air condition RENAULT SCENIC 2010 J95 / 3.G Petrol Injection S3000 Injection User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 230, PDF Size: 0.92 MB

Page 26 of 230

PETROL INJECTION

Fault finding - Replacement of components

17B

17B-26

PETROL INJECTION

Fault finding - Replacement of components

17B

17B-26V9 MR-372-J84-17B050$188.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - Replacement of components

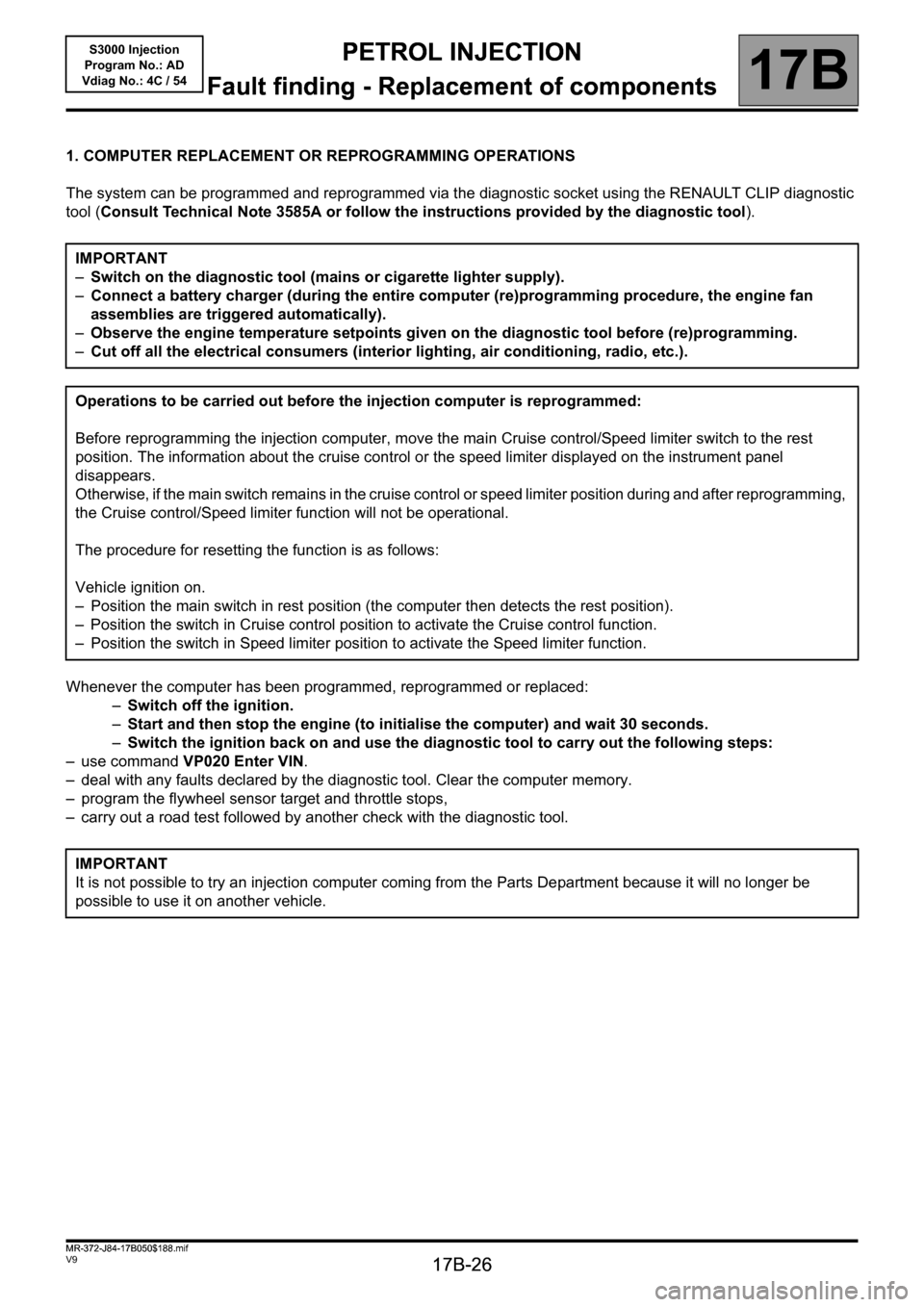

1. COMPUTER REPLACEMENT OR REPROGRAMMING OPERATIONS

The system can be programmed and reprogrammed via the diagnostic socket using the RENAULT CLIP diagnostic

tool (Consult Technical Note 3585A or follow the instructions provided by the diagnostic tool).

Whenever the computer has been programmed, reprogrammed or replaced:

–Switch off the ignition.

–Start and then stop the engine (to initialise the computer) and wait 30 seconds.

–Switch the ignition back on and use the diagnostic tool to carry out the following steps:

– use command VP020 Enter VIN.

– deal with any faults declared by the diagnostic tool. Clear the computer memory.

– program the flywheel sensor target and throttle stops,

– carry out a road test followed by another check with the diagnostic tool. IMPORTANT

–Switch on the diagnostic tool (mains or cigarette lighter supply).

–Connect a battery charger (during the entire computer (re)programming procedure, the engine fan

assemblies are triggered automatically).

–Observe the engine temperature setpoints given on the diagnostic tool before (re)programming.

–Cut off all the electrical consumers (interior lighting, air conditioning, radio, etc.).

Operations to be carried out before the injection computer is reprogrammed:

Before reprogramming the injection computer, move the main Cruise control/Speed limiter switch to the rest

position. The information about the cruise control or the speed limiter displayed on the instrument panel

disappears.

