charging RENAULT SCENIC 2010 J95 / 3.G Petrol Injection S3000 Injection User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 230, PDF Size: 0.92 MB

Page 36 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-36

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-36V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

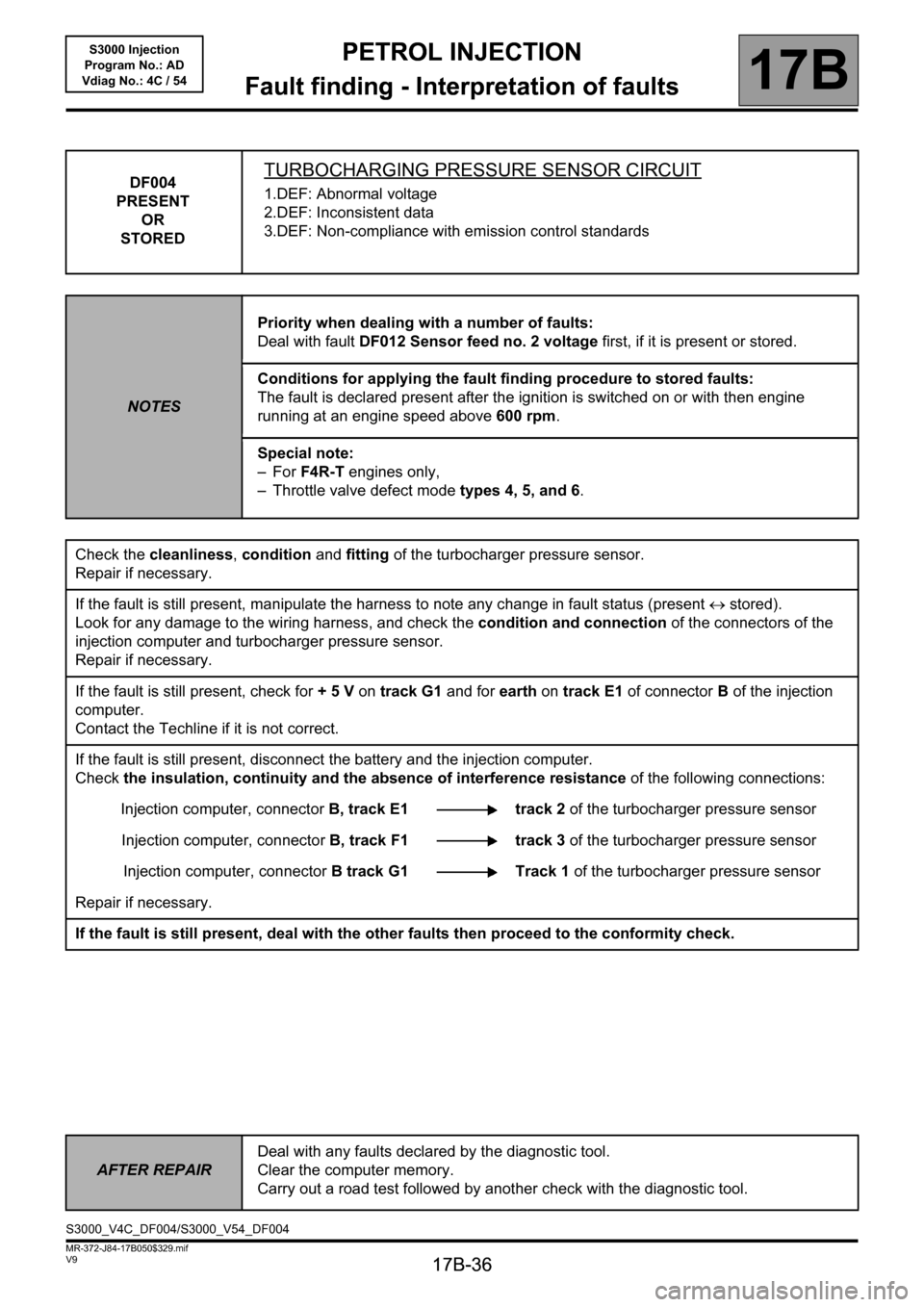

DF004

PRESENT

OR

STOREDTURBOCHARGING PRESSURE SENSOR CIRCUIT

1.DEF: Abnormal voltage

2.DEF: Inconsistent data

3.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

Deal with fault DF012 Sensor feed no. 2 voltage first, if it is present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the ignition is switched on or with then engine

running at an engine speed above 600 rpm.

Special note:

–For F4R-T engines only,

– Throttle valve defect mode types 4, 5, and 6.

Check the cleanliness, condition and fitting of the turbocharger pressure sensor.

Repair if necessary.

If the fault is still present, manipulate the harness to note any change in fault status (present↔ stored).

Look for any damage to the wiring harness, and check the condition and connection of the connectors of the

injection computer and turbocharger pressure sensor.

Repair if necessary.

