light RENAULT SCENIC 2010 J95 / 3.G Petrol Injection S3000 Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2010, Model line: SCENIC, Model: RENAULT SCENIC 2010 J95 / 3.GPages: 230, PDF Size: 0.92 MB

Page 2 of 230

PETROL INJECTION

Fault finding - Introduction

17B

17B-2

PETROL INJECTION

Fault finding - Introduction

17B

17B-2V9 MR-372-J84-17B050$047.mif

117B

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - Introduction

1. SCOPE OF THIS DOCUMENT

This document presents the fault finding procedure applicable to all computers with the following specifications:

2. PREREQUISITES FOR FAULT FINDING

Documentation type

Fault finding procedures (this document):

– Assisted fault finding (integrated into the diagnostic tool), Dialogys.

Wiring Diagrams:

– Visu-Schéma (CD-ROM), paper.

Type of diagnostic tools

–CLIP + multiplex line sensor

Special tooling required

3. REMINDERS

Procedure

To run fault finding on the vehicle's computers, switch on the ignition in fault finding mode (forced + after ignition

feed).

Proceed as follows:

– vehicle card in reader,

– press and hold the Start button (longer than 5 seconds) with start-up conditions not fulfilled,

– connect the diagnostic tool and perform the required operations.

To cut off the + after ignition feed, proceed as follows:

– disconnect the diagnostic tool,

– press the Start button twice briefly (less than 3 seconds),

– ensure that the + after ignition feed has been cut off by checking that the computer indicator lights on the instrument

panel have gone out. Vehicle(s):MEGANE II phase 2

SCENIC II phase 2

Engines:K4J 740 - K4M 766/812/813 - K4M 680 -

K4M 788 LPG

F4R 770/771 - F4R-T 776

F4R-T 774 (MEGANE II phase 2

RENAULT SPORT)

Function concerned: Petrol injectionName of computer: Sagem S3000

Program no.: AD

Vdiag No.: 4C, 54

Special tooling required

Multimeter

Ele. 1497Bornier

Elé. 1681Universal bornier

S3000_V4C_PRELI/S3000_V54_PRELI

MR-372-J84-17B050$047.mif

Page 5 of 230

PETROL INJECTION

Fault finding - Introduction

17B

17B-5

PETROL INJECTION

Fault finding - Introduction

17B

17B-5V9 MR-372-J84-17B050$047.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

4. FAULT FINDING PROCEDURE (continued)

Wiring check:

Fault finding problems:

Disconnecting the connectors and/or manipulating the wiring may temporarily remove the cause of a fault.

Electrical measurements of the voltage, resistance and insulation are generally correct, especially if the fault is not

present when the analysis is made (stored fault).

Visual inspection:

Look for damage under the bonnet and in the passenger compartment.

Carefully check the fuses, insulation and wiring routing.

Look for signs of oxidation.

Tactile inspection:

While manipulating the wiring, use the diagnostic tool to note any change in fault status from stored to present.

Check that the connectors are correctly tightened, apply light pressure to the connectors, twist the wiring harness.

If there is a change in status, try to locate the source of the fault.

Inspection of each component:

Disconnect the connectors and check the appearance of the clips and tabs, as well as their crimping (no crimping on

the insulating section).

Make sure that the clips and tabs are properly locked in the sockets.

Make sure no clips or tabs have been dislodged during connection.

Check the clip contact pressure using an appropriate model of tab.

Resistance check:

Check the continuity of entire lines, then section by section.

Look for a short circuit to earth, to + 12 V or with another wire.

If a fault is detected, repair or replace the wiring harness.

Page 14 of 230

PETROL INJECTION

Fault finding - System operation

17B

17B - 14

PETROL INJECTION

Fault finding - System operation

17B

17B - 14V9 MR-372-J84-17B050$094.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

3. OBD management

Managed OBD programming is as follows:

– catalytic converter operational fault finding,

– upstream oxygen sensor operational fault finding,

– misfiring fault finding with two levels of detection: pollutant misfiring and catalytic converter breakage

misfiring,

– fuel supply system fault finding.

The misfiring and fuel supply system fault finding is performed continuously.

The operational fault finding for the upstream sensor and the catalytic converter can be only be carried out once per

journey, and can never occur at the same time.

OBD fault manager:

The OBD faults manager does not replace or modify conventional electrical fault management. Perform to comply

with OBD standard.

