engine oil RENAULT SCENIC 2010 J95 / 3.G Petrol Injection S3000 Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 230, PDF Size: 0.92 MB

Page 11 of 230

PETROL INJECTION

Fault finding - System operation

17B

17B - 11

PETROL INJECTION

Fault finding - System operation

17B

17B - 11V9 MR-372-J84-17B050$094.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

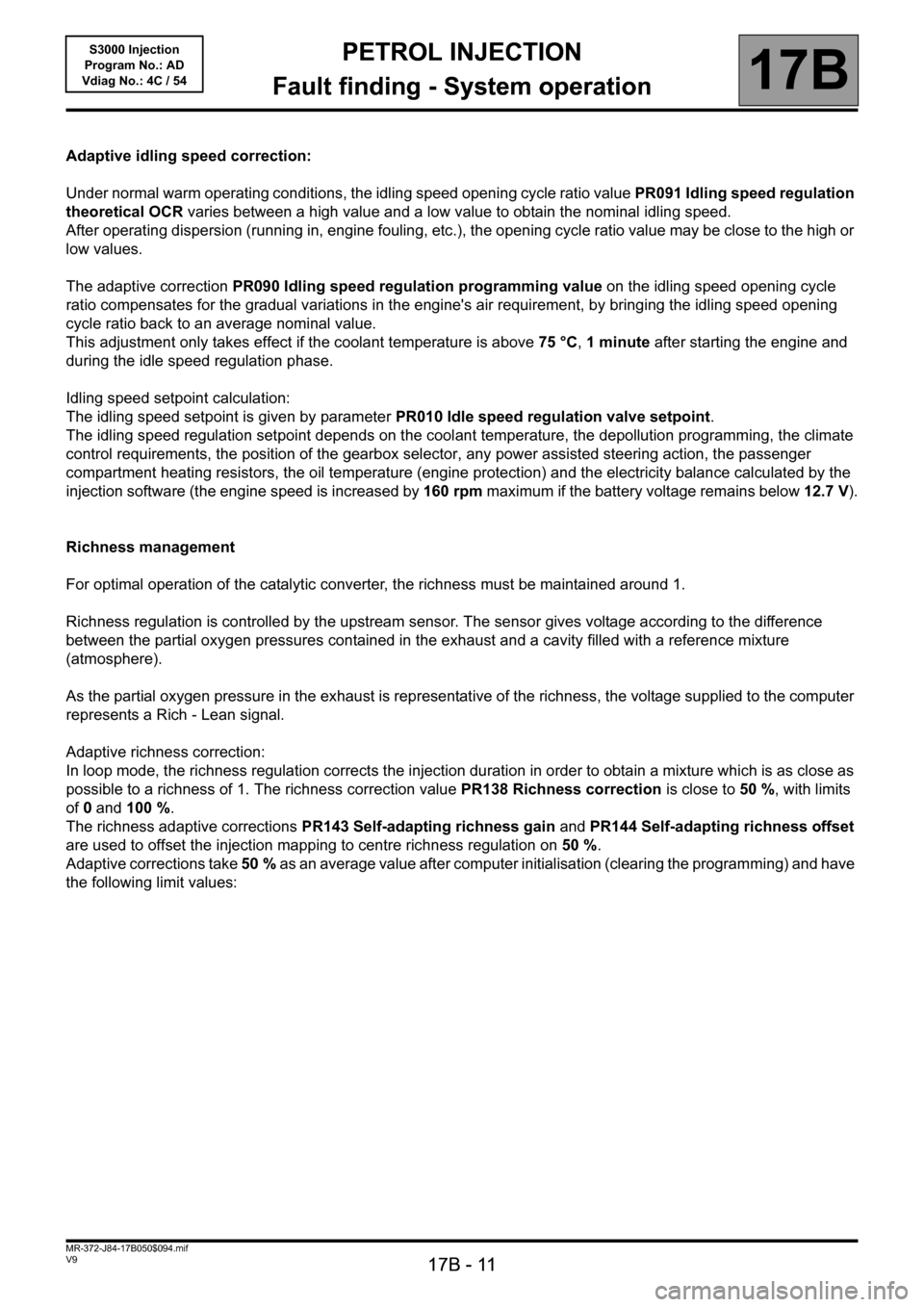

Adaptive idling speed correction:

Under normal warm operating conditions, the idling speed opening cycle ratio value PR091 Idling speed regulation

theoretical OCR varies between a high value and a low value to obtain the nominal idling speed.

After operating dispersion (running in, engine fouling, etc.), the opening cycle ratio value may be close to the high or

low values.

The adaptive correction PR090 Idling speed regulation programming value on the idling speed opening cycle

ratio compensates for the gradual variations in the engine's air requirement, by bringing the idling speed opening

cycle ratio back to an average nominal value.

This adjustment only takes effect if the coolant temperature is above 75 °C, 1 minute after starting the engine and

during the idle speed regulation phase.

Idling speed setpoint calculation:

The idling speed setpoint is given by parameter PR010 Idle speed regulation valve setpoint.

The idling speed regulation setpoint depends on the coolant temperature, the depollution programming, the climate

control requirements, the position of the gearbox selector, any power assisted steering action, the passenger

compartment heating resistors, the oil temperature (engine protection) and the electricity balance calculated by the

injection software (the engine speed is increased by 160 rpm maximum if the battery voltage remains below 12.7 V).

Richness management

For optimal operation of the catalytic converter, the richness must be maintained around 1.

Richness regulation is controlled by the upstream sensor. The sensor gives voltage according to the difference

between the partial oxygen pressures contained in the exhaust and a cavity filled with a reference mixture

(atmosphere).

As the partial oxygen pressure in the exhaust is representative of the richness, the voltage supplied to the computer

represents a Rich - Lean signal.

Adaptive richness correction:

In loop mode, the richness regulation corrects the injection duration in order to obtain a mixture which is as close as

possible to a richness of 1. The richness correction value PR138 Richness correction is close to 50 %, with limits

of 0 and 100 %.

The richness adaptive corrections PR143 Self-adapting richness gain and PR144 Self-adapting richness offset

are used to offset the injection mapping to centre richness regulation on 50 %.

