air condition RENAULT SCENIC 2010 J95 / 3.G Petrol Injection S3000 Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 230, PDF Size: 0.92 MB

Page 148 of 230

PETROL INJECTION

Fault finding - Conformity check

17B

17B-148

PETROL INJECTION

Fault finding - Conformity check

17B

17B-148V9 MR-372-J84-17B050$517.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

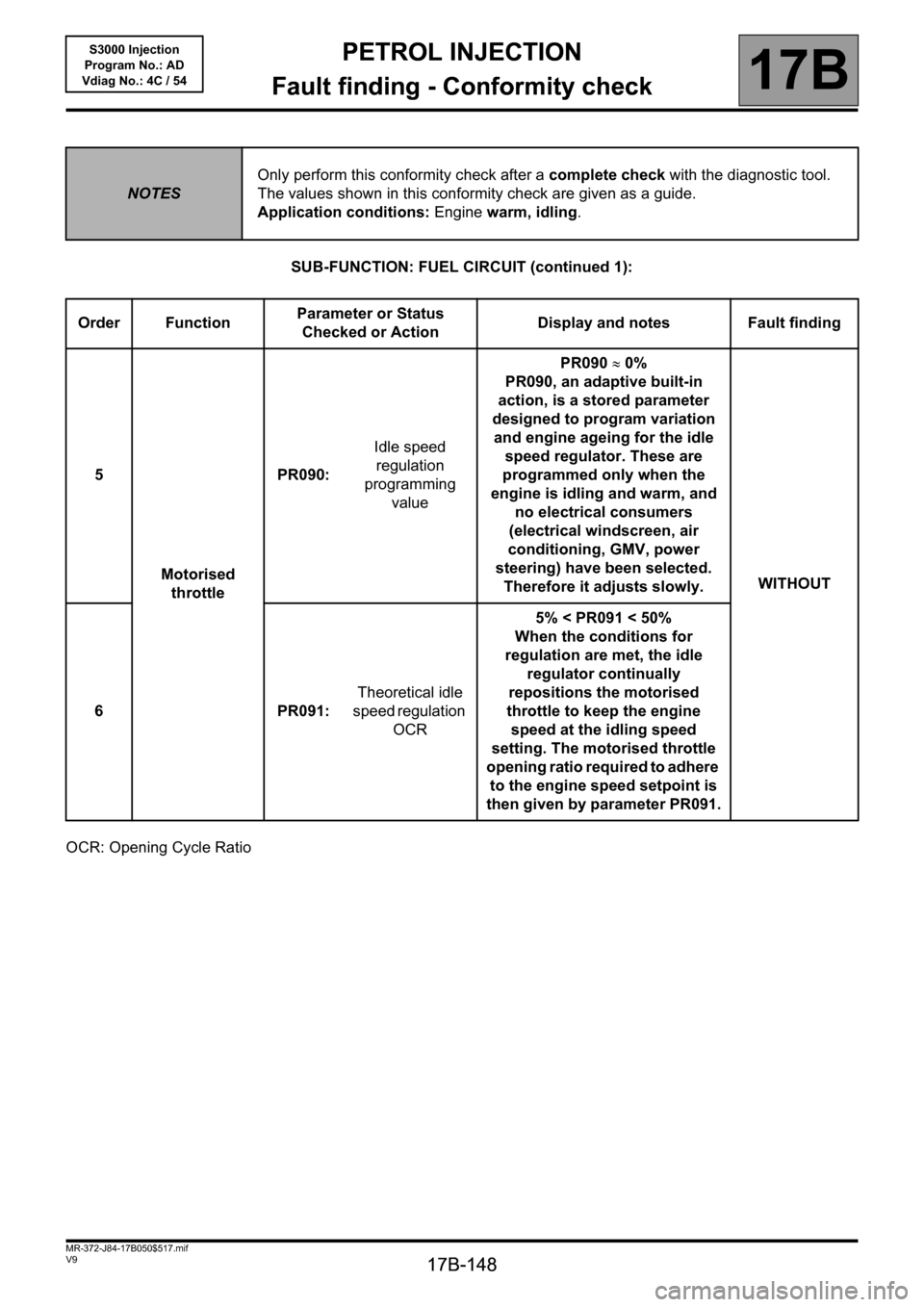

SUB-FUNCTION: FUEL CIRCUIT (continued 1):

OCR: Opening Cycle Ratio

NOTESOnly perform this conformity check after a complete check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine warm, idling.

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

5

Motorised

throttlePR090:Idle speed

regulation

programming

valuePR090≈ 0%

PR090, an adaptive built-in

action, is a stored parameter

designed to program variation

and engine ageing for the idle

speed regulator. These are

programmed only when the

engine is idling and warm, and

no electrical consumers

(electrical windscreen, air

conditioning, GMV, power

steering) have been selected.

Therefore it adjusts slowly.WITHOUT

6 PR091:Theoretical idle

speed regulation

OCR5%

regulation are met, the idle

regulator continually

repositions the motorised

throttle to keep the engine

speed at the idling speed

setting. The motorised throttle

opening ratio required to adhere

to the engine speed setpoint is

then given by parameter PR091.