The requirements are:

●storing OBD faults,

●illuminate the OBD warning light for all faults where the OBD emission thresholds are exceeded,

●flash the OBD warning light for misfire faults damaging the catalytic converter.

Operating principle.

If a fault is detected and confirmed during 3 consecutive journeys then:

●an OBD stored fault is raised,

●the OBD fault warning light receives a request to be lit continuously. This request is only recognised if the

fault in question is authorised to activate the OBD warning light.

To deactivate the warning light, no OBD faults should be detected for 3 consecutive journeys.

The electrical fault finding checks taken into consideration by the OBD faults manager are as follows:

– pressure,

– turbocharging pressure,

– coolant temperature,

– air temperature

– upstream sensor,

– downstream sensor,

– upstream sensor heating,

– downstream sensor heating,

–injector1,

–injector2,

–injector3,

–injector4,– ignition coil 1,

– ignition coil 2,

– ignition coil 3,

– ignition coil 4,

– petrol pump,

– wastegate,

– canister bleed,

– air line system,

– turbocharging system

– pinking sensor,

– camshaft dephaser.

Page 16 of 230

PETROL INJECTION

Fault finding - System operation

17B

17B - 16

PETROL INJECTION

Fault finding - System operation

17B

17B - 16V9 MR-372-J84-17B050$094.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

4. Engine coolant temperature management

Engine cooling is provided by 1 or 2 fan assemblies (depending on the vehicle layout). The injection computer

requests the UPC to actuate them via the multiplex network.

To provide cooling:

Engine running, GMV1 is requested when the coolant temperature exceeds 99 °C and stops when the coolant

temperature falls below 96 °C. GMV2 is requested when the coolant temperature exceeds 102 °C and stops when

the coolant temperature falls below 99 °C.

With the engine off, only fan assembly 1 may be activated to provide the anti-percolation function (if engine is

stopped when very hot). The anti-percolation function is active with the ignition off for a determined period. During

this period, fan assembly 1 is requested if the coolant temperature exceeds approximately 100 °C and is shut down

if the coolant temperature drops below around 95 °C.

If a fault is detected on the coolant temperature sensor circuit, then fan assembly 1 is requested to operate

continuously.

If the engine coolant temperature goes beyond the warning threshold of 11 8 ° C, the injection computer requests the

instrument panel computer via the multiplex network to illuminate on the coolant temperature warning light until the

coolant temperature falls back below 115 ° C.

In addition to the engine requirements, the injection computer centralises the cooling requirements for the Air

conditioning and BVA/BVR functions.

5. Air conditioning function

The S3000 computer manages a cold loop air conditioning system.

– air conditioning request via multiplex connection,

– acquisition of air conditioning circuit pressure,

– vehicle speed

– air conditioning compressor control,

– fan assembly control request by Protection and Switching Unit.

The injection computer recovers the power absorbed by the air conditioning compressor and the fast idling speed

request using the pressure acquired in the air conditioning circuit.

These signals are necessary for adapting the engine management (idling speed regulation, air flow correction, etc.),

for several reasons:

– air conditioning compressor efficiency,

– sturdier engine to torque bucking caused by compressor activation,

– helping the alternator.

Requests for fan assembly 1 and/or fan assembly 2 are recovered based on the air conditioning circuit pressure and

the vehicle speed. In short, the lower the speed and the higher the pressure, the greater the fan assembly requests.

Page 19 of 230

PETROL INJECTION

Fault finding - System operation

17B

17B - 19

PETROL INJECTION

Fault finding - System operation

17B

17B - 19V9 MR-372-J84-17B050$094.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