Adaptive corrections take 50 % as an average value after computer initialisation (clearing the programming) and have

the following limit values:

Page 51 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-51

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-51V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

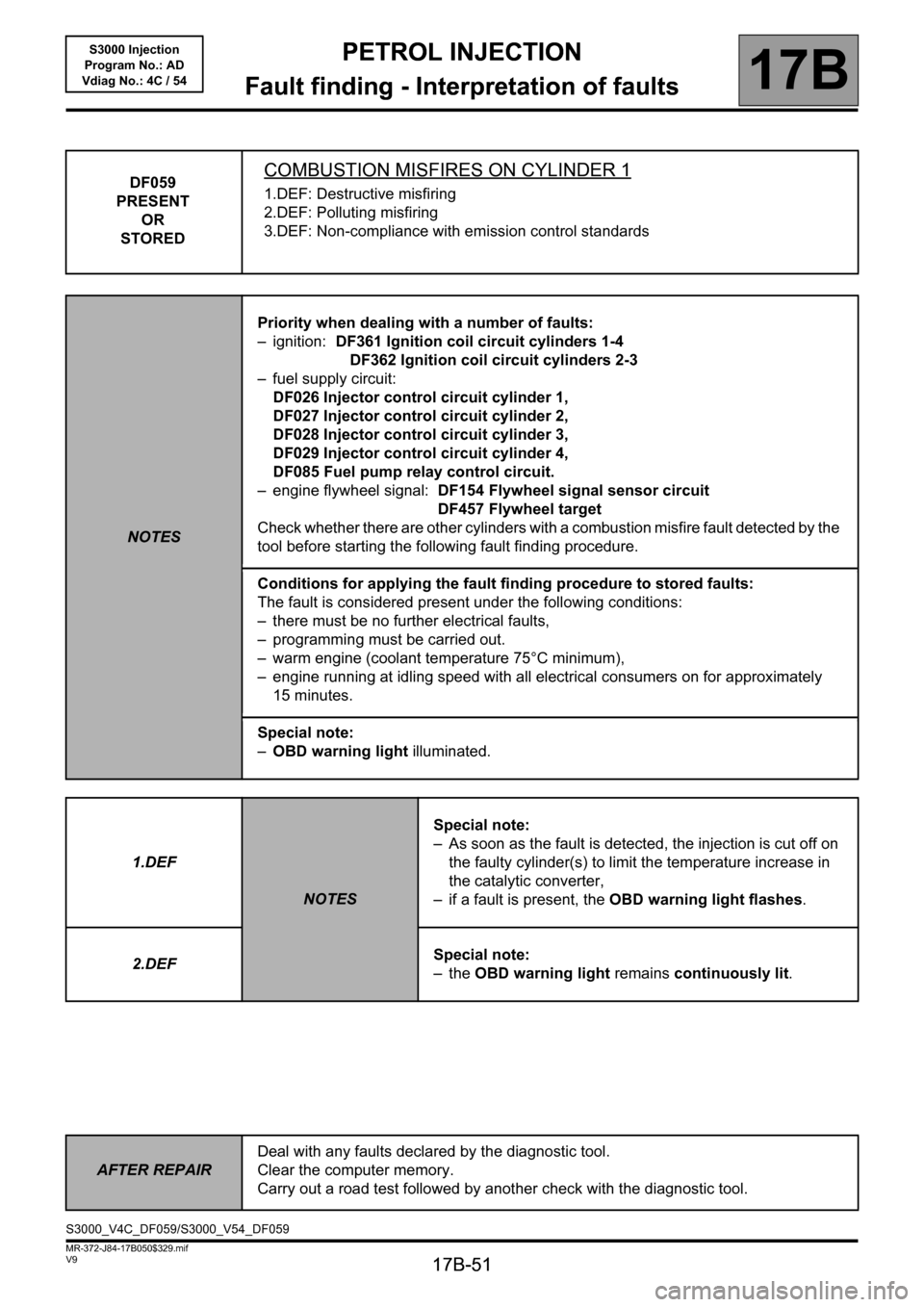

DF059

PRESENT

OR

STOREDCOMBUSTION MISFIRES ON CYLINDER 1

1.DEF: Destructive misfiring

2.DEF: Polluting misfiring

3.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

– ignition: DF361 Ignition coil circuit cylinders 1-4

DF362 Ignition coil circuit cylinders 2-3

– fuel supply circuit:

DF026 Injector control circuit cylinder 1,

DF027 Injector control circuit cylinder 2,

DF028 Injector control circuit cylinder 3,

DF029 Injector control circuit cylinder 4,

DF085 Fuel pump relay control circuit.

– engine flywheel signal: DF154 Flywheel signal sensor circuit

DF457 Flywheel target

Check whether there are other cylinders with a combustion misfire fault detected by the

tool before starting the following fault finding procedure.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present under the following conditions:

– there must be no further electrical faults,

– programming must be carried out.

– warm engine (coolant temperature 75°C minimum),

– engine running at idling speed with all electrical consumers on for approximately

15 minutes.

Special note:

–OBD warning light illuminated.

1.DEF

NOTESSpecial note:

– As soon as the fault is detected, the injection is cut off on

the faulty cylinder(s) to limit the temperature increase in

the catalytic converter,

– if a fault is present, the OBD warning light flashes.

2.DEFSpecial note:

–the OBD warning light remains continuously lit.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

S3000_V4C_DF059/S3000_V54_DF059

Page 52 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-52

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-52V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