Otherwise, if the main switch remains in the cruise control or speed limiter position during and after reprogramming,

the Cruise control/Speed limiter function will not be operational.

The procedure for resetting the function is as follows:

Vehicle ignition on.

– Position the main switch in rest position (the computer then detects the rest position).

– Position the switch in Cruise control position to activate the Cruise control function.

– Position the switch in Speed limiter position to activate the Speed limiter function.

IMPORTANT

It is not possible to try an injection computer coming from the Parts Department because it will no longer be

possible to use it on another vehicle.

MR-372-J84-17B050$188.mif

Page 28 of 230

PETROL INJECTION

17B

17B - 28

17B

17B - 28V9 MR-372-J84-17B050$235.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - Configurations and programming

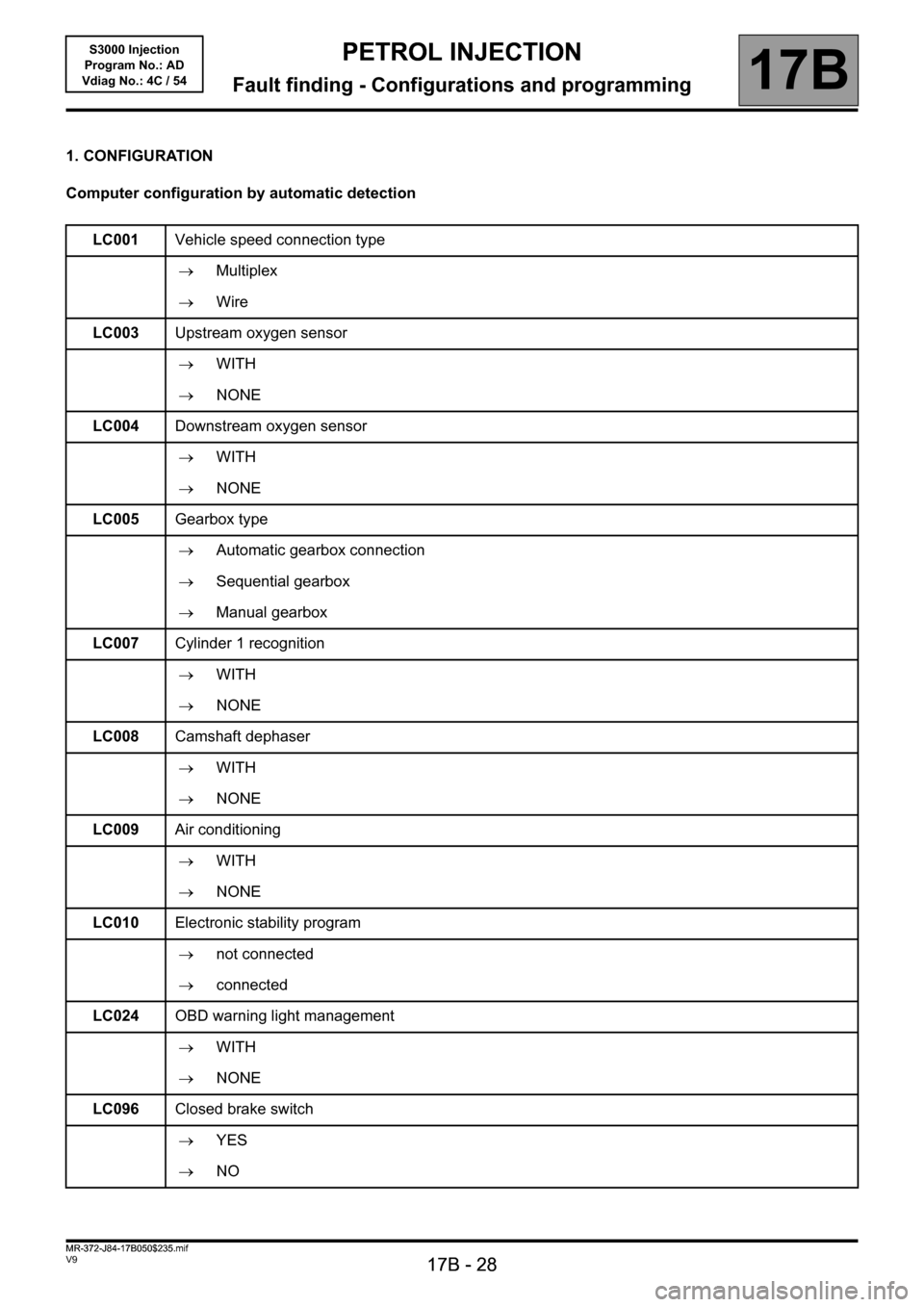

1. CONFIGURATION

Computer configuration by automatic detection

LC001Vehicle speed connection type

→Multiplex

→Wire

LC003Upstream oxygen sensor

→WITH

→NONE

LC004Downstream oxygen sensor

→WITH

→NONE

LC005Gearbox type

→Automatic gearbox connection

→Sequential gearbox

→Manual gearbox

LC007Cylinder 1 recognition

→WITH

→NONE

LC008Camshaft dephaser

→WITH

→NONE

LC009Air conditioning

→WITH

→NONE

LC010Electronic stability program

→not connected

→connected

LC024OBD warning light management

→WITH

→NONE

LC096Closed brake switch

→YES

→NO

MR-372-J84-17B050$235.mif

Page 29 of 230

PETROL INJECTION

Fault finding - Configurations and programming17B

17B - 29

17B

17B - 29V9 MR-372-J84-17B050$235.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

