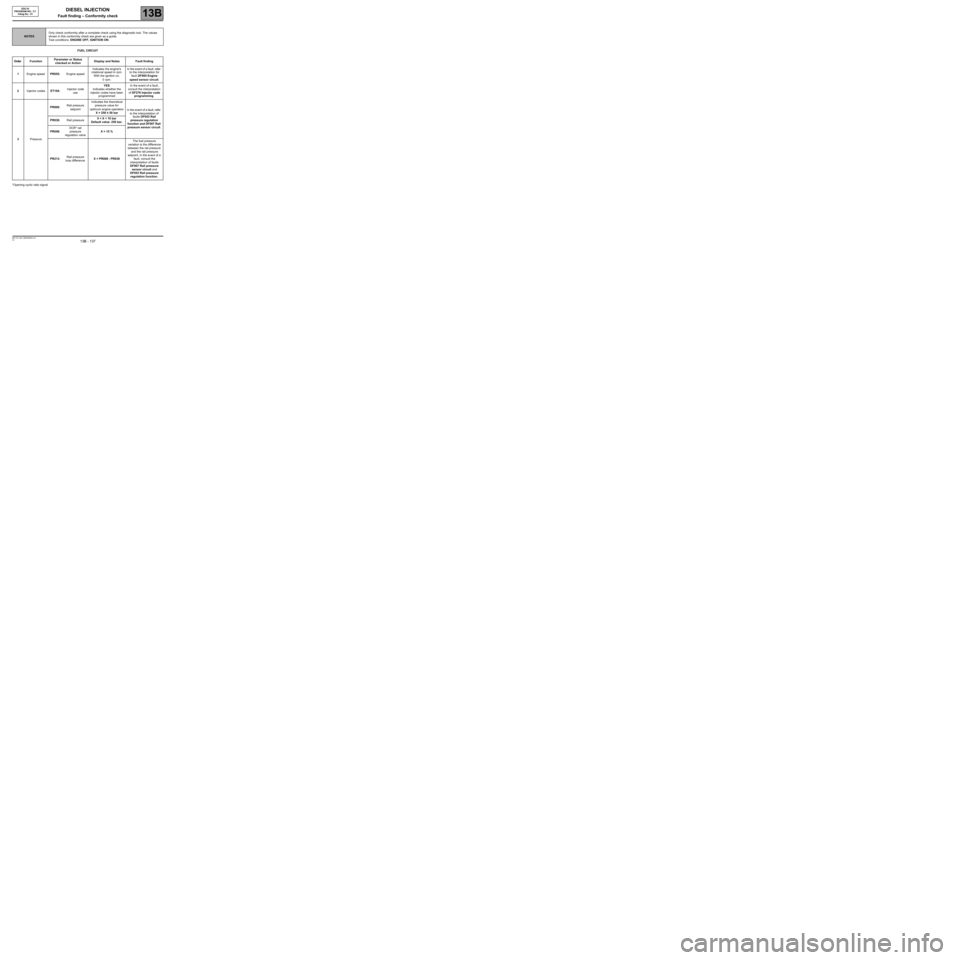

FUEL CIRCUIT

*Opening cyclic ratio signal

NOTESOnly check conformity after a complete check using the diagnostic tool. The values

shown in this conformity check are given as a guide.

Test conditions: ENGINE OFF, IGNITION ON.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

1Engine speedPR055:Engine speedIndicates the engine's

rotational speed in rpm.

With the ignition on,

0 rpm.In the event of a fault, refer

to the interpretation for

fault DF005 Engine

speed sensor circuit.

2Injector codesET104:Injector code

useYES

Indicates whether the

injector codes have been

programmedIn the event of a fault,

consult the interpretation

of DF276 Injector code

programming.