If the fault is still present, check for + 5 V on track G1 and for earth on track E1 of connectorB of the injection

computer.

Contact the Techline if it is not correct.

If the fault is still present, disconnect the battery and the injection computer.

Check the insulation, continuity and the absence of interference resistance of the following connections:

Injection computer, connectorB, track E1 track 2 of the turbocharger pressure sensor

Injection computer, connectorB, track F1 track 3 of the turbocharger pressure sensor

Injection computer, connectorB track G1 Track 1 of the turbocharger pressure sensor

Repair if necessary.

If the fault is still present, deal with the other faults then proceed to the conformity check.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

S3000_V4C_DF004/S3000_V54_DF004

Page 49 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-49

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-49V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

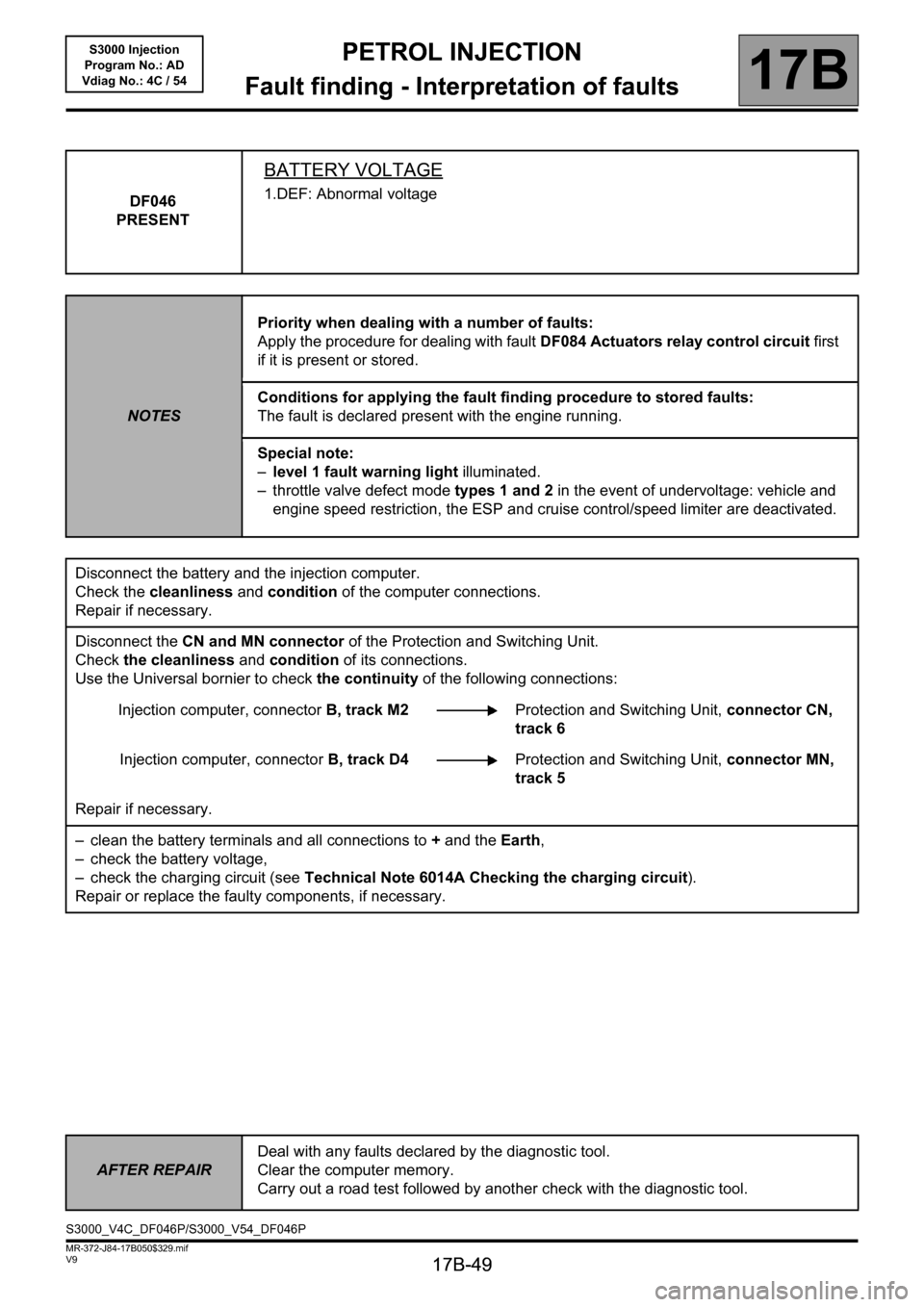

DF046

PRESENT

BATTERY VOLTAGE

1.DEF: Abnormal voltage

NOTESPriority when dealing with a number of faults:

Apply the procedure for dealing with fault DF084 Actuators relay control circuit first

if it is present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present with the engine running.

Special note:

–level 1 fault warning light illuminated.