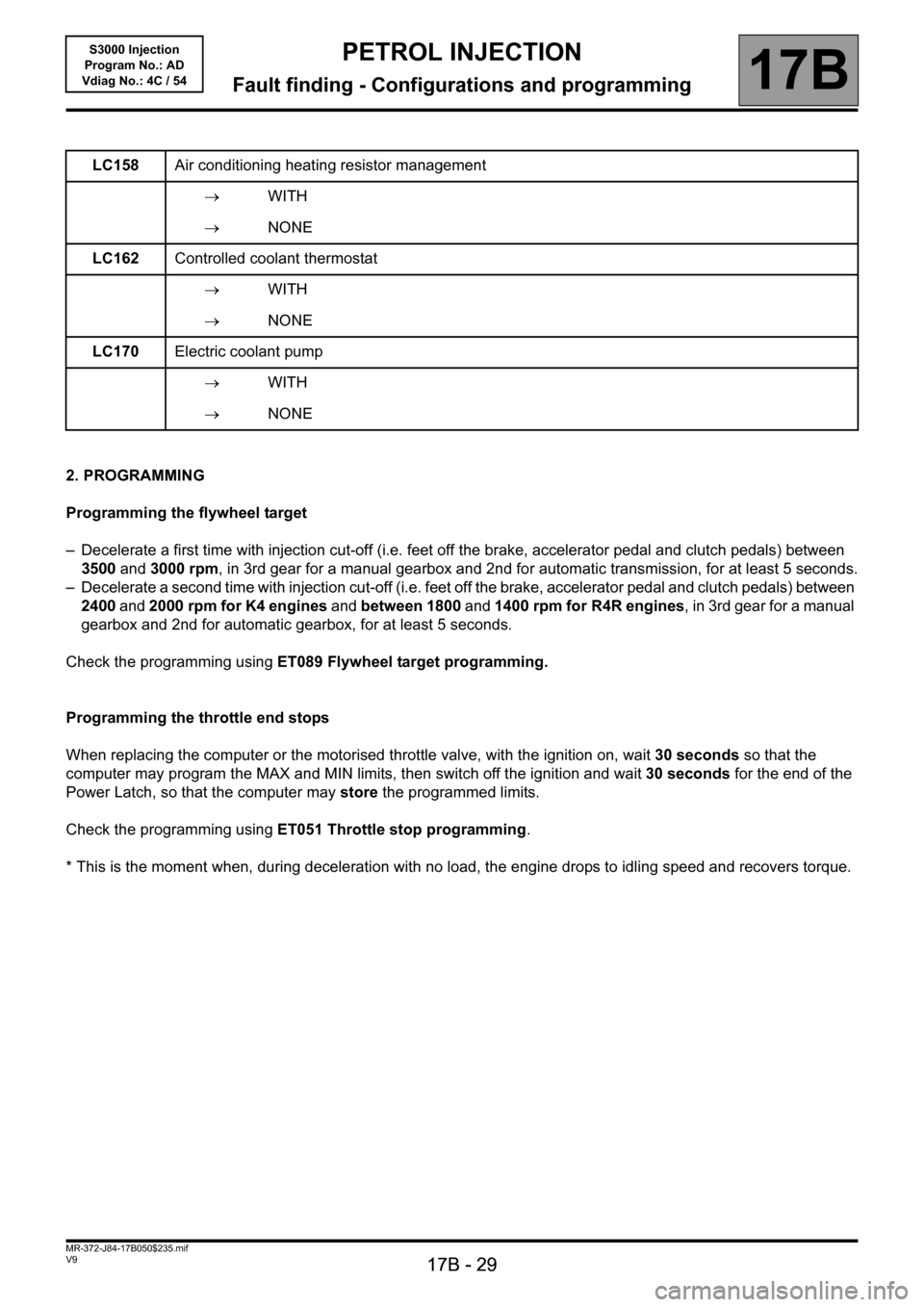

2. PROGRAMMING

Programming the flywheel target

– Decelerate a first time with injection cut-off (i.e. feet off the brake, accelerator pedal and clutch pedals) between

3500 and 3000 rpm, in 3rd gear for a manual gearbox and 2nd for automatic transmission, for at least 5 seconds.

– Decelerate a second time with injection cut-off (i.e. feet off the brake, accelerator pedal and clutch pedals) between

2400 and 2000 rpm for K4 engines and between 1800 and 1400 rpm for R4R engines, in 3rd gear for a manual

gearbox and 2nd for automatic gearbox, for at least 5 seconds.

Check the programming using ET089 Flywheel target programming.

Programming the throttle end stops

When replacing the computer or the motorised throttle valve, with the ignition on, wait 30 seconds so that the

computer may program the MAX and MIN limits, then switch off the ignition and wait 30 seconds for the end of the

Power Latch, so that the computer may store the programmed limits.

Check the programming using ET051 Throttle stop programming.

