fuel RENAULT SCENIC 2010 J95 / 3.G Petrol Injection S3000 Injection User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 230, PDF Size: 0.92 MB

Page 55 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-55

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-55V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

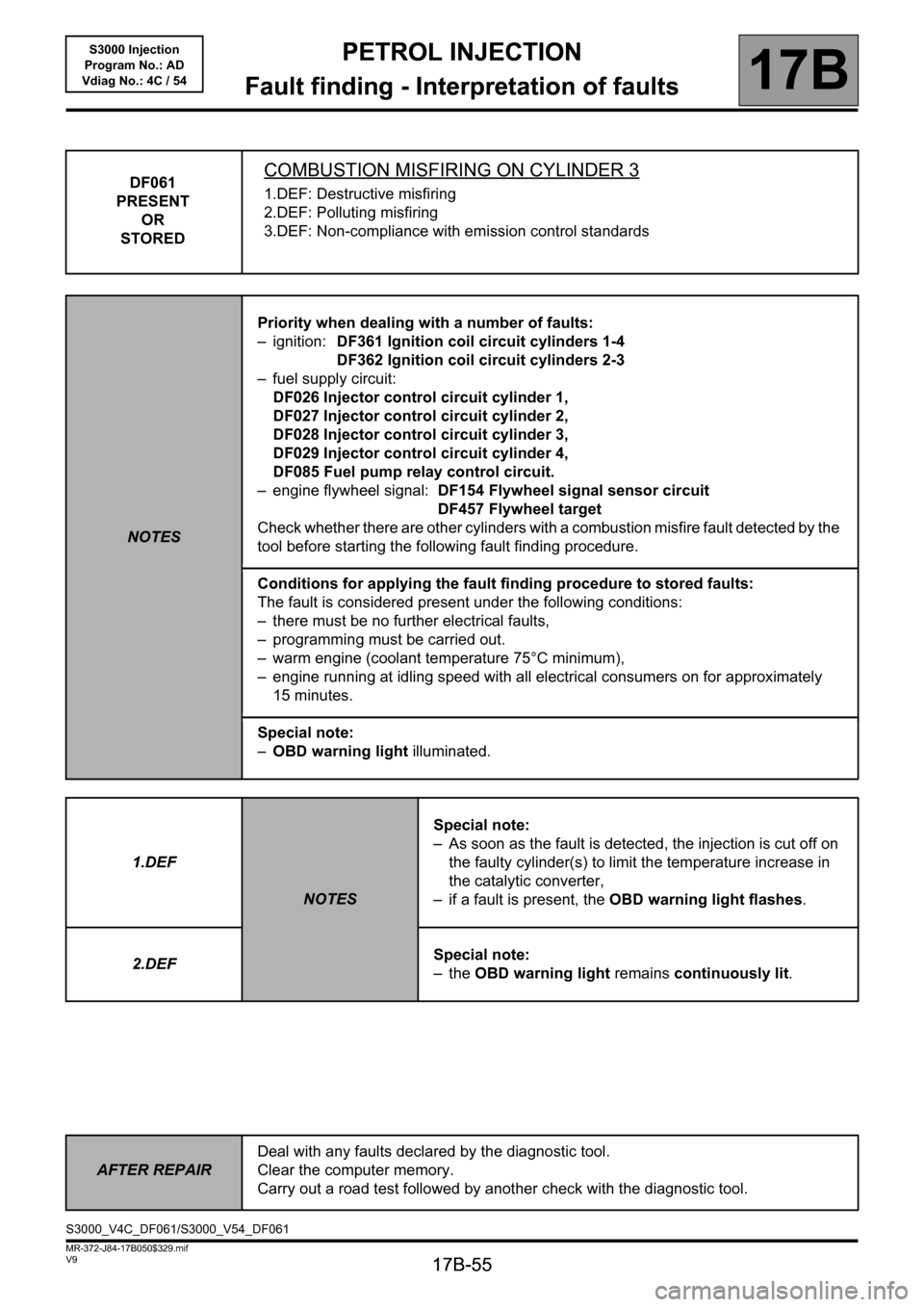

DF061

PRESENT

OR

STOREDCOMBUSTION MISFIRING ON CYLINDER 3

1.DEF: Destructive misfiring

2.DEF: Polluting misfiring

3.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

– ignition: DF361 Ignition coil circuit cylinders 1-4

DF362 Ignition coil circuit cylinders 2-3

– fuel supply circuit:

DF026 Injector control circuit cylinder 1,

DF027 Injector control circuit cylinder 2,

DF028 Injector control circuit cylinder 3,

DF029 Injector control circuit cylinder 4,

DF085 Fuel pump relay control circuit.

– engine flywheel signal: DF154 Flywheel signal sensor circuit

DF457 Flywheel target

Check whether there are other cylinders with a combustion misfire fault detected by the

tool before starting the following fault finding procedure.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present under the following conditions:

– there must be no further electrical faults,

– programming must be carried out.

– warm engine (coolant temperature 75°C minimum),

– engine running at idling speed with all electrical consumers on for approximately

15 minutes.

Special note:

–OBD warning light illuminated.

1.DEF

NOTESSpecial note:

– As soon as the fault is detected, the injection is cut off on

the faulty cylinder(s) to limit the temperature increase in

the catalytic converter,

– if a fault is present, the OBD warning light flashes.