– throttle valve defect mode types 1 and 2 in the event of undervoltage: vehicle and

engine speed restriction, the ESP and cruise control/speed limiter are deactivated.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the computer connections.

Repair if necessary.

Disconnect the CN and MN connector of the Protection and Switching Unit.

Check the cleanliness and condition of its connections.

Use the Universal bornier to check the continuity of the following connections:

Injection computer, connectorB, track M2Protection and Switching Unit, connector CN,

track 6

Injection computer, connectorB, track D4Protection and Switching Unit, connector MN,

track 5

Repair if necessary.

– clean the battery terminals and all connections to + and the Earth,

– check the battery voltage,

– check the charging circuit (see Technical Note 6014A Checking the charging circuit).

Repair or replace the faulty components, if necessary.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

S3000_V4C_DF046P/S3000_V54_DF046P

Page 50 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-50

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-50V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

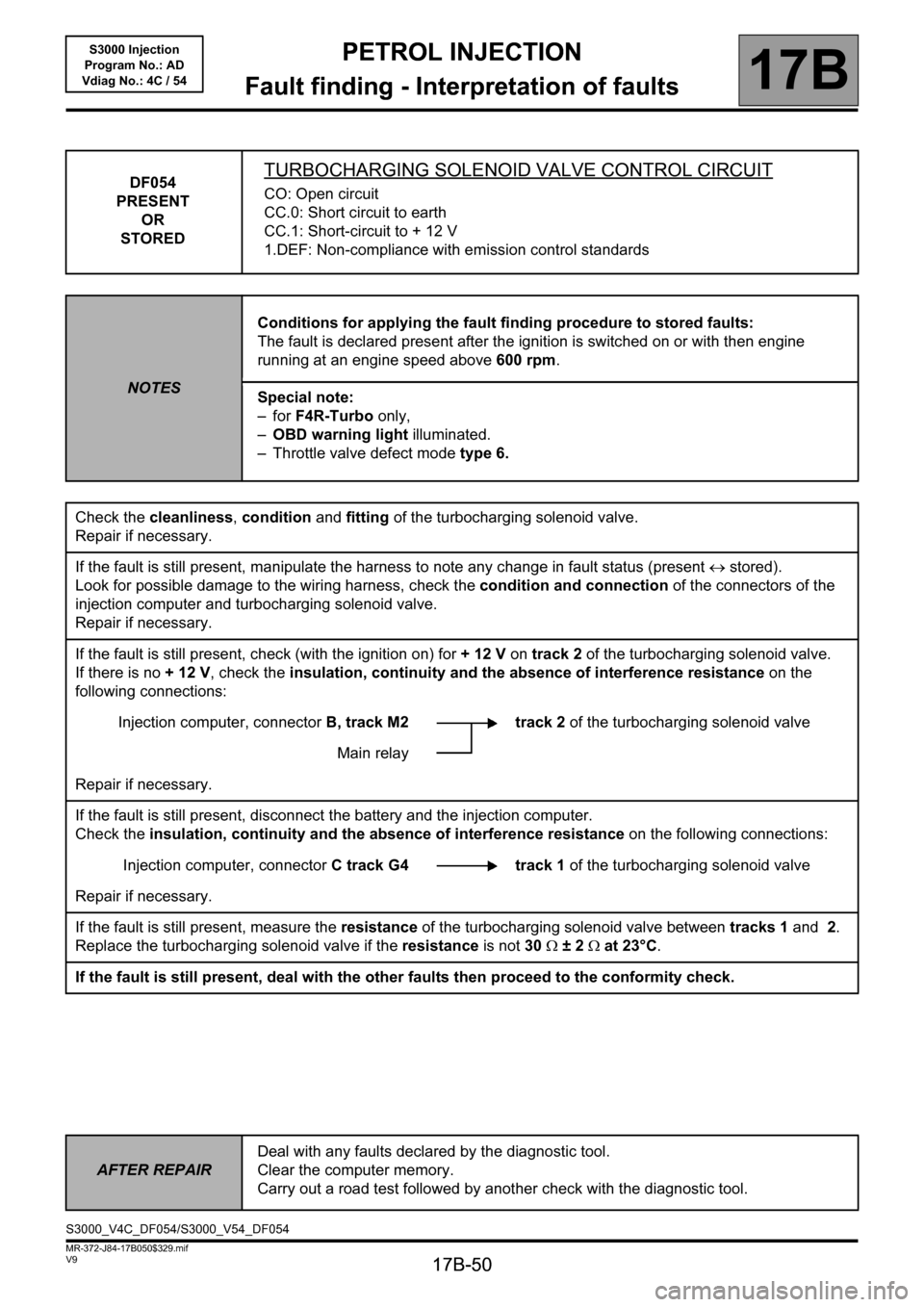

DF054

PRESENT

OR

STOREDTURBOCHARGING SOLENOID VALVE CONTROL CIRCUIT

CO: Open circuit

CC.0: Short circuit to earth

CC.1: Short-circuit to + 12 V

1.DEF: Non-compliance with emission control standards

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present after the ignition is switched on or with then engine

running at an engine speed above 600 rpm.