Page 160 of 230

PETROL INJECTION

Fault finding - Conformity check

17B

17B-160

PETROL INJECTION

Fault finding - Conformity check

17B

17B-160V9 MR-372-J84-17B050$517.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

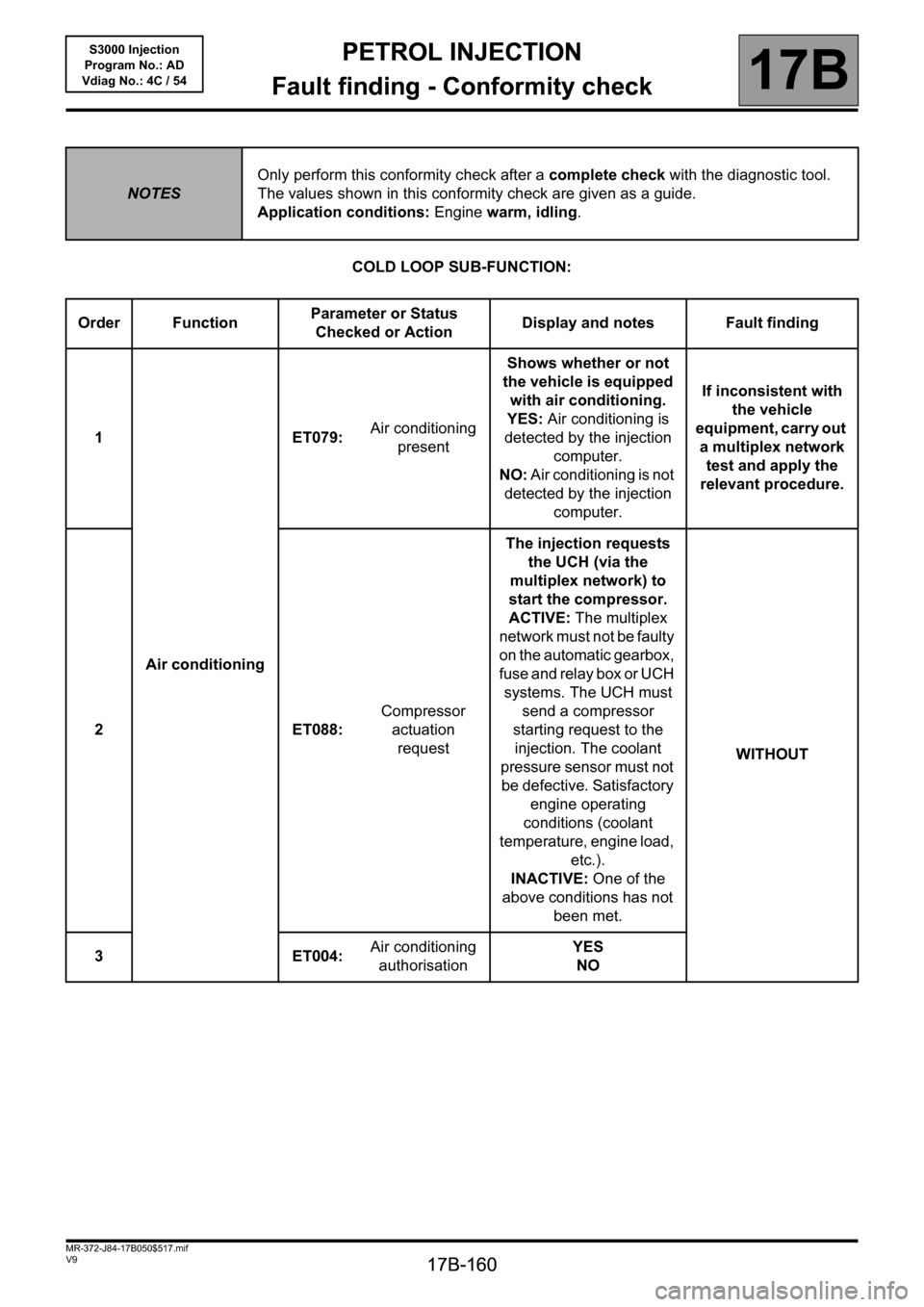

COLD LOOP SUB-FUNCTION:

NOTESOnly perform this conformity check after a complete check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine warm, idling.

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

1

Air conditioningET079:Air conditioning

presentShows whether or not

the vehicle is equipped

with air conditioning.

YES: Air conditioning is

detected by the injection

computer.

NO: Air conditioning is not

detected by the injection

computer.If inconsistent with

the vehicle

equipment, carry out

a multiplex network

test and apply the

relevant procedure.

2 ET088:Compressor

actuation

requestThe injection requests

the UCH (via the

multiplex network) to

start the compressor.

ACTIVE: The multiplex

network must not be faulty

on the automatic gearbox,

fuse and relay box or UCH

systems. The UCH must

send a compressor

starting request to the

injection. The coolant

pressure sensor must not

be defective. Satisfactory

engine operating

conditions (coolant

temperature, engine load,

etc.).

INACTIVE: One of the

above conditions has not

been met.WITHOUT

3 ET004:Air conditioning

authorisationYES

NO

Page 161 of 230

PETROL INJECTION

Fault finding - Conformity check

17B

17B-161

PETROL INJECTION

Fault finding - Conformity check

17B

17B-161V9 MR-372-J84-17B050$517.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