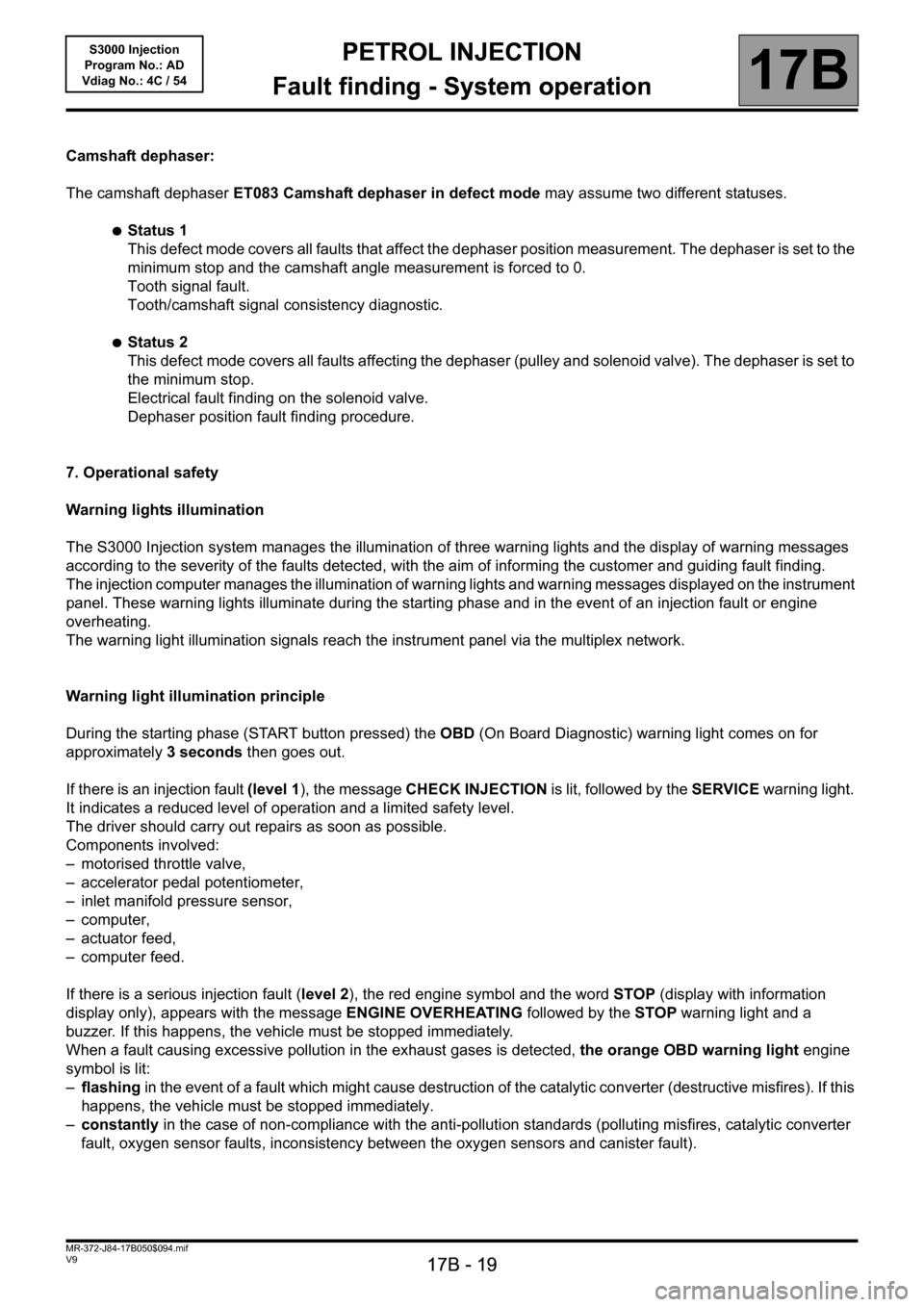

Camshaft dephaser:

The camshaft dephaser ET083 Camshaft dephaser in defect mode may assume two different statuses.

●Status 1

This defect mode covers all faults that affect the dephaser position measurement. The dephaser is set to the

minimum stop and the camshaft angle measurement is forced to 0.

Tooth signal fault.

Tooth/camshaft signal consistency diagnostic.

●Status 2

This defect mode covers all faults affecting the dephaser (pulley and solenoid valve). The dephaser is set to

the minimum stop.

Electrical fault finding on the solenoid valve.

Dephaser position fault finding procedure.

7. Operational safety

Warning lights illumination

The S3000 Injection system manages the illumination of three warning lights and the display of warning messages

according to the severity of the faults detected, with the aim of informing the customer and guiding fault finding.

The injection computer manages the illumination of warning lights and warning messages displayed on the instrument

panel. These warning lights illuminate during the starting phase and in the event of an injection fault or engine

overheating.

The warning light illumination signals reach the instrument panel via the multiplex network.

Warning light illumination principle

During the starting phase (START button pressed) the OBD (On Board Diagnostic) warning light comes on for

approximately 3 seconds then goes out.

If there is an injection fault (level 1), the message CHECK INJECTION is lit, followed by the SERVICE warning light.

It indicates a reduced level of operation and a limited safety level.

