sensor RENAULT SCENIC 2010 J95 / 3.G Petrol Injection S3000 Injection Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 230, PDF Size: 0.92 MB

Page 71 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-71

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-71V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

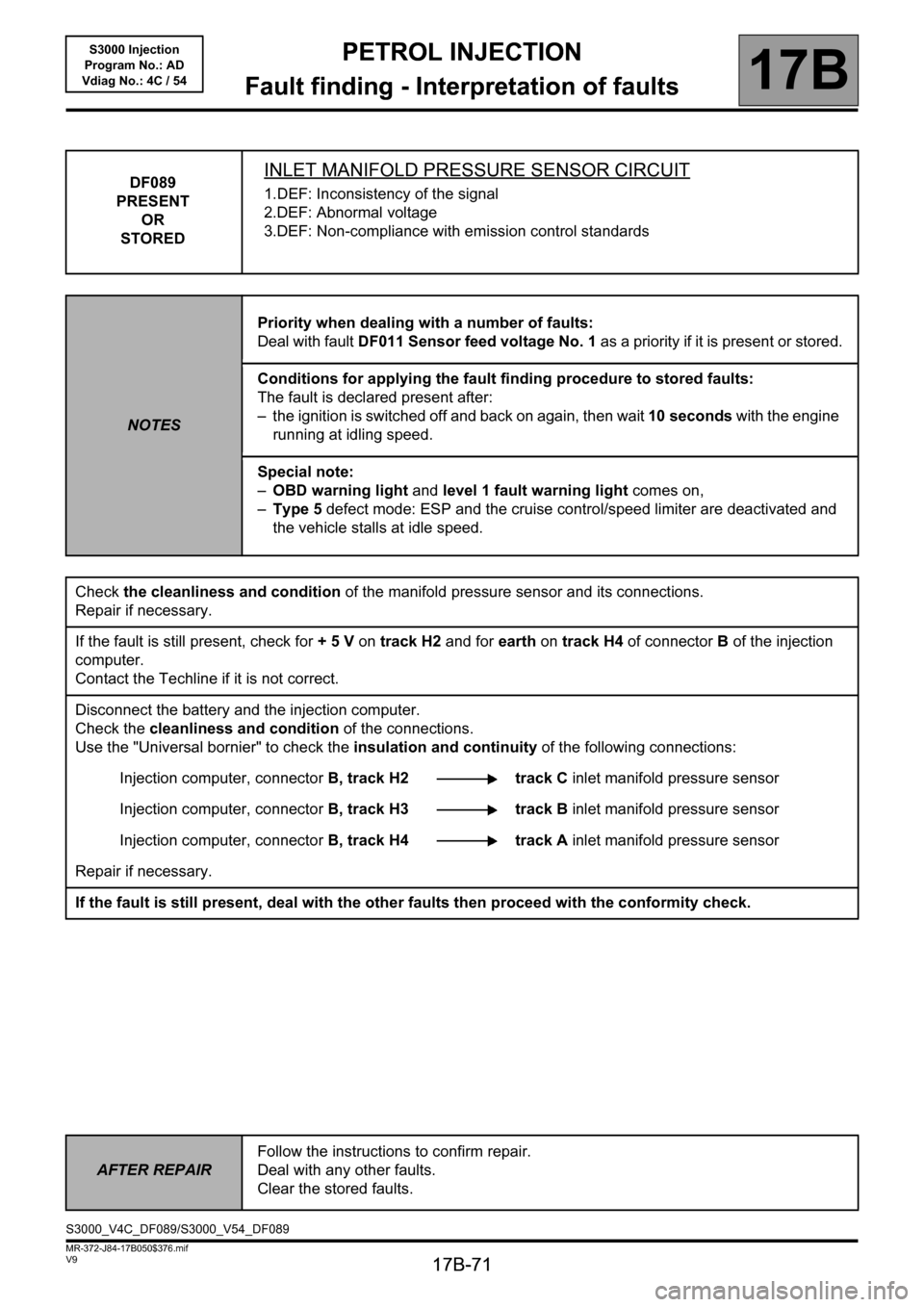

DF089

PRESENT

OR

STOREDINLET MANIFOLD PRESSURE SENSOR CIRCUIT

1.DEF: Inconsistency of the signal

2.DEF: Abnormal voltage

3.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

Deal with fault DF011 Sensor feed voltage No. 1 as a priority if it is present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after:

– the ignition is switched off and back on again, then wait 10 seconds with the engine

running at idling speed.

Special note:

–OBD warning light and level 1 fault warning light comes on,

–Type 5 defect mode: ESP and the cruise control/speed limiter are deactivated and

the vehicle stalls at idle speed.

Check the cleanliness and condition of the manifold pressure sensor and its connections.

Repair if necessary.

If the fault is still present, check for + 5 V on track H2 and for earth on track H4 of connectorB of the injection

computer.

Contact the Techline if it is not correct.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Injection computer, connectorB, track H2 track C inlet manifold pressure sensor

Injection computer, connectorB, track H3 track B inlet manifold pressure sensor

Injection computer, connectorB, track H4 track A inlet manifold pressure sensor

Repair if necessary.