3PressurePR008:Rail pressure

setpointIndicates the theoretical

pressure value for

optimum engine operation

X = 250 ± 50 barIn the event of a fault, refer

to the interpretation of

faults DF053 Rail

pressure regulation

function and DF007 Rail

pressure sensor circuit. PR038:Rail pressure0 < X < 10 bar

Default value: 250 bar.

PR048:OCR* rail

pressure

regulation valveX = 15 %

PR213:Rail pressure

loop differenceX = PR008 - PR038The fuel pressure

variation is the difference

between the rail pressure

and the rail pressure

setpoint. In the event of a

fault, consult the

interpretation of faults

DF007 Rail pressure

sensor circuit and

DF053 Rail pressure

regulation function.

Page 138 of 273

DIESEL INJECTION

Fault finding – Conformity check13B

13B - 138V3 MR-372-J84-13B250$450.mif

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

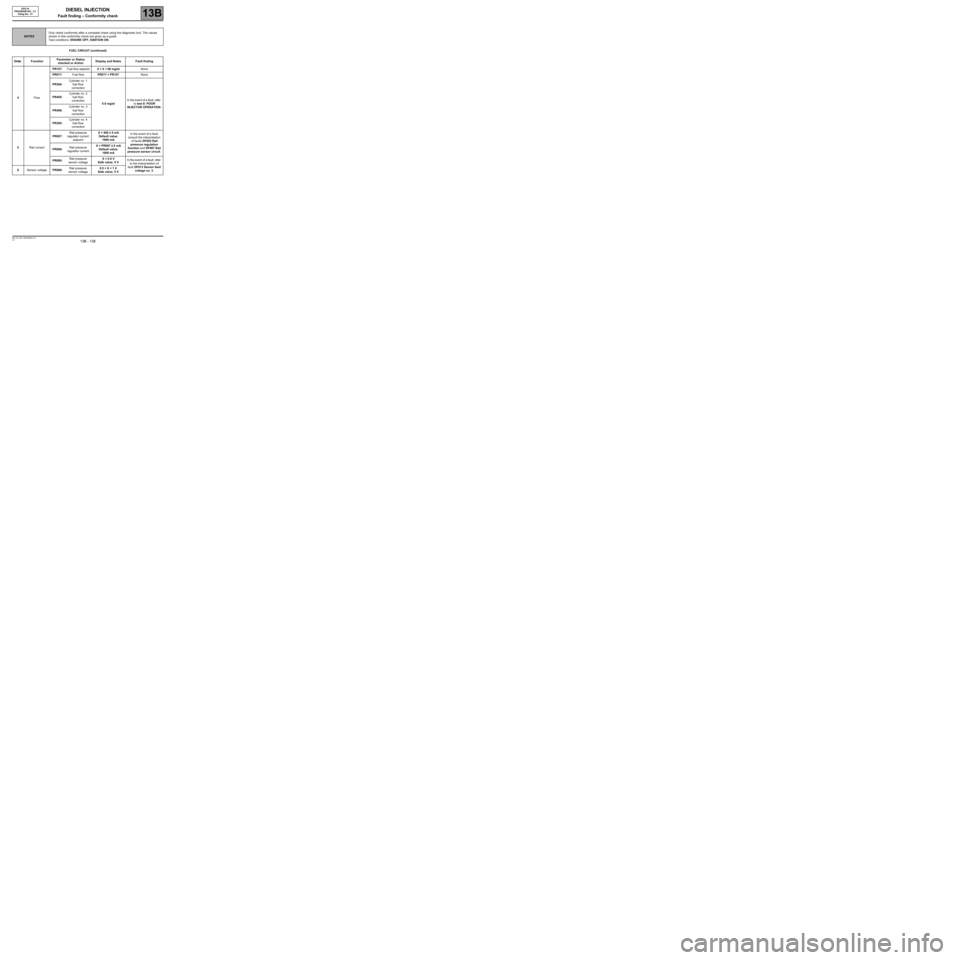

FUEL CIRCUIT (continued)

NOTESOnly check conformity after a complete check using the diagnostic tool. The values

shown in this conformity check are given as a guide.