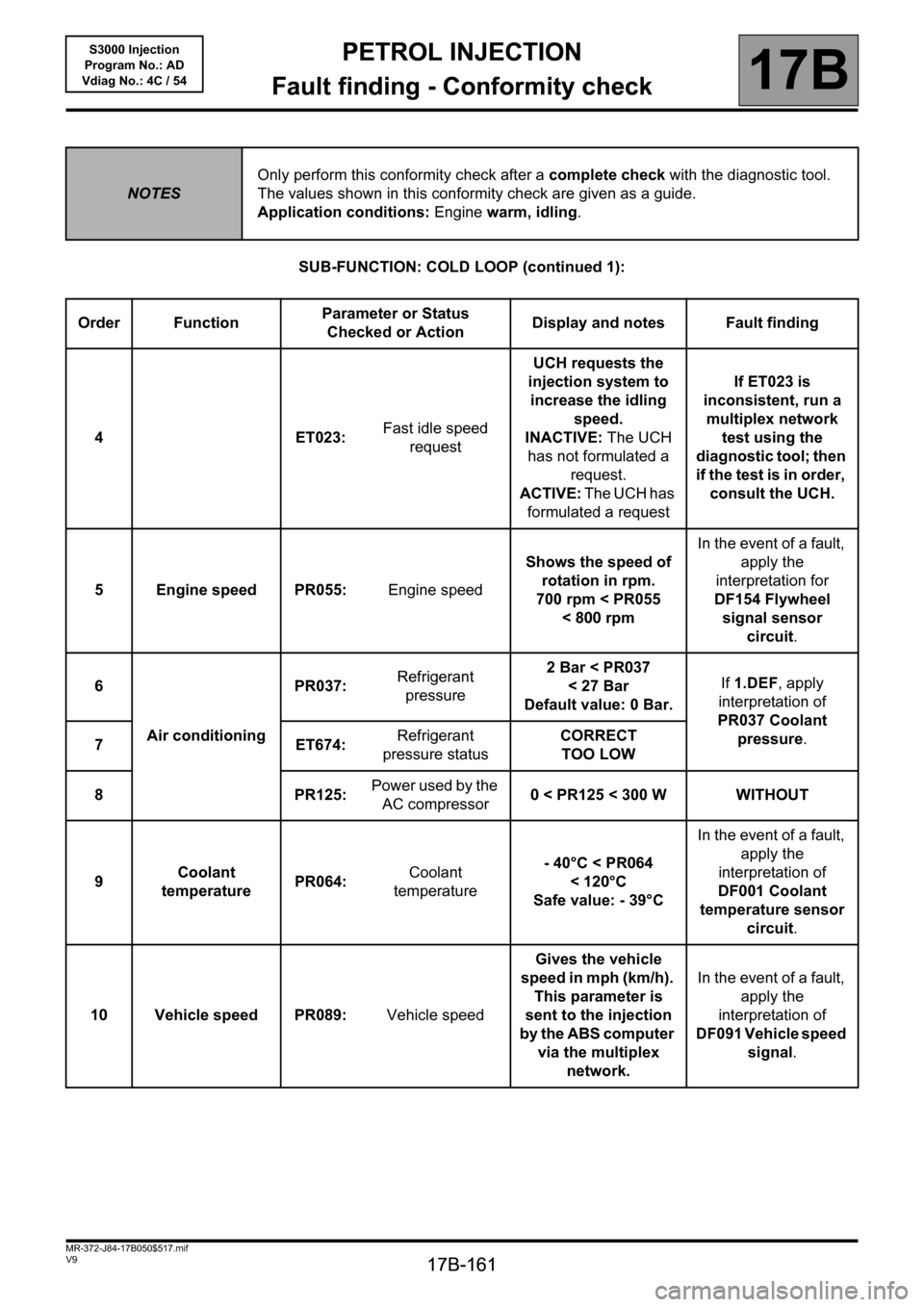

SUB-FUNCTION: COLD LOOP (continued 1):

NOTESOnly perform this conformity check after a complete check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine warm, idling.

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

4 ET023:Fast idle speed

requestUCH requests the

injection system to

increase the idling

speed.

INACTIVE: The UCH

has not formulated a

request.

ACTIVE: The UCH has

formulated a requestIf ET023 is

inconsistent, run a

multiplex network

test using the

diagnostic tool; then

if the test is in order,

consult the UCH.

5 Engine speed PR055:Engine speedShows the speed of

rotation in rpm.

700 rpm < PR055

< 800 rpmIn the event of a fault,

apply the

interpretation for

DF154 Flywheel

signal sensor

circuit.

6

Air conditioningPR037:Refrigerant

pressure2Bar

Default value: 0 Bar.If 1.DEF, apply

interpretation of

PR037 Coolant

pressure.

7 ET674:Refrigerant

pressure statusCORRECT

TOO LOW

8PR125:Power used by the

AC compressor0 < PR125 < 300 W WITHOUT

9Coolant

temperaturePR064:Coolant

temperature- 40°C < PR064

< 120°C

Safe value: - 39°CIn the event of a fault,

apply the

interpretation of

DF001 Coolant

temperature sensor

circuit.

10 Vehicle speed PR089:Vehicle speedGives the vehicle

speed in mph (km/h).

This parameter is

sent to the injection

by the ABS computer

via the multiplex

network.In the event of a fault,

apply the

interpretation of

DF091 Vehicle speed

signal.