The driver should carry out repairs as soon as possible.

Components involved:

– motorised throttle valve,

– accelerator pedal potentiometer,

– inlet manifold pressure sensor,

– computer,

– actuator feed,

– computer feed.

If there is a serious injection fault (level 2), the red engine symbol and the word STOP (display with information

display only), appears with the message ENGINE OVERHEATING followed by the STOP warning light and a

buzzer. If this happens, the vehicle must be stopped immediately.

When a fault causing excessive pollution in the exhaust gases is detected, the orange OBD warning light engine

symbol is lit:

–flashing in the event of a fault which might cause destruction of the catalytic converter (destructive misfires). If this

happens, the vehicle must be stopped immediately.

–constantly in the case of non-compliance with the anti-pollution standards (polluting misfires, catalytic converter

fault, oxygen sensor faults, inconsistency between the oxygen sensors and canister fault).

Page 20 of 230

PETROL INJECTION

Fault finding - System operation

17B

17B - 20

PETROL INJECTION

Fault finding - System operation

17B

17B - 20V9 MR-372-J84-17B050$094.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

8. Mileage travelled with fault

These two parameters PR105 Distance travelled with OBD fault warning light on and PR106 Distance travelled

with fault warning light on are used to count the distance travelled with one of the injection fault warning lights lit:

level 1 fault warning light (amber) as well as the OBD warning light.

These counters can be reset to 0 using the diagnostic tool (clear faults command).

9. Inter-system engine functions

The inter-system connections concerning the particular requirements of engine management are as follows:

–OBD warning light illumination request by the instrument panel computer to prevent a pollution fault,

–level 1 warning light illumination request to warn of an operating safety fault relating to the injection system,

–level 2 warning light illumination request to warn of an operating safety fault or provide an engine

overheating alert,

– request for fan assembly activation for engine cooling, but also for the air conditioning and automatic

gearbox,

– air conditioning compressor shut-down request for engine programming requirements such as pulling away,

performance, anti-stalling, overspeed, etc.

– passenger compartment heating resistor shut-down or fixing request for engine programming requirements

such as pulling away, performance, anti-stall, overspeed, etc.

Page 26 of 230

PETROL INJECTION

Fault finding - Replacement of components

17B

17B-26

PETROL INJECTION

Fault finding - Replacement of components

17B

17B-26V9 MR-372-J84-17B050$188.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - Replacement of components