* This is the moment when, during deceleration with no load, the engine drops to idling speed and recovers torque. LC158Air conditioning heating resistor management

→WITH

→NONE

LC162Controlled coolant thermostat

→WITH

→NONE

LC170Electric coolant pump

→WITH

→NONE

Page 34 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-34

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-34V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - Interpretation of faults

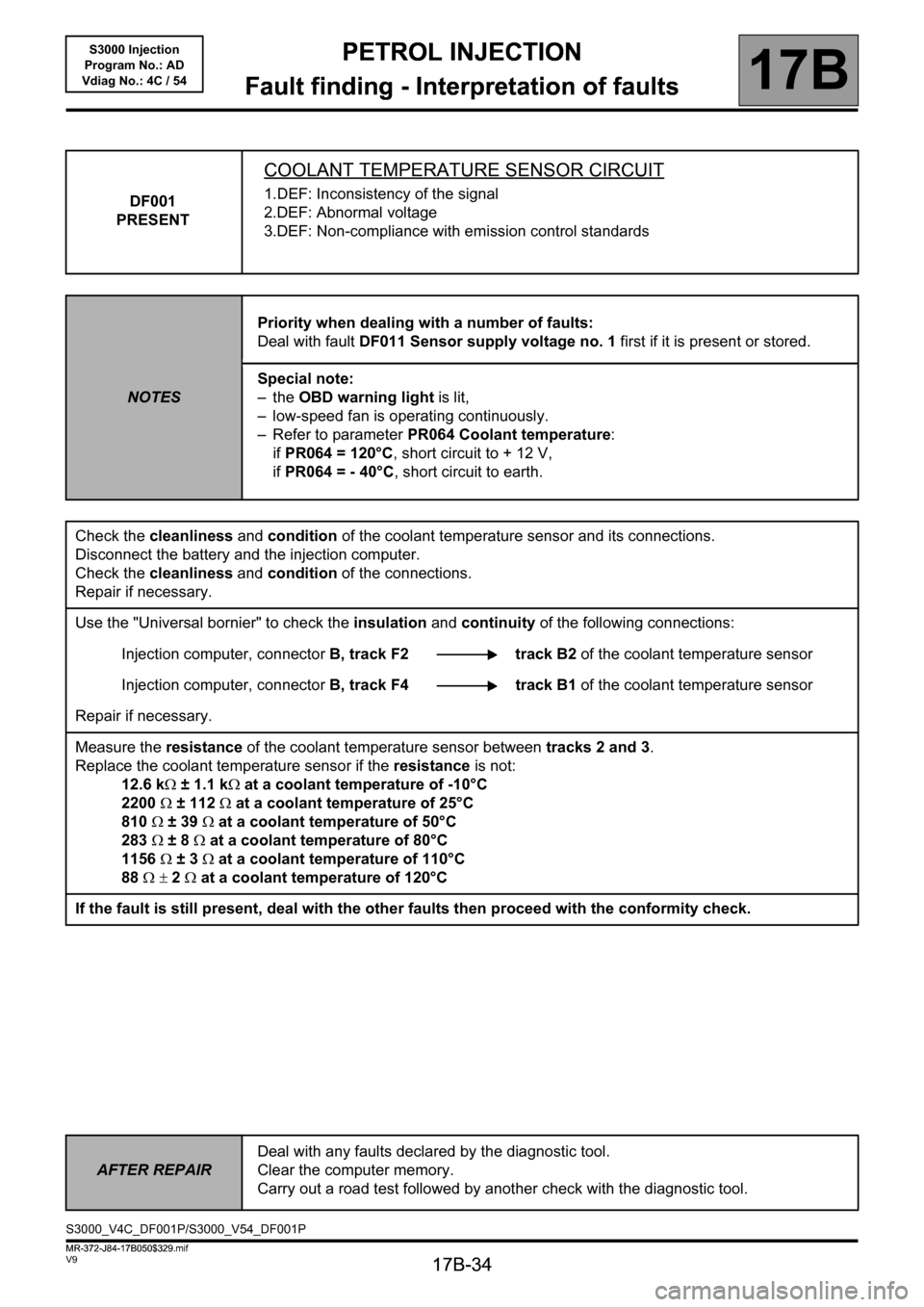

DF001

PRESENT

COOLANT TEMPERATURE SENSOR CIRCUIT

1.DEF: Inconsistency of the signal

2.DEF: Abnormal voltage

3.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

Deal with fault DF011 Sensor supply voltage no. 1 first if it is present or stored.

Special note:

–the OBD warning light is lit,

– low-speed fan is operating continuously.

– Refer to parameter PR064 Coolant temperature:

if PR064 = 120°C, short circuit to + 12 V,

if PR064 = - 40°C, short circuit to earth.

Check the cleanliness and condition of the coolant temperature sensor and its connections.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Repair if necessary.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Injection computer, connectorB, track F2 track B2 of the coolant temperature sensor

Injection computer, connectorB, track F4 track B1 of the coolant temperature sensor

Repair if necessary.

Measure the resistance of the coolant temperature sensor between tracks 2 and 3.

Replace the coolant temperature sensor if the resistance is not:

12.6 kΩ ±1.1kΩ at a coolant temperature of -10°C

2200Ω ± 112Ω at a coolant temperature of 25°C

810Ω ±39Ω at a coolant temperature of 50°C

283Ω ±8Ω at a coolant temperature of 80°C

1156Ω ±3Ω at a coolant temperature of 110°C

88Ω ±2Ω at a coolant temperature of 120°C

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

S3000_V4C_DF001P/S3000_V54_DF001P

MR-372-J84-17B050$329.mif

Page 35 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-35

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-35V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