2.DEFSpecial note:

–the OBD warning light remains continuously lit.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

S3000_V4C_DF061/S3000_V54_DF061

Page 56 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-56

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-56V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

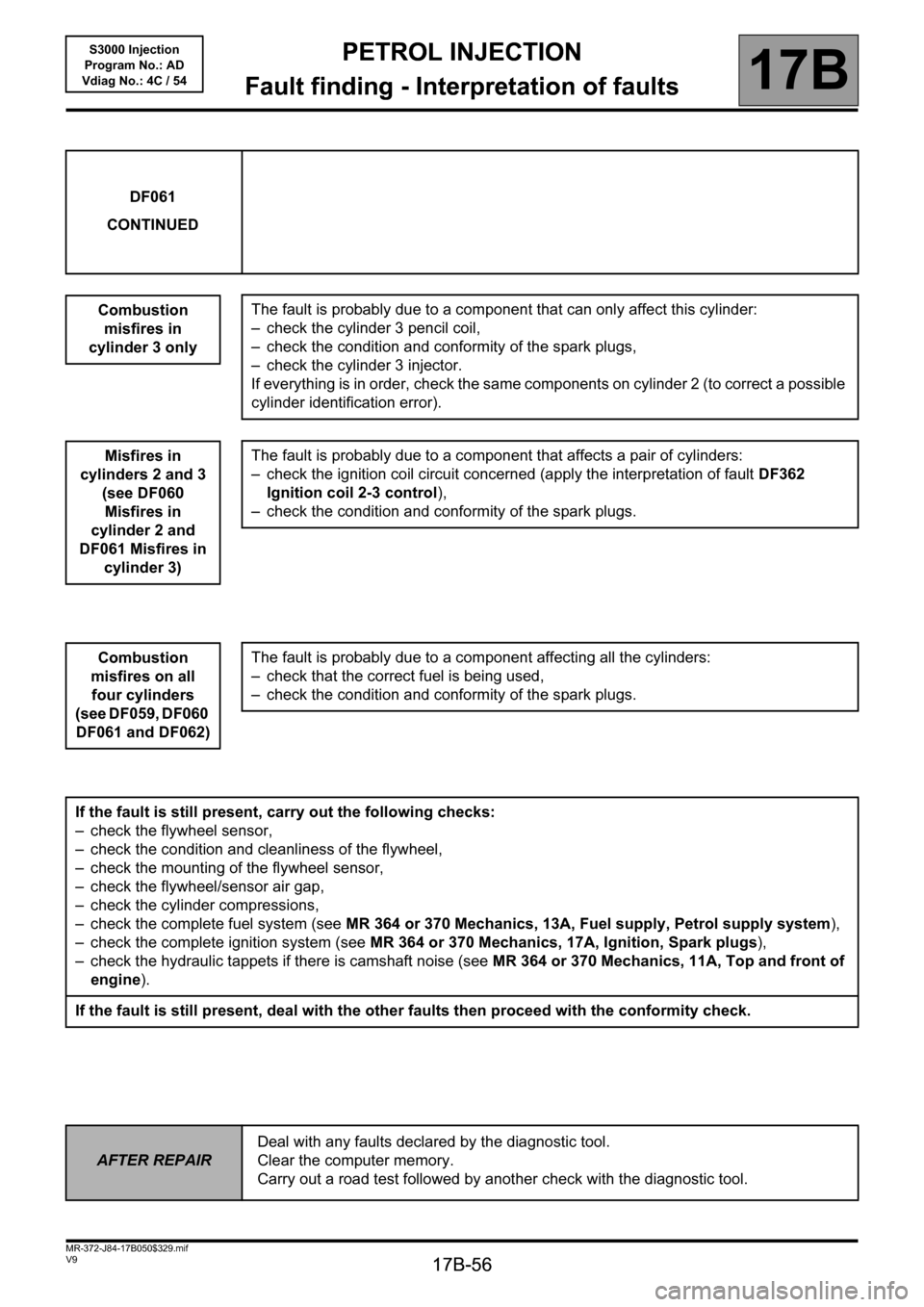

DF061

CONTINUED

Combustion

misfires in

cylinder 3 only

Misfires in

cylinders 2 and 3

(see DF060

Misfires in

cylinder 2 and

DF061 Misfires in

cylinder 3)

Combustion

misfires on all

four cylinders

(see DF059, DF060

DF061 and DF062)

The fault is probably due to a component that can only affect this cylinder:

– check the cylinder 3 pencil coil,

– check the condition and conformity of the spark plugs,

– check the cylinder 3 injector.

If everything is in order, check the same components on cylinder 2 (to correct a possible

cylinder identification error).

The fault is probably due to a component that affects a pair of cylinders:

– check the ignition coil circuit concerned (apply the interpretation of fault DF362

Ignition coil 2-3 control),

– check the condition and conformity of the spark plugs.

The fault is probably due to a component affecting all the cylinders:

– check that the correct fuel is being used,

– check the condition and conformity of the spark plugs.

If the fault is still present, carry out the following checks:

– check the flywheel sensor,

– check the condition and cleanliness of the flywheel,

– check the mounting of the flywheel sensor,

– check the flywheel/sensor air gap,

– check the cylinder compressions,

– check the complete fuel system (see MR 364 or 370 Mechanics, 13A, Fuel supply, Petrol supply system),

– check the complete ignition system (see MR 364 or 370 Mechanics, 17A, Ignition, Spark plugs),

– check the hydraulic tappets if there is camshaft noise (see MR 364 or 370 Mechanics, 11A, Top and front of

engine).