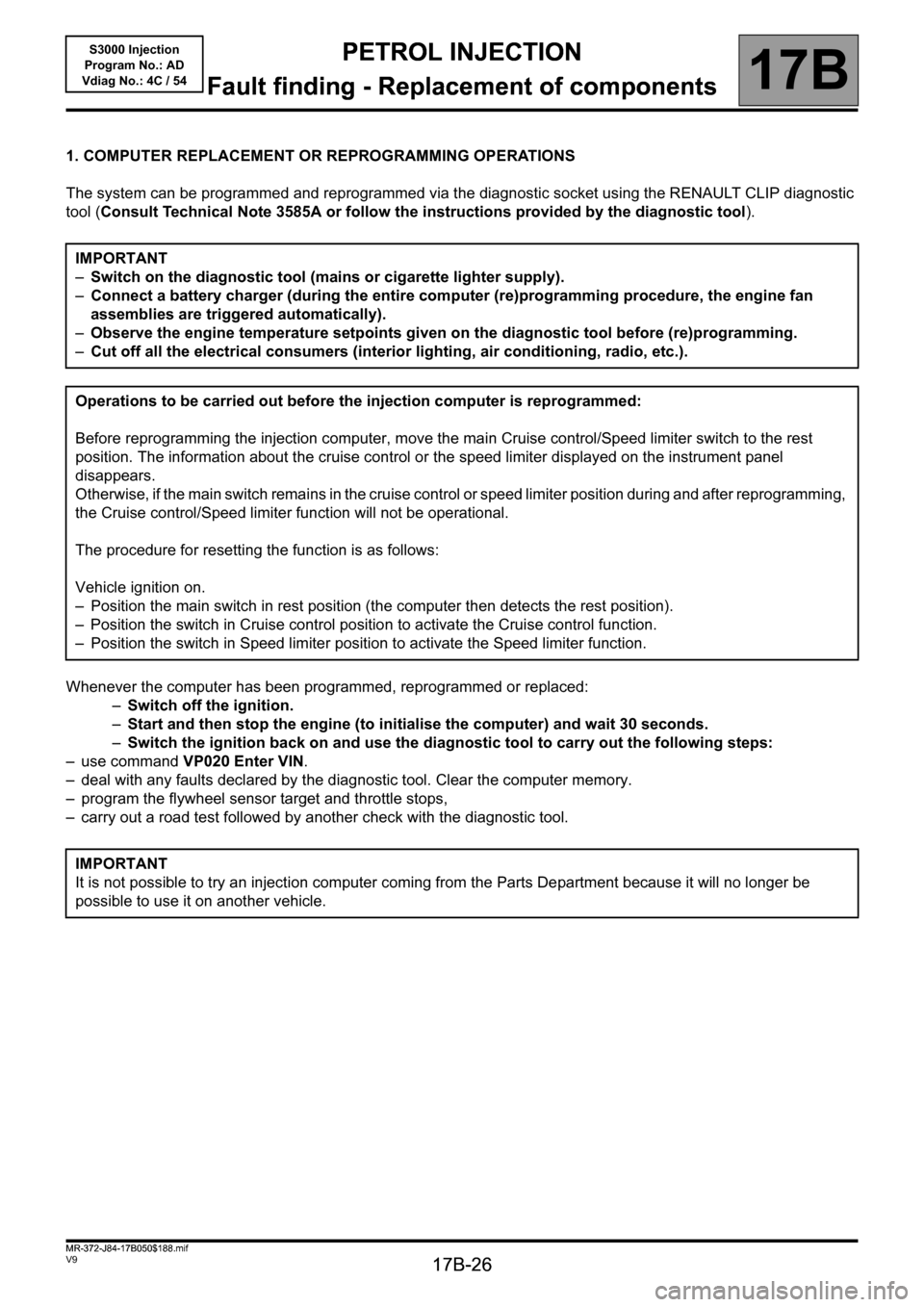

1. COMPUTER REPLACEMENT OR REPROGRAMMING OPERATIONS

The system can be programmed and reprogrammed via the diagnostic socket using the RENAULT CLIP diagnostic

tool (Consult Technical Note 3585A or follow the instructions provided by the diagnostic tool).

Whenever the computer has been programmed, reprogrammed or replaced:

–Switch off the ignition.

–Start and then stop the engine (to initialise the computer) and wait 30 seconds.

–Switch the ignition back on and use the diagnostic tool to carry out the following steps:

– use command VP020 Enter VIN.

– deal with any faults declared by the diagnostic tool. Clear the computer memory.

– program the flywheel sensor target and throttle stops,

– carry out a road test followed by another check with the diagnostic tool. IMPORTANT

–Switch on the diagnostic tool (mains or cigarette lighter supply).

–Connect a battery charger (during the entire computer (re)programming procedure, the engine fan

assemblies are triggered automatically).

–Observe the engine temperature setpoints given on the diagnostic tool before (re)programming.

–Cut off all the electrical consumers (interior lighting, air conditioning, radio, etc.).

Operations to be carried out before the injection computer is reprogrammed:

Before reprogramming the injection computer, move the main Cruise control/Speed limiter switch to the rest

position. The information about the cruise control or the speed limiter displayed on the instrument panel

disappears.

Otherwise, if the main switch remains in the cruise control or speed limiter position during and after reprogramming,

the Cruise control/Speed limiter function will not be operational.

The procedure for resetting the function is as follows:

Vehicle ignition on.

– Position the main switch in rest position (the computer then detects the rest position).

– Position the switch in Cruise control position to activate the Cruise control function.

– Position the switch in Speed limiter position to activate the Speed limiter function.

IMPORTANT

It is not possible to try an injection computer coming from the Parts Department because it will no longer be

possible to use it on another vehicle.

