ABS RENAULT SCENIC 2009 J84 / 2.G Engine And Peripherals EDC16 Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: SCENIC, Model: RENAULT SCENIC 2009 J84 / 2.GPages: 273

Page 215 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -215V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

AC001

PREHEATING UNIT

NOTESThis command is only carried out if the fault DF025 Preheating unit fault finding

connection, or DF017 Preheating unit control circuit is present or stored and if no

other fault is present.

Refer to the Wiring diagrams Technical Note for the vehicle to locate the fuses and

relays concerned.

Connect the diagnostic tool and turn on the ignition.

With the preheating unit connected:

–connect the negative terminal of the voltmeter to track 8 of the preheating unit,

–connect the positive terminal of the voltmeter to the + 12 V battery,

–run command AC001 Preheating unit.

if the voltmeter does not indicate the battery voltage while the command is running (ten 1 second ON/OFF cycles):

1Check the condition of the preheating unit supply fuse F01 (70A).

Replace it if necessary.

2Check the following connections for continuity and the absence of interference resistance:

Injection computer connector C track E2 track 8 of the preheating unit connector

Injection computer connector C track A4 Track 3 of the preheating unit connector

Repair if necessary.

3Check the connections on the pre-postheating unit, heater plugs and injection computer.

Repair if necessary.

4Measure the resistance of the heater plugs. If this resistance is greater than 2 Ω replace the faulty plug(s).

5Check the continuity and absence of interference resistance between:

preheating unit track 1 cylinder 3 heater plug

preheating unit track 2 cylinder 1 heater plug

preheating unit track 6 cylinder 4 heater plug

preheating unit track 7 cylinder 2 heater plug.

6Then check for + 12 V supply on track 4 of the preheating relay connector.

If the fault is still present, replace the preheating unit.

EDC16_V51_AC001

Page 218 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -218V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

* Opening cyclic ratio signalAC011

RAIL PRESSURE REGULATOR

NOTESThis command is used to check:

–the operation of the pressure regulator,

–and the high pressure injection circuit.

Step 1

Measure the pressure regulator resistance between tracks 1 and 2.

–Replace the regulator if its resistance is not approximately: 3 Ω ± 0.5 at 20˚C.

Check the continuity and absence of interference resistance of the following connections:

Injection computer brown 48-track connector B,

track M4track 2 of the rail pressure regulator connector

+ 12 V after relaytrack 1 of the rail pressure regulator connector

If, when running command AC011, you can hear a slight whistling noise and a crunching noise from the pressure

regulator, go to step 2. Otherwise, ensure that the computer output stage is functioning correctly:

Using a voltmeter:

With the solenoid valve connected, connect the voltmeter earth lead to track 2 of the fuel pressure solenoid valve

and the positive cable to track 1. Clear any fuel pressure solenoid valve faults, then run command AC011:

●The voltmeter should display two successive voltages: ~ 2.5 V for an opening cyclic ratio of 20% then ~ 8.75 V

for an opening cyclic ratio* of 70% (ten cycles).

Or using an oscilloscope (range 5 V/division and with time base 1 ms/division):

With the solenoid valve connected, connect the oscilloscope earth to the battery earth and the positive contact point

on track 2 of the fuel pressure solenoid valve; clear any fuel pressure solenoid valve faults then run command

AC011:

●the oscilloscope should display a square wave signal with an amplitude of 12.5 V at a frequency of 185 Hz (with

an OCR* passing from 20 to 70%).

If the measurement is correct, replace the regulator.

If the measurement is not correct, contact the Techline.

EDC16_V51_AC011

Page 220 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -220V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

AC012

DAMPER VALVE

NOTESThis command allows you to check the operation of the damper valve.

–Measure the resistance of the damper valve solenoid valve between tracks 1 and 2.

Replace the solenoid valve if the resistance is not: 46 ± 3 Ω at + 25˚C.

–Check for continuity and for the absence of interference resistance on the following connections:

Injection computer, brown 48-track connector

B, track M1track 1 of the damper valve solenoid valve

connector

+ 12 V after relaytrack 2 of the damper valve solenoid valve

connector

A) Engine running at idle speed

Make sure that there is a pressure of ~ 900 mbar on the solenoid valve inlet hose.

Make the necessary repairs (pressure circuit conformity and seal).