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

Page 57 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-57

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-57V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

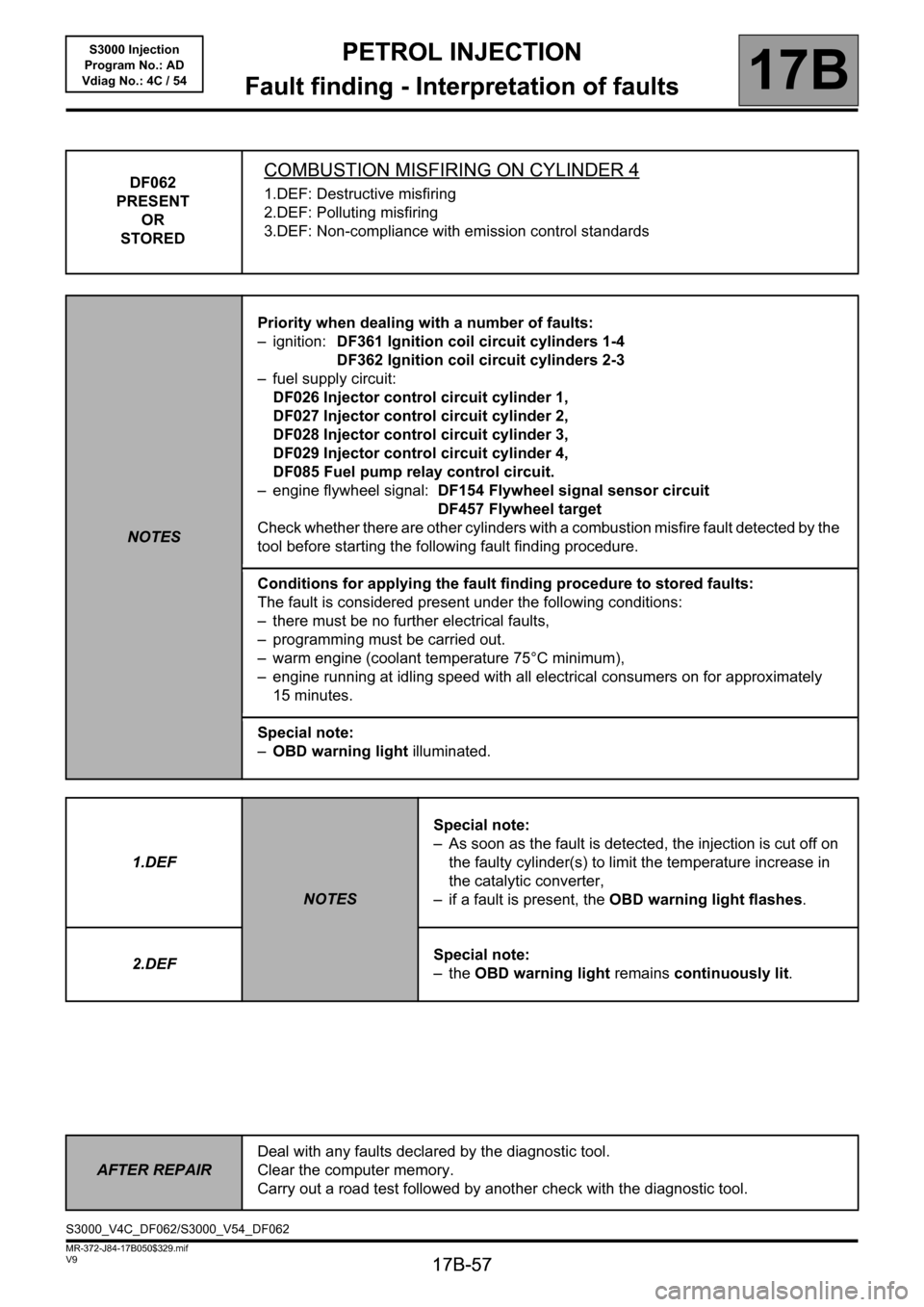

DF062

PRESENT

OR

STOREDCOMBUSTION MISFIRING ON CYLINDER 4

1.DEF: Destructive misfiring

2.DEF: Polluting misfiring

3.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

– ignition: DF361 Ignition coil circuit cylinders 1-4

DF362 Ignition coil circuit cylinders 2-3

– fuel supply circuit:

DF026 Injector control circuit cylinder 1,

DF027 Injector control circuit cylinder 2,

DF028 Injector control circuit cylinder 3,

DF029 Injector control circuit cylinder 4,

DF085 Fuel pump relay control circuit.

– engine flywheel signal: DF154 Flywheel signal sensor circuit

DF457 Flywheel target

Check whether there are other cylinders with a combustion misfire fault detected by the

tool before starting the following fault finding procedure.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present under the following conditions:

– there must be no further electrical faults,

– programming must be carried out.

– warm engine (coolant temperature 75°C minimum),

– engine running at idling speed with all electrical consumers on for approximately

15 minutes.

Special note:

–OBD warning light illuminated.

1.DEF

NOTESSpecial note:

– As soon as the fault is detected, the injection is cut off on

the faulty cylinder(s) to limit the temperature increase in

the catalytic converter,

– if a fault is present, the OBD warning light flashes.

