fuel RENAULT SCENIC 2010 J95 / 3.G Petrol Injection S3000 Injection Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 230, PDF Size: 0.92 MB

Page 177 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 177

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 177V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

ET056

CONTINUED 2

Check:

– the condition of the air filter,

– that the air inlet circuit is not blocked,

– the condition and conformity of the spark plugs,

– the sealing between the throttle valve and inlet manifold,

– the manifold pressure sensor sealing,

– the fuel vapour absorber bleed, which must not be jammed open,

– the fuel vapour absorber bleed system sealing,

– the brake servo system sealing,

– the cylinder head oil vapour recovery system sealing,

– the sealing between the inlet manifold and cylinder head,

– the exhaust pipe sealing between the cylinder head and catalytic converter.

– the fuel flow rate and pressure.

If the idle speed is not stable, check:

– the timing adjustment,

– the hydraulic tappets if there is camshaft noise (see MR 364 or 370 Mechanics, 11A, Top and front of engine),

– the cylinder compressions.

Drive the vehicle to check the repair.

Repair the defective components.

AFTER REPAIRRepeat the conformity check from the start.

Page 183 of 230

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 183

PETROL INJECTION

Fault finding - Interpretation of statuses

17B

17B - 183V9 MR-372-J84-17B050$611.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

ET072

TRANSITION FROM LPG MODE TO PETROL MODE

IN PROGRESS

COMPLETE

NOTESThere must be no present or stored faults.

Ignition on, engine stopped.

Check that the fuel pump starts when petrol mode is entered.

Check status ET025 Fuel pump changes to ACTIVE.

If the fuel pump does not start, check:

– the fuel pump cut-off relay (see DF024 Fuel pump cut-off relay circuit),

– the petrol computer (see17B, Petrol injection).

This fault is detected by the LPG injection computer.

Repair or replace the faulty components, if necessary.

If the status is still not correct, contact the Techline.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_ET072/S3000_V54_ET072

Page 202 of 230

PETROL INJECTION

17B

17B - 202

17B

17B - 202V9 MR-372-J84-17B050$658.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