Page 166 of 230

PETROL INJECTION

Fault finding - Conformity check

17B

17B-166

PETROL INJECTION

Fault finding - Conformity check

17B

17B-166V9 MR-372-J84-17B050$517.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

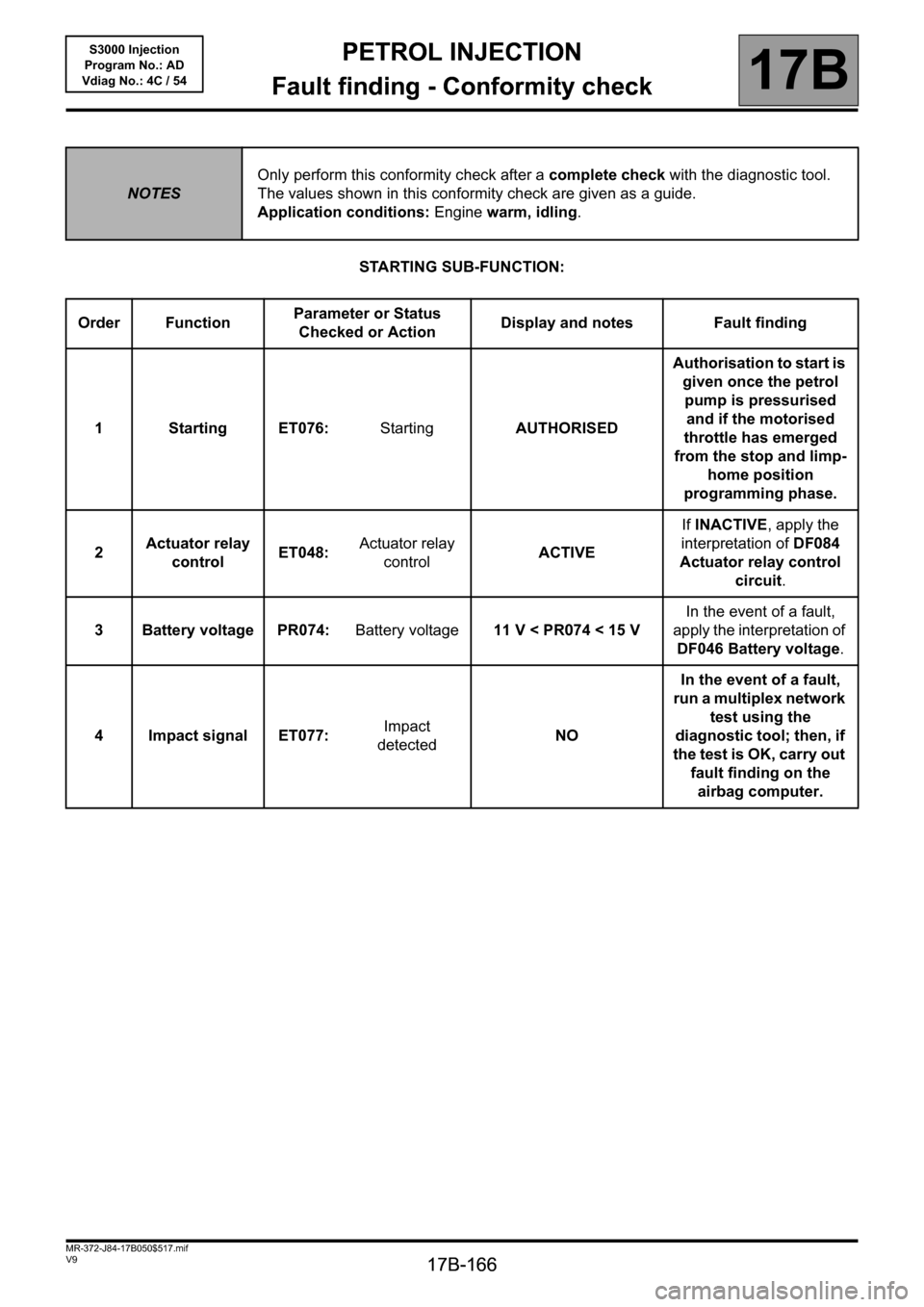

STARTING SUB-FUNCTION:

NOTESOnly perform this conformity check after a complete check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine warm, idling.

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

1StartingET076:StartingAUTHORISEDAuthorisation to start is

given once the petrol

pump is pressurised

and if the motorised

throttle has emerged

from the stop and limp-

home position

programming phase.

2Actuator relay

controlET048:Actuator relay

controlACTIVEIf INACTIVE, apply the

interpretation of DF084

Actuator relay control

circuit.

3 Battery voltage PR074:Battery voltage11 V < PR074 < 15 VIn the event of a fault,

apply the interpretation of

DF046 Battery voltage.

4 Impact signal ET077:Impact

detectedNOIn the event of a fault,

run a multiplex network

test using the

diagnostic tool; then, if

the test is OK, carry out

fault finding on the

airbag computer.

Page 168 of 230

PETROL INJECTION

Fault finding - Status summary table

17B

17B - 168

PETROL INJECTION

Fault finding - Status summary table

17B

17B - 168V9 MR-372-J84-17B050$564.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - Status summary table