Special note:

–for F4R-Turbo only,

–OBD warning light illuminated.

– Throttle valve defect mode type 6.

Check the cleanliness, condition and fitting of the turbocharging solenoid valve.

Repair if necessary.

If the fault is still present, manipulate the harness to note any change in fault status (present↔ stored).

Look for possible damage to the wiring harness, check the condition and connection of the connectors of the

injection computer and turbocharging solenoid valve.

Repair if necessary.

If the fault is still present, check (with the ignition on) for +12V on track 2 of the turbocharging solenoid valve.

If there is no + 12 V, check the insulation, continuity and the absence of interference resistance on the

following connections:

Injection computer, connectorB, track M2 track 2 of the turbocharging solenoid valve

Main relay

Repair if necessary.

If the fault is still present, disconnect the battery and the injection computer.

Check the insulation, continuity and the absence of interference resistance on the following connections:

Injection computer, connectorC track G4 track 1 of the turbocharging solenoid valve

Repair if necessary.

If the fault is still present, measure the resistance of the turbocharging solenoid valve between tracks 1 and 2.

Replace the turbocharging solenoid valve if the resistance is not 30Ω ±2Ω at 23°C.

If the fault is still present, deal with the other faults then proceed to the conformity check.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

S3000_V4C_DF054/S3000_V54_DF054

Page 121 of 230

PETROL INJECTION

Fault finding - Conformity check

17B

17B-121

PETROL INJECTION

Fault finding - Conformity check

17B

17B-121V9 MR-372-J84-17B050$470.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