B) With the vehicle ignition on, engine stopped

Make sure the damper valve is open.

If not, clean or replace the air vent unit.

Disconnect the solenoid valve inlet and outlet hoses,

Connect a vacuum pump to the inlet union and apply a pressure of ~900 mbar

If there is a leak, replace the solenoid valve.

Run command AC012.

Otherwise, with the solenoid valve connected, check operation of the computer output stage with a voltmeter:

Voltmeter earth cabletrack 1 of the solenoid valve

Voltmeter positive leadtrack 2 of the solenoid valve

Clear any solenoid valve faults,

Run command AC012.

The voltmeter should display ten ON-OFF cycles (8.75 V then 2.5 V).

If the measurement is correct, replace the solenoid valve.

If the measurement does not show any lights, contact the Techline.

C) Vehicle with ignition off

Connect a vacuum pump to the flap control diaphragm and apply a pressure of ~900 mbar:

If the diaphragm does not maintain the negative pressure, replace the air vent unit (the diaphragm cannot be

disconnected).

If the diaphragm maintains the vacuum and the flap does not operate, clean or replace the air vent unit.

If the diaphragm maintains the underpressure and the valve operates, then operate it several times to ensure

that there is no blockage.

Check for clogging of the air vent unit and its valve, and clean if necessary.

EDC16_V51_AC012

Page 221 of 273

DIESEL INJECTION

Fault finding – Interpretation of commands13B

13B -221V3 MR-372-J84-13B250$765.mif

EDC16

PROGRAM No: C1

Vdiag No.: 51

AC195

ELECTRIC COOLANT PUMP

NOTESThis command allows you to check the operation of the electric coolant pump.

Test the electric coolant pump relay (A 20A) and check it is operating correctly.

Check the injection computer connections.

Repair if necessary.

Check the continuity between the following connections: Tracks B1 and B5 of the coolant pump relay mounting.

If the checks yield the correct results, check the continuity and absence of interference resistance on the

following connections:

Injection computer brown 48-track connector B,

track H4Track B2 of the coolant pump relay mounting

Injection supply relay mounting, Track 5Track B1 of the coolant pump relay mounting

Injection supply relay mounting, Track 5Track B5 of the coolant pump relay mounting

Turbocharger bearing coolant pump connector,

Track 1Track B3 of the coolant pump relay mounting

Turbocharger bearing coolant pump connector,

Track 2Earth

Repair if necessary.

If the fault is still present, contact the Techline.

EDC16_V51_AC195

Page 223 of 273

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

13B -223V3 MR-372-J84-13B250$855.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51DIESEL INJECTION