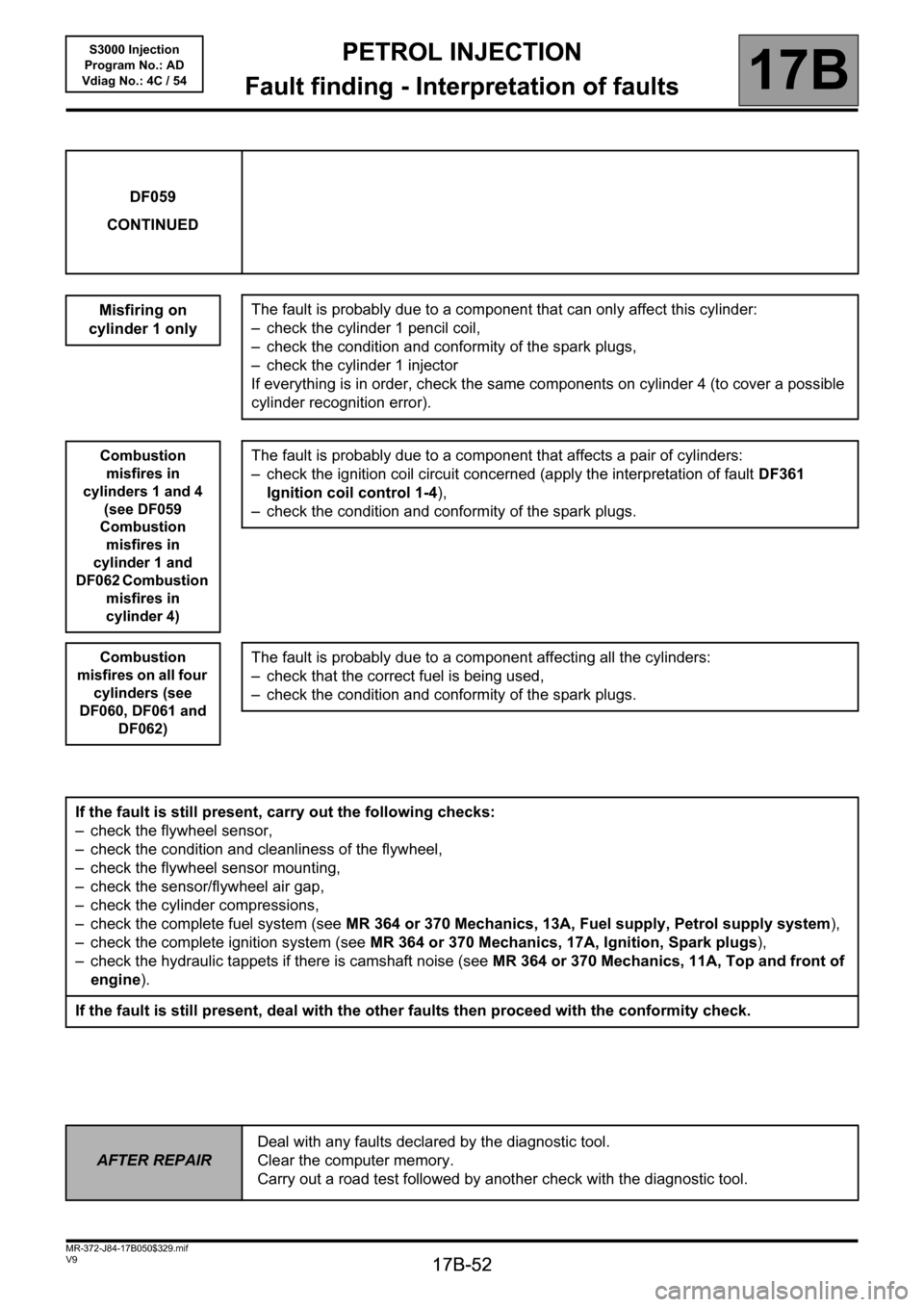

DF059

CONTINUED

Misfiring on

cylinder 1 only

Combustion

misfires in

cylinders 1 and 4

(see DF059

Combustion

misfires in

cylinder 1 and

DF062 Combustion

misfires in

cylinder 4)

Combustion

misfires on all four

cylinders (see

DF060, DF061 and

DF062)

The fault is probably due to a component that can only affect this cylinder:

– check the cylinder 1 pencil coil,

– check the condition and conformity of the spark plugs,

– check the cylinder 1 injector

If everything is in order, check the same components on cylinder 4 (to cover a possible

cylinder recognition error).

The fault is probably due to a component that affects a pair of cylinders:

– check the ignition coil circuit concerned (apply the interpretation of fault DF361

Ignition coil control 1-4),

– check the condition and conformity of the spark plugs.

The fault is probably due to a component affecting all the cylinders:

– check that the correct fuel is being used,

– check the condition and conformity of the spark plugs.

If the fault is still present, carry out the following checks:

– check the flywheel sensor,

– check the condition and cleanliness of the flywheel,

– check the flywheel sensor mounting,

– check the sensor/flywheel air gap,

– check the cylinder compressions,

– check the complete fuel system (see MR 364 or 370 Mechanics, 13A, Fuel supply, Petrol supply system),

– check the complete ignition system (see MR 364 or 370 Mechanics, 17A, Ignition, Spark plugs),

– check the hydraulic tappets if there is camshaft noise (see MR 364 or 370 Mechanics, 11A, Top and front of

engine).

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

Page 53 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-53

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-53V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

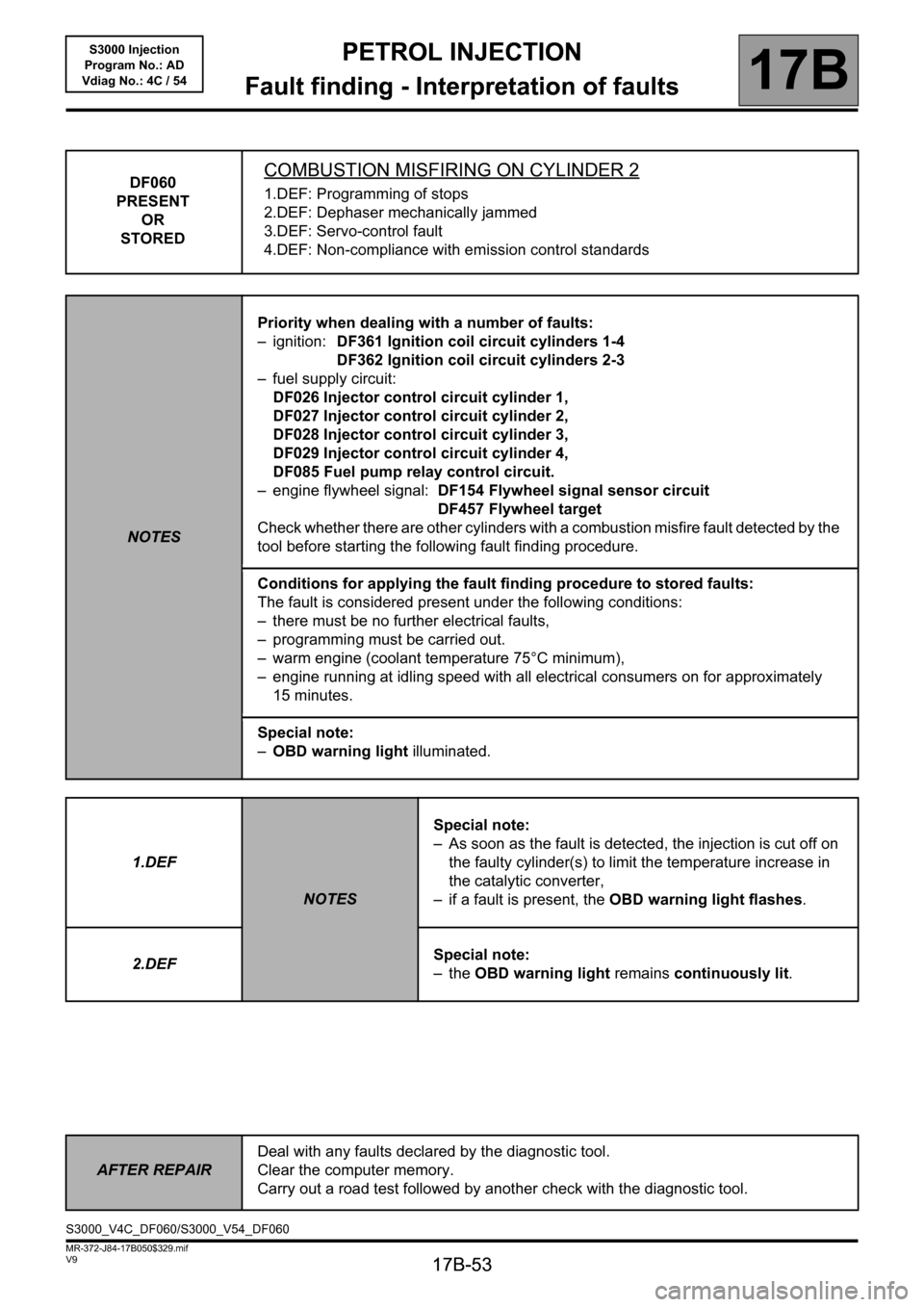

DF060

PRESENT

OR

STOREDCOMBUSTION MISFIRING ON CYLINDER 2

1.DEF: Programming of stops

2.DEF: Dephaser mechanically jammed

3.DEF: Servo-control fault

4.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

– ignition: DF361 Ignition coil circuit cylinders 1-4

DF362 Ignition coil circuit cylinders 2-3

– fuel supply circuit:

DF026 Injector control circuit cylinder 1,

DF027 Injector control circuit cylinder 2,

DF028 Injector control circuit cylinder 3,

DF029 Injector control circuit cylinder 4,

DF085 Fuel pump relay control circuit.