Test conditions: ENGINE OFF, IGNITION ON.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

4FlowPR157:Fuel flow setpoint0 < X < 60 mg/stNone

PR017:Fuel flowPR017 = PR157None

PR364:Cylinder no. 1

fuel flow

correction

0.0 mg/stIn the event of a fault, refer

to test 8: POOR

INJECTOR OPERATION. PR405:Cylinder no. 2

fuel flow

correction

PR406:Cylinder no. 3

fuel flow

correction

PR365:Cylinder no. 4

fuel flow

correction

5Rail currentPR007:Rail pressure

regulator current

setpointX = 400 ± 5 mA

Default value:

1600 mAIn the event of a fault,

consult the interpretation

of faults DF053 Rail

pressure regulation

function and DF007 Rail

pressure sensor circuit. PR006:Rail pressure

regulator currentX = PR007 ± 5 mA

Default value:

1600 mA

PR080:Rail pressure

sensor voltageX = 0.5 V

Safe value: 5 VIn the event of a fault, refer

to the interpretation of

fault DF013 Sensor feed

voltage no. 3. 6Sensor voltagePR080:Rail pressure

sensor voltage0.5 < X < 1 V

Safe value: 5 V

Page 156 of 273

DIESEL INJECTION

Fault finding – Conformity check13B

13B - 156V3 MR-372-J84-13B250$450.mif

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

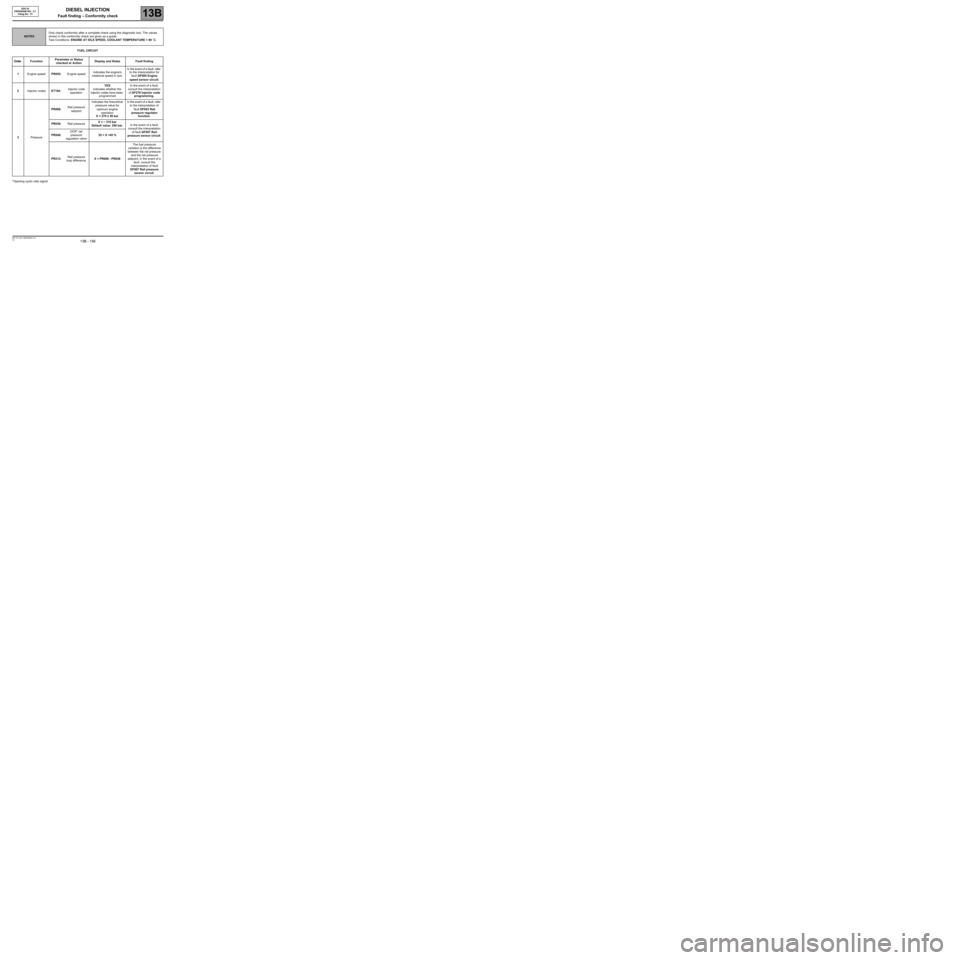

FUEL CIRCUIT

*Opening cyclic ratio signal

NOTESOnly check conformity after a complete check using the diagnostic tool. The values

shown in this conformity check are given as a guide.

Test Conditions: ENGINE AT IDLE SPEED, COOLANT TEMPERATURE > 80 ˚C.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

1Engine speedPR055:Engine speedIndicates the engine's

rotational speed in rpm.In the event of a fault, refer

to the interpretation for

fault DF005 Engine

speed sensor circuit.

2Injector codesET104:Injector code

operationYES

Indicates whether the

injector codes have been

programmedIn the event of a fault,

consult the interpretation

of DF276 Injector code

programming.

3PressurePR008:Rail pressure

setpointIndicates the theoretical

pressure value for

optimum engine

operation

X = 270 ± 50 barIn the event of a fault, refer

to the interpretation of

fault DF053 Rail

pressure regulator

function.

PR038:Rail pressureX = ~ 315 bar

Default value: 250 bar.In the event of a fault,

consult the interpretation

of fault DF007 Rail

pressure sensor circuit. PR048:OCR* rail

pressure

regulation valve35 < X <45 %

PR213:Rail pressure

loop differenceX = PR008 - PR038The fuel pressure

variation is the difference

between the rail pressure

and the rail pressure

setpoint. In the event of a

fault, consult the

interpretation of fault

DF007 Rail pressure

sensor circuit.