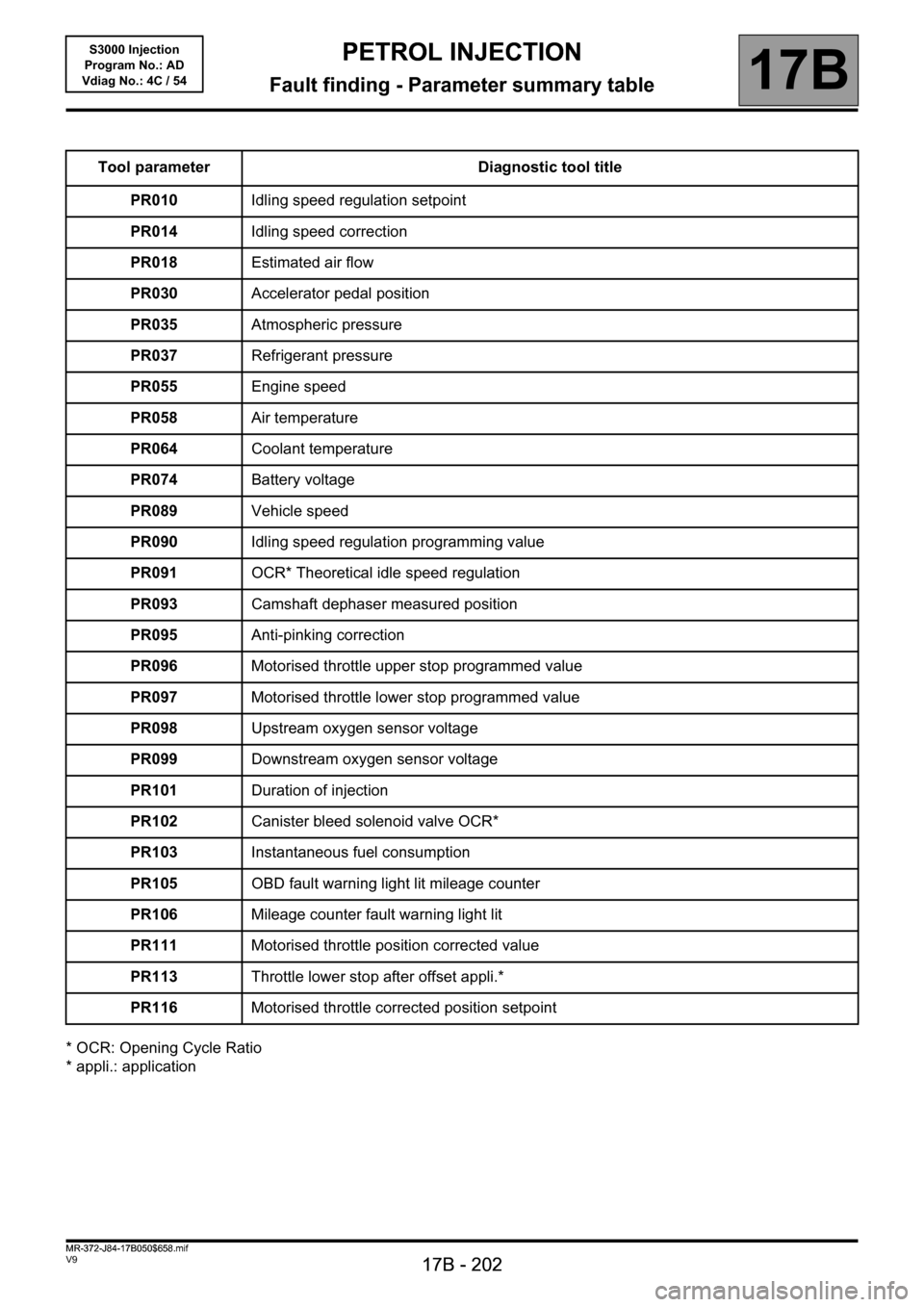

Fault finding - Parameter summary table

* OCR: Opening Cycle Ratio

* appli.: applicationTool parameter Diagnostic tool title

PR010Idling speed regulation setpoint

PR014Idling speed correction

PR018Estimated air flow

PR030Accelerator pedal position

PR035Atmospheric pressure

PR037Refrigerant pressure

PR055Engine speed

PR058Air temperature

PR064Coolant temperature

PR074Battery voltage

PR089Vehicle speed

PR090Idling speed regulation programming value

PR091OCR* Theoretical idle speed regulation

PR093Camshaft dephaser measured position

PR095Anti-pinking correction

PR096Motorised throttle upper stop programmed value

PR097Motorised throttle lower stop programmed value

PR098Upstream oxygen sensor voltage

PR099Downstream oxygen sensor voltage

PR101Duration of injection

PR102Canister bleed solenoid valve OCR*

PR103Instantaneous fuel consumption

PR105OBD fault warning light lit mileage counter

PR106Mileage counter fault warning light lit

PR111Motorised throttle position corrected value

PR113Throttle lower stop after offset appli.*

PR116Motorised throttle corrected position setpoint

MR-372-J84-17B050$658.mif

Page 207 of 230

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 207

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 207V9 MR-372-J84-17B050$705.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

PR095

ANTI-PINKING CORRECTION

NOTESThere must be no present or stored faults.

The pinking sensor must not supply a zero signal, proving that it is recording the mechanical vibrations

of the engine.

Check that there is the correct fuel in the fuel tank.

Repair if necessary.

Check the condition and conformity of the spark plugs.

Repair if necessary.

Check the pinking sensor tightness.

Repair if necessary.

Check the cleanliness and condition of the pinking sensor connectors.

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the Universal bornier, check the insulation and continuity of the following connections:

Injection computer, connectorB, track B3 track 2 of the pinking sensor

Injection computer, connectorB, track B4 track 1 of the pinking sensor

Injection computer, connectorB, track B2 Pinking sensor screening

Repair if necessary.