– engine flywheel signal: DF154 Flywheel signal sensor circuit

DF457 Flywheel target

Check whether there are other cylinders with a combustion misfire fault detected by the

tool before starting the following fault finding procedure.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present under the following conditions:

– there must be no further electrical faults,

– programming must be carried out.

– warm engine (coolant temperature 75°C minimum),

– engine running at idling speed with all electrical consumers on for approximately

15 minutes.

Special note:

–OBD warning light illuminated.

1.DEF

NOTESSpecial note:

– As soon as the fault is detected, the injection is cut off on

the faulty cylinder(s) to limit the temperature increase in

the catalytic converter,

– if a fault is present, the OBD warning light flashes.

2.DEFSpecial note:

–the OBD warning light remains continuously lit.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

S3000_V4C_DF060/S3000_V54_DF060

Page 54 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-54

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-54V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

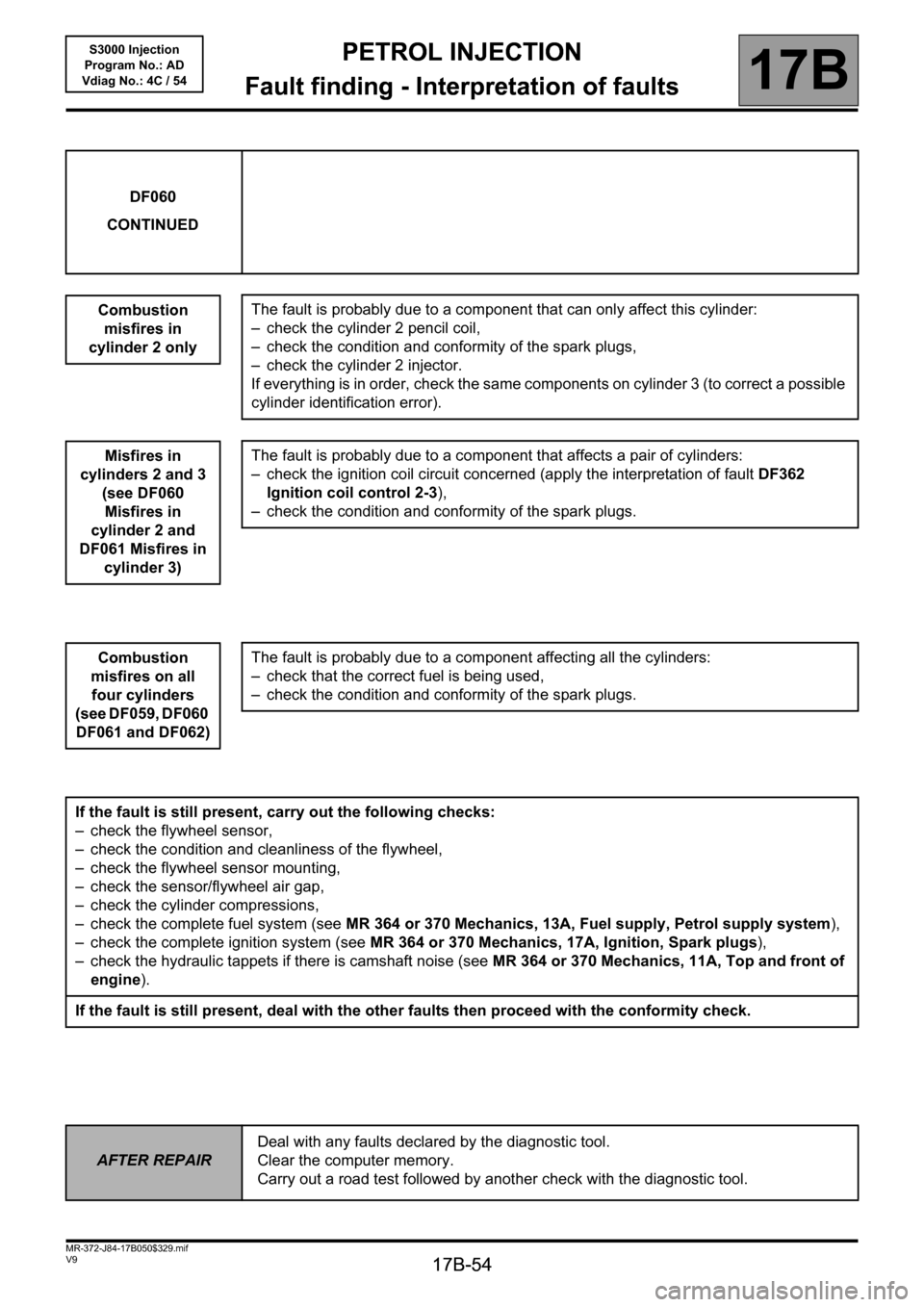

DF060

CONTINUED

Combustion

misfires in

cylinder 2 only

Misfires in

cylinders 2 and 3

(see DF060

Misfires in

cylinder 2 and

DF061 Misfires in

cylinder 3)

Combustion

misfires on all

four cylinders

(see DF059, DF060

DF061 and DF062)

The fault is probably due to a component that can only affect this cylinder:

– check the cylinder 2 pencil coil,

– check the condition and conformity of the spark plugs,

– check the cylinder 2 injector.

If everything is in order, check the same components on cylinder 3 (to correct a possible

cylinder identification error).

The fault is probably due to a component that affects a pair of cylinders:

– check the ignition coil circuit concerned (apply the interpretation of fault DF362

Ignition coil control 2-3),

– check the condition and conformity of the spark plugs.

The fault is probably due to a component affecting all the cylinders:

– check that the correct fuel is being used,

– check the condition and conformity of the spark plugs.