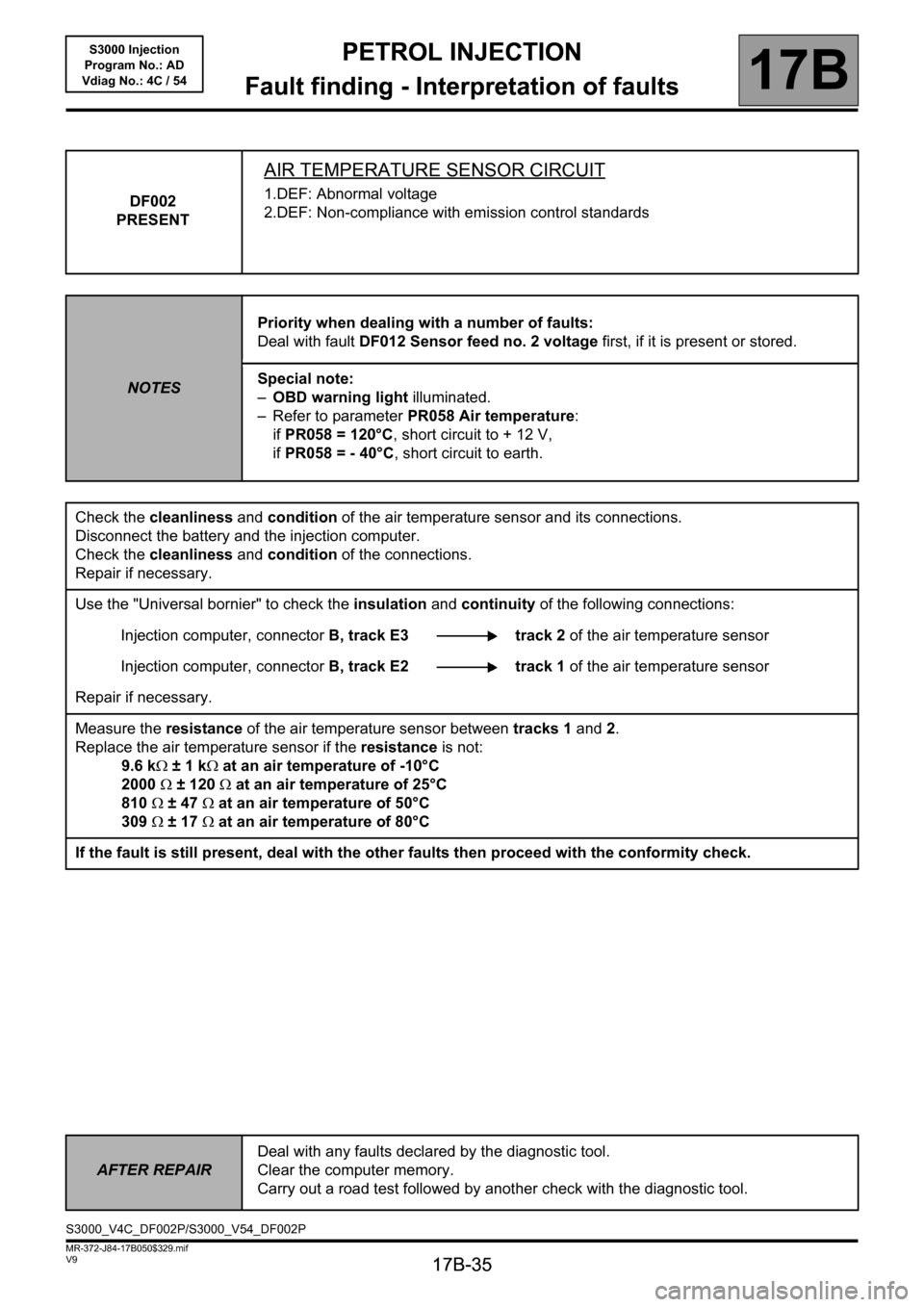

DF002

PRESENT

AIR TEMPERATURE SENSOR CIRCUIT

1.DEF: Abnormal voltage

2.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

Deal with fault DF012 Sensor feed no. 2 voltage first, if it is present or stored.

Special note:

–OBD warning light illuminated.

– Refer to parameter PR058 Air temperature:

if PR058 = 120°C, short circuit to + 12 V,

if PR058 = - 40°C, short circuit to earth.

Check the cleanliness and condition of the air temperature sensor and its connections.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Repair if necessary.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Injection computer, connectorB, track E3 track 2 of the air temperature sensor

Injection computer, connectorB, track E2 track 1 of the air temperature sensor

Repair if necessary.

Measure the resistance of the air temperature sensor between tracks 1 and 2.

Replace the air temperature sensor if the resistance is not:

9.6 kΩ ±1kΩ at an air temperature of -10°C

2000Ω ± 120Ω at an air temperature of 25°C

810Ω ±47Ω at an air temperature of 50°C

309Ω ±17Ω at an air temperature of 80°C

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

S3000_V4C_DF002P/S3000_V54_DF002P

Page 36 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-36

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-36V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