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF089/S3000_V54_DF089

Page 73 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-73

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-73V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

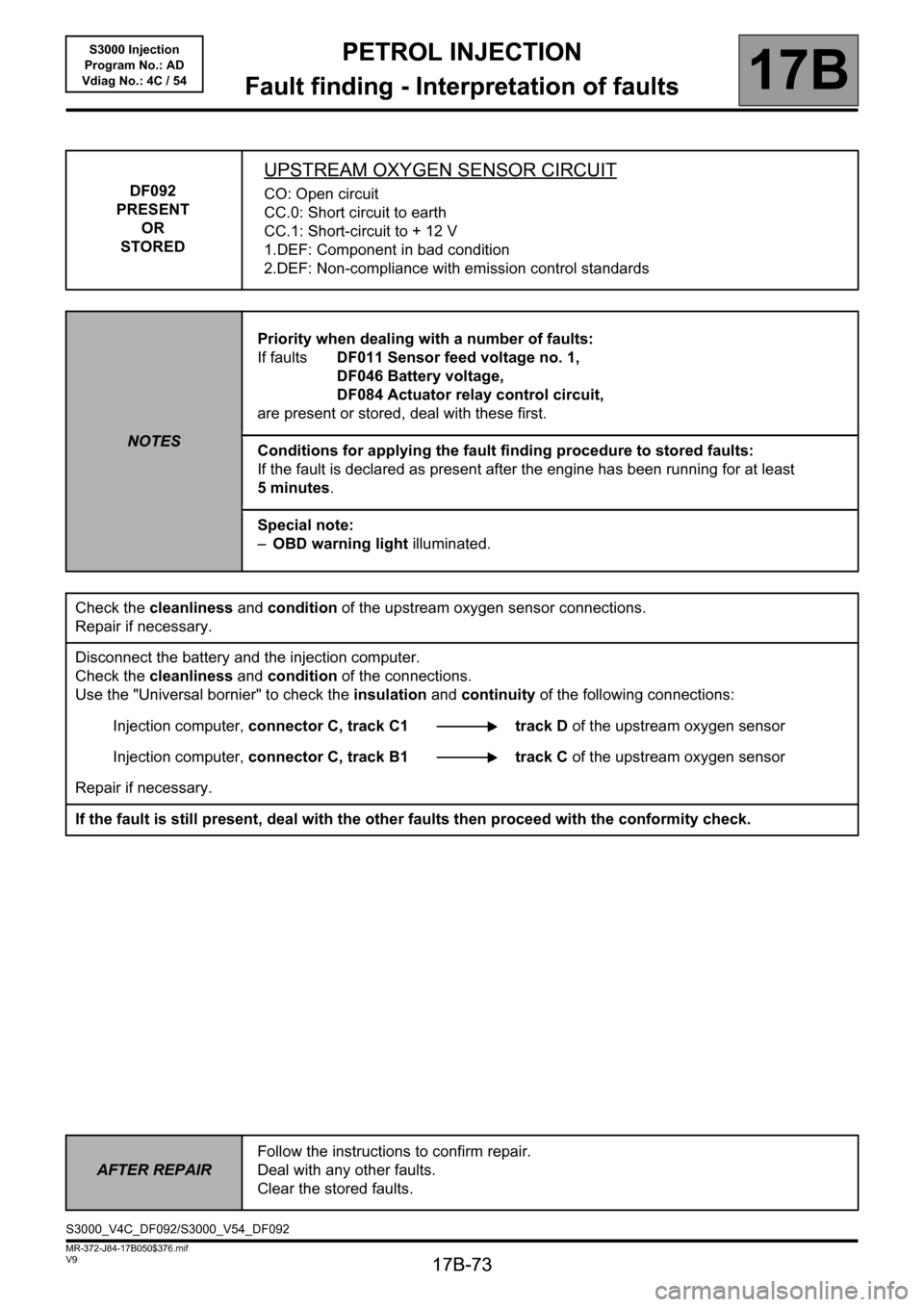

DF092

PRESENT

OR

STORED

UPSTREAM OXYGEN SENSOR CIRCUIT

CO: Open circuit

CC.0: Short circuit to earth

CC.1: Short-circuit to + 12 V

1.DEF: Component in bad condition

2.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

If faults DF011 Sensor feed voltage no. 1,

DF046 Battery voltage,

DF084 Actuator relay control circuit,

are present or stored, deal with these first.

Conditions for applying the fault finding procedure to stored faults:

If the fault is declared as present after the engine has been running for at least

5 minutes.

Special note:

–OBD warning light illuminated.

Check the cleanliness and condition of the upstream oxygen sensor connections.

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Injection computer, connector C, track C1 track D of the upstream oxygen sensor

Injection computer, connector C, track B1 track C of the upstream oxygen sensor

Repair if necessary.

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF092/S3000_V54_DF092

Page 74 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-74

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-74V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