If the fault is still present, carry out the following checks:

– check the flywheel sensor,

– check the condition and cleanliness of the flywheel,

– check the flywheel sensor mounting,

– check the sensor/flywheel air gap,

– check the cylinder compressions,

– check the complete fuel system (see MR 364 or 370 Mechanics, 13A, Fuel supply, Petrol supply system),

– check the complete ignition system (see MR 364 or 370 Mechanics, 17A, Ignition, Spark plugs),

– check the hydraulic tappets if there is camshaft noise (see MR 364 or 370 Mechanics, 11A, Top and front of

engine).

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

Page 55 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-55

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-55V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

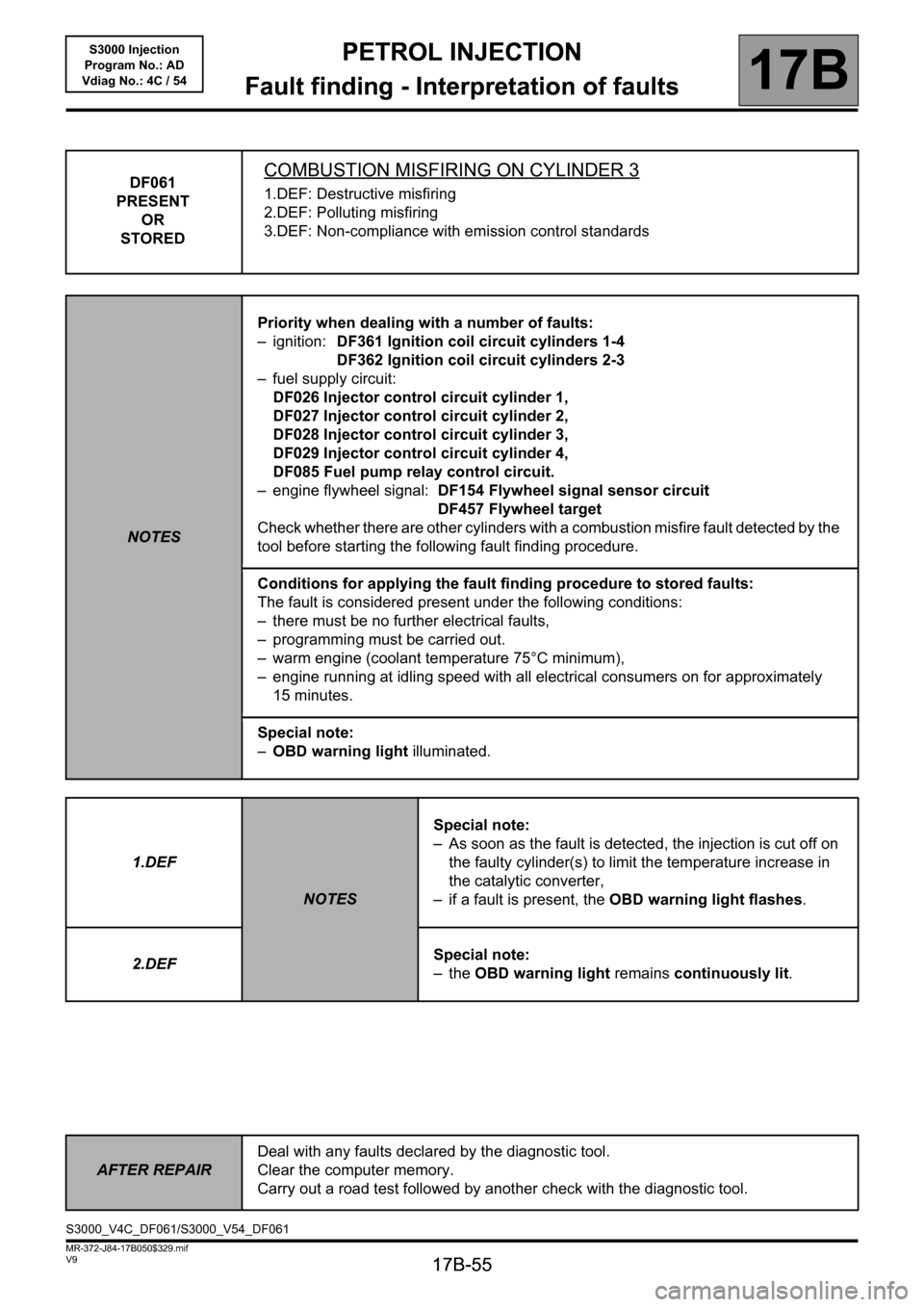

DF061

PRESENT

OR

STOREDCOMBUSTION MISFIRING ON CYLINDER 3

1.DEF: Destructive misfiring

2.DEF: Polluting misfiring

3.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

– ignition: DF361 Ignition coil circuit cylinders 1-4

DF362 Ignition coil circuit cylinders 2-3

– fuel supply circuit:

DF026 Injector control circuit cylinder 1,

DF027 Injector control circuit cylinder 2,

DF028 Injector control circuit cylinder 3,

DF029 Injector control circuit cylinder 4,

DF085 Fuel pump relay control circuit.

– engine flywheel signal: DF154 Flywheel signal sensor circuit

DF457 Flywheel target

Check whether there are other cylinders with a combustion misfire fault detected by the

tool before starting the following fault finding procedure.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present under the following conditions:

– there must be no further electrical faults,

– programming must be carried out.

– warm engine (coolant temperature 75°C minimum),

– engine running at idling speed with all electrical consumers on for approximately

15 minutes.

Special note:

–OBD warning light illuminated.

1.DEF

NOTESSpecial note:

– As soon as the fault is detected, the injection is cut off on

the faulty cylinder(s) to limit the temperature increase in

the catalytic converter,

– if a fault is present, the OBD warning light flashes.

2.DEFSpecial note:

–the OBD warning light remains continuously lit.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

S3000_V4C_DF061/S3000_V54_DF061

Page 56 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-56

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-56V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