Fault finding – Fault Finding Chart

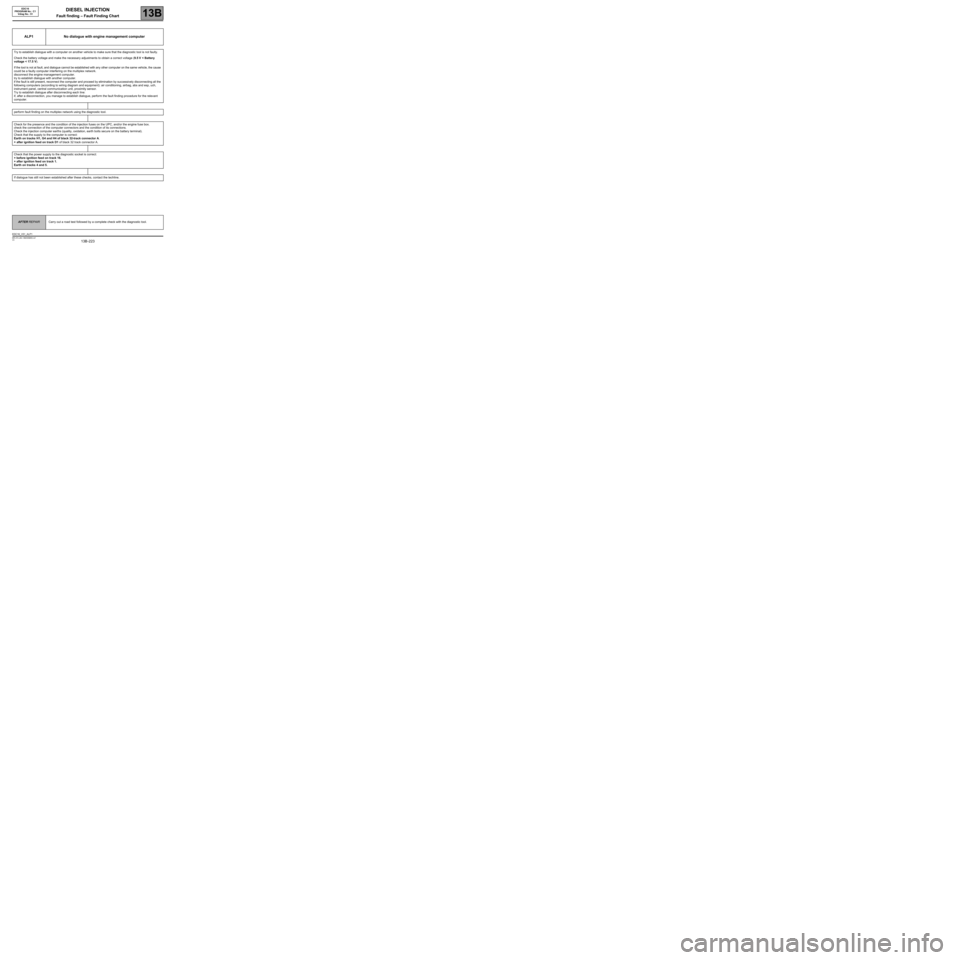

ALP1 No dialogue with engine management computer

Try to establish dialogue with a computer on another vehicle to make sure that the diagnostic tool is not faulty.

Check the battery voltage and make the necessary adjustments to obtain a correct voltage (9.5 V < Battery

voltage < 17.5 V).

If the tool is not at fault, and dialogue cannot be established with any other computer on the same vehicle, the cause

could be a faulty computer interfering on the multiplex network.

disconnect the engine management computer.

try to establish dialogue with another computer.

if the fault is still present, reconnect the computer and proceed by elimination by successively disconnecting all the

following computers (according to wiring diagram and equipment): air conditioning, airbag, abs and esp, uch,

instrument panel, central communication unit, proximity sensor.

Try to establish dialogue after disconnecting each line:

if, after a disconnection, you manage to establish dialogue, perform the fault finding procedure for the relevant

computer.

perform fault finding on the multiplex network using the diagnostic tool.

Check for the presence and the condition of the injection fuses on the UPC, and/or the engine fuse box.

check the connection of the computer connectors and the condition of its connections.

Check the injection computer earths (quality, oxidation, earth bolts secure on the battery terminal).

Check that the supply to the computer is correct:

Earth on tracks H1, G4 and H4 of black 32-track connector A.

+ after ignition feed on track D1 of black 32 track connector A.

Check that the power supply to the diagnostic socket is correct:

+ before ignition feed on track 16.

+ after ignition feed on track 1.

Earth on tracks 4 and 5.

If dialogue has still not been established after these checks, contact the techline.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16_V51_ALP1

