air condition RENAULT SCENIC 2010 J95 / 3.G Petrol Injection S3000 Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 230, PDF Size: 0.92 MB

Page 178 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 178

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 178V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

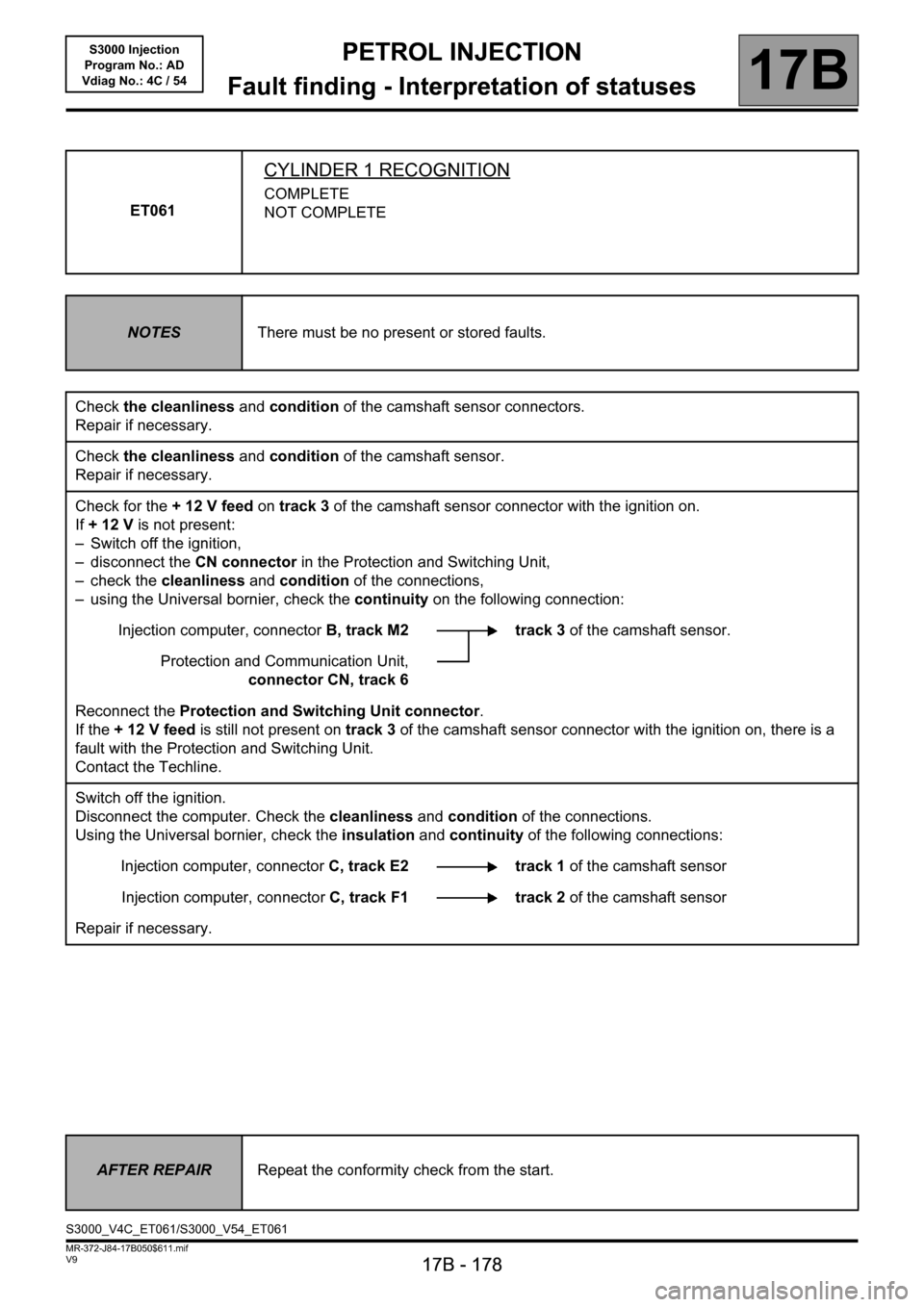

ET061

CYLINDER 1 RECOGNITION

COMPLETE

NOT COMPLETE

NOTESThere must be no present or stored faults.