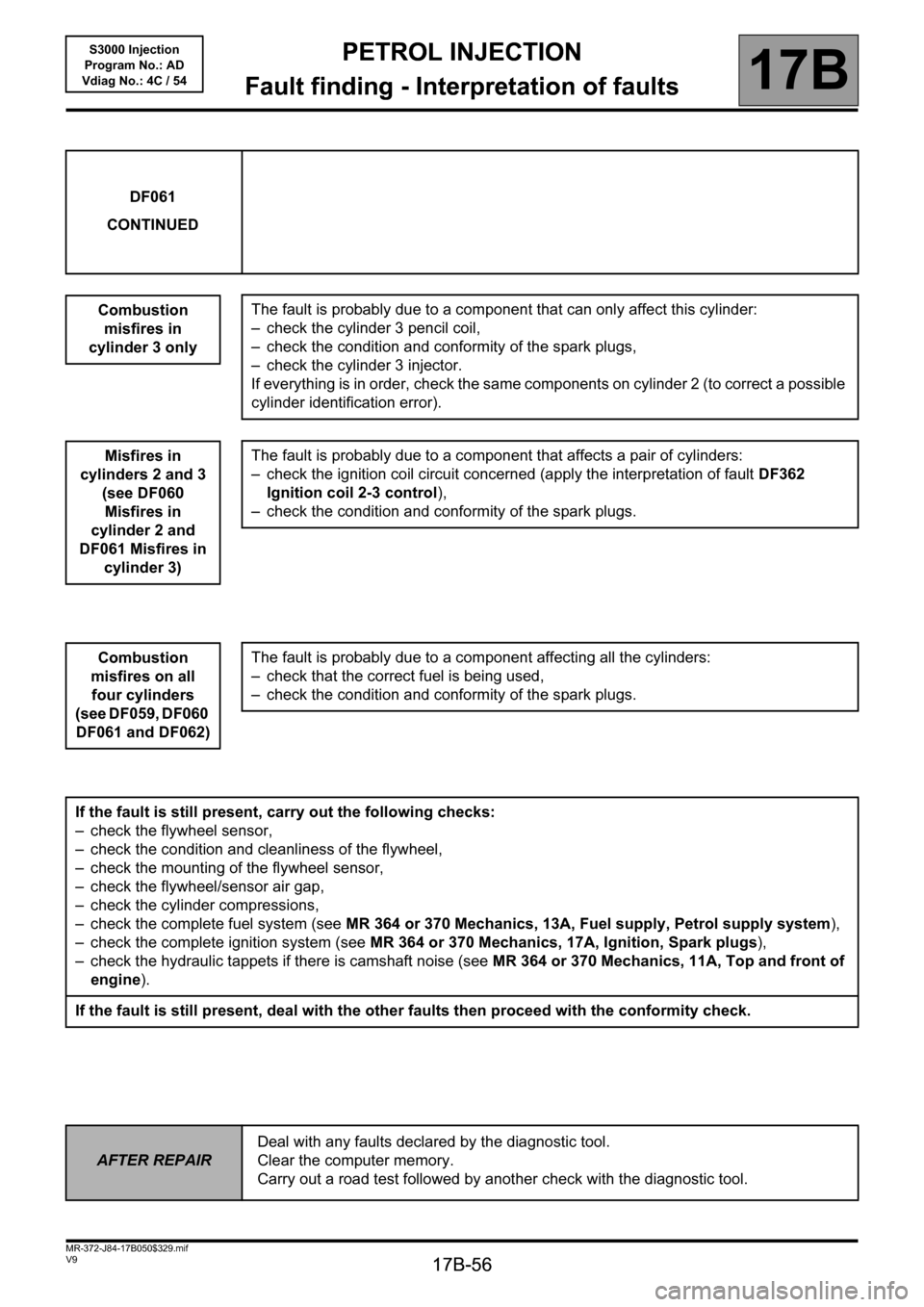

DF061

CONTINUED

Combustion

misfires in

cylinder 3 only

Misfires in

cylinders 2 and 3

(see DF060

Misfires in

cylinder 2 and

DF061 Misfires in

cylinder 3)

Combustion

misfires on all

four cylinders

(see DF059, DF060

DF061 and DF062)

The fault is probably due to a component that can only affect this cylinder:

– check the cylinder 3 pencil coil,

– check the condition and conformity of the spark plugs,

– check the cylinder 3 injector.

If everything is in order, check the same components on cylinder 2 (to correct a possible

cylinder identification error).

The fault is probably due to a component that affects a pair of cylinders:

– check the ignition coil circuit concerned (apply the interpretation of fault DF362

Ignition coil 2-3 control),

– check the condition and conformity of the spark plugs.

The fault is probably due to a component affecting all the cylinders:

– check that the correct fuel is being used,

– check the condition and conformity of the spark plugs.

If the fault is still present, carry out the following checks:

– check the flywheel sensor,

– check the condition and cleanliness of the flywheel,

– check the mounting of the flywheel sensor,

– check the flywheel/sensor air gap,

– check the cylinder compressions,

– check the complete fuel system (see MR 364 or 370 Mechanics, 13A, Fuel supply, Petrol supply system),

– check the complete ignition system (see MR 364 or 370 Mechanics, 17A, Ignition, Spark plugs),

– check the hydraulic tappets if there is camshaft noise (see MR 364 or 370 Mechanics, 11A, Top and front of

engine).

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

Page 57 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-57

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-57V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