Page 157 of 273

DIESEL INJECTION

Fault finding – Conformity check13B

13B - 157V3 MR-372-J84-13B250$450.mif

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

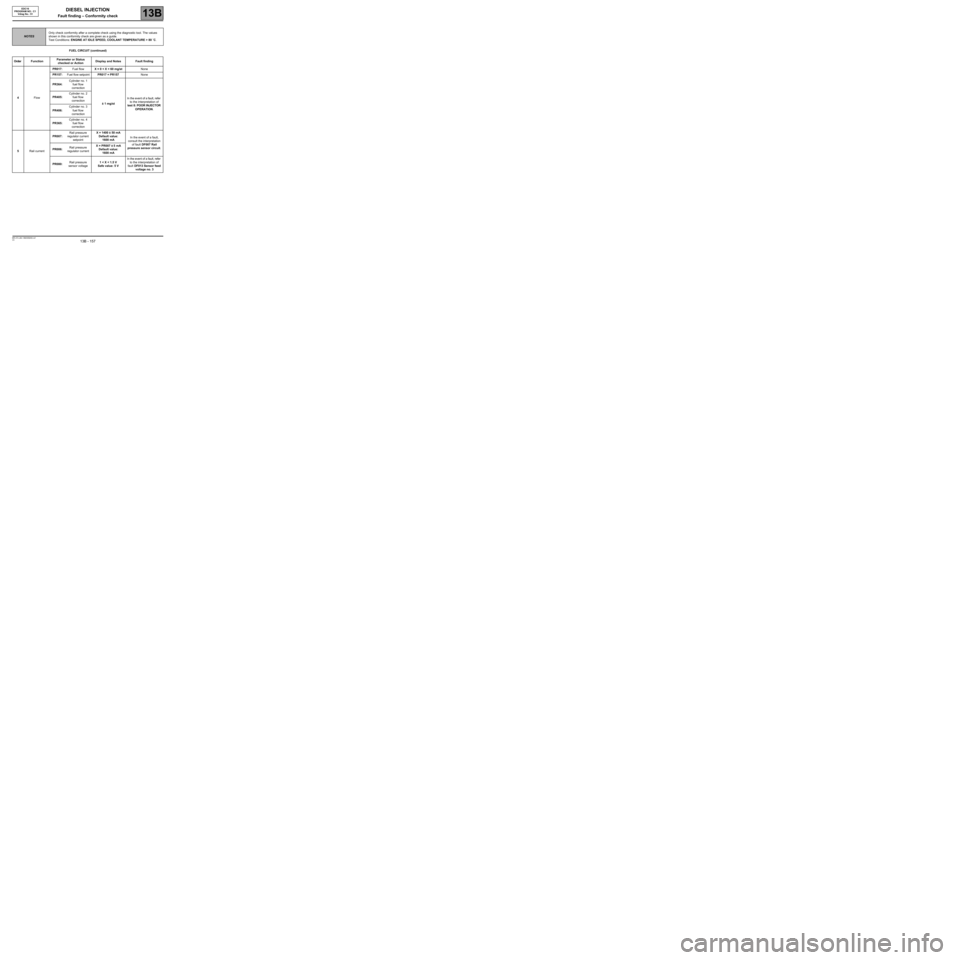

FUEL CIRCUIT (continued)

NOTESOnly check conformity after a complete check using the diagnostic tool. The values

shown in this conformity check are given as a guide.

Test Conditions: ENGINE AT IDLE SPEED, COOLANT TEMPERATURE > 80 ˚C.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

4FlowPR017:Fuel flowX = 0 < X < 60 mg/stNone

PR157:Fuel flow setpointPR017 = PR157None

PR364:Cylinder no. 1

fuel flow

correction

± 1 mg/stIn the event of a fault, refer

to the interpretation of

test 8: POOR INJECTOR

OPERATION. PR405:Cylinder no. 2

fuel flow

correction

PR406:Cylinder no. 3

fuel flow

correction

PR365:Cylinder no. 4

fuel flow

correction

5Rail currentPR007:Rail pressure

regulator current

setpointX = 1400 ± 50 mA

Default value:

1600 mAIn the event of a fault,

consult the interpretation

of fault DF007 Rail

pressure sensor circuit.

PR006:Rail pressure

regulator currentX = PR007 ± 5 mA

Default value:

1600 mA

PR080:Rail pressure

sensor voltage1 < X < 1.5 V

Safe value: 5 VIn the event of a fault, refer

to the interpretation of

fault DF013 Sensor feed

voltage no. 3

Page 206 of 273

DIESEL INJECTION

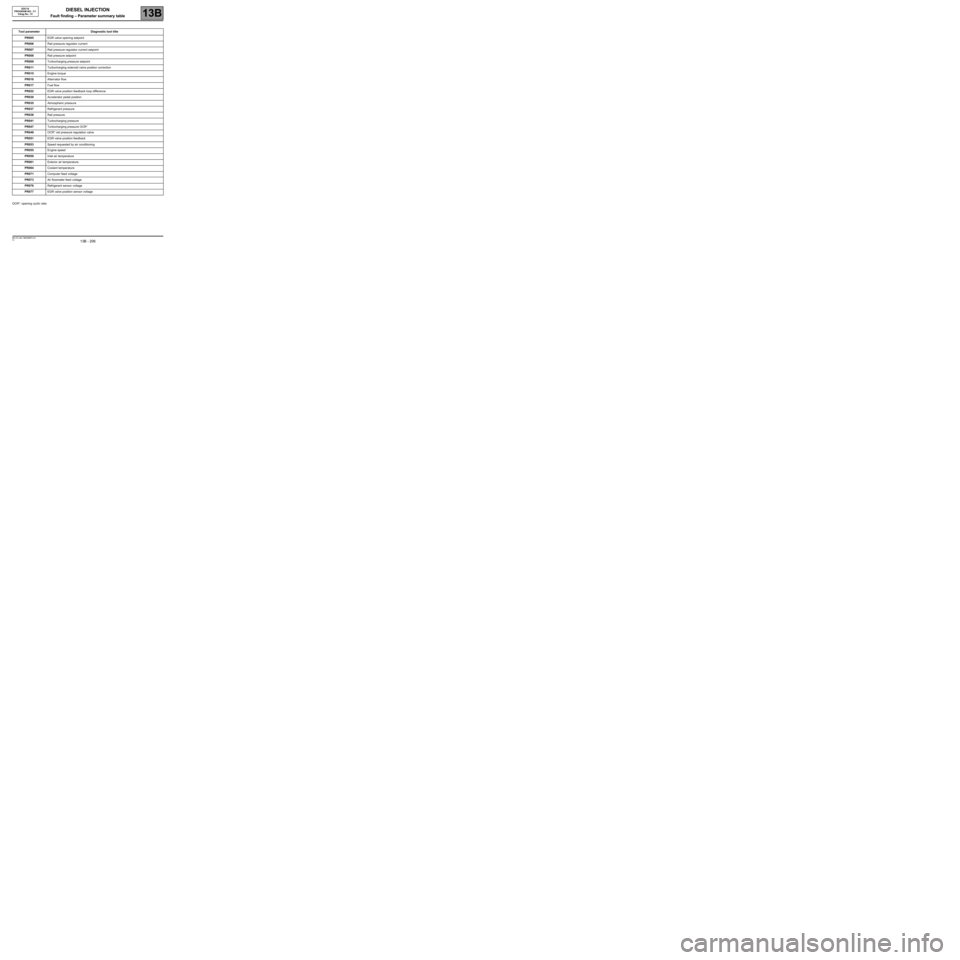

Fault finding – Parameter summary table13B

13B - 206V3 MR-372-J84-13B250$675.mif

EDC16

PROGRAM NO.: C1

Vdiag No.: 51DIESEL INJECTION

Fault finding – Parameter summary table

OCR*: opening cyclic ratioTool parameter Diagnostic tool title

PR005EGR valve opening setpoint

PR006Rail pressure regulator current

PR007Rail pressure regulator current setpoint

PR008Rail pressure setpoint

PR009Turbocharging pressure setpoint

PR011Turbocharging solenoid valve position correction

PR015Engine torque

PR016Alternator flow

PR017Fuel flow

PR022EGR valve position feedback loop difference

PR030Accelerator pedal position

PR035Atmospheric pressure

PR037Refrigerant pressure

PR038Rail pressure

PR041Turbocharging pressure

PR047Turbocharging pressure OCR*

PR048OCR* rail pressure regulation valve

PR051EGR valve position feedback

PR053Speed requested by air conditioning

PR055Engine speed

PR059Inlet air temperature

PR061Exterior air temperature

PR064Coolant temperature

PR071Computer feed voltage