Page 229 of 273

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

13B -229V3 MR-372-J84-13B250$855.mif

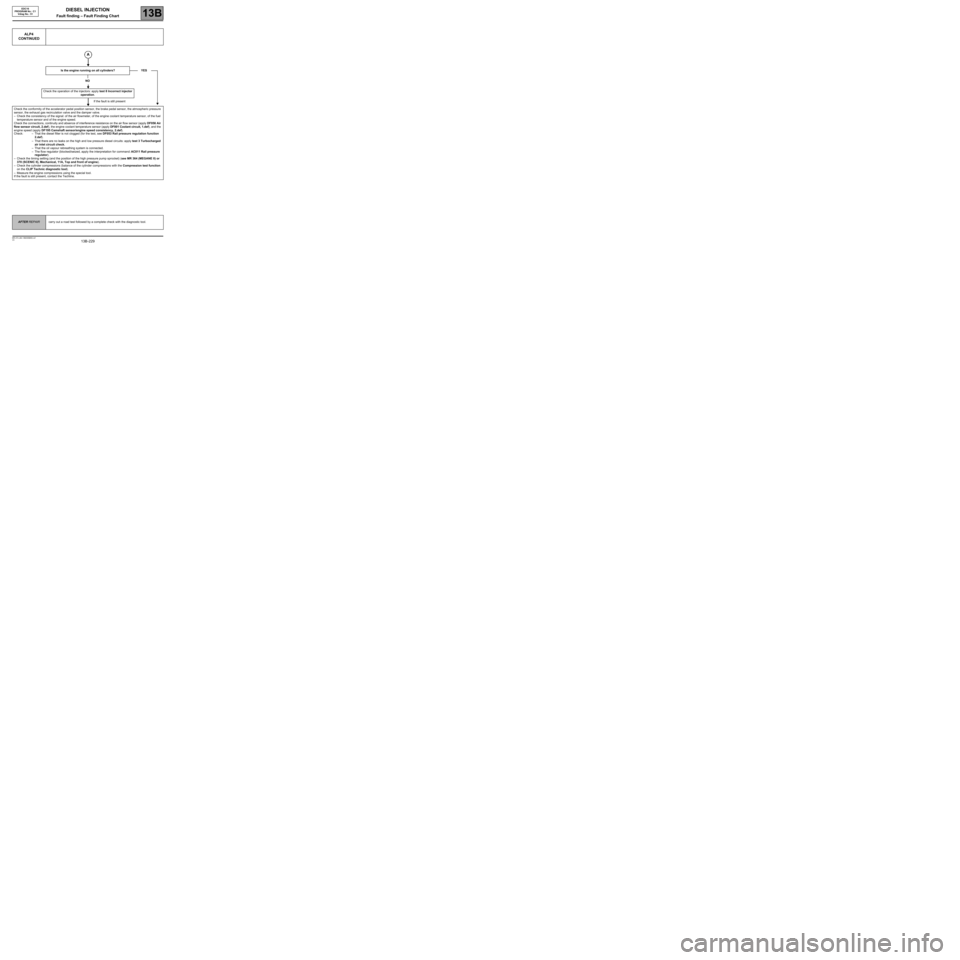

ALP4

CONTINUED

Is the engine running on all cylinders?

NO

Check the operation of the injectors: apply test 8 Incorrect injector

operation.

If the fault is still present

Check the conformity of the accelerator pedal position sensor, the brake pedal sensor, the atmospheric pressure

sensor, the exhaust gas recirculation valve and the damper valve.

–Check the consistency of the signal: of the air flowmeter, of the engine coolant temperature sensor, of the fuel

temperature sensor and of the engine speed.

Check the connections, continuity and absence of interference resistance on the air flow sensor (apply DF056 Air

flow sensor circuit, 2.def), the engine coolant temperature sensor (apply DF001 Coolant circuit, 1.def), and the

engine speed (apply DF195 Camshaft sensor/engine speed consistency, 2.def).

Check: – That the diesel filter is not clogged (for the test, see DF053 Rail pressure regulation function

2.def).

–That there are no leaks on the high and low pressure diesel circuits: apply test 3 Turbocharged

air inlet circuit check.

–That the oil vapour rebreathing system is connected.

–The flow regulator (blocked/seized, apply the interpretation for command: AC011 Rail pressure

regulator).

–Check the timing setting (and the position of the high pressure pump sprocket) (see MR 364 (MEGANE II) or

370 (SCENIC II), Mechanical, 11A, Top and front of engine).

–Check the cylinder compressions (balance of the cylinder compressions with the Compression test function

on the CLIP Technic diagnostic tool).

–Measure the engine compressions using the special tool.

If the fault is still present, contact the Techline.YES

EDC16

PROGRAM No.: C1

Vdiag No.: 51

AFTER REPAIRcarry out a road test followed by a complete check with the diagnostic tool.