Check the cleanliness and condition of the camshaft sensor connectors.

Repair if necessary.

Check the cleanliness and condition of the camshaft sensor.

Repair if necessary.

Check for the + 12 V feed on track 3 of the camshaft sensor connector with the ignition on.

If +12V is not present:

– Switch off the ignition,

– disconnect the CN connector in the Protection and Switching Unit,

– check the cleanliness and condition of the connections,

– using the Universal bornier, check the continuity on the following connection:

Injection computer, connectorB, track M2 track 3 of the camshaft sensor.

Protection and Communication Unit,

connector CN, track 6

Reconnect the Protection and Switching Unit connector.

If the + 12 V feed is still not present on track 3 of the camshaft sensor connector with the ignition on, there is a

fault with the Protection and Switching Unit.

Contact the Techline.

Switch off the ignition.

Disconnect the computer. Check the cleanliness and condition of the connections.

Using the Universal bornier, check the insulation and continuity of the following connections:

Injection computer, connectorC, track E2 track 1 of the camshaft sensor

Injection computer, connectorC, track F1 track 2 of the camshaft sensor

Repair if necessary.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_ET061/S3000_V54_ET061

Page 179 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 179

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 179V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

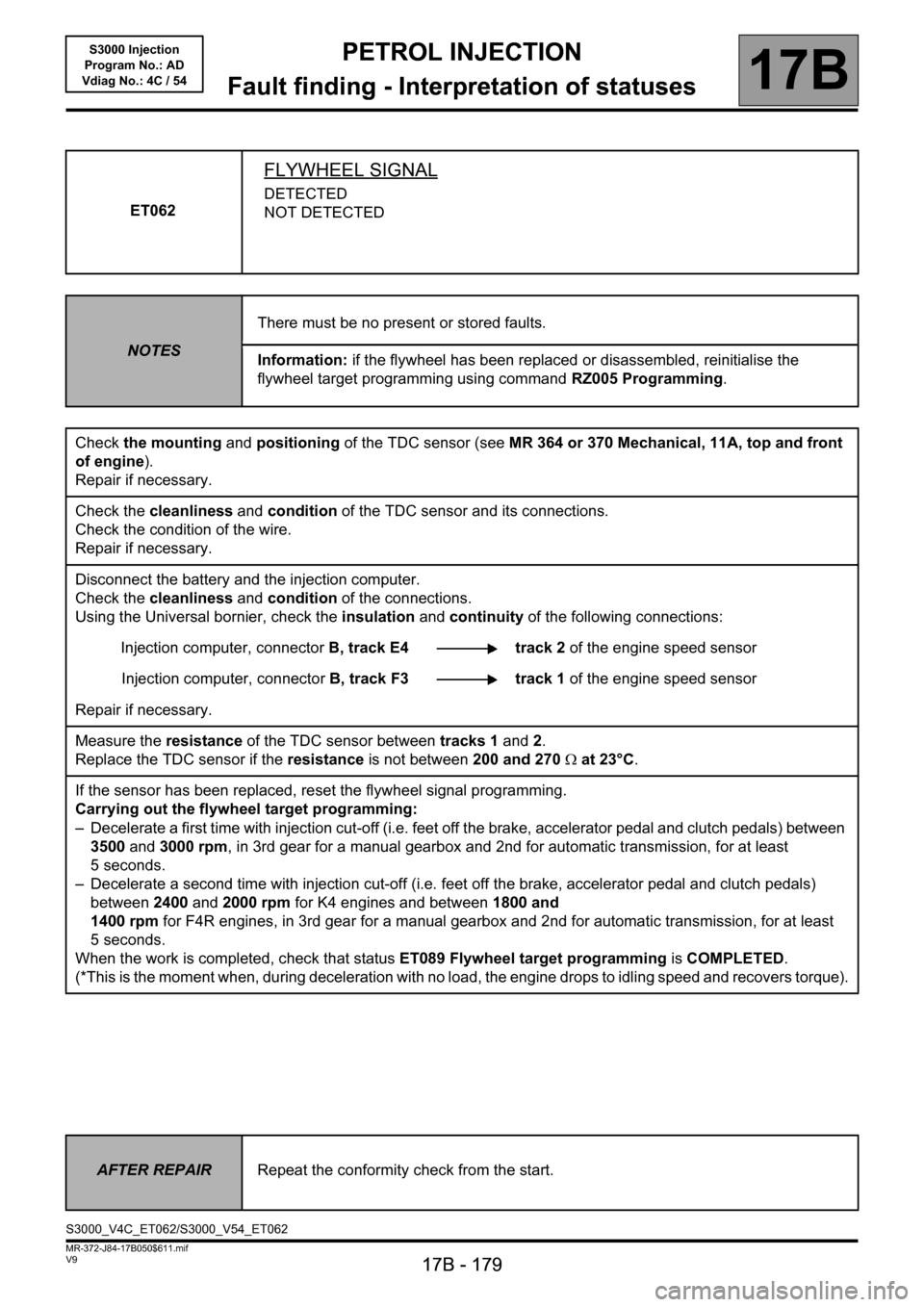

ET062

FLYWHEEL SIGNAL

DETECTED

NOT DETECTED

NOTESThere must be no present or stored faults.

Information: if the flywheel has been replaced or disassembled, reinitialise the

flywheel target programming using command RZ005 Programming.