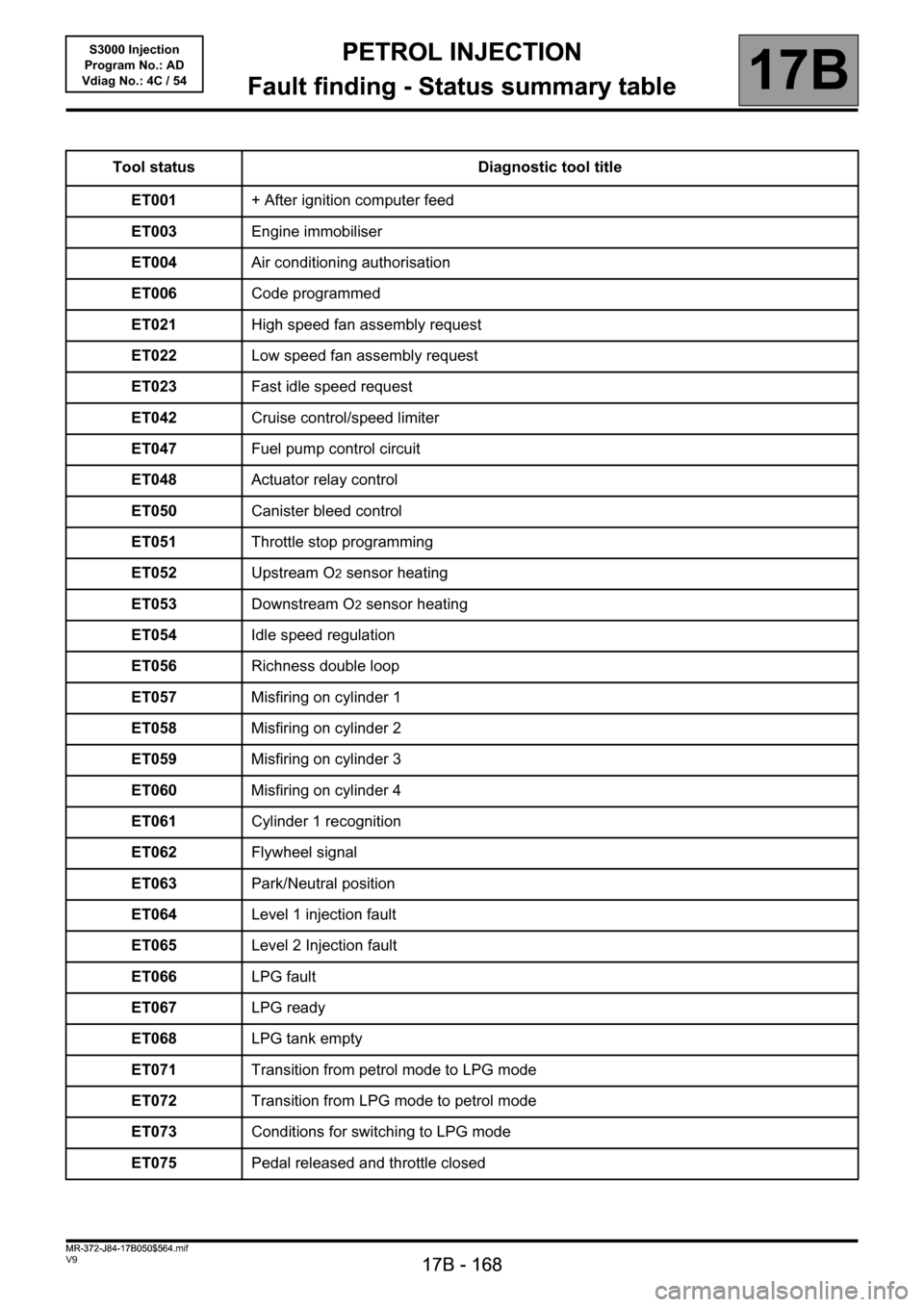

Tool status Diagnostic tool title

ET001+ After ignition computer feed

ET003Engine immobiliser

ET004Air conditioning authorisation

ET006Code programmed

ET021High speed fan assembly request

ET022Low speed fan assembly request

ET023Fast idle speed request

ET042Cruise control/speed limiter

ET047Fuel pump control circuit

ET048Actuator relay control

ET050Canister bleed control

ET051Throttle stop programming

ET052Upstream O

2 sensor heating

ET053Downstream O

2 sensor heating

ET054Idle speed regulation

ET056Richness double loop

ET057Misfiring on cylinder 1

ET058Misfiring on cylinder 2

ET059Misfiring on cylinder 3

ET060Misfiring on cylinder 4

ET061Cylinder 1 recognition

ET062Flywheel signal

ET063Park/Neutral position

ET064Level 1 injection fault

ET065Level 2 Injection fault

ET066LPG fault

ET067LPG ready

ET068LPG tank empty

ET071Transition from petrol mode to LPG mode

ET072Transition from LPG mode to petrol mode

ET073Conditions for switching to LPG mode

ET075Pedal released and throttle closed

MR-372-J84-17B050$564.mif

Page 169 of 230

PETROL INJECTION

Fault finding - Status summary table

17B

17B - 169

PETROL INJECTION

Fault finding - Status summary table

17B

17B - 169V9 MR-372-J84-17B050$564.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