Page 245 of 273

DIESEL INJECTION

Fault finding – Test13B

13B -245V3 MR-372-J84-13B250$900.mif

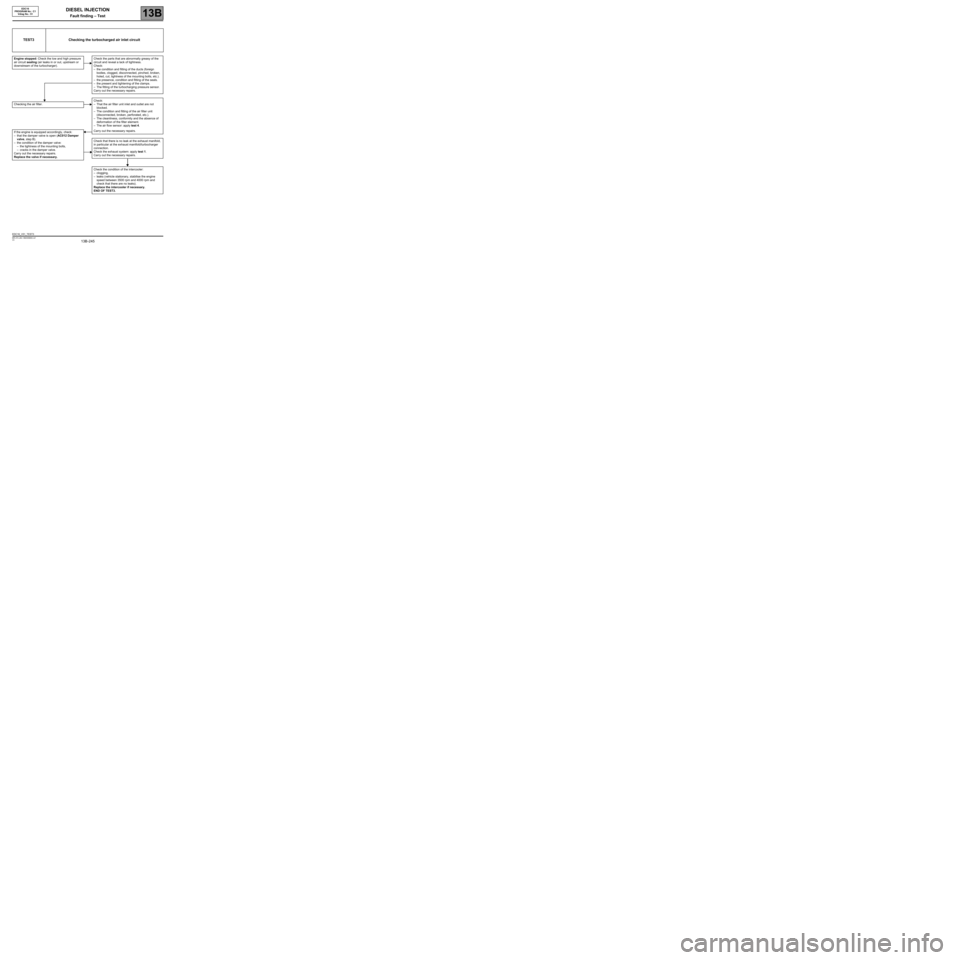

Checking the air filter.

If the engine is equipped accordingly, check:

–that the damper valve is open (AC012 Damper

valve, step B).

–the condition of the damper valve:

–the tightness of the mounting bolts,

–cracks in the damper valve.

Carry out the necessary repairs.

Replace the valve if necessary.

EDC16

PROGRAM No.: C1

Vdiag No.: 51

TEST3 Checking the turbocharged air inlet circuit

Engine stopped: Check the low and high pressure

air circuit sealing (air leaks in or out, upstream or

downstream of the turbocharger).Check the parts that are abnormally greasy of the

circuit and reveal a lack of tightness.

Check:

–the condition and fitting of the ducts (foreign

bodies, clogged, disconnected, pinched, broken,

holed, cut, tightness of the mounting bolts, etc.).

–the presence, condition and fitting of the seals.

–the present and tightening of the clamps.

–The fitting of the turbocharging pressure sensor.

Carry out the necessary repairs.

Check:

–That the air filter unit inlet and outlet are not

blocked.

–The condition and fitting of the air filter unit

(disconnected, broken, perforated, etc.).

–The cleanliness, conformity and the absence of

deformation of the filter element.

–The air flow sensor: apply test 4.

Carry out the necessary repairs.

Check that there is no leak at the exhaust manifold,

in particular at the exhaust manifold/turbocharger

connection.

Check the exhaust system: apply test 1.

Carry out the necessary repairs.

Check the condition of the intercooler:

–clogging,

–leaks (vehicle stationary, stabilise the engine

speed between 3500 rpm and 4000 rpm and

check that there are no leaks).

Replace the intercooler if necessary.

END OF TEST3.