2.DEFSpecial note:

–the OBD warning light remains continuously lit.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

S3000_V4C_DF062/S3000_V54_DF062

Page 58 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-58

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-58V9 MR-372-J84-17B050$329.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

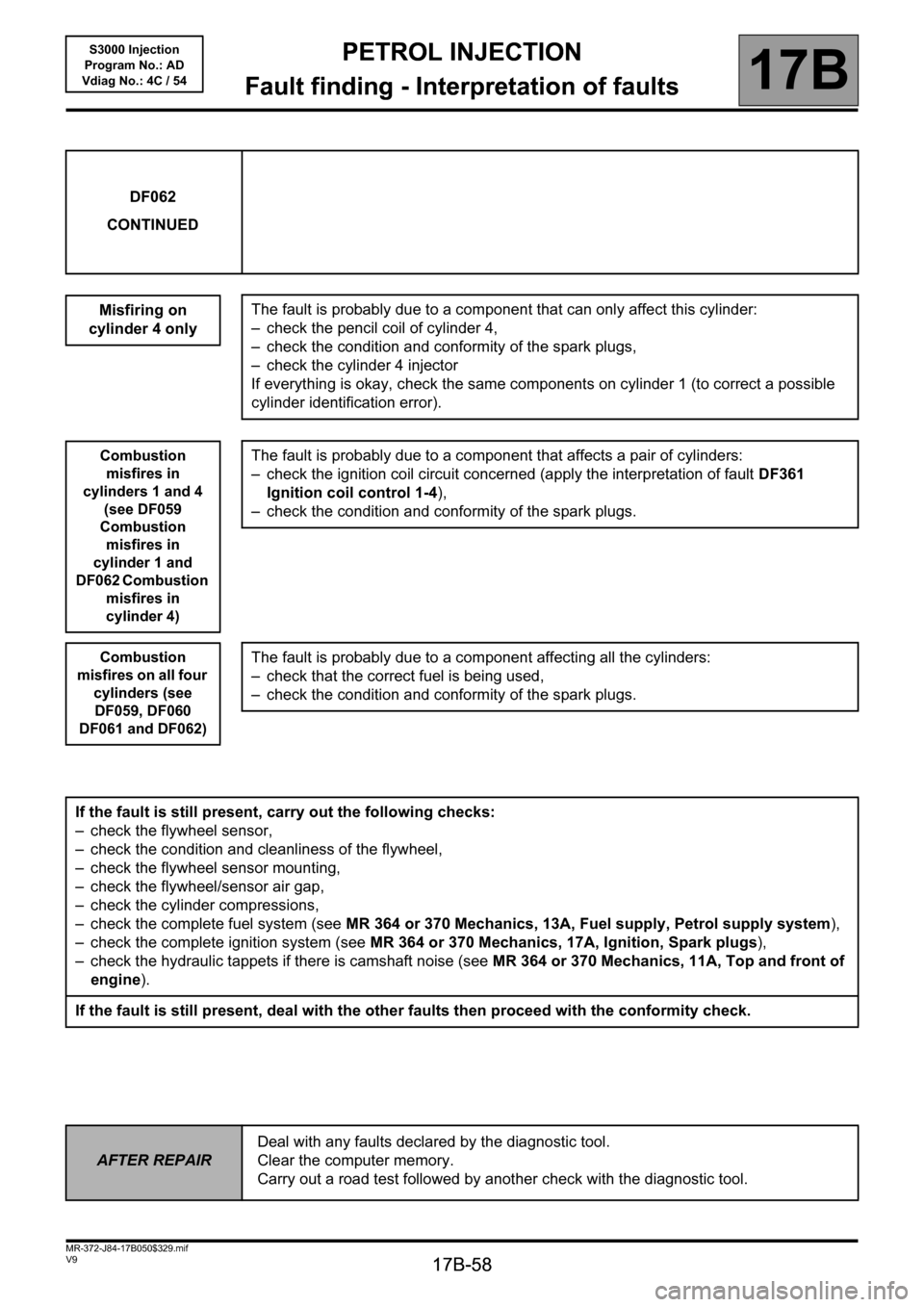

DF062

CONTINUED

Misfiring on

cylinder 4 only

Combustion

misfires in

cylinders 1 and 4

(see DF059

Combustion

misfires in

cylinder 1 and

DF062 Combustion

misfires in

cylinder 4)

Combustion

misfires on all four

cylinders (see

DF059, DF060

DF061 and DF062)

The fault is probably due to a component that can only affect this cylinder:

– check the pencil coil of cylinder 4,

– check the condition and conformity of the spark plugs,

– check the cylinder 4 injector

If everything is okay, check the same components on cylinder 1 (to correct a possible

cylinder identification error).

The fault is probably due to a component that affects a pair of cylinders:

– check the ignition coil circuit concerned (apply the interpretation of fault DF361

Ignition coil control 1-4),

– check the condition and conformity of the spark plugs.

The fault is probably due to a component affecting all the cylinders:

– check that the correct fuel is being used,

– check the condition and conformity of the spark plugs.

If the fault is still present, carry out the following checks:

– check the flywheel sensor,

– check the condition and cleanliness of the flywheel,

– check the flywheel sensor mounting,

– check the flywheel/sensor air gap,

– check the cylinder compressions,

– check the complete fuel system (see MR 364 or 370 Mechanics, 13A, Fuel supply, Petrol supply system),

– check the complete ignition system (see MR 364 or 370 Mechanics, 17A, Ignition, Spark plugs),

– check the hydraulic tappets if there is camshaft noise (see MR 364 or 370 Mechanics, 11A, Top and front of

engine).