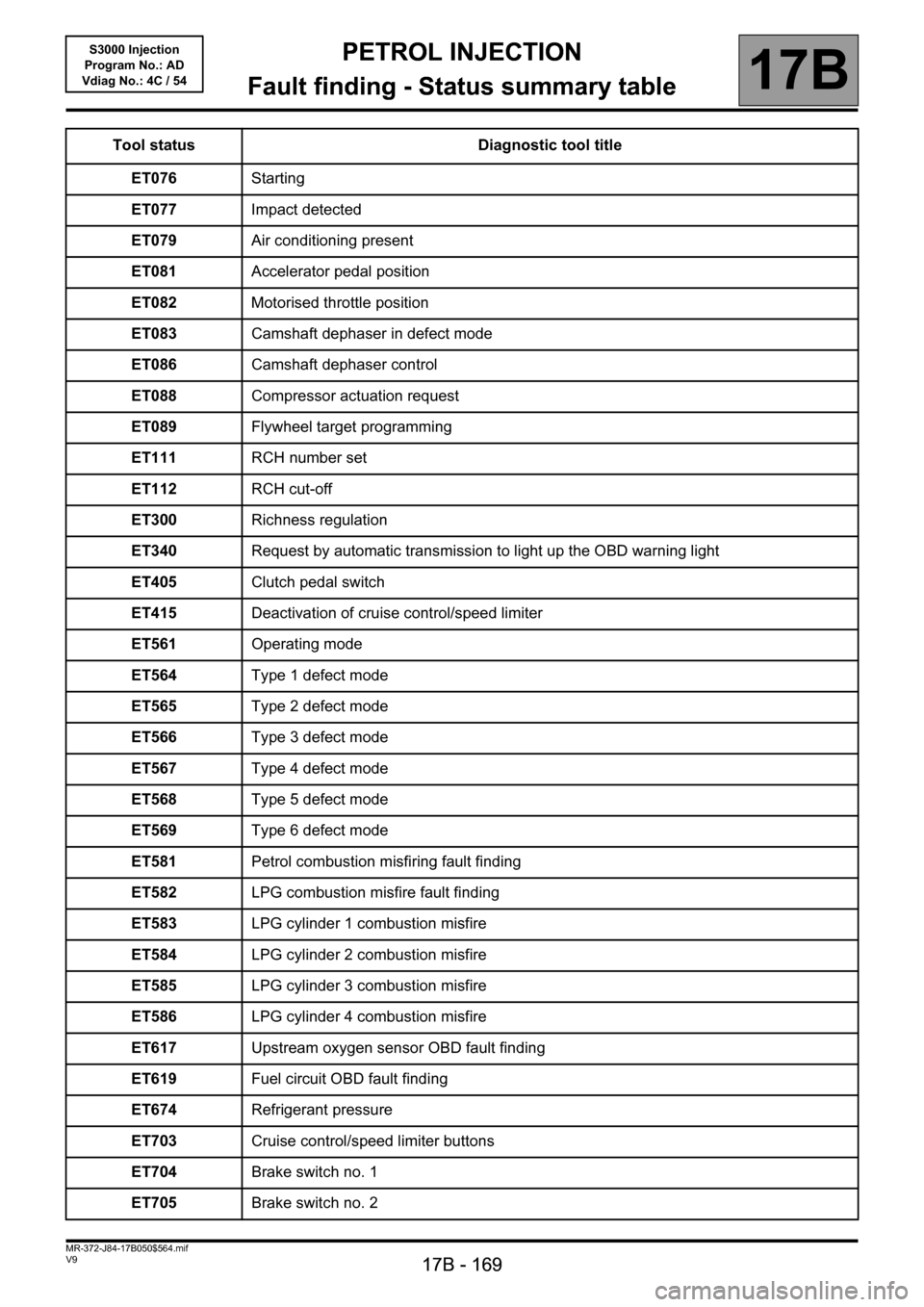

Tool status Diagnostic tool title

ET076Starting

ET077Impact detected

ET079Air conditioning present

ET081Accelerator pedal position

ET082Motorised throttle position

ET083Camshaft dephaser in defect mode

ET086Camshaft dephaser control

ET088Compressor actuation request

ET089Flywheel target programming

ET111RCH number set

ET112RCH cut-off

ET300Richness regulation

ET340Request by automatic transmission to light up the OBD warning light

ET405Clutch pedal switch

ET415Deactivation of cruise control/speed limiter

ET561Operating mode

ET564Type 1 defect mode

ET565Type 2 defect mode

ET566Type 3 defect mode

ET567Type 4 defect mode

ET568Type 5 defect mode

ET569Type 6 defect mode

ET581Petrol combustion misfiring fault finding

ET582LPG combustion misfire fault finding

ET583LPG cylinder 1 combustion misfire

ET584LPG cylinder 2 combustion misfire

ET585LPG cylinder 3 combustion misfire

ET586LPG cylinder 4 combustion misfire

ET617Upstream oxygen sensor OBD fault finding

ET619Fuel circuit OBD fault finding

ET674Refrigerant pressure

ET703Cruise control/speed limiter buttons

ET704Brake switch no. 1

ET705Brake switch no. 2

Page 174 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 174

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 174V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