EDC16_V51_TEST3

Page 250 of 273

DIESEL INJECTION

Fault finding – Test13B

13B -250V3 MR-372-J84-13B250$900.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

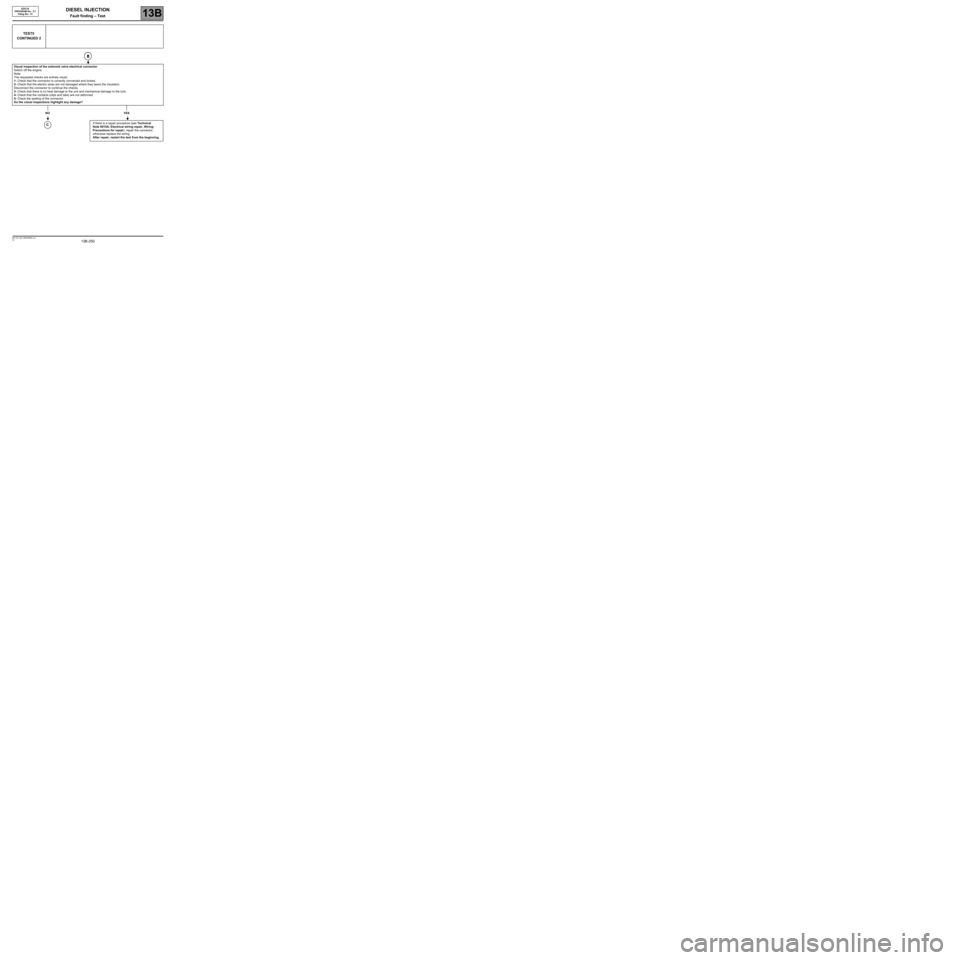

TEST5

CONTINUED 2

Visual inspection of the solenoid valve electrical connector

Switch off the engine.

Note:

The requested checks are entirely visual.

1- Check that the connector is correctly connected and locked.

2- Check that the electric wires are not damaged where they leave the insulation.

Disconnect the connector to continue the checks.

3- Check that there is no heat damage to the unit and mechanical damage to the lock.

4- Check that the contacts (clips and tabs) are not deformed.

5- Check the sealing of the connector.

Do the visual inspections highlight any damage?

NO YES

If there is a repair procedure (see Technical

Note 6015A, Electrical wiring repair, Wiring:

Precautions for repair), repair the connector,

otherwise replace the wiring.

After repair, restart the test from the beginning.

C

1

Page 257 of 273

DIESEL INJECTION

Fault finding – Test13B

13B -257V3 MR-372-J84-13B250$900.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

TEST8 Incorrect injector operation

Section A: Fuel regulation balance check for each injector (individual correction):

–In the CLIP diagnostic tool, choose the Fuel circuit subfunction.

–With the engine idling and the fuel temperature > 50˚C, display the flow correction values of each injector

(individual correction), i.e.:

–PR364 Cylinder no. 1 fuel flow correction.

–PR405 Cylinder no. 2 fuel flow correction.

–PR406 Cylinder no. 3 fuel flow correction.

