air filter RENAULT SCENIC 2009 J84 / 2.G Engine And Peripherals EDC16 Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: SCENIC, Model: RENAULT SCENIC 2009 J84 / 2.GPages: 273

Page 252 of 273

DIESEL INJECTION

Fault finding – Test13B

13B -252V3 MR-372-J84-13B250$900.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

TEST6 Turbocharger

IMPORTANT

Perform these checks without removing the turbocharger and with the vehicle ignition switched off.

Check the turbocharger shaft

WARNING

Respect the following safety precautions:

–wear heat resistant gloves when the engine is hot,

–do not wear loose or baggy clothing and do not wear loose hanging jewellery,

–be aware that the cooling fan assembly may be triggered and pay attention to the operation of the accessories

belt or belts.

Note:

The turbocharger shaft is the shaft connecting the compressor wheel and the turbine wheel.

According to the vehicle type, maximum visual access will either be from above or from below.

Disconnect the air pipe located between the turbocharger and the air filter.

Wearing gloves, check the operation of the turbocharger shaft by turning the vanes manually without forcing.

Is there a point of resistance when the shaft is rotated?

Does the compressor wheel touch the turbocharger housing?

If for these 2 questions the response is NOIf YES for one of these 2 questions

Replace the turbocharger (see MR 364 (Mégane II) or

370 (Scénic II), Mechanical, 12B, Turbocharging,

Turbocharger: Removal - Refitting and Technical

Note 3938A, Broken turbocharger: Replacement

instructions).

EDC16_V51_TEST6

Page 264 of 273

DIESEL INJECTION

Fault finding – Test13B

13B -264V3 MR-372-J84-13B250$900.mif

TEST9 Air path around the turbocharger

Check for the air filter

Check the replacement frequency for the air filter in the Maintenance Booklet.

Compare the part numbers of the air filter fitted to the vehicle and that of the air filter recommended by the

manufacturer.

Check the air filter direction of fitting.

Is the air filter fitted to the vehicle correct?

YES NO

Check the condition of the air filter

Visually inspect the condition of the filter

section of the air filter.

Is either the air filter or its seal

damaged?

Is the air filter clogged (does it contain

a lot of impurities)?YESReplace the air filter (see MR 364

(Mégane II) or 370 (Scénic II),

Mechanical, 12A, Fuel mixture, Air

filter, Removal - Refitting).

NO

Low pressure circuit check

Note:

According to the vehicle type, maximum

visual access will either be from above or

from below.

Visually inspect the condition of the

following components:

–fresh air inlet scoop on the front end

panel of the vehicle,

–air filter air inlet pipe,

–filter air pipe up to the compressor

inlet,

–air flowmeter mountings.

Is one of these components incorrect

(disconnected, cut, bent, pierced or

kinked pipes)?YESReplace the defective parts (see MR 364

(Mégane II) or 370 (Scénic II),

Mechanical, 12B, Turbocharging).

EDC16

PROGRAM No.: C1

Vdiag No.: 51

EDC16_V51_TEST9

Page 266 of 273

DIESEL INJECTION

Fault finding – Test13B

13B -266V3 MR-372-J84-13B250$900.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

TEST10 Diesel fuel conformity check

WARNING

During t hisop eration, it is essential t o:

–refrain from smoking or bringing incandescent objects close to the work area,

–protect yourself against fuel splashes due to residual pressure in the pipes,

–wear safety goggles with side guards,

–wear leaktight gloves (Nitrile type).

IMPORTA NT

–To avoid any corrosion or damage, protect the areas on which fuel is likely to run.

–To prevent impurities from entering the circuit, place protective plugs on all fuel circuit components

exposed to the open air.

Preparations:

Weigh an empty 1300 ml plastic cup (part no. 77 11 171 413) with its cover (part no. 77 11 171 416) using

electronic scales such as those used in body paint workshops (example: PANDA part no. 77 11 224 995). Record

the weight of the empty plastic cup.

This type of plastic cup is used to prepare paint.

Remove 1 litre of fuel at the diesel filter outlet (see MR 364 (Mégane II) or MR 370 (Scénic II), Mechanical,

19C, Tank, Draining the fuel tank), using a pneumatic transfer pump (part no. 634-200) and place it in the

1300 ml plastic cup.

Cover the plastic cup with its cover and let it settle for approximately 2 minutes.

Is the fuel cloudy or does it

separate into two parts?YESThe diesel fuel contains water and is not compliant.

Drain the fuel circuit, including the tank (see MR 364

(Mégane II) or MR 370 (Scénic II), Mechanical, 19C,

Tank, Draining the fuel tank).