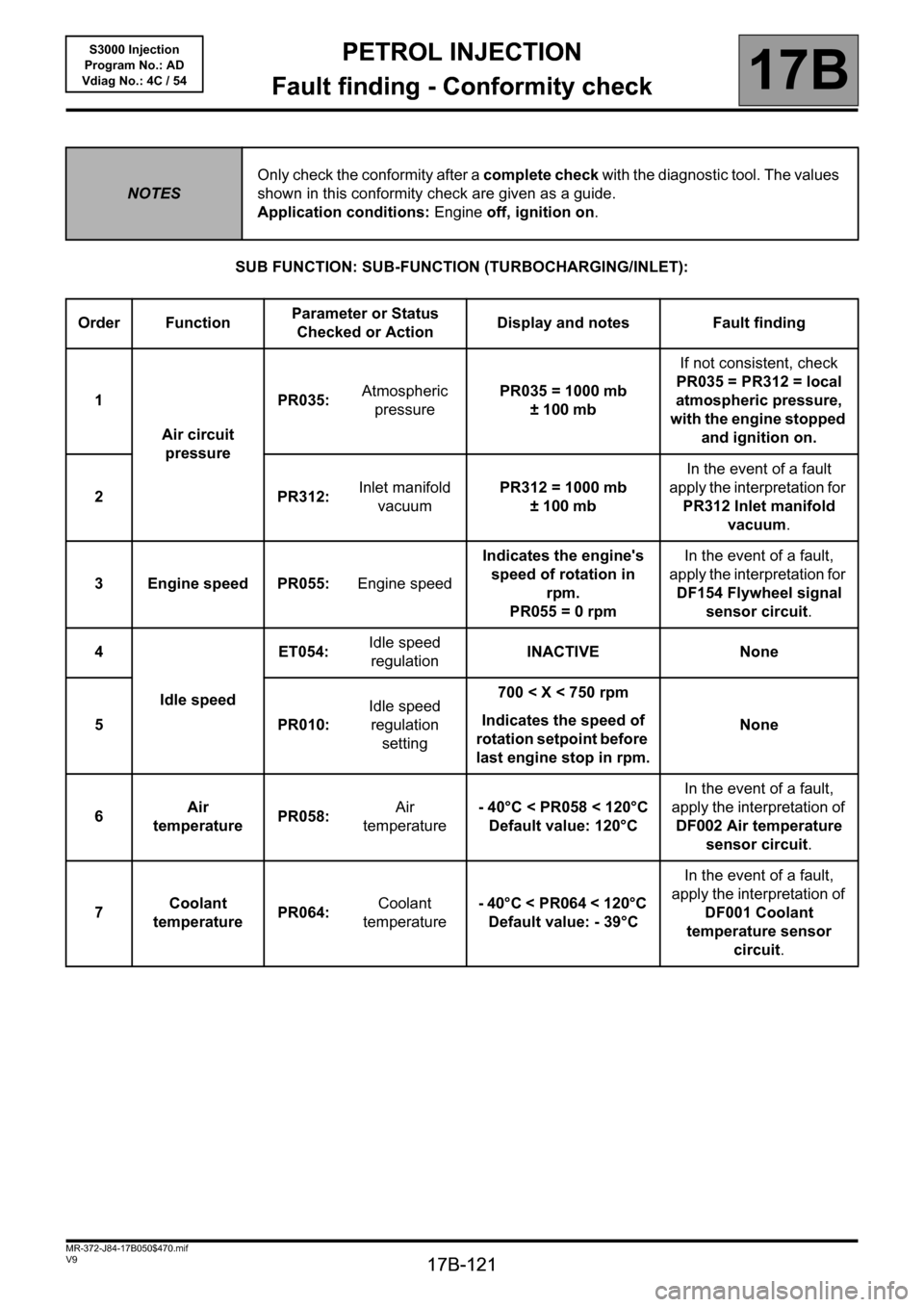

SUB FUNCTION: SUB-FUNCTION (TURBOCHARGING/INLET):

NOTESOnly check the conformity after a complete check with the diagnostic tool. The values

shown in this conformity check are given as a guide.

Application conditions: Engine off, ignition on.

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

1

Air circuit

pressurePR035:Atmospheric

pressurePR035 = 1000 mb

± 100 mbIf not consistent, check

PR035 = PR312 = local

atmospheric pressure,

with the engine stopped

and ignition on.

2 PR312:Inlet manifold

vacuumPR312 = 1000 mb

± 100 mbIn the event of a fault

apply the interpretation for

PR312 Inlet manifold

vacuum.

3 Engine speed PR055:Engine speedIndicates the engine's

speed of rotation in

rpm.

PR055 = 0 rpmIn the event of a fault,

apply the interpretation for

DF154 Flywheel signal

sensor circuit.

4

Idle speedET054:Idle speed

regulationINACTIVE None

5 PR010:Idle speed

regulation

setting700 < X < 750 rpm

Indicates the speed of

rotation setpoint before

last engine stop in rpm.None

6Air

temperaturePR058:Air

temperature- 40°C < PR058 < 120°C

Default value: 120°CIn the event of a fault,

apply the interpretation of

DF002 Air temperature

sensor circuit.

7 Coolant

temperaturePR064:Coolant

temperature- 40°C < PR064 < 120°C

Default value: - 39°CIn the event of a fault,

apply the interpretation of

DF001 Coolant

temperature sensor

circuit.