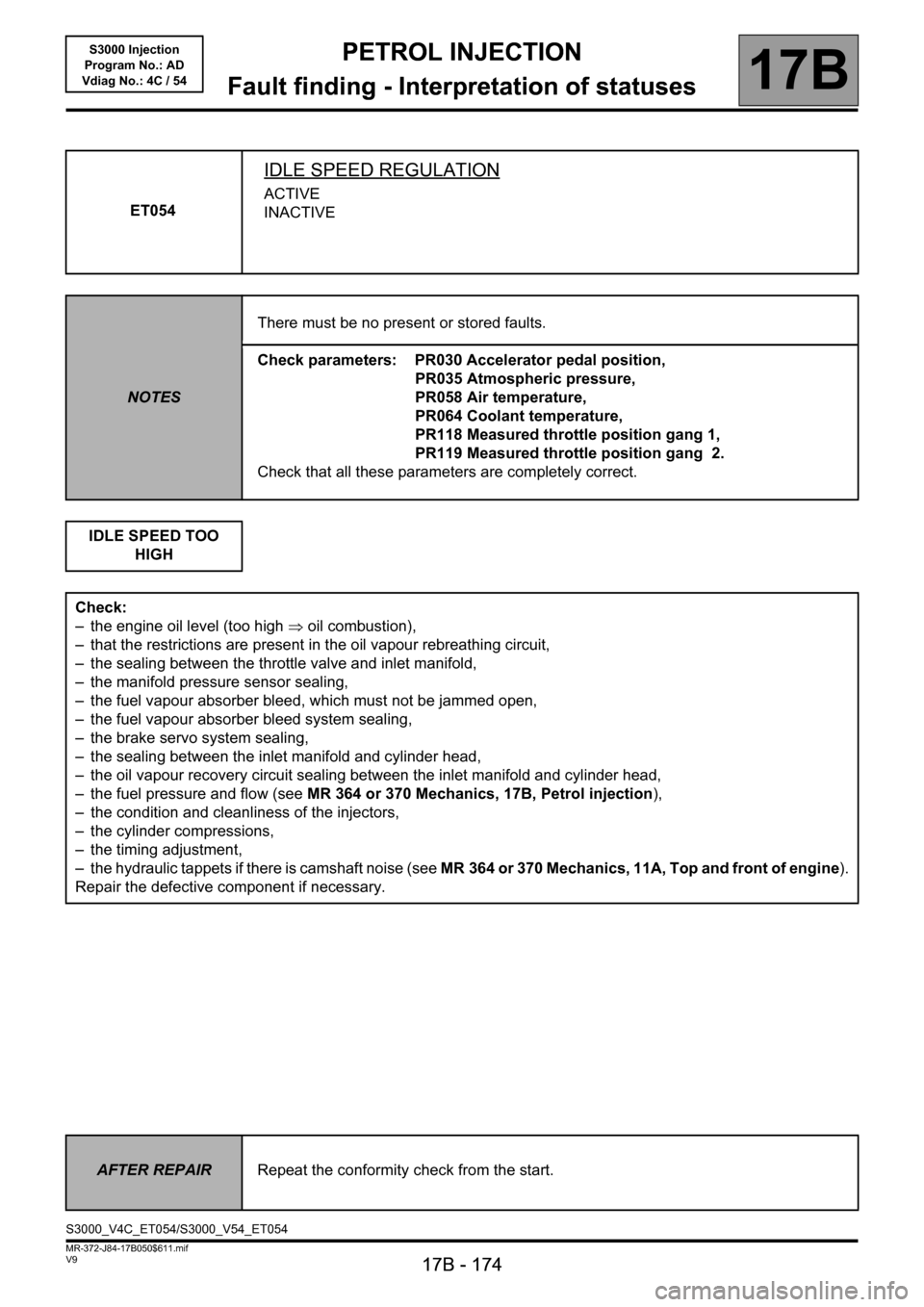

ET054

IDLE SPEED REGULATION

ACTIVE

INACTIVE

NOTESThere must be no present or stored faults.

Check parameters: PR030 Accelerator pedal position,

PR035 Atmospheric pressure,

PR058 Air temperature,

PR064 Coolant temperature,

PR118 Measured throttle position gang 1,

PR119 Measured throttle position gang 2.

Check that all these parameters are completely correct.

IDLE SPEED TOO

HIGH

Check:

– the engine oil level (too high ⇒ oil combustion),

– that the restrictions are present in the oil vapour rebreathing circuit,

– the sealing between the throttle valve and inlet manifold,

– the manifold pressure sensor sealing,

– the fuel vapour absorber bleed, which must not be jammed open,

– the fuel vapour absorber bleed system sealing,

– the brake servo system sealing,

– the sealing between the inlet manifold and cylinder head,

– the oil vapour recovery circuit sealing between the inlet manifold and cylinder head,

– the fuel pressure and flow (see MR 364 or 370 Mechanics, 17B, Petrol injection),

– the condition and cleanliness of the injectors,

– the cylinder compressions,

– the timing adjustment,

– the hydraulic tappets if there is camshaft noise (see MR 364 or 370 Mechanics, 11A, Top and front of engine).

Repair the defective component if necessary.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_ET054/S3000_V54_ET054

Page 175 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 175

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 175V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