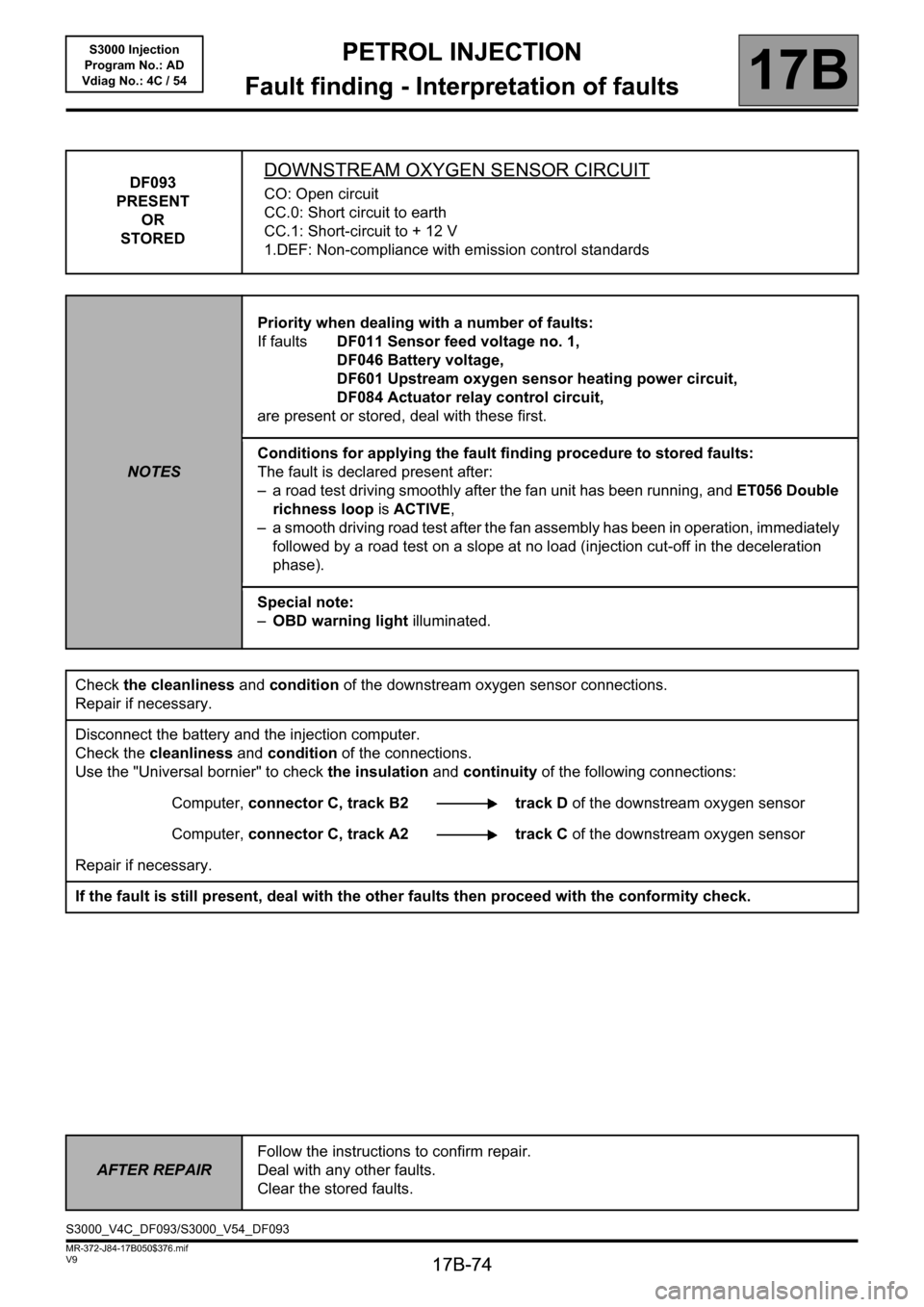

DF093

PRESENT

OR

STOREDDOWNSTREAM OXYGEN SENSOR CIRCUIT

CO: Open circuit

CC.0: Short circuit to earth

CC.1: Short-circuit to + 12 V

1.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

If faults DF011 Sensor feed voltage no. 1,

DF046 Battery voltage,

DF601 Upstream oxygen sensor heating power circuit,

DF084 Actuator relay control circuit,

are present or stored, deal with these first.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after:

– a road test driving smoothly after the fan unit has been running, and ET056 Double

richness loop is ACTIVE,

– a smooth driving road test after the fan assembly has been in operation, immediately

followed by a road test on a slope at no load (injection cut-off in the deceleration

phase).

Special note:

–OBD warning light illuminated.

Check the cleanliness and condition of the downstream oxygen sensor connections.

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Computer, connector C, track B2 track D of the downstream oxygen sensor

Computer, connector C, track A2 track C of the downstream oxygen sensor

Repair if necessary.

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF093/S3000_V54_DF093

Page 75 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-75

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-75V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