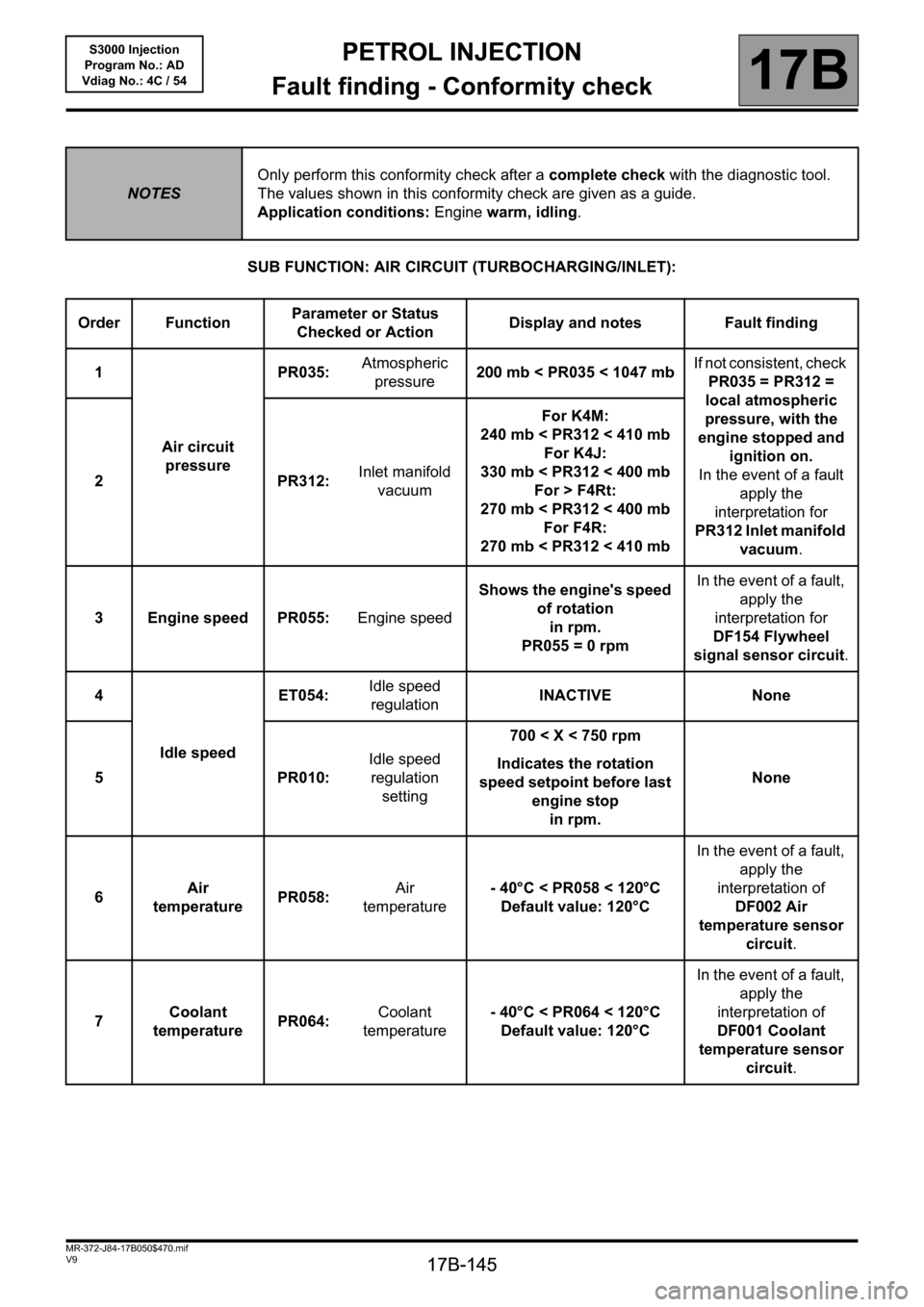

Page 145 of 230

PETROL INJECTION

Fault finding - Conformity check

17B

17B-145

PETROL INJECTION

Fault finding - Conformity check

17B

17B-145V9 MR-372-J84-17B050$470.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

SUB FUNCTION: AIR CIRCUIT (TURBOCHARGING/INLET):

NOTESOnly perform this conformity check after a complete check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine warm, idling.

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

1

Air circuit

pressurePR035:Atmospheric

pressure200 mb < PR035 < 1047 mbIf not consistent, check

PR035 = PR312 =

local atmospheric

pressure, with the

engine stopped and

ignition on.

In the event of a fault

apply the

interpretation for

PR312 Inlet manifold

vacuum. 2 PR312:Inlet manifold

vacuumFor K4M:

240 mb < PR312 < 410 mb

For K4J:

330 mb < PR312 < 400 mb

For > F4Rt:

270 mb < PR312 < 400 mb

For F4R:

270 mb < PR312 < 410 mb

3 Engine speed PR055:Engine speedShows the engine's speed

of rotation

in rpm.

PR055= 0rpmIn the event of a fault,

apply the

interpretation for

DF154 Flywheel

signal sensor circuit.

4

Idle speedET054:Idle speed

regulationINACTIVE None

5 PR010:Idle speed

regulation

setting700 < X < 750 rpm

Indicates the rotation

speed setpoint before last

engine stop

in rpm.None

6Air

temperaturePR058:Air

temperature- 40°C < PR058 < 120°C

Default value: 120°CIn the event of a fault,

apply the

interpretation of

DF002 Air

temperature sensor

circuit.

7 Coolant

temperaturePR064:Coolant

temperature- 40°C < PR064 < 120°C

Default value: 120°CIn the event of a fault,

apply the

interpretation of

DF001 Coolant

temperature sensor

circuit.