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

Page 65 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-65

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-65V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

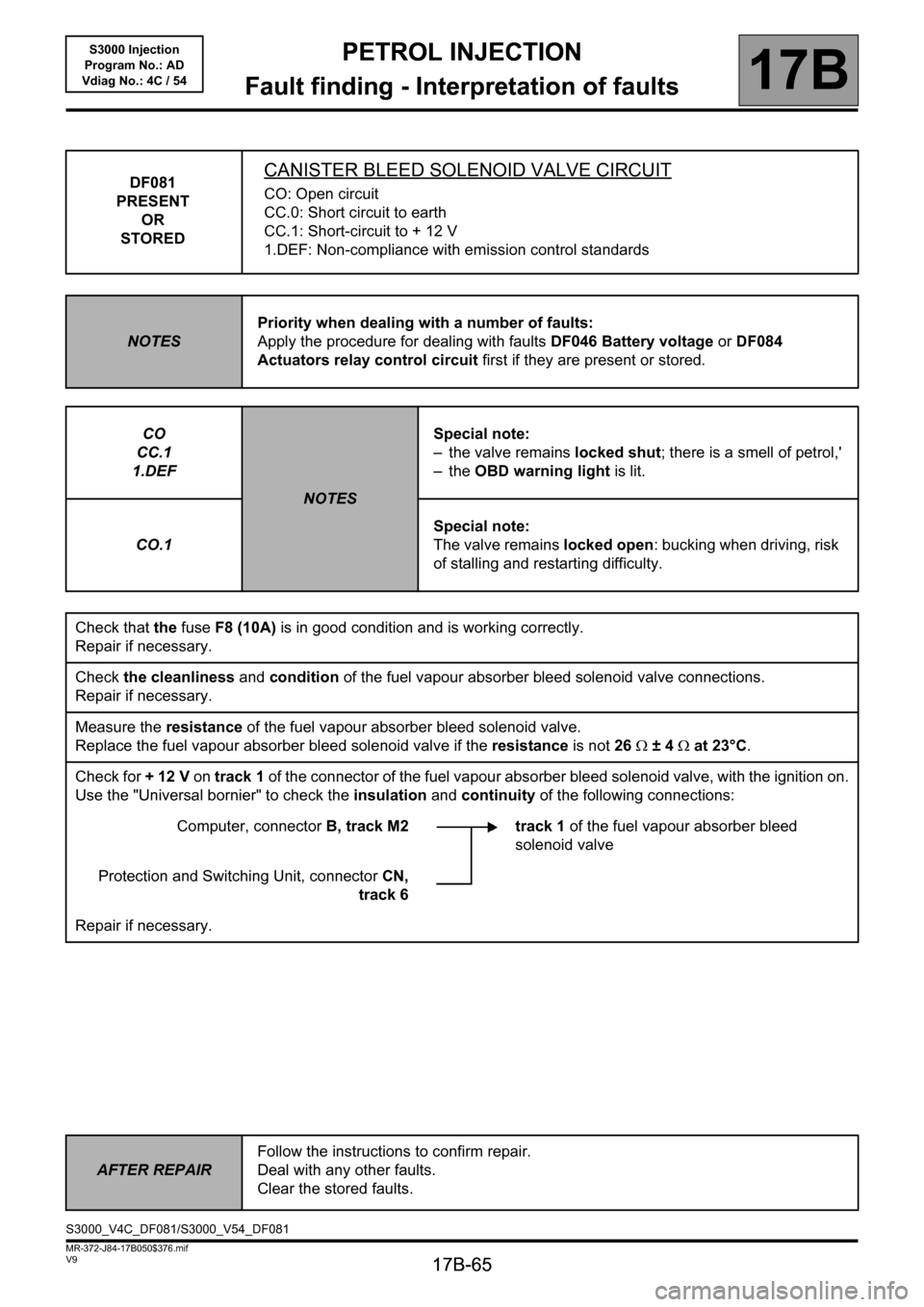

DF081

PRESENT

OR

STOREDCANISTER BLEED SOLENOID VALVE CIRCUIT

CO: Open circuit

CC.0: Short circuit to earth

CC.1: Short-circuit to + 12 V

1.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

Apply the procedure for dealing with faults DF046 Battery voltage or DF084

Actuators relay control circuit first if they are present or stored.

CO

CC.1

1.DEF

NOTESSpecial note:

– the valve remains locked shut; there is a smell of petrol,'

–the OBD warning light is lit.

CO.1Special note:

The valve remains locked open: bucking when driving, risk

of stalling and restarting difficulty.

Check that the fuseF8 (10A) is in good condition and is working correctly.

Repair if necessary.

Check the cleanliness and condition of the fuel vapour absorber bleed solenoid valve connections.

Repair if necessary.

Measure the resistance of the fuel vapour absorber bleed solenoid valve.

Replace the fuel vapour absorber bleed solenoid valve if the resistance is not 26Ω ±4Ω at 23°C.

Check for + 12 V on track 1 of the connector of the fuel vapour absorber bleed solenoid valve, with the ignition on.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Computer, connectorB, track M2 track 1 of the fuel vapour absorber bleed

solenoid valve

Protection and Switching Unit, connectorCN,

track 6

Repair if necessary.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF081/S3000_V54_DF081

Page 67 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-67

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-67V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