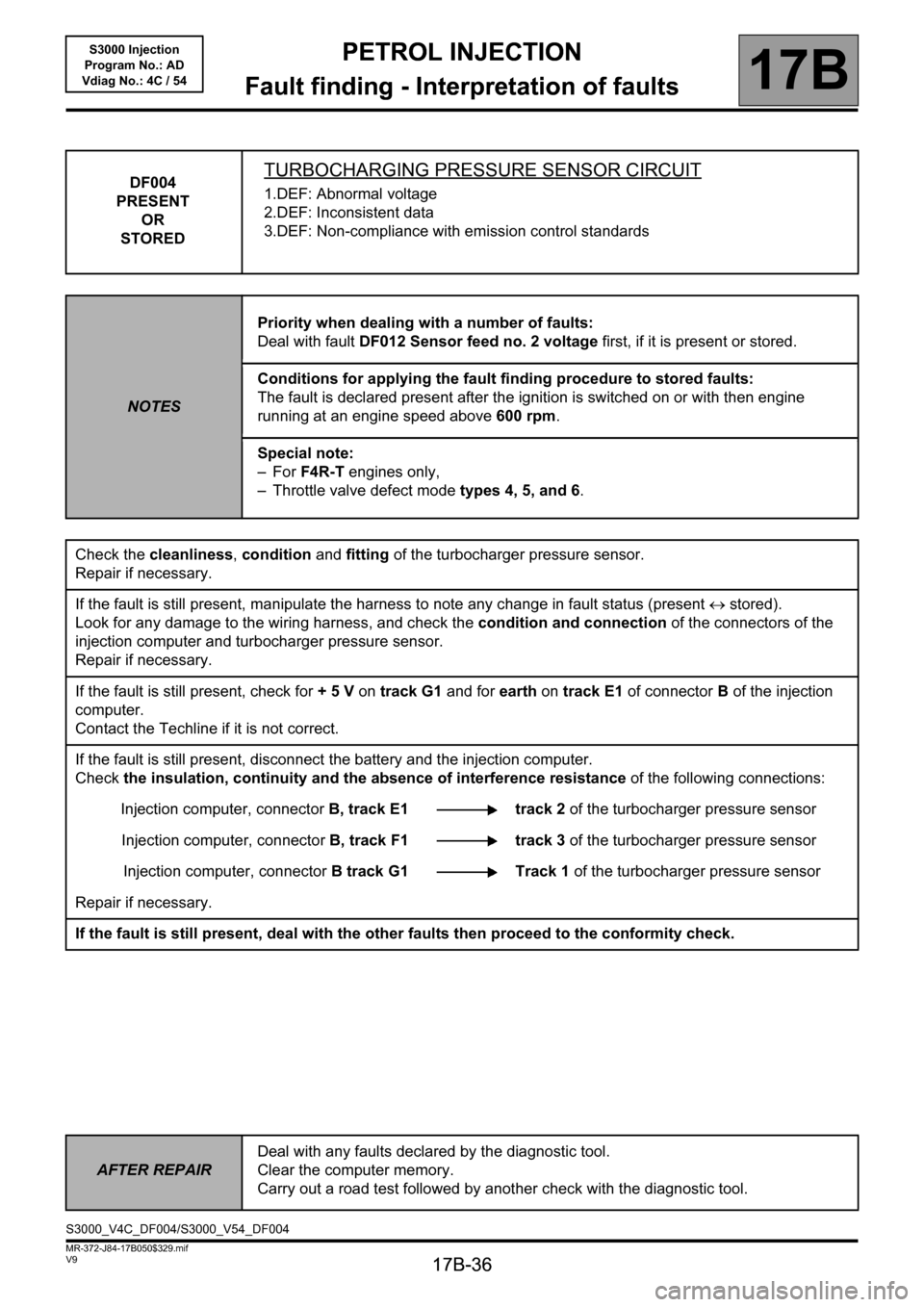

DF004

PRESENT

OR

STOREDTURBOCHARGING PRESSURE SENSOR CIRCUIT

1.DEF: Abnormal voltage

2.DEF: Inconsistent data

3.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

Deal with fault DF012 Sensor feed no. 2 voltage first, if it is present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the ignition is switched on or with then engine

running at an engine speed above 600 rpm.

Special note:

–For F4R-T engines only,

– Throttle valve defect mode types 4, 5, and 6.

Check the cleanliness, condition and fitting of the turbocharger pressure sensor.

Repair if necessary.

If the fault is still present, manipulate the harness to note any change in fault status (present↔ stored).

Look for any damage to the wiring harness, and check the condition and connection of the connectors of the

injection computer and turbocharger pressure sensor.

Repair if necessary.

If the fault is still present, check for + 5 V on track G1 and for earth on track E1 of connectorB of the injection

computer.

Contact the Techline if it is not correct.

If the fault is still present, disconnect the battery and the injection computer.

Check the insulation, continuity and the absence of interference resistance of the following connections:

Injection computer, connectorB, track E1 track 2 of the turbocharger pressure sensor

Injection computer, connectorB, track F1 track 3 of the turbocharger pressure sensor

Injection computer, connectorB track G1 Track 1 of the turbocharger pressure sensor

Repair if necessary.

If the fault is still present, deal with the other faults then proceed to the conformity check.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

S3000_V4C_DF004/S3000_V54_DF004

Page 37 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-37

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-37V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