If the fault is still present, replace the pinking sensor.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_PR095/S3000_V54_PR095

Page 209 of 230

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 209

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 209V9 MR-372-J84-17B050$705.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

PR098

CONTINUED

If the fault is still present, replace the upstream oxygen sensor.

If the fault has still not been cured, continue with the checks.

Check:

– the condition of the air filter,

– that the air inlet circuit is not blocked,

– the condition and conformity of the spark plugs,

– that the catalytic converter is not clogged,

– the sealing between the throttle valve and inlet manifold,

– the manifold pressure sensor sealing,

– the fuel vapour absorber bleed, which must not be jammed open,'

– the fuel vapour absorber bleed system sealing,

– the brake servo system sealing,

– the cylinder head oil vapour recovery system sealing,

– the sealing between the inlet manifold and cylinder head,

– the exhaust pipe sealing between the cylinder head and catalytic converter.

– the fuel flow rate and pressure.

If the idle speed is not stable, check:

– the timing adjustment,

– the hydraulic tappets if there is camshaft noise (see MR 364 or 370 Mechanics, 11A, Top and front of engine),

– the cylinder compressions.

Drive the vehicle to check the repair.

AFTER REPAIRRepeat the conformity check from the start.

Page 211 of 230

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 211

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 211V9 MR-372-J84-17B050$705.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

PR099

CONTINUED

Replace the downstream oxygen sensor.

If the fault is still present, the catalytic converter is certainly damaged.

If the catalytic converter is defective, determine the cause of the destruction, otherwise the new catalytic

converter may be damaged in turn.

Remove the catalytic converter.

Various things may destroy a catalytic converter:

–deformation (impact),

–thermal shock (cold water splashed onto a hot catalytic converter can damage it),

–defective injector or ignition: the catalytic converter is damaged by contact with fuel (coil fault, coil control fault,

injector jammed open),

–injector leak,

–abnormal oil or coolant consumption (defective cylinder head gasket),

–use of a fuel additive or other equivalent product (obtain information from the customer because this type of

product can contaminate the catalytic converter and render it useless sooner or later).

Look up the service history of the vehicle or, if this is not possible, ask the customer if the vehicle has had injection

or ignition faults.

If the cause of the catalytic converter damage has been found and the fault has disappeared, replace the

catalytic converter.

AFTER REPAIRRepeat the conformity check from the start.

Page 212 of 230

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 212

PETROL INJECTION

Fault finding - Interpretation of parameters

17B

17B - 212V9 MR-372-J84-17B050$705.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

PR312

MANIFOLD PRESSURE

NOTESThere must be no present or stored faults.

Check the cleanliness and condition of the manifold pressure sensor and its connections.

Repair if necessary.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the Universal bornier, check the insulation and continuity of the following connections:

Injection computer, connectorB, track H2 track C of the manifold pressure sensor

Injection computer, connectorB, track H3 track B of the manifold pressure sensor

Injection computer, connectorB, track H4 track A of the manifold pressure sensor

Repair if necessary.

If the fault is still present, replace the manifold pressure sensor.

If the fault is still present, carry out the following checks:

The inlet line must be perfectly sealed, from the throttle valve to the cylinder head.

Check:

– the condition of the air filter,

– that the air inlet circuit is not blocked,

– the sealing between the throttle valve and inlet manifold,

– the manifold pressure sensor sealing,

– the fuel vapour absorber bleed, which must not be jammed open,

– the fuel vapour absorber bleed system sealing,

– the brake servo system sealing,

– the cylinder head oil vapour recovery system sealing,

– the sealing between the inlet manifold and cylinder head,

– the exhaust pipe sealing between the cylinder head and catalytic converter.