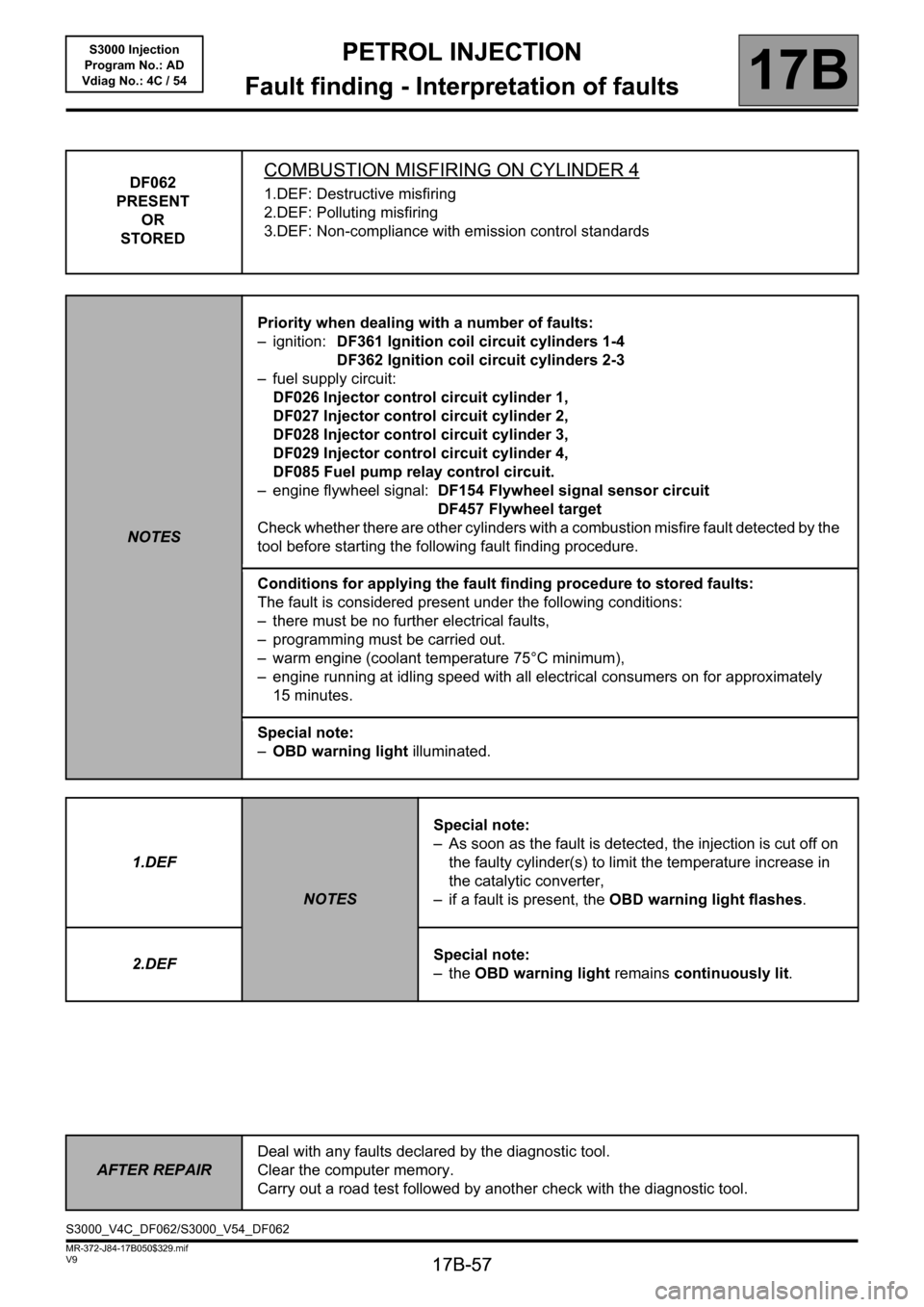

DF062

PRESENT

OR

STOREDCOMBUSTION MISFIRING ON CYLINDER 4

1.DEF: Destructive misfiring

2.DEF: Polluting misfiring

3.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

– ignition: DF361 Ignition coil circuit cylinders 1-4

DF362 Ignition coil circuit cylinders 2-3

– fuel supply circuit:

DF026 Injector control circuit cylinder 1,

DF027 Injector control circuit cylinder 2,

DF028 Injector control circuit cylinder 3,

DF029 Injector control circuit cylinder 4,

DF085 Fuel pump relay control circuit.

– engine flywheel signal: DF154 Flywheel signal sensor circuit

DF457 Flywheel target

Check whether there are other cylinders with a combustion misfire fault detected by the

tool before starting the following fault finding procedure.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present under the following conditions:

– there must be no further electrical faults,

– programming must be carried out.

– warm engine (coolant temperature 75°C minimum),

– engine running at idling speed with all electrical consumers on for approximately

15 minutes.

Special note:

–OBD warning light illuminated.

1.DEF

NOTESSpecial note:

– As soon as the fault is detected, the injection is cut off on

the faulty cylinder(s) to limit the temperature increase in

the catalytic converter,

– if a fault is present, the OBD warning light flashes.

2.DEFSpecial note:

–the OBD warning light remains continuously lit.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

S3000_V4C_DF062/S3000_V54_DF062

Page 58 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-58

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-58V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

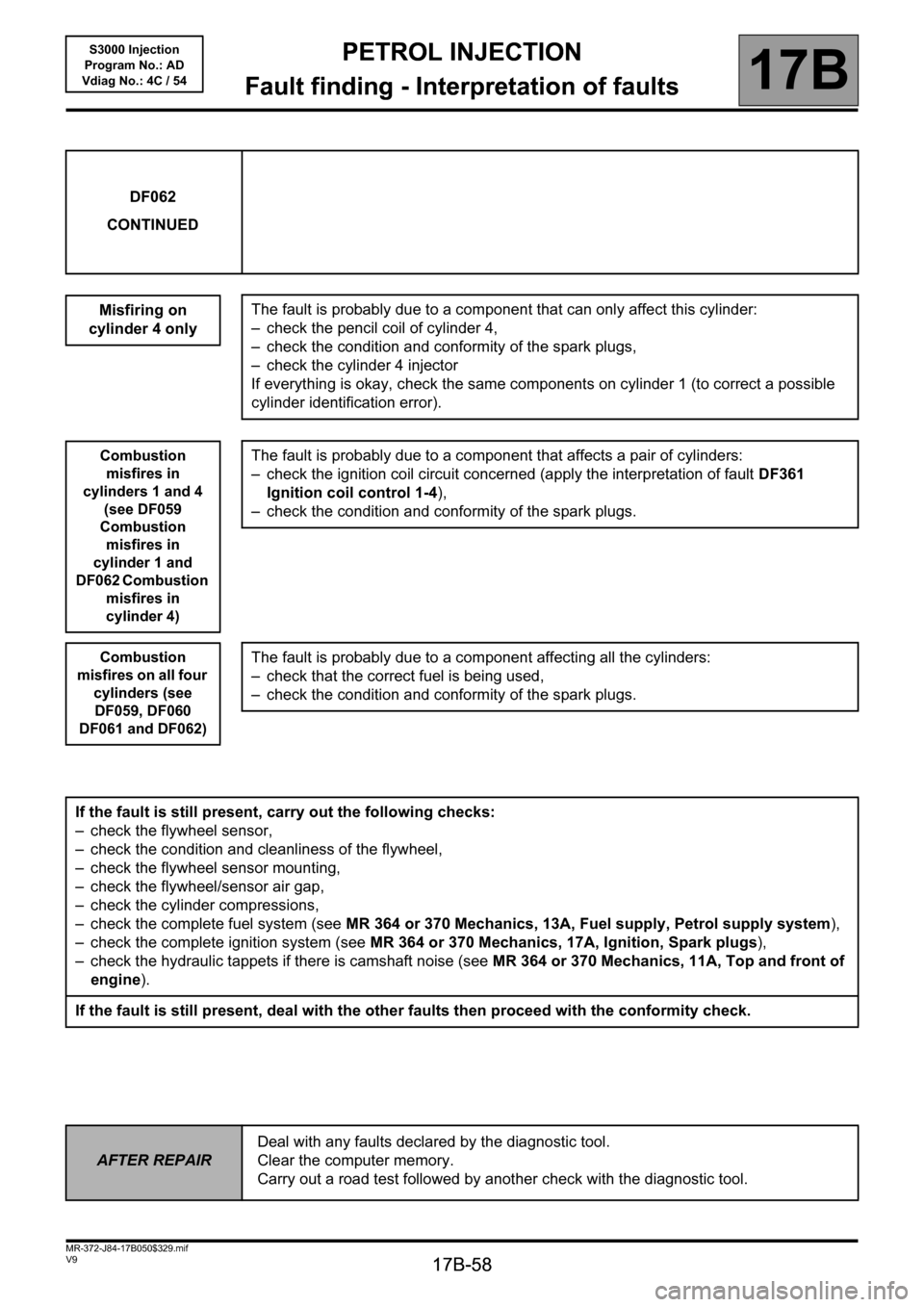

DF062

CONTINUED

Misfiring on

cylinder 4 only

Combustion

misfires in

cylinders 1 and 4

(see DF059

Combustion

misfires in

cylinder 1 and

DF062 Combustion

misfires in

cylinder 4)

Combustion

misfires on all four

cylinders (see

DF059, DF060

DF061 and DF062)

The fault is probably due to a component that can only affect this cylinder:

– check the pencil coil of cylinder 4,

– check the condition and conformity of the spark plugs,

– check the cylinder 4 injector

If everything is okay, check the same components on cylinder 1 (to correct a possible

cylinder identification error).