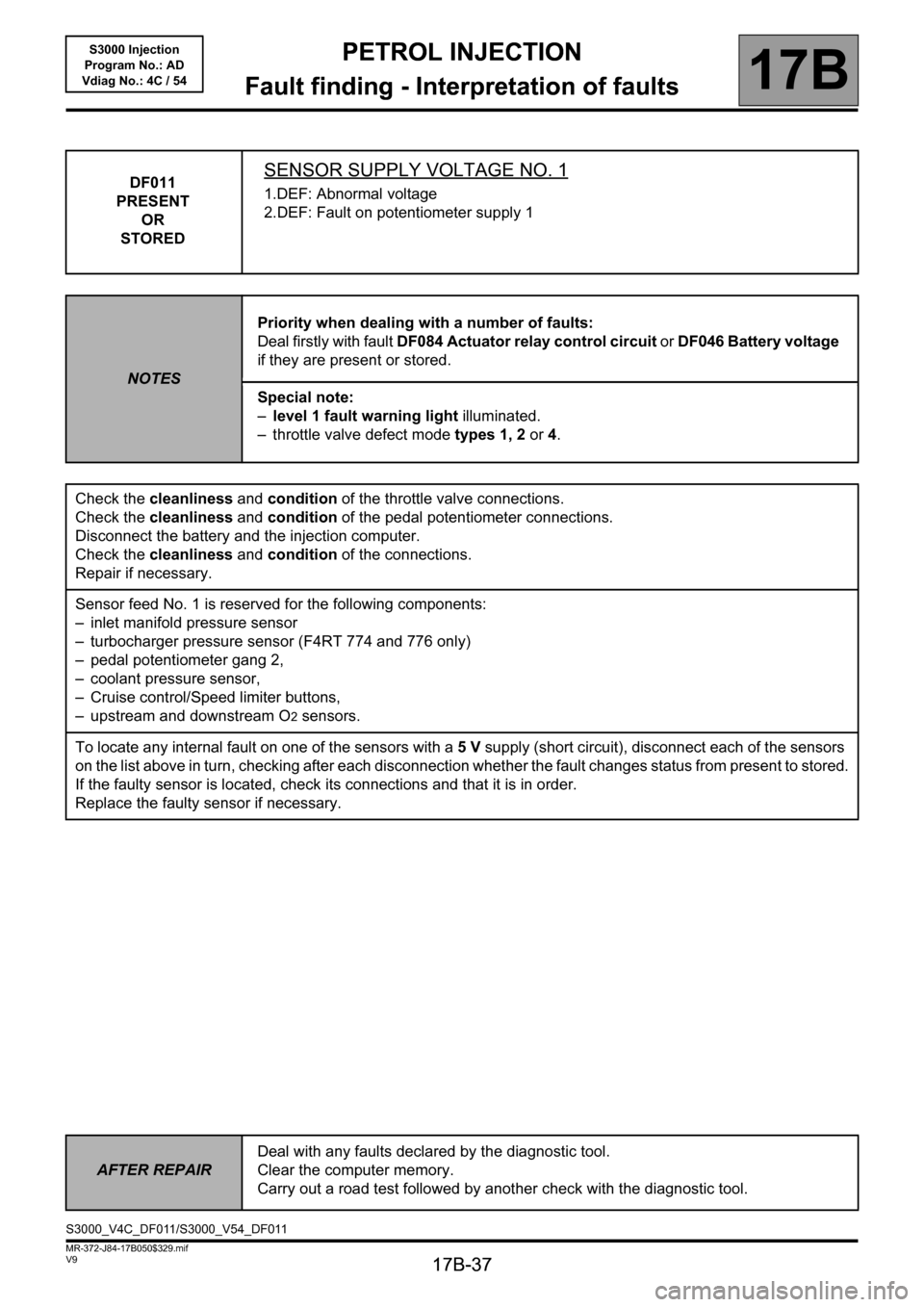

DF011

PRESENT

OR

STOREDSENSOR SUPPLY VOLTAGE NO. 1

1.DEF: Abnormal voltage

2.DEF: Fault on potentiometer supply 1

NOTESPriority when dealing with a number of faults:

Deal firstly with fault DF084 Actuator relay control circuit or DF046 Battery voltage

if they are present or stored.

Special note:

–level 1 fault warning light illuminated.

– throttle valve defect mode types 1, 2 or 4.

Check the cleanliness and condition of the throttle valve connections.

Check the cleanliness and condition of the pedal potentiometer connections.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Repair if necessary.

Sensor feed No. 1 is reserved for the following components:

– inlet manifold pressure sensor

– turbocharger pressure sensor (F4RT 774 and 776 only)

– pedal potentiometer gang 2,

– coolant pressure sensor,

– Cruise control/Speed limiter buttons,

– upstream and downstream O

2 sensors.

To locate any internal fault on one of the sensors with a 5V supply (short circuit), disconnect each of the sensors

on the list above in turn, checking after each disconnection whether the fault changes status from present to stored.

If the faulty sensor is located, check its connections and that it is in order.

Replace the faulty sensor if necessary.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

S3000_V4C_DF011/S3000_V54_DF011

Page 39 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-39

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-39V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