Repair if necessary.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_PR312/S3000_V54_PR312

Page 214 of 230

PETROL INJECTION

Fault finding - Interpretation of commands

17B

17B - 214

PETROL INJECTION

Fault finding - Interpretation of commands

17B

17B - 214V9 MR-372-J84-17B050$799.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - Interpretation of commands

AC017

CANISTER BLEED SOLENOID VALVE

NOTESThere must be no present or stored faults.

Check the cleanliness and condition of the fuel vapour absorber bleed solenoid valve connections.

Repair if necessary.

Measure the resistance of the petrol vapour absorber bleed solenoid valve.

Replace the bleed solenoid valve for the fuel vapour absorber if the resistance is not 26Ω ±4Ω at 23 °C.

Check for + 12 V feed on track 1 of the fuel vapour absorber bleed solenoid valve with the ignition on.

If +12V is not present:

– using the Universal bornier, check for continuity on the following connections:

Fuel computer, connectorB, track M2 track 1 of the petrol vapour absorber bleed

solenoid valve

Main relaytrack 1 of the petrol vapour absorber bleed

solenoid valve

Repair if necessary.

Disconnect the battery.

Disconnect the computer. Check the cleanliness and condition of the connections.

Using the Universal bornier, check the insulation and continuity of the following connection:

Petrol computer, connector C, track E1 track 2 of the fuel vapour absorber bleed

solenoid valve

Repair if necessary.

If the fault is still present, replace the solenoid valve.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_AC017/S3000_V54_AC017

MR-372-J84-17B050$799.mif

Page 216 of 230

PETROL INJECTION

Fault finding - Interpretation of commands

17B

17B - 216

PETROL INJECTION

Fault finding - Interpretation of commands

17B

17B - 216V9 MR-372-J84-17B050$799.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

AC079

ACTUATOR STATIC TEST

NOTESThere must be no present or stored faults.

Switch the ignition on and run command AC079 Actuator static test.

If the following actuators are not working, apply the interpretation of the associated fault:

– Fuel pump relay, apply the interpretation of DF085 Fuel pump relay circuit.

– The motorised throttle, apply the interpretation of DF079 Motorised throttle valve servo control.

– The electric coolant pump, apply the interpretation of DF570 Coolant pump relay.

–Upstream O

2 sensor heating, apply the interpretation of DF601 Upstream O2 sensor heating power circuit.

– Downstream O

2 sensor heating, apply the interpretation of DF602 Downstream O2 sensor heating power

circuit.

AFTER REPAIRRepeat the conformity check from the start.