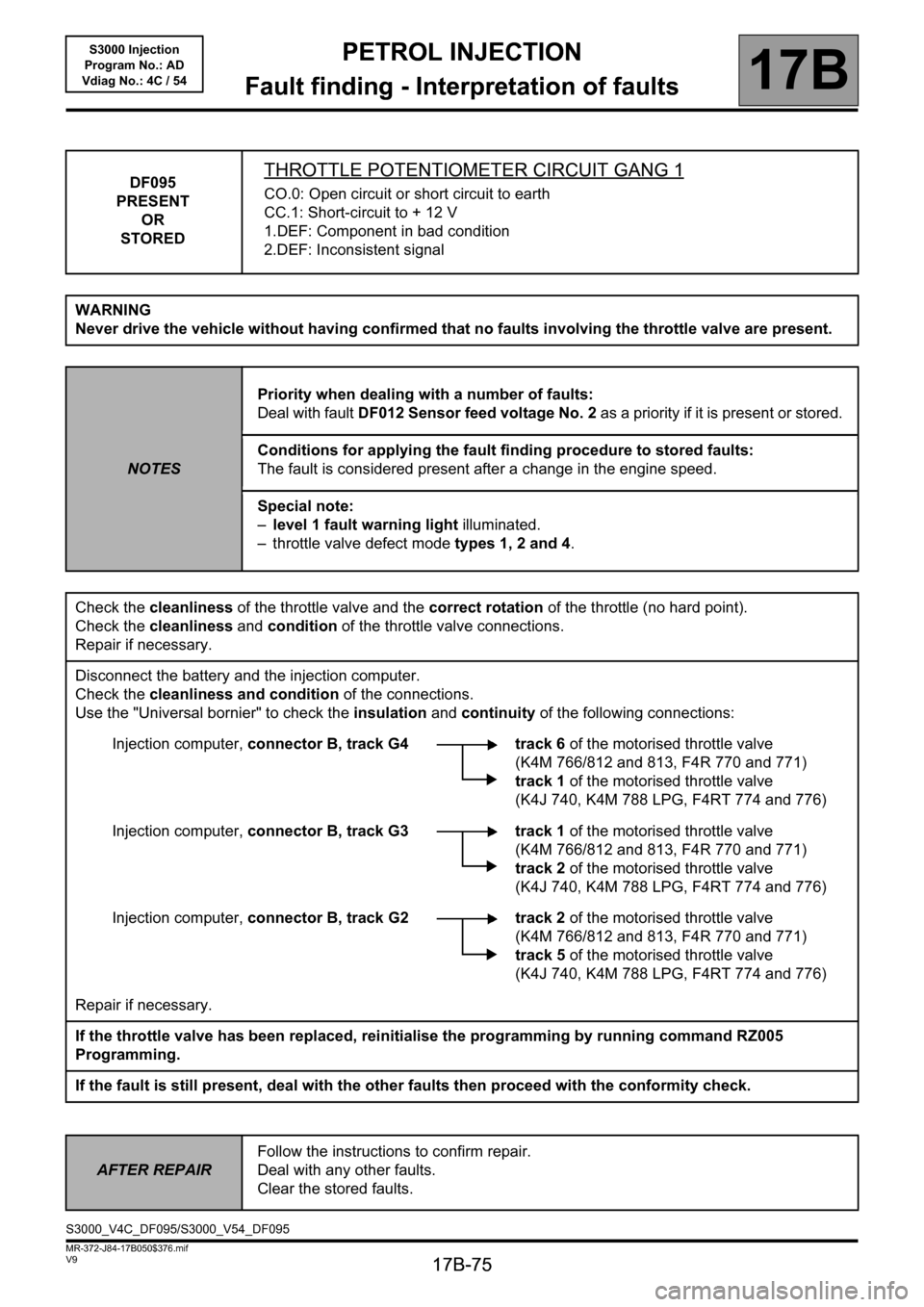

DF095

PRESENT

OR

STOREDTHROTTLE POTENTIOMETER CIRCUIT GANG 1

CO.0: Open circuit or short circuit to earth

CC.1: Short-circuit to + 12 V

1.DEF: Component in bad condition

2.DEF: Inconsistent signal

WARNING

Never drive the vehicle without having confirmed that no faults involving the throttle valve are present.

NOTESPriority when dealing with a number of faults:

Deal with fault DF012 Sensor feed voltage No. 2 as a priority if it is present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present after a change in the engine speed.

Special note:

–level 1 fault warning light illuminated.

– throttle valve defect mode types 1, 2 and 4.

Check the cleanliness of the throttle valve and the correct rotation of the throttle (no hard point).

Check the cleanliness and condition of the throttle valve connections.

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Injection computer, connector B, track G4 track 6 of the motorised throttle valve

(K4M 766/812 and 813, F4R 770 and 771)

track 1 of the motorised throttle valve

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

Injection computer, connector B, track G3 track 1 of the motorised throttle valve

(K4M 766/812 and 813, F4R 770 and 771)

track 2 of the motorised throttle valve

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

Injection computer, connector B, track G2 track 2 of the motorised throttle valve

(K4M 766/812 and 813, F4R 770 and 771)

track 5 of the motorised throttle valve

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

Repair if necessary.

If the throttle valve has been replaced, reinitialise the programming by running command RZ005

Programming.

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF095/S3000_V54_DF095

Page 76 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-76

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-76V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