Check the mounting and positioning of the TDC sensor (see MR 364 or 370 Mechanical, 11A, top and front

of engine).

Repair if necessary.

Check the cleanliness and condition of the TDC sensor and its connections.

Check the condition of the wire.

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the Universal bornier, check the insulation and continuity of the following connections:

Injection computer, connectorB, track E4 track 2 of the engine speed sensor

Injection computer, connectorB, track F3 track 1 of the engine speed sensor

Repair if necessary.

Measure the resistance of the TDC sensor between tracks 1 and 2.

Replace the TDC sensor if the resistance is not between 200 and 270Ω at 23°C.

If the sensor has been replaced, reset the flywheel signal programming.

Carrying out the flywheel target programming:

– Decelerate a first time with injection cut-off (i.e. feet off the brake, accelerator pedal and clutch pedals) between

3500 and 3000 rpm, in 3rd gear for a manual gearbox and 2nd for automatic transmission, for at least

5 seconds.

– Decelerate a second time with injection cut-off (i.e. feet off the brake, accelerator pedal and clutch pedals)

between 2400 and 2000 rpm for K4 engines and between 1800 and

1400 rpm for F4R engines, in 3rd gear for a manual gearbox and 2nd for automatic transmission, for at least

5 seconds.

When the work is completed, check that status ET089 Flywheel target programming is COMPLETED.

(*This is the moment when, during deceleration with no load, the engine drops to idling speed and recovers torque).

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_ET062/S3000_V54_ET062

Page 181 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 181

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 181V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