PR073Air flowmeter feed voltage

PR076Refrigerant sensor voltage

PR077EGR valve position sensor voltage

MR-372-J84-13B250$675.mif

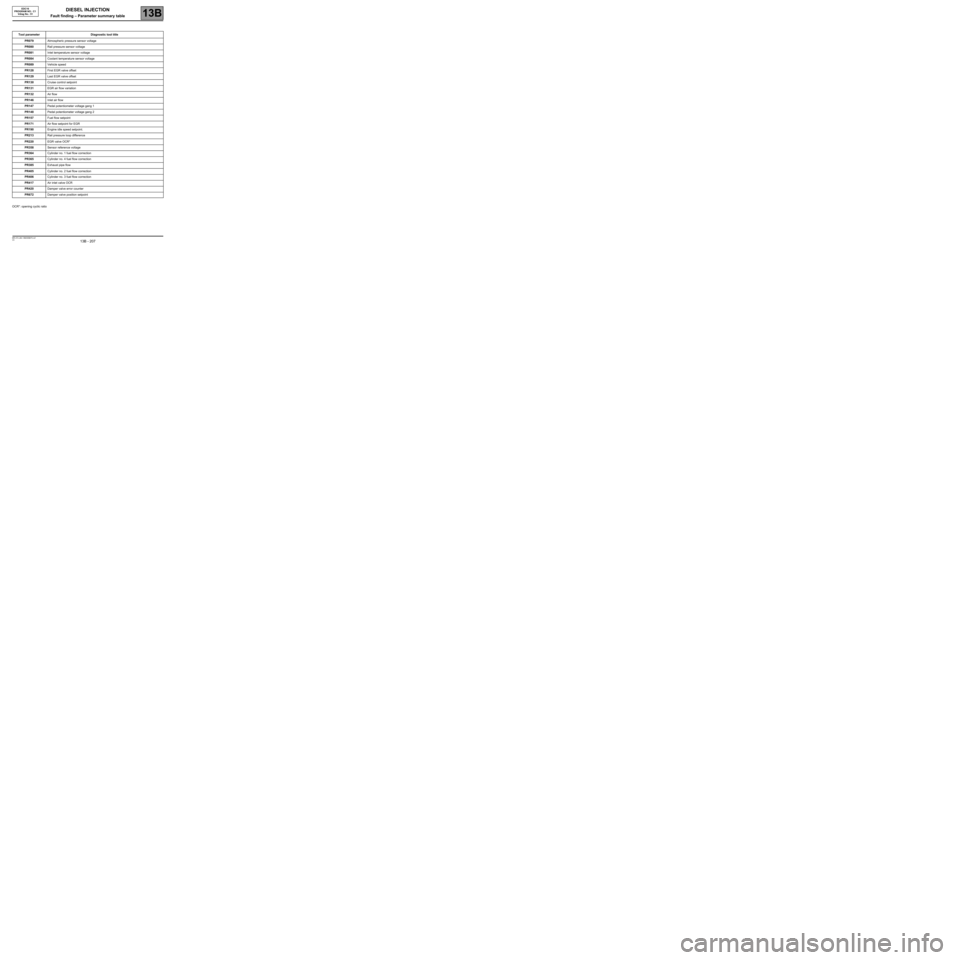

Page 207 of 273

DIESEL INJECTION

Fault finding – Parameter summary table13B

13B - 207V3 MR-372-J84-13B250$675.mif

EDC16

PROGRAM NO.: C1

Vdiag No.: 51

OCR*: opening cyclic ratioTool parameter Diagnostic tool title

PR079Atmospheric pressure sensor voltage

PR080Rail pressure sensor voltage

PR081Inlet temperature sensor voltage

PR084Coolant temperature sensor voltage

PR089Vehicle speed

PR128First EGR valve offset

PR129Last EGR valve offset

PR130Cruise control setpoint

PR131EGR air flow variation

PR132Air flow

PR146Inlet air flow

PR147Pedal potentiometer voltage gang 1

PR148Pedal potentiometer voltage gang 2

PR157Fuel flow setpoint

PR171Air flow setpoint for EGR

PR190Engine idle speed setpoint.

PR213Rail pressure loop difference

PR220EGR valve OCR*

PR358Sensor reference voltage

PR364Cylinder no. 1 fuel flow correction

PR365Cylinder no. 4 fuel flow correction

PR385Exhaust pipe flow

PR405Cylinder no. 2 fuel flow correction

PR406Cylinder no. 3 fuel flow correction

PR417Air inlet valve OCR

PR420Damper valve error counter

PR672Damper valve position setpoint