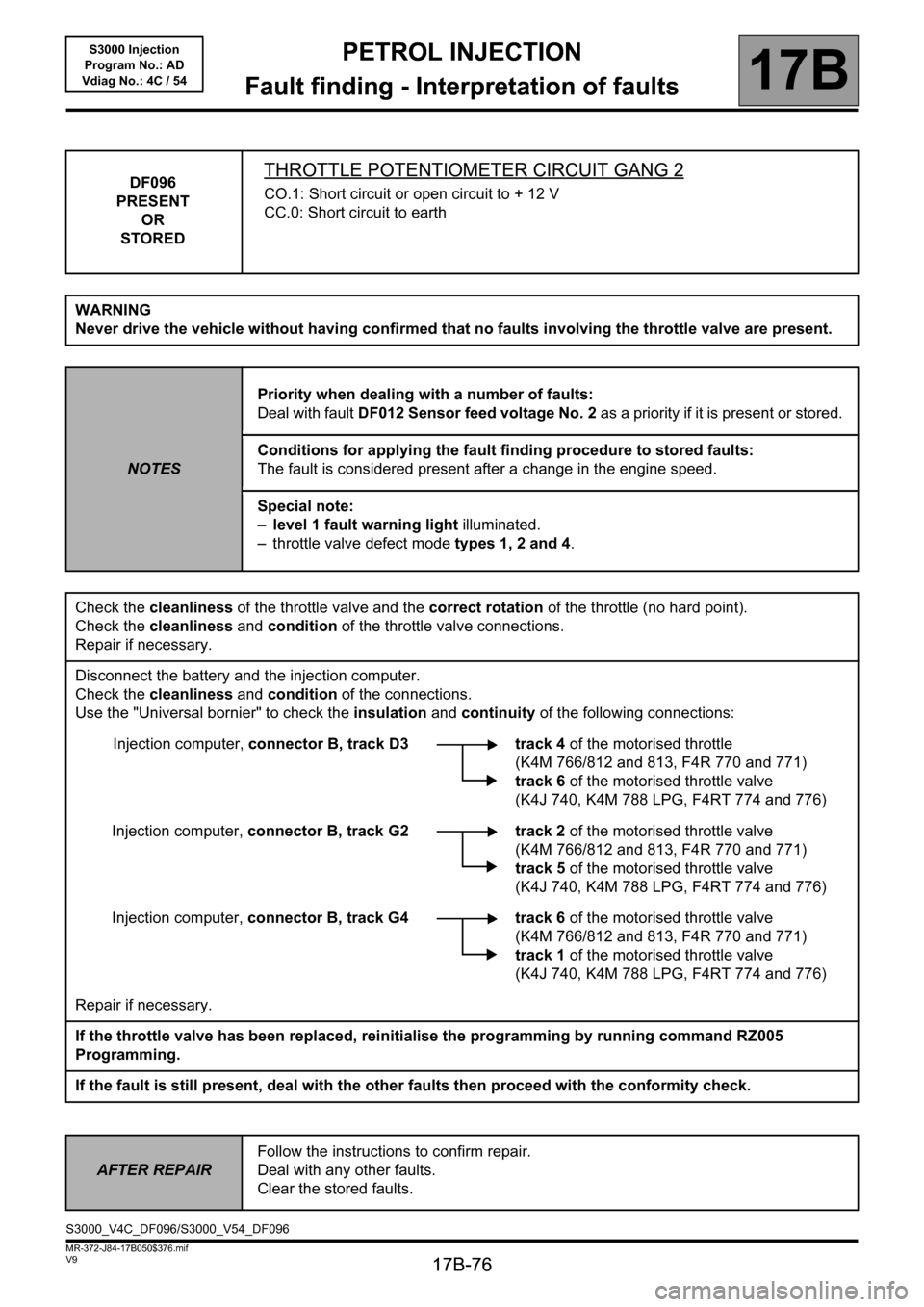

DF096

PRESENT

OR

STOREDTHROTTLE POTENTIOMETER CIRCUIT GANG 2

CO.1: Short circuit or open circuit to + 12 V

CC.0: Short circuit to earth

WARNING

Never drive the vehicle without having confirmed that no faults involving the throttle valve are present.

NOTESPriority when dealing with a number of faults:

Deal with fault DF012 Sensor feed voltage No. 2 as a priority if it is present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present after a change in the engine speed.

Special note:

–level 1 fault warning light illuminated.

– throttle valve defect mode types 1, 2 and 4.

Check the cleanliness of the throttle valve and the correct rotation of the throttle (no hard point).

Check the cleanliness and condition of the throttle valve connections.

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Injection computer, connector B, track D3 track 4of the motorised throttle

(K4M 766/812 and 813, F4R 770 and 771)

track 6 of the motorised throttle valve

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

Injection computer, connector B, track G2 track 2 of the motorised throttle valve

(K4M 766/812 and 813, F4R 770 and 771)

track 5 of the motorised throttle valve

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

Injection computer, connector B, track G4 track 6 of the motorised throttle valve

(K4M 766/812 and 813, F4R 770 and 771)

track 1 of the motorised throttle valve

(K4J 740, K4M 788 LPG, F4RT 774 and 776)

Repair if necessary.

If the throttle valve has been replaced, reinitialise the programming by running command RZ005

Programming.

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF096/S3000_V54_DF096

Page 83 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-83

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-83V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