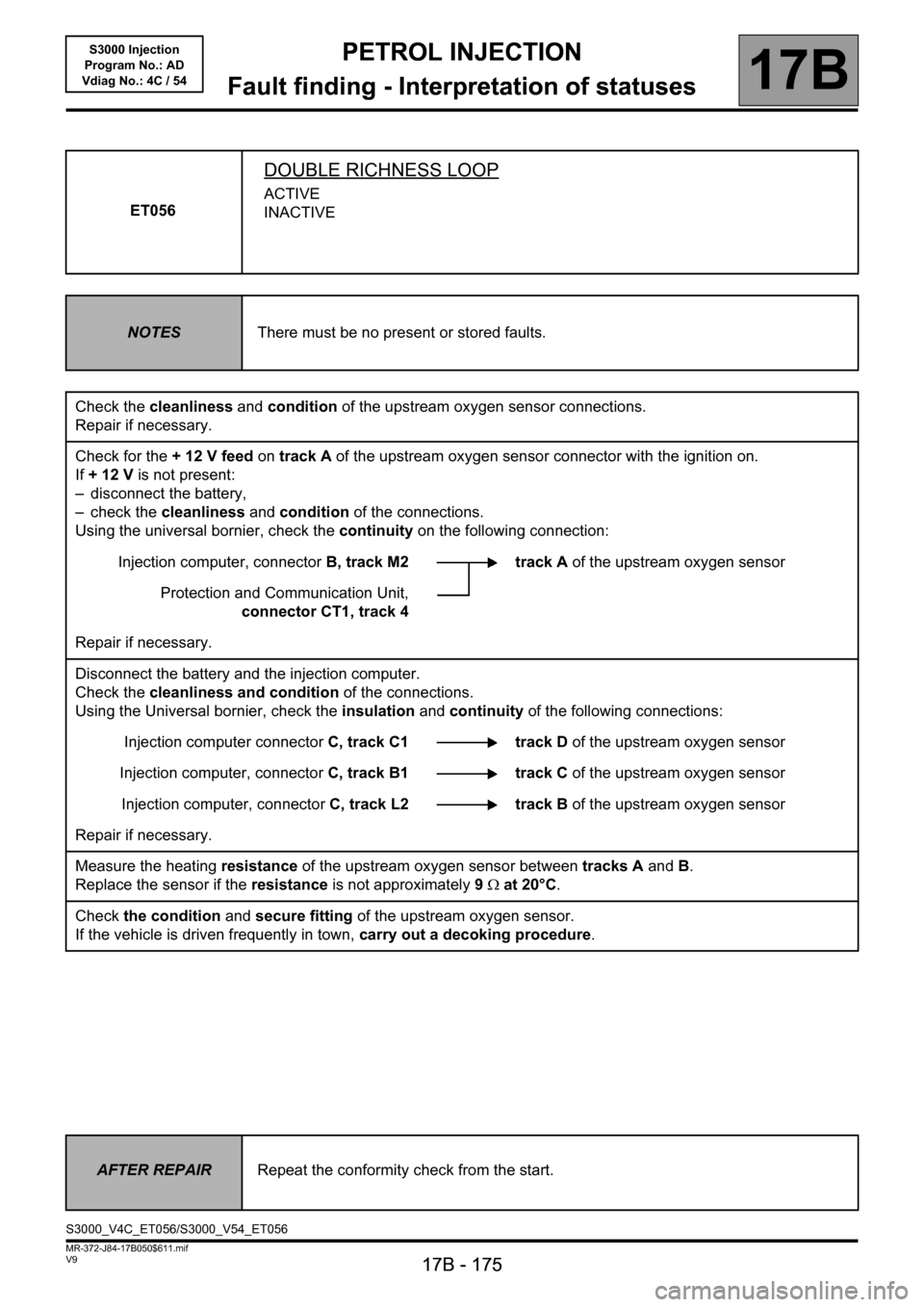

ET056

DOUBLE RICHNESS LOOP

ACTIVE

INACTIVE

NOTESThere must be no present or stored faults.

Check the cleanliness and condition of the upstream oxygen sensor connections.

Repair if necessary.

Check for the + 12 V feed on track A of the upstream oxygen sensor connector with the ignition on.

If +12V is not present:

– disconnect the battery,

– check the cleanliness and condition of the connections.

Using the universal bornier, check the continuity on the following connection:

Injection computer, connectorB, track M2 track A of the upstream oxygen sensor

Protection and Communication Unit,

connector CT1, track 4

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the Universal bornier, check the insulation and continuity of the following connections:

Injection computer connectorC, track C1 track D of the upstream oxygen sensor

Injection computer, connectorC, track B1 track C of the upstream oxygen sensor

Injection computer, connectorC, track L2 track B of the upstream oxygen sensor

Repair if necessary.

Measure the heating resistance of the upstream oxygen sensor between tracks A and B.

Replace the sensor if the resistance is not approximately 9Ω at 20°C.

Check the condition and secure fitting of the upstream oxygen sensor.

If the vehicle is driven frequently in town, carry out a decoking procedure.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_ET056/S3000_V54_ET056

Page 176 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 176

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 176V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

ET056

CONTINUED 1

Check the cleanliness and condition of the downstream oxygen sensor connections.

Repair if necessary.

Check for the + 12 V feed on track A of the downstream oxygen sensor connector with the ignition on.

If +12V is not present:

– disconnect the battery,

– check the cleanliness and condition of the connections.

Using the universal bornier, check the continuity on the following connection:

Injection computer, connectorB, track M2 track A of the downstream oxygen sensor

Protection and Communication Unit,

connector CT1, track 4

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the Universal bornier, check the insulation and continuity of the following connections:

Injection computer, connectorC, track B2 track D of the downstream oxygen sensor

Injection computer, connectorC, track A2 track C of the downstream oxygen sensor

Injection computer, connectorC, track L3 track B of the downstream oxygen sensor

Repair if necessary.

Measure the heating resistance of the downstream oxygen sensor between tracks A and B.

Replace the sensor if the resistance is not approximately 9Ω at 20°C.

Check the condition and for secure fitting of the downstream oxygen sensor.

If the vehicle is normally driven in urban conditions, there is a risk of contamination of the oxygen sensor.

AFTER REPAIRRepeat the conformity check from the start.

Page 177 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 177

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 177V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

ET056

CONTINUED 2

Check:

– the condition of the air filter,

– that the air inlet circuit is not blocked,

– the condition and conformity of the spark plugs,

– the sealing between the throttle valve and inlet manifold,

– the manifold pressure sensor sealing,

– the fuel vapour absorber bleed, which must not be jammed open,

– the fuel vapour absorber bleed system sealing,

– the brake servo system sealing,

– the cylinder head oil vapour recovery system sealing,

– the sealing between the inlet manifold and cylinder head,

– the exhaust pipe sealing between the cylinder head and catalytic converter.

– the fuel flow rate and pressure.

If the idle speed is not stable, check:

– the timing adjustment,

– the hydraulic tappets if there is camshaft noise (see MR 364 or 370 Mechanics, 11A, Top and front of engine),

– the cylinder compressions.

Drive the vehicle to check the repair.

Repair the defective components.

AFTER REPAIRRepeat the conformity check from the start.