–PR365 Cylinder no. 4 fuel flow correction.

A flow correction value greater than or equal to 5 mg/st absolute value can indicate an injector fault or cylinder

sealing fault.

–If this has not already been carried out, check the injector connections and wiring.

–Check the connections and wiring of the engine management computer to the injectors.

–Repair if necessary.

–Check the IMA injector codes, comparing the IMA codes on the injectors (the IMA codes must be read from left

to right) and the IMA codes read in the CLIP diagnostic tool.

–If the IMA codes are correct, continue the fault finding procedure,

–If not, change the incorrect IMA codes using command SC002 Enter injector codes (see Interpretation of

commands).

To confirm the repair, consult part B of this test.

CASE No. 1: If at least one of the values is greater than or equal to + 5 mg/st

–Check the valve clearance.

–Check the condition of the engine and the compressions (using the Clip diagnostic tool or a compression

gauge).

–If the compression test reveals a cylinder fault, carry out the necessary repairs.

–If the compression is correct, check the fitting conformity of the injector (see MR 364 (Mégane II) or 370 (Scénic

II), 13B, Diesel injection, Diesel injector: Removal - Refitting)

In particular, check that each injector has one compression washer.

Check the fuel regulation again for each injector (individual correction).

–If not, replace the injector and check for the sealing washer. Modify the IMA code using command SC002 Enter

injector codes (see Interpretation of commands).

–Apply Part B of this test to confirm the fault finding.

CASE No. 2: If at least one of the values is less than or equal to - 5 mg/st

–Check the valve clearance.

–Check the level and condition of the engine oil.

–Remove the injector with the largest correction.

–If there is diesel fuel contamination, check the condition of the cylinder concerned (cylinder, piston, valves).

Use an endoscope if possible.

–Only replace the removed injector, and modify the IMA code using command SC002 Enter injector codes

(see Interpretation of commands).

–Apply Part B of this test to confirm the fault finding.

EDC16_V51_TEST8

Page 262 of 273

DIESEL INJECTION

Fault finding – Test13B

13B -262V3 MR-372-J84-13B250$900.mif

EDC16

PROGRAM No.: C1

Vdiag No.: 51

2 - Checking the balance of the injector return flows:

3 - Removing the tool:

Disconnect the pipe from an injector:

–press on the injector clip,

–pull vertically on the end piece of the pipe of tool Mot.1760, placing a wipe on the end piece to prevent run-off.

Lift the end piece vertically so that the fuel contained in the pipes flows into the measuring cylinders of tool Mot.1760.

Remove the other 3 pipes using the same procedure.

TEST8

CONTINUED 5

Does the engine start? – Fit Mot. 1760 as shown in the tool fitting procedure.

–Start the vehicle or perform a 15 second starting sequence

(with ignition key).

–Measure the length travelled by the diesel fuel in the pipes of the

Mot. 1760.

–Replace the injector if the length travelled by the fuel is more than

10 cm compared with the average of the other three injectors. NO

YES

–The injector return pipes must be fitted to the injectors.

–Start the engine.

–Display the Fuel circuit sub-function in the CLIP diagnostic tool.

–Raise the temperature of the engine.

–Read the diesel fuel temperature with PR063 Fuel temperature until a diesel fuel temperature greater than

50˚C is reached

–Switch off the engine.

–Fit Mot. 1760 as shown in the installation procedure (see step 1).

–Check the value of the PR038 Rail pressure.

–Ask another Cotech to monitor the rise in fuel in the cans during engine turnover, as one of the cans will fill up

quickly if one of the injectors is leaking.

–Start the engine.

–Accelerate the engine until the pressure in the rail is 550 bar:

●if the engine speed is less than 3,000 rpm, maintain this pressure.

●if the engine speed is greater than 3000 rpm, reduce the engine speed until the rail pressure is 500 bar and

maintain this pressure.

–Maintain these conditions for one minute.

–Release the accelerator pedal and maintain the idle speed for 10 seconds.

–Switch off the engine.

–Measure the quantity of fuel contained in each measuring cylinder.

–Replace the injector if the quantity of fuel is more than 50 ml.

–Remove Mot. 1760 as shown in the tool removal procedure (see step 3).

IMPORTANT:

Use a cleaning cloth (part number 77 11 211 707) to absorb fuel run-off.