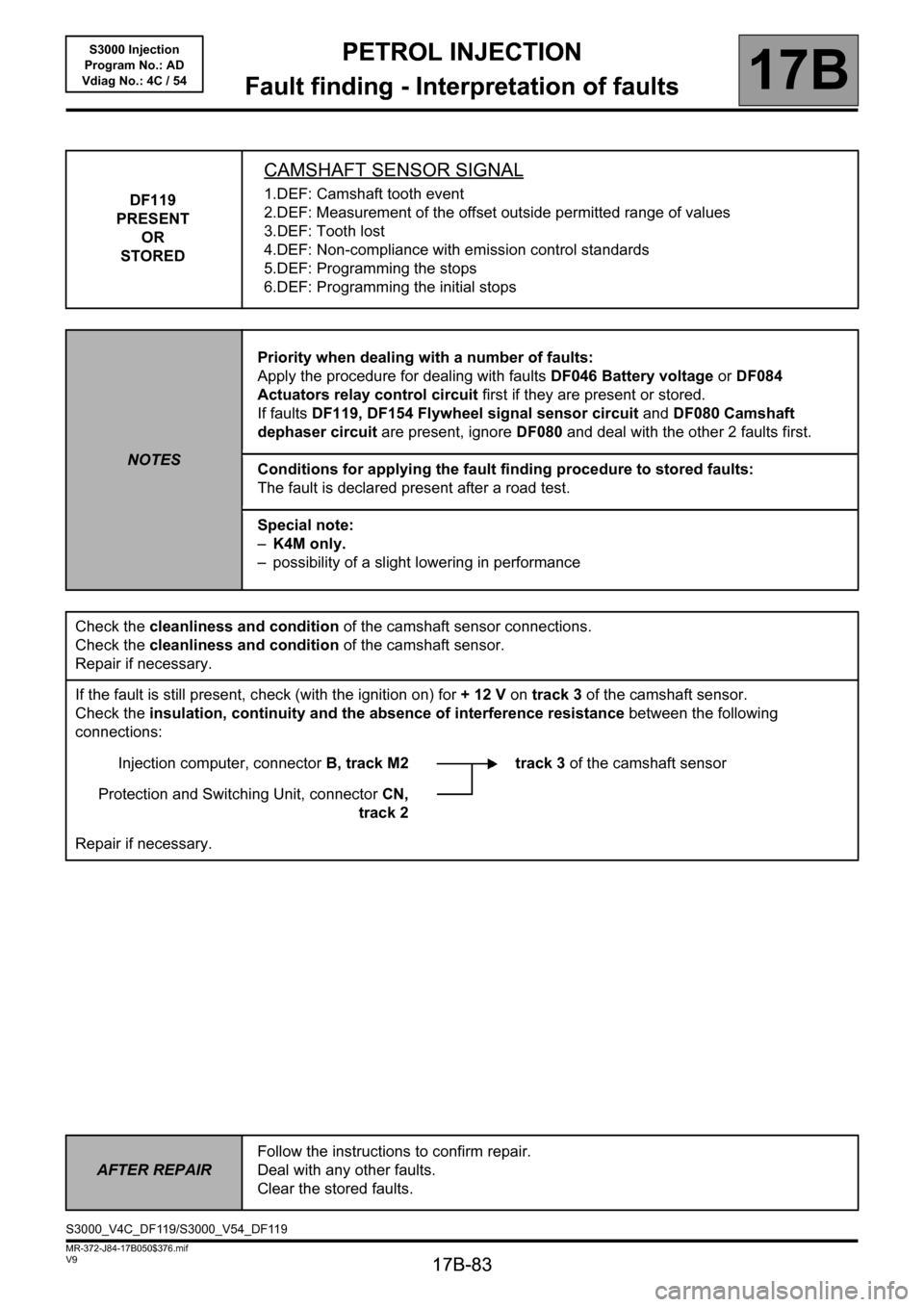

DF119

PRESENT

OR

STORED

CAMSHAFT SENSOR SIGNAL

1.DEF: Camshaft tooth event

2.DEF: Measurement of the offset outside permitted range of values

3.DEF: Tooth lost

4.DEF: Non-compliance with emission control standards

5.DEF: Programming the stops

6.DEF: Programming the initial stops

NOTESPriority when dealing with a number of faults:

Apply the procedure for dealing with faults DF046 Battery voltage or DF084

Actuators relay control circuit first if they are present or stored.

If faults DF119, DF154 Flywheel signal sensor circuit and DF080 Camshaft

dephaser circuit are present, ignore DF080 and deal with the other 2 faults first.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after a road test.

Special note:

–K4M only.

– possibility of a slight lowering in performance

Check the cleanliness and condition of the camshaft sensor connections.

Check the cleanliness and condition of the camshaft sensor.

Repair if necessary.

If the fault is still present, check (with the ignition on) for + 12 V on track 3 of the camshaft sensor.

Check the insulation, continuity and the absence of interference resistance between the following

connections:

Injection computer, connectorB, track M2 track 3 of the camshaft sensor

Protection and Switching Unit, connectorCN,

track 2

Repair if necessary.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF119/S3000_V54_DF119

Page 84 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-84

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-84V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