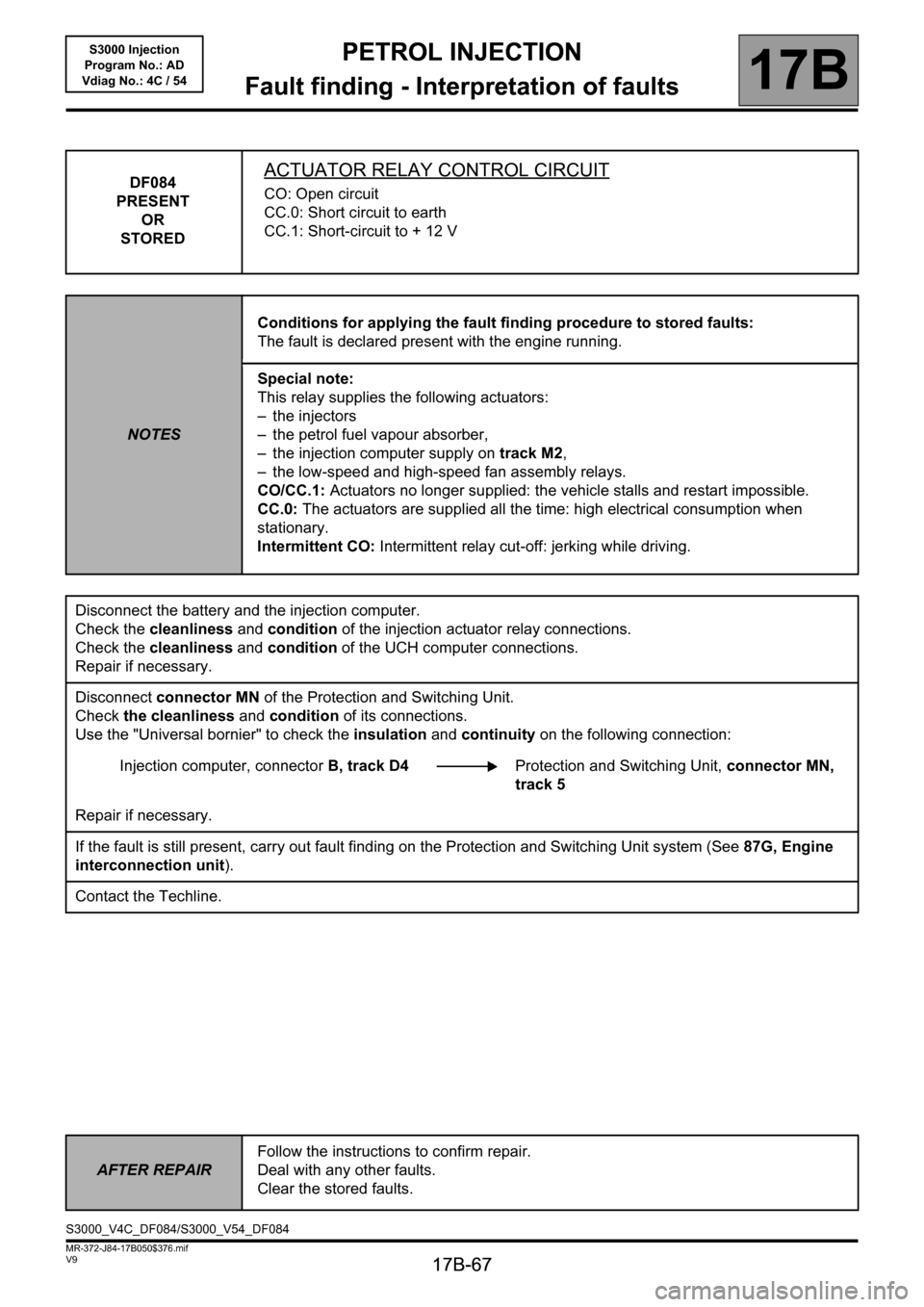

DF084

PRESENT

OR

STOREDACTUATOR RELAY CONTROL CIRCUIT

CO: Open circuit

CC.0: Short circuit to earth

CC.1: Short-circuit to + 12 V

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present with the engine running.

Special note:

This relay supplies the following actuators:

– the injectors

– the petrol fuel vapour absorber,

– the injection computer supply on track M2,

– the low-speed and high-speed fan assembly relays.

CO/CC.1: Actuators no longer supplied: the vehicle stalls and restart impossible.

CC.0: The actuators are supplied all the time: high electrical consumption when

stationary.

Intermittent CO: Intermittent relay cut-off: jerking while driving.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the injection actuator relay connections.

Check the cleanliness and condition of the UCH computer connections.

Repair if necessary.

Disconnect connector MN of the Protection and Switching Unit.

Check the cleanliness and condition of its connections.

Use the "Universal bornier" to check the insulation and continuity on the following connection:

Injection computer, connectorB, track D4Protection and Switching Unit, connector MN,

track 5

Repair if necessary.

If the fault is still present, carry out fault finding on the Protection and Switching Unit system (See87G, Engine

interconnection unit).

Contact the Techline.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF084/S3000_V54_DF084

Page 68 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-68

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-68V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