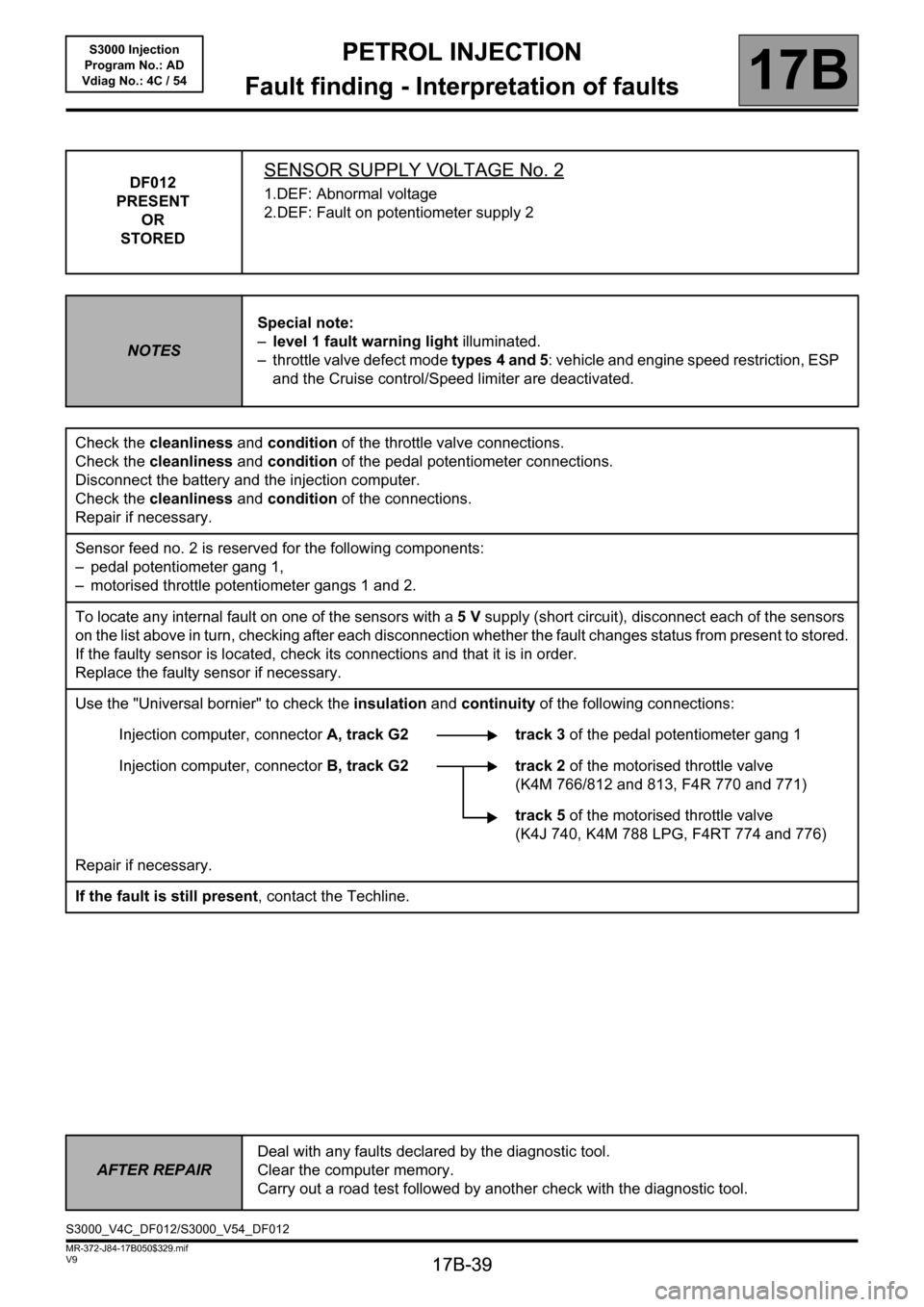

DF012

PRESENT

OR

STOREDSENSOR SUPPLY VOLTAGE No. 2

1.DEF: Abnormal voltage

2.DEF: Fault on potentiometer supply 2

NOTESSpecial note:

–level 1 fault warning light illuminated.

– throttle valve defect mode types 4 and 5: vehicle and engine speed restriction, ESP

and the Cruise control/Speed limiter are deactivated.

Check the cleanliness and condition of the throttle valve connections.

Check the cleanliness and condition of the pedal potentiometer connections.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Repair if necessary.

Sensor feed no. 2 is reserved for the following components:

– pedal potentiometer gang 1,

– motorised throttle potentiometer gangs 1 and 2.

To locate any internal fault on one of the sensors with a 5V supply (short circuit), disconnect each of the sensors

on the list above in turn, checking after each disconnection whether the fault changes status from present to stored.

If the faulty sensor is located, check its connections and that it is in order.

Replace the faulty sensor if necessary.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Injection computer, connectorA, track G2 track 3 of the pedal potentiometer gang 1

Injection computer, connectorB, track G2 track 2 of the motorised throttle valve

(K4M 766/812 and 813, F4R 770 and 771)

track 5 of the motorised throttle valve

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

Repair if necessary.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

S3000_V4C_DF012/S3000_V54_DF012

Page 40 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-40

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-40V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

DF026

PRESENT

OR

STOREDCYLINDER 1 INJECTOR CONTROL CIRCUIT

CO: Open circuit

CC.0: Short circuit to earth

CC.1: Short-circuit to + 12 V

1.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

Deal with faults DF084 Actuator relay control circuit or DF046 Battery voltage first

if they are present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the engine has been running for a timed period of

10 seconds.

Special note:

–OBD warning light illuminated.

CO

CC.1

NOTESSpecial note:

No injection on cylinder 1, severe deterioration in

performance.

CC.0Special note:

The injector is always open: risk of stalling and damage to

the engine on starting, severe deterioration in performance.

Check the cleanliness and condition of the cylinder 1 injector and its connections.

Repair if necessary.

With the ignition on, check for + 12 V on track 1 of the cylinder 1 injector connector.

If there is no + 12 V feed, use the "universal bornier" to check the continuity of the following connections:

Injection computer, connectorB, track M2 track 1 of cylinder 1 injector

Protection and Switching Unit, connector CN,

track 6

Repair if necessary.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

S3000_V4C_DF026/S3000_V54_DF026

Page 41 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-41

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-41V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

DF026

CONTINUED

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Repair if necessary.

Use the "Universal bornier" to check the insulation and continuity on the following connection:

Injection computer, connectorB, track A1 Track 2 of cylinder 1 injector

Repair if necessary.

Measure the resistance of cylinder 1 injector between tracks 1 and 2.

Replace the cylinder 1 injector if the resistance is not

14.5Ω ± 0.7Ω at 20°C (except F4RT 774 RS)

12Ω ±0.6Ω at 20°C (F4RT 774 RS only)

If the fault is still present, replace the cylinder 1 injector.

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.