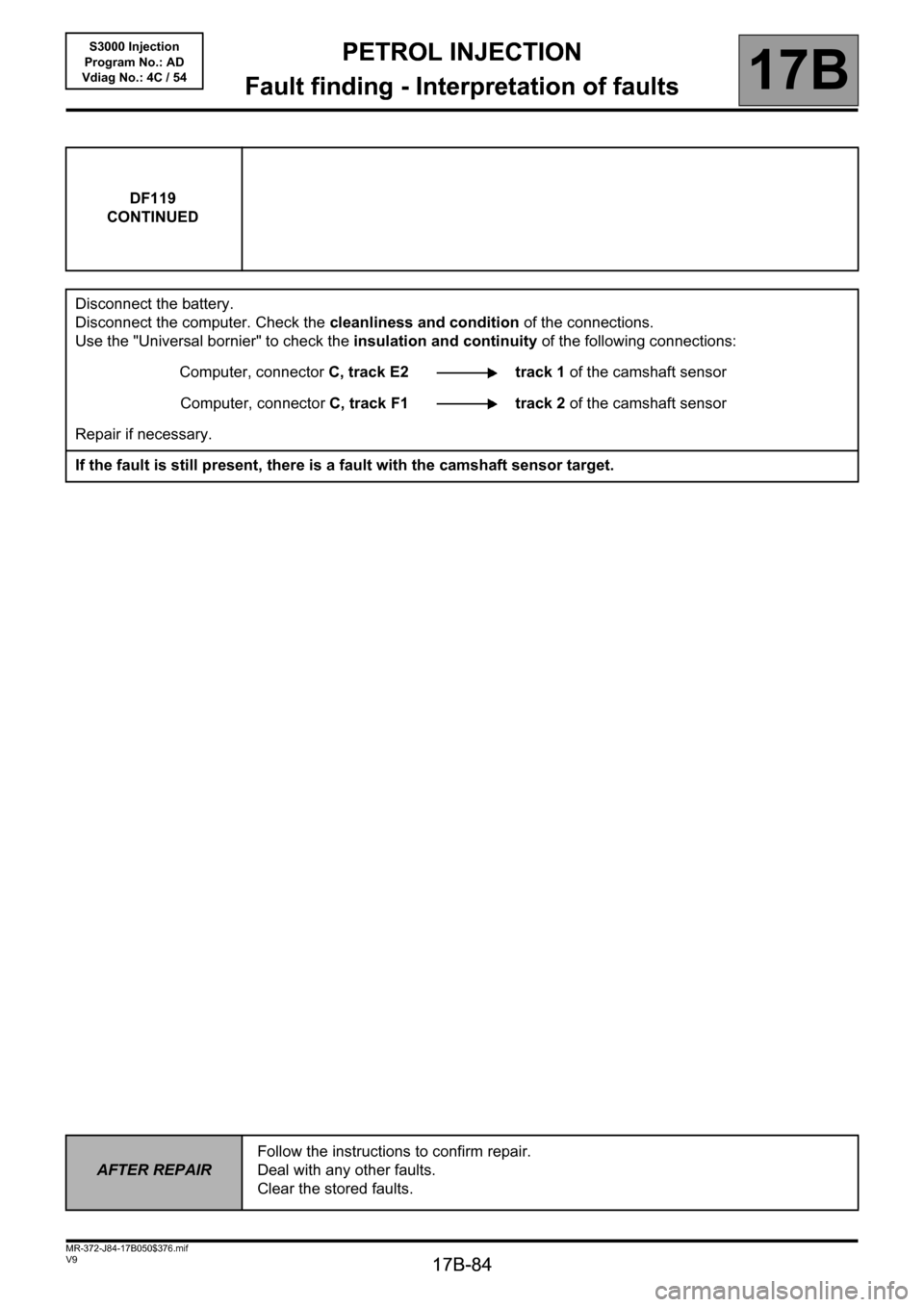

DF119

CONTINUED

Disconnect the battery.

Disconnect the computer. Check the cleanliness and condition of the connections.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Computer, connectorC, track E2 track 1 of the camshaft sensor

Computer, connectorC, track F1 track 2 of the camshaft sensor

Repair if necessary.

If the fault is still present, there is a fault with the camshaft sensor target.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

Page 88 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-88

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-88V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