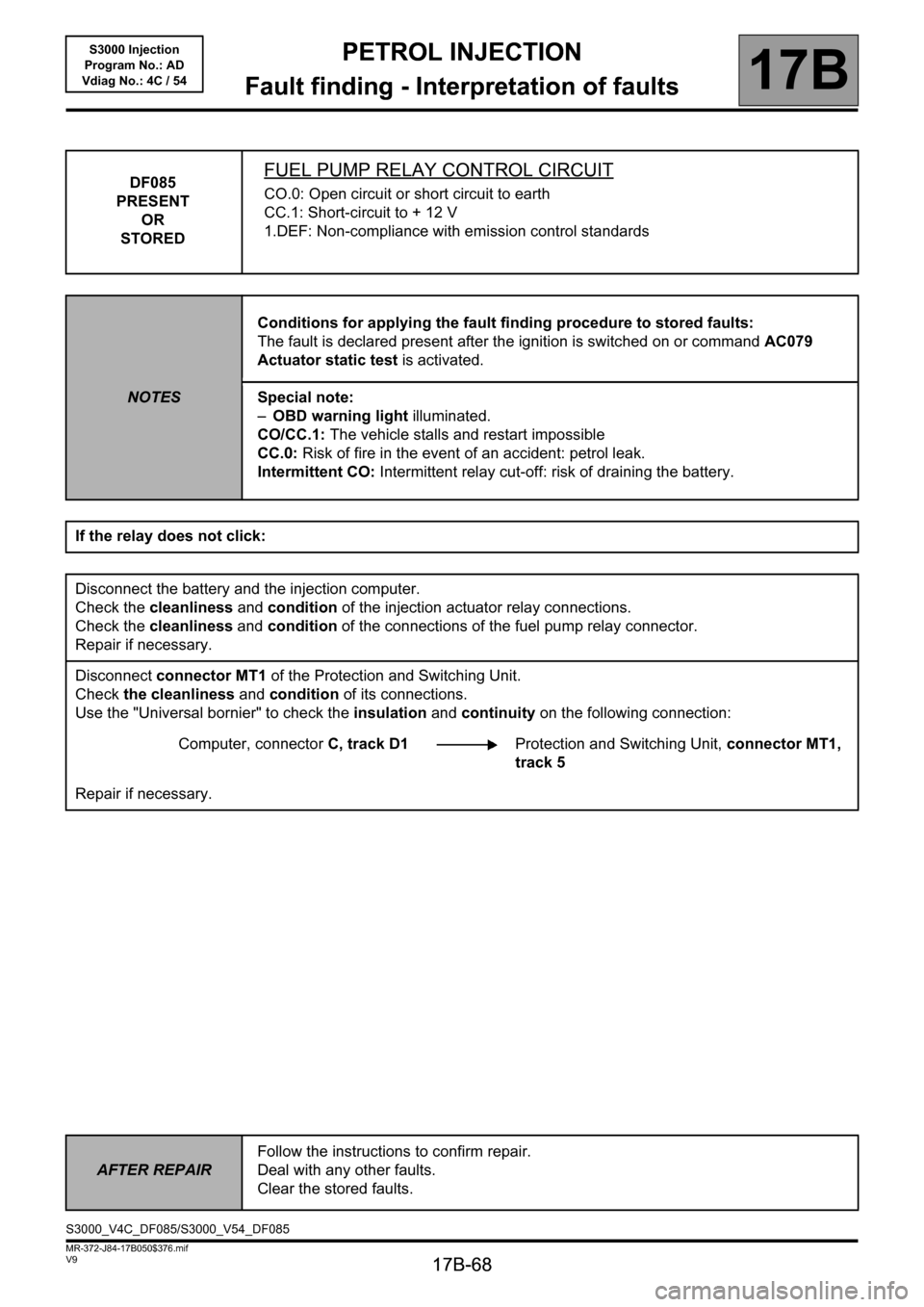

DF085

PRESENT

OR

STOREDFUEL PUMP RELAY CONTROL CIRCUIT

CO.0: Open circuit or short circuit to earth

CC.1: Short-circuit to + 12 V

1.DEF: Non-compliance with emission control standards

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present after the ignition is switched on or command AC079

Actuator static test is activated.

Special note:

–OBD warning light illuminated.

CO/CC.1: The vehicle stalls and restart impossible

CC.0: Risk of fire in the event of an accident: petrol leak.

Intermittent CO: Intermittent relay cut-off: risk of draining the battery.

If the relay does not click:

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the injection actuator relay connections.

Check the cleanliness and condition of the connections of the fuel pump relay connector.

Repair if necessary.

Disconnect connector MT1 of the Protection and Switching Unit.

Check the cleanliness and condition of its connections.

Use the "Universal bornier" to check the insulation and continuity on the following connection:

Computer, connectorC, track D1Protection and Switching Unit, connector MT1,

track 5

Repair if necessary.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF085/S3000_V54_DF085

Page 69 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-69

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-69V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