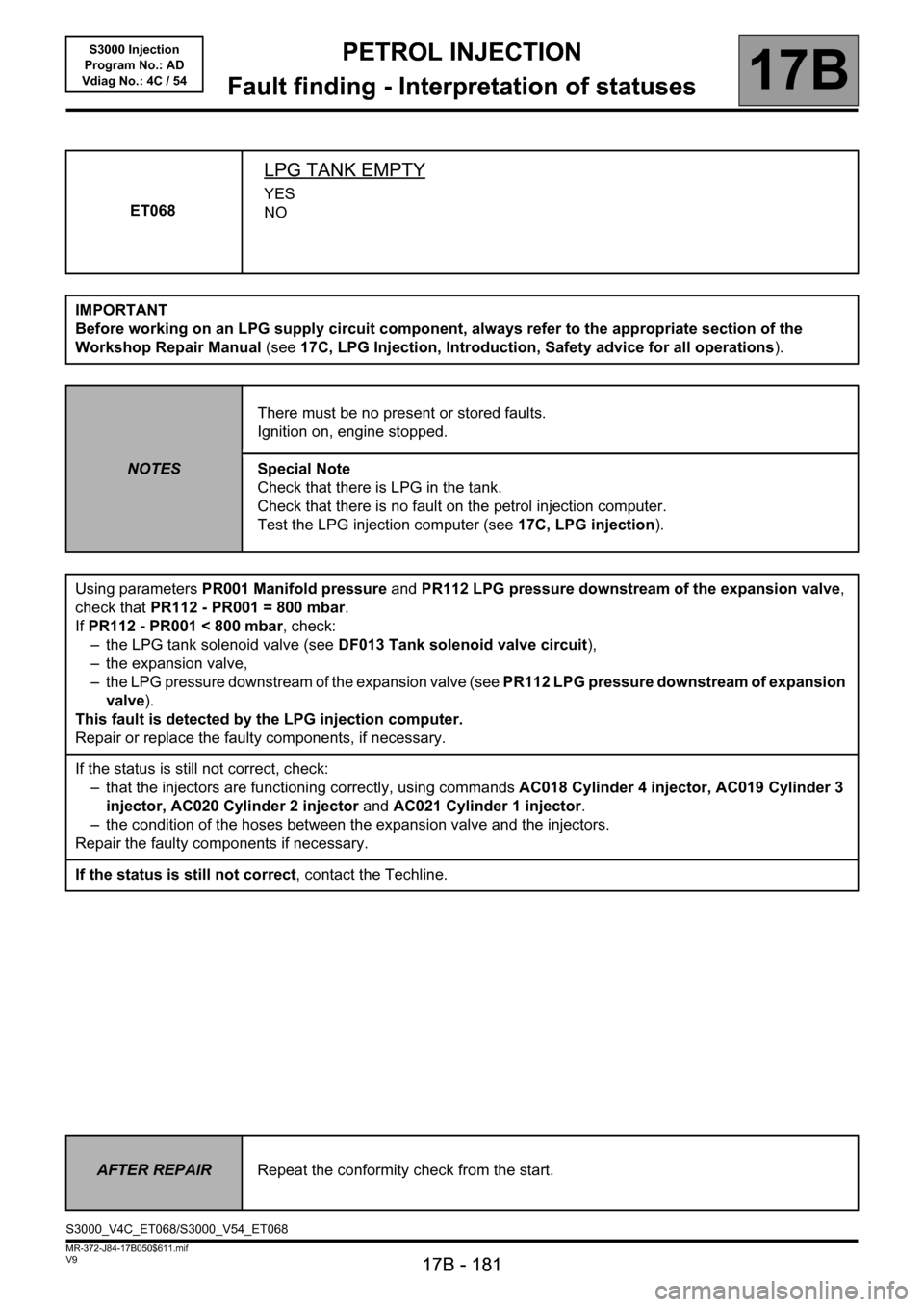

ET068

LPG TANK EMPTY

YES

NO

IMPORTANT

Before working on an LPG supply circuit component, always refer to the appropriate section of the

Workshop Repair Manual (see17C, LPG Injection, Introduction, Safety advice for all operations).

NOTESThere must be no present or stored faults.

Ignition on, engine stopped.

Special Note

Check that there is LPG in the tank.

Check that there is no fault on the petrol injection computer.

Test the LPG injection computer (see17C, LPG injection).

Using parameters PR001 Manifold pressure and PR112 LPG pressure downstream of the expansion valve,

check that PR112 - PR001 = 800 mbar.

If PR112 - PR001 < 800 mbar, check:

– the LPG tank solenoid valve (see DF013 Tank solenoid valve circuit),

– the expansion valve,

– the LPG pressure downstream of the expansion valve (see PR112 LPG pressure downstream of expansion

valve).

This fault is detected by the LPG injection computer.

Repair or replace the faulty components, if necessary.

If the status is still not correct, check:

– that the injectors are functioning correctly, using commands AC018 Cylinder 4 injector, AC019 Cylinder 3

injector, AC020 Cylinder 2 injector and AC021 Cylinder 1 injector.

– the condition of the hoses between the expansion valve and the injectors.

Repair the faulty components if necessary.

