PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 192

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 192V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

ET509

OBD DOWNSTREAM OXYGEN SENSOR HEATING CIRCUIT

NOTESThere must be no present or stored faults.

Check the cleanliness and condition of the downstream oxygen sensor and its connections.

Repair if necessary.

With the ignition on, check for + 12 V feed on track A of the downstream oxygen sensor connector.

If +12V is not present:

– disconnect the battery,

– disconnect the CN connector in the Protection and Switching Unit,

– check the cleanliness and condition of the connections,

– using the Universal bornier, check the continuity on the following connection:

Protection and Switching Unit, connector CN,

track 6track A of the downstream oxygen sensor

Reconnect the Protection and Switching Unit connector and reconnect the battery.

With the ignition on, if the +12V is still not present on the downstream oxygen sensor connector, there is a fault

in the Protection and Switching Unit.

Contact the Techline.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the Universal bornier, check the insulation and continuity on the following connection:

Injection computer, connectorC, track L3 track B of the downstream oxygen sensor

Repair if necessary.

Measure the heating resistance between tracks A and B of the downstream oxygen sensor.

Replace the downstream oxygen sensor if the resistance is not approximately 9Ω at 20°C.

If the fault is still present, replace the downstream oxygen sensor.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_ET509/S3000_V54_ET509

PETROL INJECTION

17B

17B-213

PETROL INJECTION

17B

17B-213V9 MR-372-J84-17B050$752.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

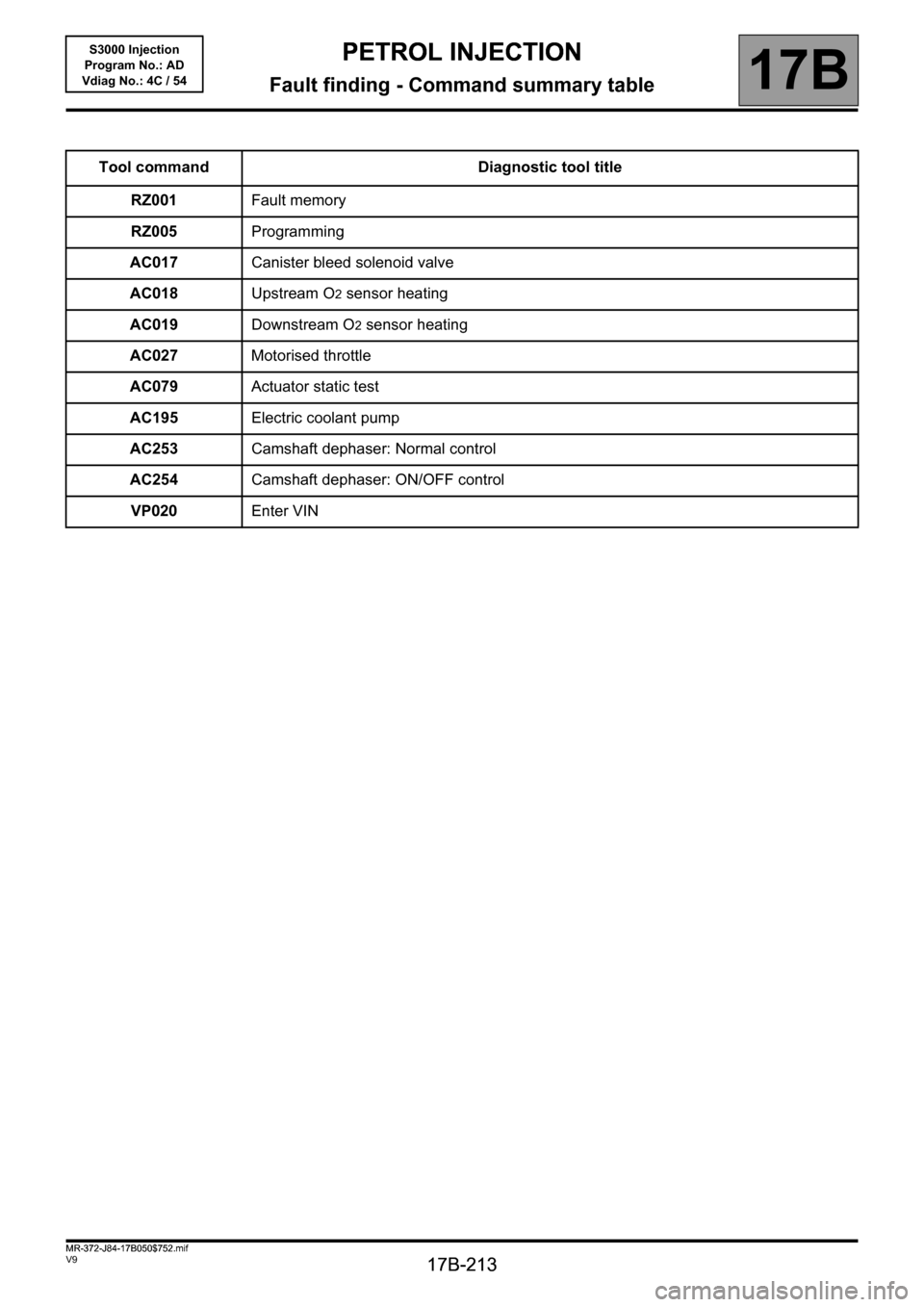

Fault finding - Command summary table

Tool command Diagnostic tool title

RZ001Fault memory

RZ005Programming

AC017Canister bleed solenoid valve

AC018Upstream O

2 sensor heating

AC019Downstream O

2 sensor heating

AC027Motorised throttle

AC079Actuator static test

AC195Electric coolant pump

AC253Camshaft dephaser: Normal control

AC254Camshaft dephaser: ON/OFF control

VP020Enter VIN

MR-372-J84-17B050$752.mif

PETROL INJECTION

Fault finding - Interpretation of commands

17B

17B - 216

PETROL INJECTION

Fault finding - Interpretation of commands

17B

17B - 216V9 MR-372-J84-17B050$799.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

AC079

ACTUATOR STATIC TEST

NOTESThere must be no present or stored faults.

Switch the ignition on and run command AC079 Actuator static test.

If the following actuators are not working, apply the interpretation of the associated fault:

– Fuel pump relay, apply the interpretation of DF085 Fuel pump relay circuit.

– The motorised throttle, apply the interpretation of DF079 Motorised throttle valve servo control.

– The electric coolant pump, apply the interpretation of DF570 Coolant pump relay.

–Upstream O

2 sensor heating, apply the interpretation of DF601 Upstream O2 sensor heating power circuit.

– Downstream O

2 sensor heating, apply the interpretation of DF602 Downstream O2 sensor heating power

circuit.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_AC079/S3000_V54_AC079