NO

EDC16_V51_TEST10

Page 273 of 273

DIESEL INJECTION

Fault finding – Glossary13B

13B -273V3 MR-372-J84-13B250$945.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51DIESEL INJECTION

Fault finding – Glossary

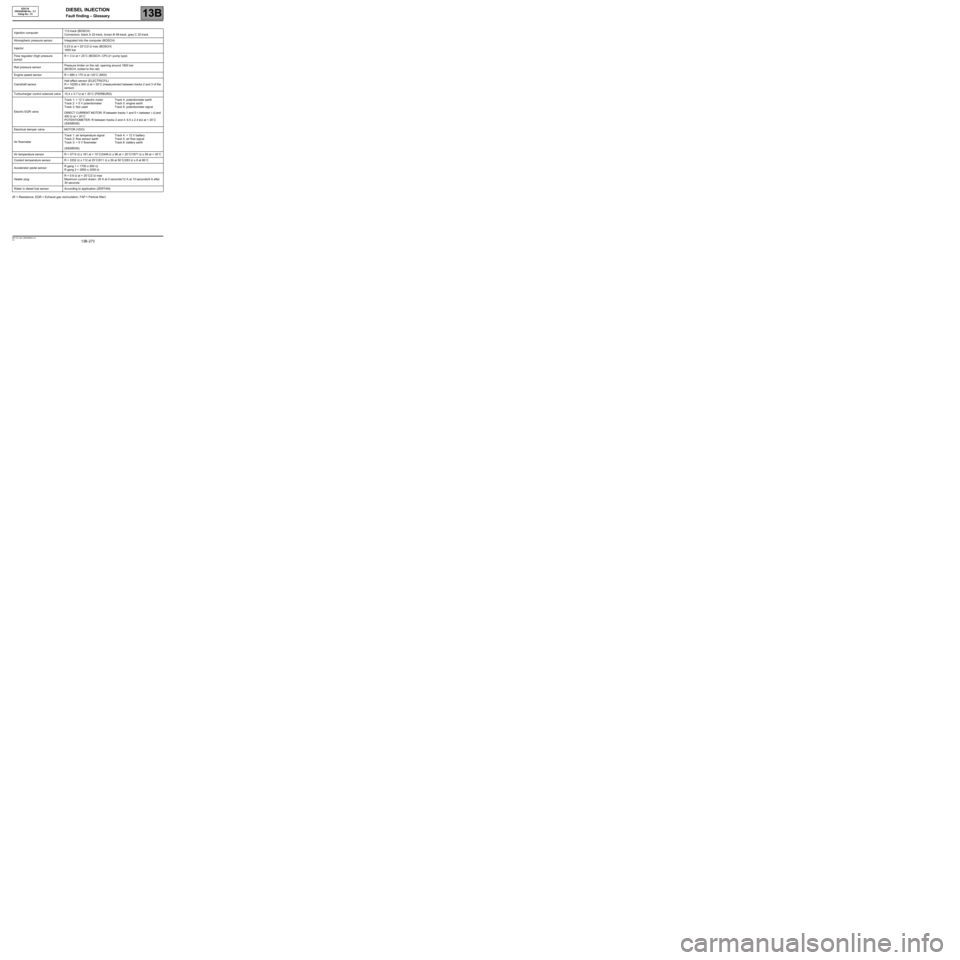

(R = Resistance, EGR = Exhaust gas recirculation, FAP = Particle filter)Injection computer112-track (BOSCH)

Connectors: black A 32-track, brown B 48-track, grey C 32-track

Atmospheric pressure sensor Integrated into the computer (BOSCH)

Injector0.23 Ω at + 20˚C/2 Ω max (BOSCH)

1600 bar

Flow regulator (high pressure

pump)R = 3 Ω at + 20˚C (BOSCH, CP3.2+ pump type)

Rail pressure sensorPressure limiter on the rail: opening around 1800 bar

(BOSCH, bolted to the rail)

Engine speed sensor R = 680 ± 170 Ω at +20˚C (MGI)

Camshaft sensorHall effect sensor (ELECTRICFIL)

R = 10250 ± 500 Ω at + 20˚C (measurement between tracks 2 and 3 of the

sensor)

Turbocharger control solenoid valve 15.4 ± 0.7 Ω at + 20˚C (PIERBURG)

Electric EGR valveTrack 1: + 12 V electric motor

Track 2: + 5 V potentiometer

Track 3: Not usedTrack 4: potentiometer earth

Track 5: engine earth

Track 6: potentiometer signal

DIRECT CURRENT MOTOR: R between tracks 1 and 5 = between 1 Ω and

400 Ω at + 20˚C

POTENTIOMETER: R between tracks 2 and 4: 6.5 ± 2.4 kΩ at + 20˚C

(SIEMENS)

Electrical damper valve MOTOR (VDO)

Air flowmeterTrack 1: air temperature signal

Track 2: flow sensor earth

Track 3: + 5 V flowmeterTrack 4: + 12 V battery

Track 5: air flow signal

Track 6: battery earth

(SIEMENS)

Air temperature sensor R = 3714 Ω ± 161 at + 10˚C/2448 Ω ± 96 at + 20˚C/1671 Ω ± 59 at + 30˚C

Coolant temperature sensor R = 2252 Ω ± 112 at 25˚C/811 Ω ± 39 at 50˚C/283 Ω ± 8 at 80˚C

Accelerator pedal sensorR gang 1 = 1700 ± 900 Ω;

R gang 2 = 2850 ± 2050 Ω

Heater plugR = 0.6 Ω at + 20˚C/2 Ω max

Maximum current drawn: 28 A at 0 seconds/12 A at 10 seconds/9 A after

30 seconds

Water in diesel fuel sensor According to application (ZERTAN)