If the status is still not correct, contact the Techline.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_ET068/S3000_V54_ET068

Page 184 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 184

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 184V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

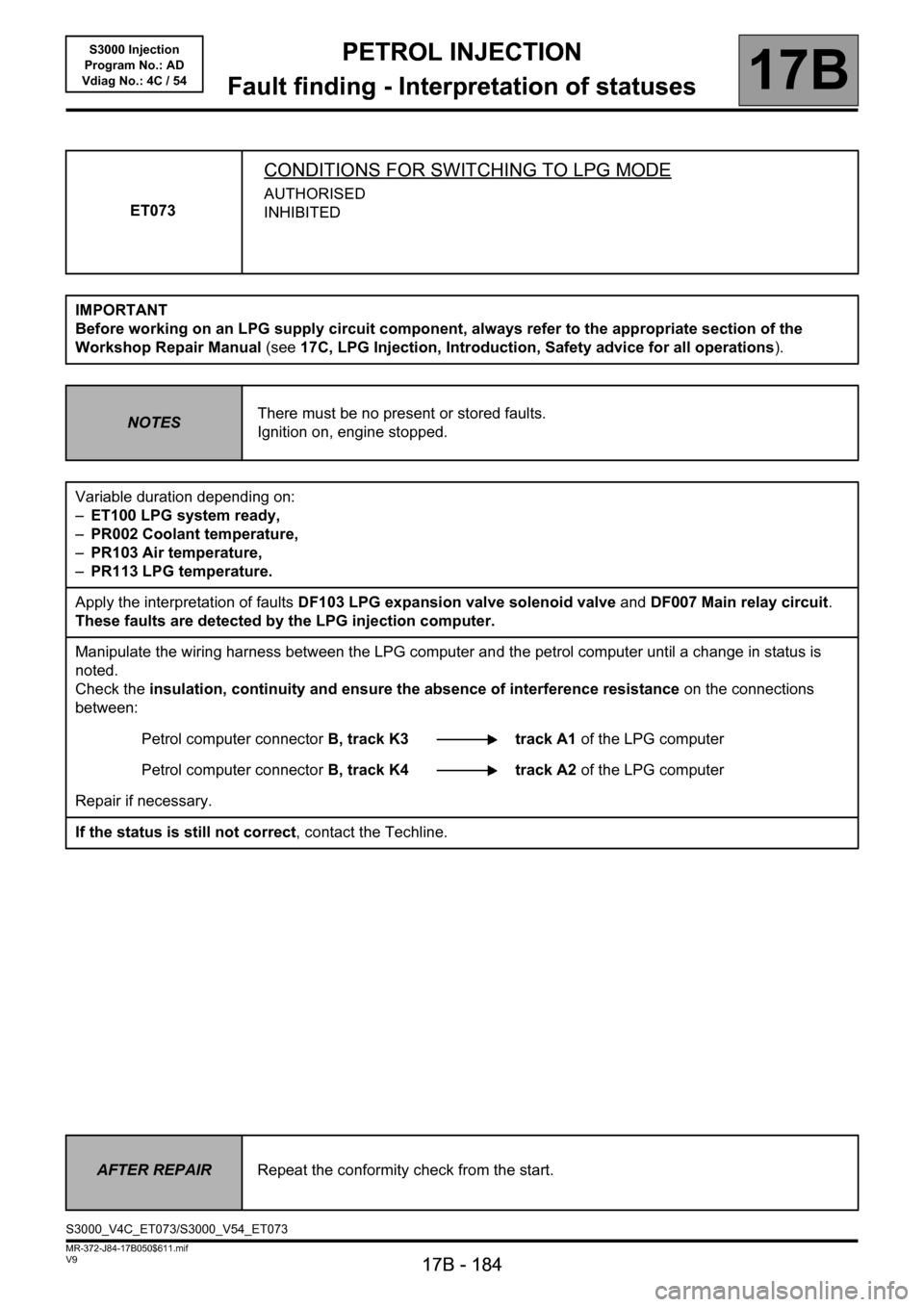

ET073

CONDITIONS FOR SWITCHING TO LPG MODE

AUTHORISED

INHIBITED

IMPORTANT

Before working on an LPG supply circuit component, always refer to the appropriate section of the

Workshop Repair Manual (see17C, LPG Injection, Introduction, Safety advice for all operations).

NOTESThere must be no present or stored faults.

Ignition on, engine stopped.

Variable duration depending on:

–ET100 LPG system ready,

–PR002 Coolant temperature,

–PR103 Air temperature,

–PR113 LPG temperature.

Apply the interpretation of faults DF103 LPG expansion valve solenoid valve and DF007 Main relay circuit.

These faults are detected by the LPG injection computer.