The fault is probably due to a component that affects a pair of cylinders:

– check the ignition coil circuit concerned (apply the interpretation of fault DF361

Ignition coil control 1-4),

– check the condition and conformity of the spark plugs.

The fault is probably due to a component affecting all the cylinders:

– check that the correct fuel is being used,

– check the condition and conformity of the spark plugs.

If the fault is still present, carry out the following checks:

– check the flywheel sensor,

– check the condition and cleanliness of the flywheel,

– check the flywheel sensor mounting,

– check the flywheel/sensor air gap,

– check the cylinder compressions,

– check the complete fuel system (see MR 364 or 370 Mechanics, 13A, Fuel supply, Petrol supply system),

– check the complete ignition system (see MR 364 or 370 Mechanics, 17A, Ignition, Spark plugs),

– check the hydraulic tappets if there is camshaft noise (see MR 364 or 370 Mechanics, 11A, Top and front of

engine).

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

Page 94 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-94

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-94V9 MR-372-J84-17B050$423.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - Interpretation of faults

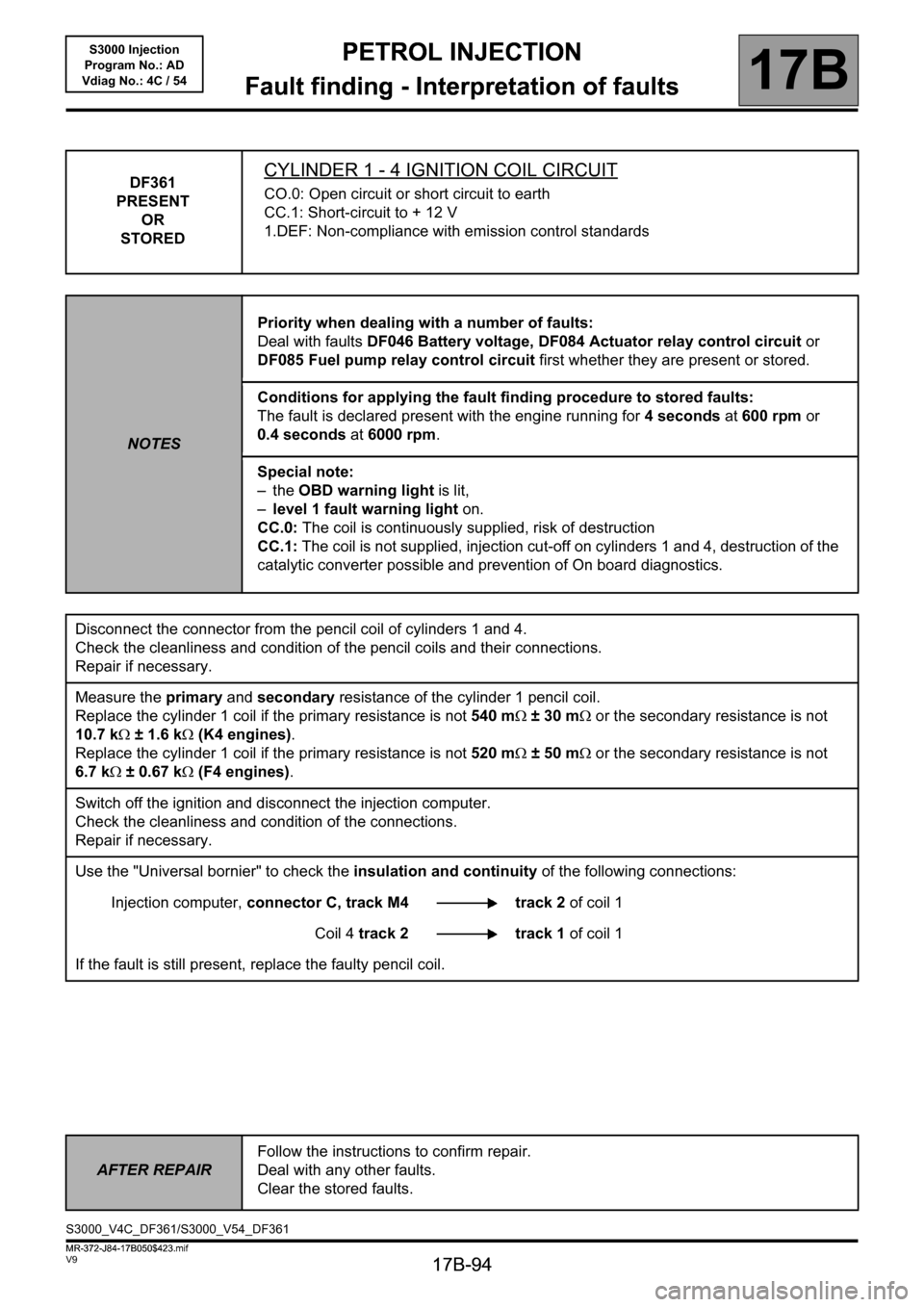

DF361

PRESENT

OR

STOREDCYLINDER 1 - 4 IGNITION COIL CIRCUIT

CO.0: Open circuit or short circuit to earth

CC.1: Short-circuit to + 12 V

1.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

Deal with faults DF046 Battery voltage, DF084 Actuator relay control circuit or

DF085 Fuel pump relay control circuit first whether they are present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present with the engine running for 4 seconds at 600 rpm or

0.4 seconds at 6000 rpm.

Special note:

–the OBD warning light is lit,

–level 1 fault warning light on.

CC.0: The coil is continuously supplied, risk of destruction

CC.1: The coil is not supplied, injection cut-off on cylinders 1 and 4, destruction of the

catalytic converter possible and prevention of On board diagnostics.

Disconnect the connector from the pencil coil of cylinders 1 and 4.

Check the cleanliness and condition of the pencil coils and their connections.

Repair if necessary.

Measure the primary and secondary resistance of the cylinder 1 pencil coil.

Replace the cylinder 1 coil if the primary resistance is not 540 mΩ ±30mΩ or the secondary resistance is not

10.7 kΩ ± 1.6 kΩ (K4 engines).

Replace the cylinder 1 coil if the primary resistance is not 520 mΩ ±50mΩ or the secondary resistance is not

6.7 kΩ ± 0.67 kΩ (F4 engines).

Switch off the ignition and disconnect the injection computer.

Check the cleanliness and condition of the connections.

Repair if necessary.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Injection computer, connector C, track M4 track 2 of coil 1

Coil 4 track 2 track 1 of coil 1

If the fault is still present, replace the faulty pencil coil.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF361/S3000_V54_DF361

MR-372-J84-17B050$423.mif