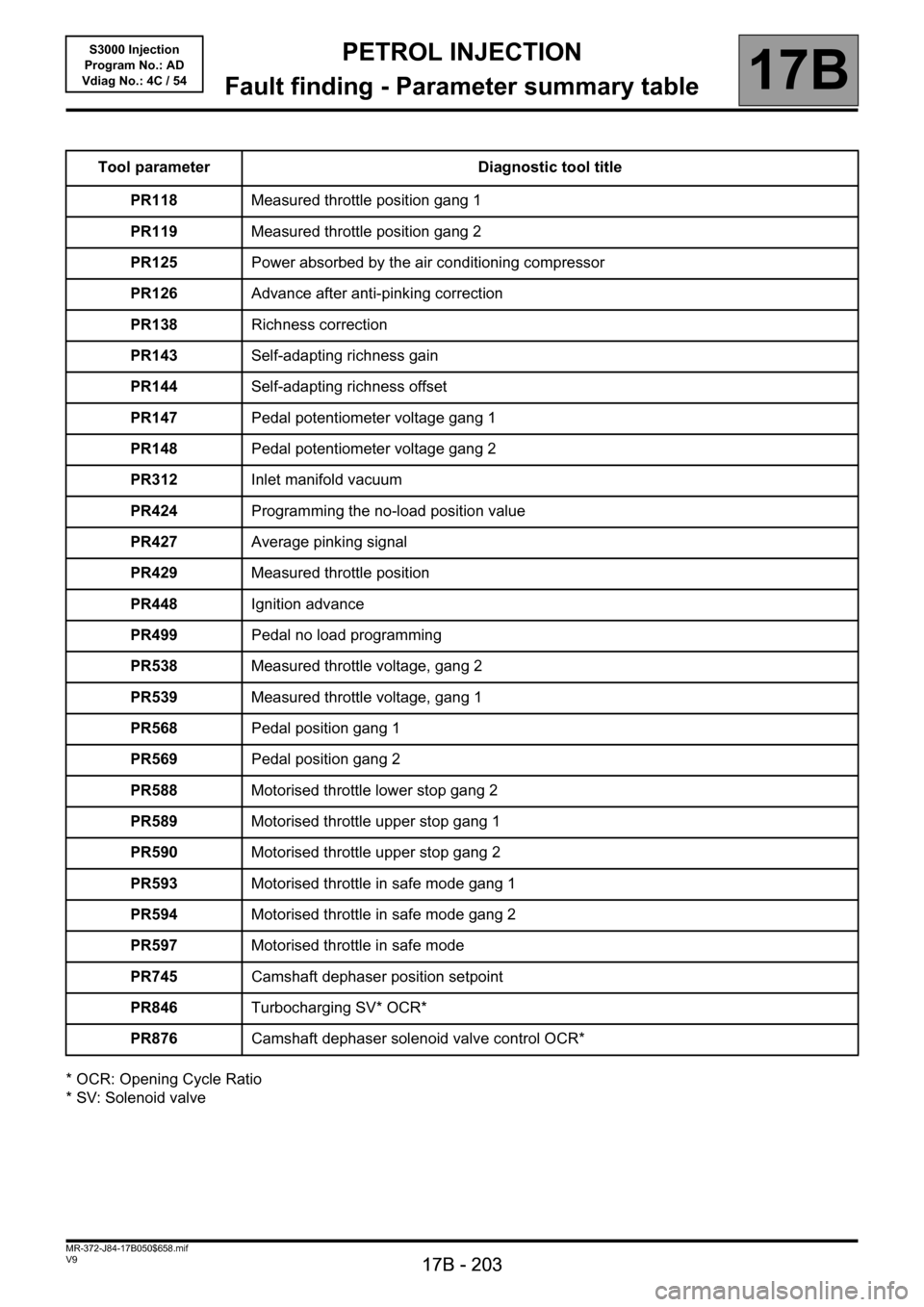

Page 203 of 230

PETROL INJECTION

Fault finding - Parameter summary table

17B

17B - 203

17B

17B - 203V9 MR-372-J84-17B050$658.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