Manipulate the wiring harness between the LPG computer and the petrol computer until a change in status is

noted.

Check the insulation, continuity and ensure the absence of interference resistance on the connections

between:

Petrol computer connectorB, track K3 track A1 of the LPG computer

Petrol computer connectorB, track K4 track A2 of the LPG computer

Repair if necessary.

If the status is still not correct, contact the Techline.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_ET073/S3000_V54_ET073

Page 185 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 185

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 185V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

ET405

CLUTCH PEDAL SWITCH

NOTESSpecial note:

Only perform the tests if the statuses do not correspond with the system programming

functions.

ACTIVECheck the condition and fitting of the clutch pedal switch.

Remove the clutch pedal switch then check the insulation between tracks 1 and 2, with

the switch in the rest position.

Repeat this operation with the switch pressed and check the continuity between tracks

1 and 2.

If these two checks are not in order, replace the switch.

INACTIVECheck the condition and fitting of the clutch pedal switch.

Remove the clutch pedal switch then check the insulation between tracks 1 and 2, with

the switch in the rest position.

Repeat this operation with the switch pressed and check the continuity between tracks

1 and 2.

If these two checks are not in order, replace the switch.

Then check the continuity and make sure there is no interference resistance

on the following connection:

Injection computer connector A, black, 32-track, track C4 Track 1 clutch

connector

Check for earth on track 2 of the clutch switch connector.

If there is a repair method (see Technical Note 6015A, Electrical wiring repair,

Wiring: Repair precautions), repair the wiring, otherwise replace it.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

S3000_V4C_ET405/S3000_V54_ET405

Page 191 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 191

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 191V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

ET507

OBD UPSTREAM OXYGEN SENSOR HEATING CIRCUIT

NOTESThere must be no present or stored faults.

Check the cleanliness and condition of the upstream oxygen sensor and its connections.

Repair if necessary.

With the ignition on, check for + 12 V on track A of the upstream oxygen sensor connector.

If +12V is not present:

– disconnect the battery,

– disconnect the CN connector in the Protection and Switching Unit,

– check the cleanliness and condition of the connections,

– using the universal bornier, check for continuity on the following connection:

Protection and Switching Unit, connector CN,

track 6track A of the upstream oxygen sensor

Reconnect the Protection and Switching Unit connector and reconnect the battery.

With the ignition on, if there is still no +12V at the upstream oxygen sensor connector, there is a fault in the

Protection and Switching Unit.

Contact the Techline.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the Universal bornier, check the insulation and continuity on the following connection:

Injection computer, connectorC, track L2 track B of the upstream oxygen sensor

Repair if necessary.

Measure the heating resistance between tracks A and B of the upstream oxygen sensor.

Replace the upstream oxygen sensor if the resistance is not approximately 9Ω at 20°C.

If the fault is still present, replace the upstream oxygen sensor.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_ET507/S3000_V54_ET507

Page 192 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 192

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 192V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

ET509

OBD DOWNSTREAM OXYGEN SENSOR HEATING CIRCUIT

NOTESThere must be no present or stored faults.

Check the cleanliness and condition of the downstream oxygen sensor and its connections.

Repair if necessary.

With the ignition on, check for + 12 V feed on track A of the downstream oxygen sensor connector.

If +12V is not present:

– disconnect the battery,

– disconnect the CN connector in the Protection and Switching Unit,

– check the cleanliness and condition of the connections,

– using the Universal bornier, check the continuity on the following connection:

Protection and Switching Unit, connector CN,

track 6track A of the downstream oxygen sensor

Reconnect the Protection and Switching Unit connector and reconnect the battery.

With the ignition on, if the +12V is still not present on the downstream oxygen sensor connector, there is a fault

in the Protection and Switching Unit.

Contact the Techline.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the Universal bornier, check the insulation and continuity on the following connection:

Injection computer, connectorC, track L3 track B of the downstream oxygen sensor

Repair if necessary.

Measure the heating resistance between tracks A and B of the downstream oxygen sensor.

Replace the downstream oxygen sensor if the resistance is not approximately 9Ω at 20°C.