S3000_V4C_AC079/S3000_V54_AC079

Page 226 of 230

PETROL INJECTION

Fault finding - Fault Finding Chart

17B

17B-226

PETROL INJECTION

Fault finding - Fault Finding Chart

17B

17B-226V9 MR-372-J84-17B050$940.mif

S3000 Injection

Program No.: AD

Vdiag No.:4C / 54

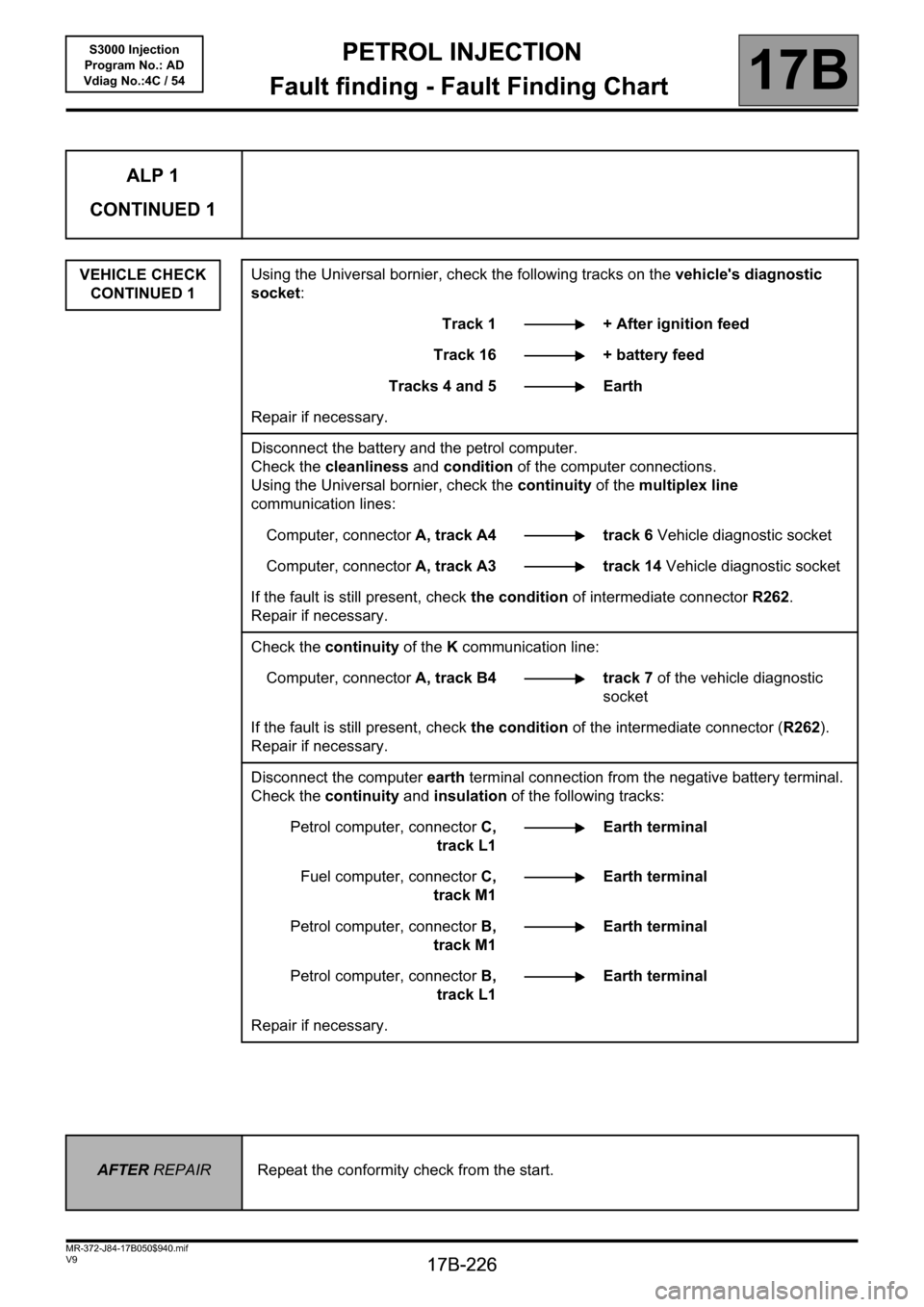

ALP 1

CONTINUED 1

VEHICLE CHECK

CONTINUED 1Using the Universal bornier, check the following tracks on the vehicle's diagnostic

socket:

Track 1 + After ignition feed

Track 16 + battery feed

Tracks 4 and 5 Earth

Repair if necessary.

Disconnect the battery and the petrol computer.

Check the cleanliness and condition of the computer connections.

Using the Universal bornier, check the continuity of the multiplex line

communication lines:

Computer, connector A, track A4 track 6 Vehicle diagnostic socket

Computer, connector A, track A3 track 14 Vehicle diagnostic socket

If the fault is still present, check the condition of intermediate connector R262.

Repair if necessary.

Check the continuity of the K communication line:

Computer, connector A, track B4 track 7 of the vehicle diagnostic

socket

If the fault is still present, check the condition of the intermediate connector (R262).

Repair if necessary.

Disconnect the computer earth terminal connection from the negative battery terminal.

Check the continuity and insulation of the following tracks:

Petrol computer, connectorC,

track L1Earth terminal

Fuel computer, connectorC,

track M1Earth terminal

Petrol computer, connectorB,

track M1Earth terminal

Petrol computer, connectorB,

track L1Earth terminal

Repair if necessary.

AFTER REPAIRRepeat the conformity check from the start.