* OCR: Opening Cycle Ratio

* SV: Solenoid valveTool parameter Diagnostic tool title

PR118Measured throttle position gang 1

PR119Measured throttle position gang 2

PR125Power absorbed by the air conditioning compressor

PR126Advance after anti-pinking correction

PR138Richness correction

PR143Self-adapting richness gain

PR144Self-adapting richness offset

PR147Pedal potentiometer voltage gang 1

PR148Pedal potentiometer voltage gang 2

PR312Inlet manifold vacuum

PR424Programming the no-load position value

PR427Average pinking signal

PR429Measured throttle position

PR448Ignition advance

PR499Pedal no load programming

PR538Measured throttle voltage, gang 2

PR539Measured throttle voltage, gang 1

PR568Pedal position gang 1

PR569Pedal position gang 2

PR588Motorised throttle lower stop gang 2

PR589Motorised throttle upper stop gang 1

PR590Motorised throttle upper stop gang 2

PR593Motorised throttle in safe mode gang 1

PR594Motorised throttle in safe mode gang 2

PR597Motorised throttle in safe mode

PR745Camshaft dephaser position setpoint

PR846Turbocharging SV* OCR*

PR876Camshaft dephaser solenoid valve control OCR*

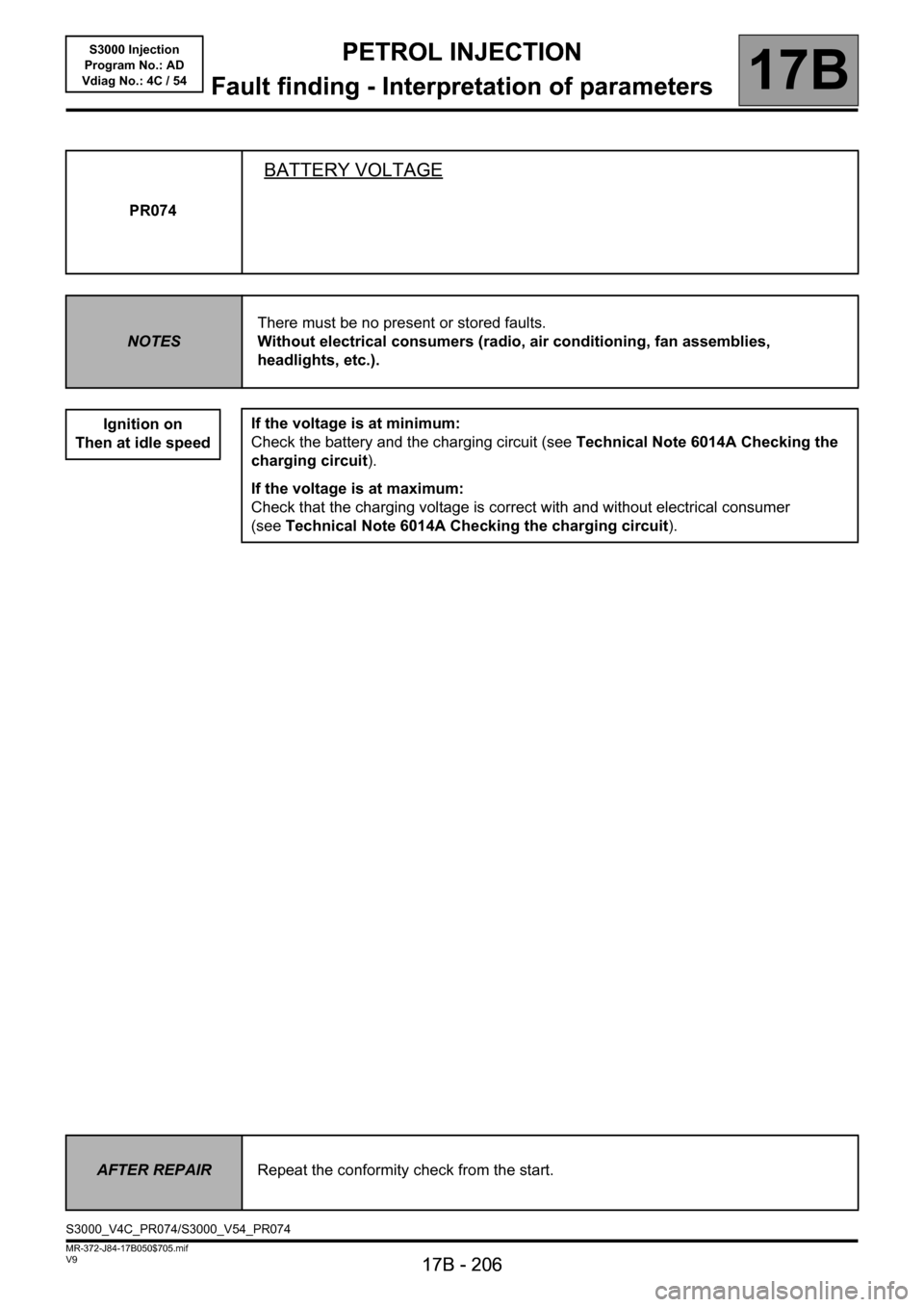

Page 206 of 230

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 206

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 206V9 MR-372-J84-17B050$705.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

PR074

BATTERY VOLTAGE

NOTESThere must be no present or stored faults.

Without electrical consumers (radio, air conditioning, fan assemblies,

headlights, etc.).

Ignition on

Then at idle speed

If the voltage is at minimum:

Check the battery and the charging circuit (see Technical Note 6014A Checking the

charging circuit).

If the voltage is at maximum:

Check that the charging voltage is correct with and without electrical consumer

(seeTechnical Note 6014A Checking the charging circuit).

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_PR074/S3000_V54_PR074

Page 228 of 230

PETROL INJECTION

Fault finding - Fault Finding Chart

17B

17B-228

PETROL INJECTION

Fault finding - Fault Finding Chart

17B

17B-228V9 MR-372-J84-17B050$940.mif

S3000 Injection

Program No.: AD

Vdiag No.:4C / 54

ALP 2 The engine will not start

NOTESFollow ALP 2 after a complete check with the diagnostic tool.

WARNING

Never drive the vehicle without checking first that there are no throttle valve

faults.

If the starter motor does not engage, there may be an engine immobiliser fault.

Carry out fault finding on the UCH (see87B, Passenger Compartment Connection Unit).

Check the condition of the battery.

Check the cleanliness, condition and tightness of the battery terminals.

Check that the battery is correctly earthed to the vehicle bodywork.

Check that the + battery leads are correctly connected.

Check that the starter motor is properly connected.

Check the starter is working properly (see Technical Note 6014A Checking the charging circuit).

Check the condition and conformity of the spark plugs.

Check the mounting, cleanliness and condition of the flywheel signal sensor.

Check the flywheel signal sensor air gap.

Check the condition of the flywheel.

Check that the air filter is not clogged.

Check that the air inlet circuit is not blocked.

Check that there is fuel in the tank (fuel sender fault).

Check that the tank vent is not blocked.

Check that the fuel is of the correct type.

Check that there are no leaks in the fuel system, from the tank to the injectors.

Check that there are no kinked hoses (especially after a removal operation).

Check the fuel flow rate and pressure.

Check the sealing of the injectors, and that they are working properly.

Check that the exhaust system is not blocked and the catalytic converter not clogged.

Check the timing setting.

Check the cylinder compressions.

Check the hydraulic tappets if there is camshaft noise.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_ALP2/S3000_V54_ALP2