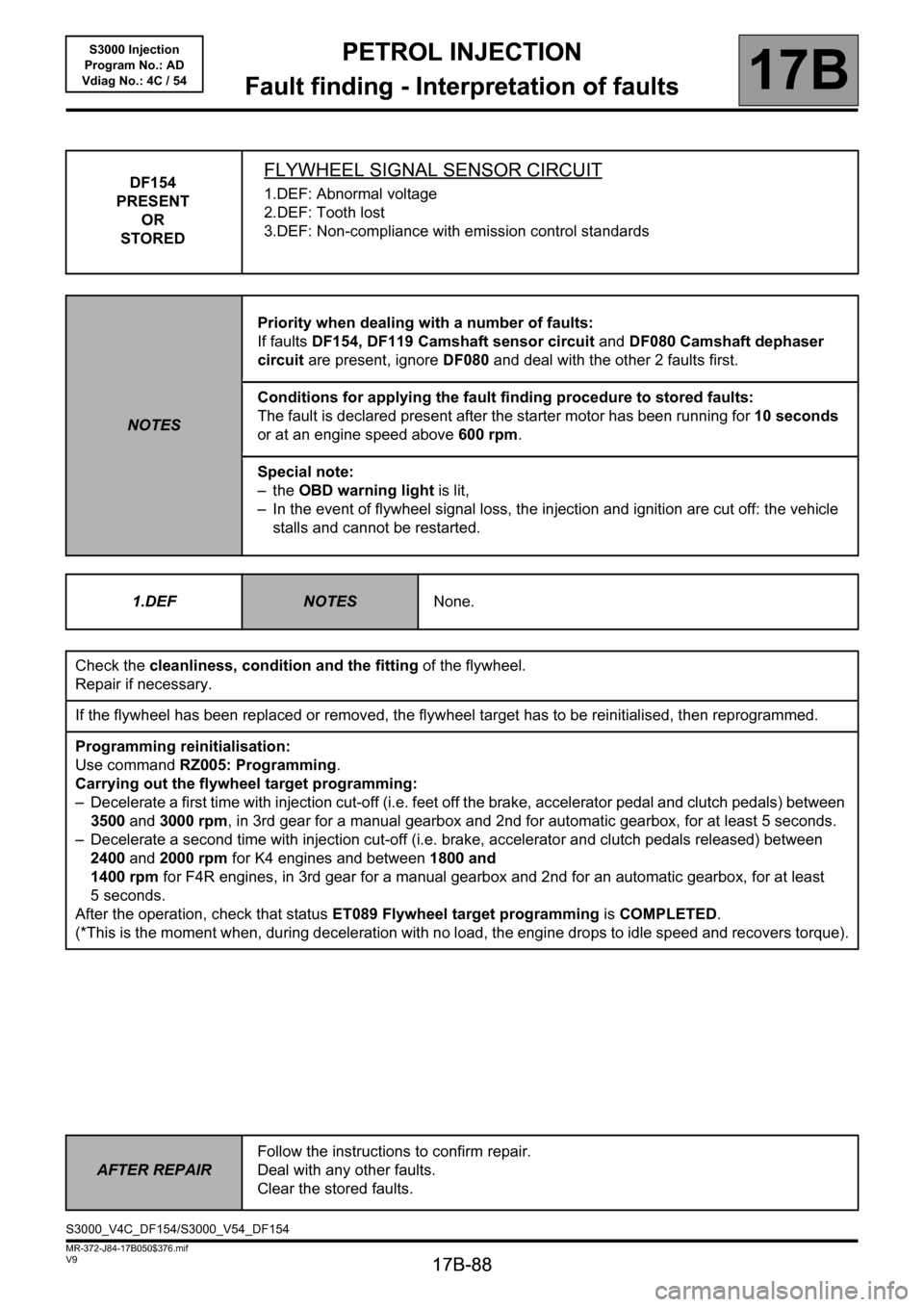

DF154

PRESENT

OR

STOREDFLYWHEEL SIGNAL SENSOR CIRCUIT

1.DEF: Abnormal voltage

2.DEF: Tooth lost

3.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

If faults DF154, DF119 Camshaft sensor circuit and DF080 Camshaft dephaser

circuit are present, ignore DF080 and deal with the other 2 faults first.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the starter motor has been running for 10 seconds

or at an engine speed above 600 rpm.

Special note:

–the OBD warning light is lit,

– In the event of flywheel signal loss, the injection and ignition are cut off: the vehicle

stalls and cannot be restarted.

1.DEF

NOTESNone.

Check the cleanliness, condition and the fitting of the flywheel.

Repair if necessary.

If the flywheel has been replaced or removed, the flywheel target has to be reinitialised, then reprogrammed.

Programming reinitialisation:

Use command RZ005: Programming.

Carrying out the flywheel target programming:

– Decelerate a first time with injection cut-off (i.e. feet off the brake, accelerator pedal and clutch pedals) between

3500 and 3000 rpm, in 3rd gear for a manual gearbox and 2nd for automatic gearbox, for at least 5 seconds.

– Decelerate a second time with injection cut-off (i.e. brake, accelerator and clutch pedals released) between

2400and 2000 rpm for K4 engines and between 1800 and

1400 rpm for F4R engines, in 3rd gear for a manual gearbox and 2nd for an automatic gearbox, for at least

5 seconds.

After the operation, check that status ET089 Flywheel target programming is COMPLETED.

(*This is the moment when, during deceleration with no load, the engine drops to idle speed and recovers torque).

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF154/S3000_V54_DF154

Page 89 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-89

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-89V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

DF154

CONTINUED

2.DEF

NOTESNone.

Check that the engine speed sensor is correctly fitted and positioned (see MR 364 or 370 Mechanics, 17B,

Petrol injection, engine speed and position sensor).

Check the cleanliness and condition of the engine speed sensor.

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Computer, connector B, track E4 track 2 or B of the engine speed sensor

Computer, connector B, track F3 track 1 or A of the engine speed sensor

Repair if necessary.

Check the resistance of the engine speed sensor between tracks 1 and 2:

Replace the engine speed sensor if the resistance is not between 235 ± 60Ω at 20°C.

If the engine speed sensor has been replaced, the flywheel target has to be reinitialised, then reprogrammed.

Programming reinitialisation:

Use command RZ005: Programming.

Carrying out the flywheel target programming:

– Decelerate a first time with injection cut-off (i.e. feet off the brake, accelerator pedal and clutch pedals) between

3500 and 3000 rpm, in 3rd gear for a manual gearbox and 2nd for automatic gearbox, for at least 5 seconds.

– Decelerate a second time with injection cut-off (i.e. brake, accelerator and clutch pedals released) between

2400and 2000 rpm for K4 engines and between 1800 and

1400 rpm for F4R engines, in 3rd gear for a manual gearbox and 2nd for an automatic gearbox, for at least

5 seconds.

After the operation, check that status ET089 Flywheel target programming is COMPLETED.

(*This is the moment when, during deceleration with no load, the engine drops to idle speed and recovers torque).

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

Page 90 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-90

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-90V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

DF196

PRESENT

OR

STOREDPEDAL SENSOR CIRCUIT GANG 1

CO.0: Open circuit or short circuit to earth

1.DEF: Inconsistency

2.DEF: Component in bad condition

NOTESPriority when dealing with a number of faults:

Deal with fault DF012 Sensor feed no. 2 voltage first, if it is present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the accelerator pedal changes from no load to full

load.

Special note:

–severity 1 fault warning light illuminated.

CO/CO.0/CC.1: defect mode type 4: speed limiter at 54 mph (90 km/h) and loss of

power during acceleration (pedal feels soft).

1.DEF: defect modes type 3 and 4: regulation of pedal's engine or vehicle speed

setpoint, speed limiter at 54mph (90 km/h) and loss of power during acceleration

(pedal feels soft).

Check that the pedal mechanism has not seized.

Check the cleanliness and condition of the pedal potentiometer connections.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Repair if necessary.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Injection computer, connectorA, track H3 track 5 of the pedal potentiometer gang 1

Injection computer, connectorA, track G2 track 3 of the pedal potentiometer gang 1

Injection computer, connectorA, track H2 track 4 of the pedal potentiometer gang 1

Repair if necessary.

Measure the resistance of the pedal sensor gang 1 between tracks 4 and 2.

Replace the accelerator potentiometer if the resistance is not 1.7 kΩ ± 0.9 kΩ.

If necessary replace the sensor.

If the fault is still present, contact the Techline.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF196/S3000_V54_DF196