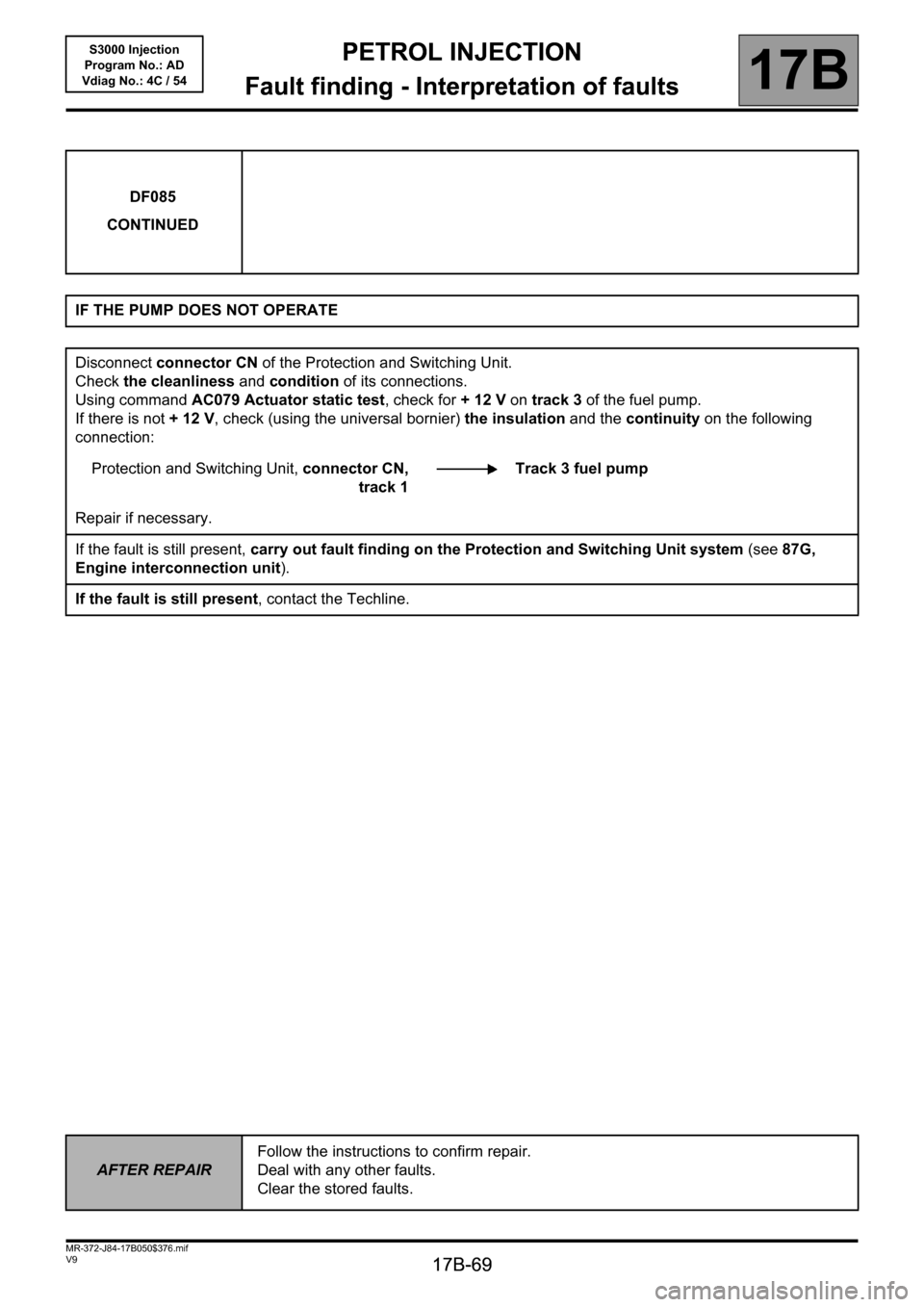

DF085

CONTINUED

IF THE PUMP DOES NOT OPERATE

Disconnect connector CN of the Protection and Switching Unit.

Check the cleanliness and condition of its connections.

Using command AC079 Actuator static test, check for + 12 V on track 3 of the fuel pump.

If there is not + 12 V, check (using the universal bornier) the insulation and the continuity on the following

connection:

Protection and Switching Unit, connector CN,

track 1Track 3 fuel pump

Repair if necessary.

If the fault is still present, carry out fault finding on the Protection and Switching Unit system (see87G,

Engine interconnection unit).

If the fault is still present, contact the Techline.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

Page 70 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-70

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-70V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

DF088

PRESENT

OR

STOREDPINKING SENSOR CIRCUIT

1.DEF: Abnormal voltage

2.DEF: Non-compliance with emission control standards

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present during a road test with a warm engine at an engine speed

above 1500 rpm.

Special note:

The wiring harness connecting the injection computer to the pinking sensor is

"shielded", from this a short circuit to + 12 V is improbable.

Check the cleanliness and condition of the pinking sensor and its connections.

Check the tightness of the pinking sensor.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Use the "Universal bornier" to check the insulation and continuity of the following connections:

Computer, connectorB, track B3 track 2 of the pinking sensor

Computer, connectorB, track B4 track 1of the pinking sensor

Computer, connectorB, track B2Pinking sensor screening

Repair if necessary.

Check the conformity of the fuel in the tank.

Check the conformity of the spark plugs.

If the fault is still present, deal with the other faults then proceed with the conformity check.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

S3000_V4C_DF088/S3000_V54_DF088

Page 82 of 230

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-82

PETROL INJECTION

Fault finding - Interpretation of faults

17B

17B-82V9 MR-372-J84-17B050$376.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

DF109

PRESENT

OR

STOREDLOW FUEL LEVEL MISFIRING

1.DEF: Destructive misfiring

2.DEF: Polluting misfiring

3.DEF: Non-compliance with emission control standards

NOTESPriority when dealing with a number of faults:

– fuel supply circuit:

DF085 Fuel pump relay control circuit,

DF026 Injector control circuit cylinder 1,

DF027 Injector control circuit cylinder 2,

DF028 Injector control circuit cylinder 3,

DF029 Injector control circuit cylinder 4

– combustion misfiring:

DF059 Combustion misfire in cylinder 1,

DF060 Combustion misfire in cylinder 2,

DF061 Combustion misfire in cylinder 3,

DF062 Combustion misfire in cylinder 4.

Conditions for applying the fault finding procedure to stored faults:

The fault is present after starting the engine and under the following conditions:

– there must be no further electrical faults,

– programming must be carried out.

– warm engine (coolant temperature 75°C minimum),

– engine running with electrical consumers on for 15 minutes.

Special note:

–OBD warning light illuminated.

Check the presence and conformity of the fuel in the tank.

If there is no present or stored combustion misfire fault, the misfire was caused by the low fuel level.

Clear fault DF109.

AFTER REPAIREnsure that all the faults have been dealt with.

Do not clear the programming.

To check that the system has been repaired correctly:

– there must be no further electrical faults,

– programming has been carried out,

– warm engine (minimum 75°C).

– running at idle speed with all electrical consumers drawing power for 15 minutes.

If the fault reappears, continue the fault finding procedure.

S3000_V4C_DF109/S3000_V54_DF109