If the fault is still present, replace the downstream oxygen sensor.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_ET509/S3000_V54_ET509

Page 198 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 198

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 198V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

ET703

CRUISE CONTROL/SPEED LIMITER BUTTONS

NOTESSpecial notes:

Only perform the tests if the statuses do not correspond with the system programming

functions.

INACTIVEStatus ET703 becomes "INACTIVE" when none of the cruise control/speed limiter

buttons is pressed. These buttons are located on the steering wheel.

If status ET703 does not display "INACTIVE",

●check the condition of the cruise control/speed limiter +/- button and the condition of

its connector,

●check the condition of the cruise control/speed limiter R/0 button and the condition of

its connector.

INCREASEStatus ET703 becomes PLUS when the cruise control/speed limiter + button is pressed.

This button is on the steering wheel, on the left-hand side.

If status ET703 does not display PLUS, check the condition of the cruise control/speed

limiter +/- button, and the condition of its connector. Repair if necessary.

To carry out these checks and measurements in complete safety, observe the

recommendations for removing the driver's front airbag (see MR 364 Mechanical, 88C,

Airbag and seat belt pretensioners, Driver's front airbag, Removal - Refitting)

Measure the resistance on the following connection with the "+" button pressed:

Injection computer,

connector A, black, 32-track track D2 "+/-" button track 2.

connector A, black, 32-track track D3 "+/-" button track 1.

If the resistance is not approximately 300 Ω, check the continuity of the connection when

the button is not pressed.

If there is continuity, replace the +/- control button.

If there is a repair procedure (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

S3000_V4C_ET703/S3000_V54_ET703

Page 199 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 199

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 199V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

ET703

CONTINUED 1

DECREASEStatus ET703 becomes MINUS when the cruise control/speed limiter - button is pressed.

This button is on the steering wheel, on the left-hand side.

If status ET703 does not change to MINUS, check the condition of the cruise control/

speed limiter "+/-" button, and the condition of its connector. Repair if necessary.

To carry out these checks and measurements in complete safety, observe the

recommendations for removing the driver's front airbag (see MR 364 Mechanical, 88C,

Airbag and pretensioners, Driver's front airbag, Removal - Refitting).

Measure the resistance on the following connection with the "-" button pressed:

Injection computer,

connector A, black, 32-track track D2 "+/-" button track 2.

connector A, black, 32-track track D3 "+/-" button track 1.

If the resistance is not approximately 100Ω, check the continuity of the connection when

the button is not pressed.

If there is continuity, replace the "+/-" control button.

If there is a repair procedure (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

RESUMEStatus ET703 becomes RESUME when the cruise control/speed limiter R button is

pressed. This button is located on the steering wheel, to the right.

If status ET703 does not change to RESUME, check the condition of the cruise control/

speed limiter R/0 button, and the condition of its connector. Repair if necessary.

To carry out these checks and measurements in complete safety, observe the

recommendations for removing the driver's front airbag (see MR 364 Mechanical, 88C,

Airbag and pretensioners, Driver's front airbag, Removal - Refitting)

Measure the resistance of the following connection with the "R" button pressed:

Injection computer,

connector A, black, 32-track track D2 "+/-" button track 2.

connector A, black, 32-track track D3 "+/-" button track 1.

If the resistance is not approximately 900 Ω, check the continuity of the connection when

the button is not pressed.

If there is continuity, replace the "R/0" control button.

If there is a repair procedure (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

Page 200 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 200

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 200V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

ET703

CONTINUED 2

SUSPENDStatus ET703 becomes SUSPEND when the cruise control/speed limiter 0 button is

pressed. This button is located on the steering wheel, to the right.

If status ET703 does not change to SUSPEND, check the condition of the cruise control/

speed limiter R/0 button, and the condition of its connector.

To carry out these checks and measurements in complete safety, observe the

recommendations for removing the driver's front airbag (see MR 364 Mechanical, 88C,

Airbag and pretensioners, Driver's front airbag, Removal - Refitting)

Measure the resistance of the following connection with the "0" button pressed:

Injection computer,

connector A, black, 32-track track D2 "+/-" button track 2.

connector A, black, 32-track track D3 "+/-" button track 1.

If the resistance is not approximately 0 Ω, replace the R/0 control button.

If there is continuity, replace the "R/0" control button.

If there is a repair procedure (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.