MR-372-J84-17B050$188.mif

Page 28 of 230

PETROL INJECTION

17B

17B - 28

17B

17B - 28V9 MR-372-J84-17B050$235.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - Configurations and programming

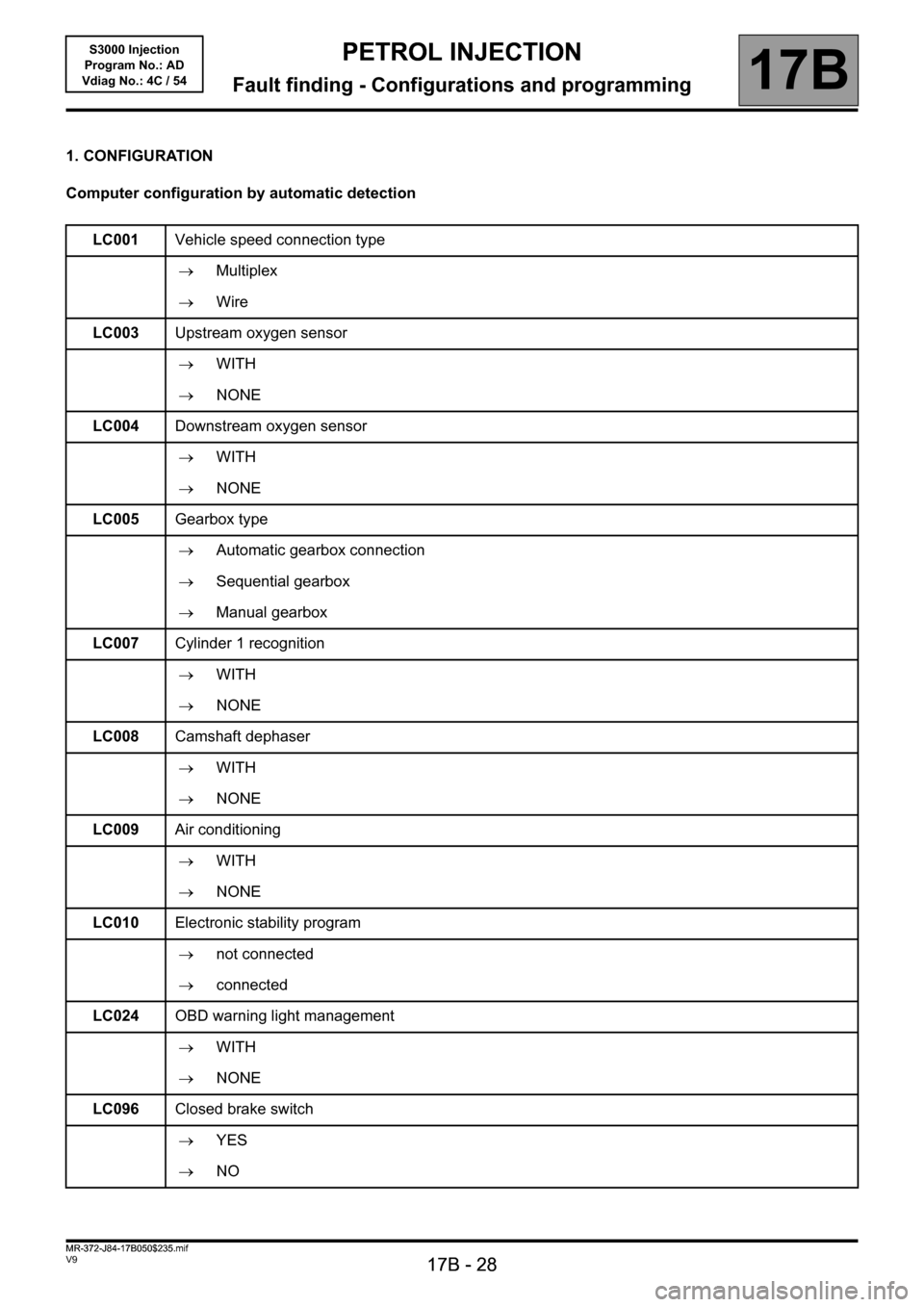

1. CONFIGURATION

Computer configuration by automatic detection

LC001Vehicle speed connection type

→Multiplex

→Wire

LC003Upstream oxygen sensor

→WITH

→NONE

LC004Downstream oxygen sensor

→WITH

→NONE

LC005Gearbox type

→Automatic gearbox connection

→Sequential gearbox

→Manual gearbox

LC007Cylinder 1 recognition

→WITH

→NONE

LC008Camshaft dephaser

→WITH

→NONE

LC009Air conditioning

→WITH

→NONE

LC010Electronic stability program

→not connected

→connected

LC024OBD warning light management

→WITH

→NONE

LC096Closed brake switch

→YES

→NO

MR-372-J84-17B050$235.mif

Page 30 of 230

PETROL INJECTION

17B

17B-30

PETROL INJECTION

17B

17B-30V9 MR-372-J84-17B050$282.mif

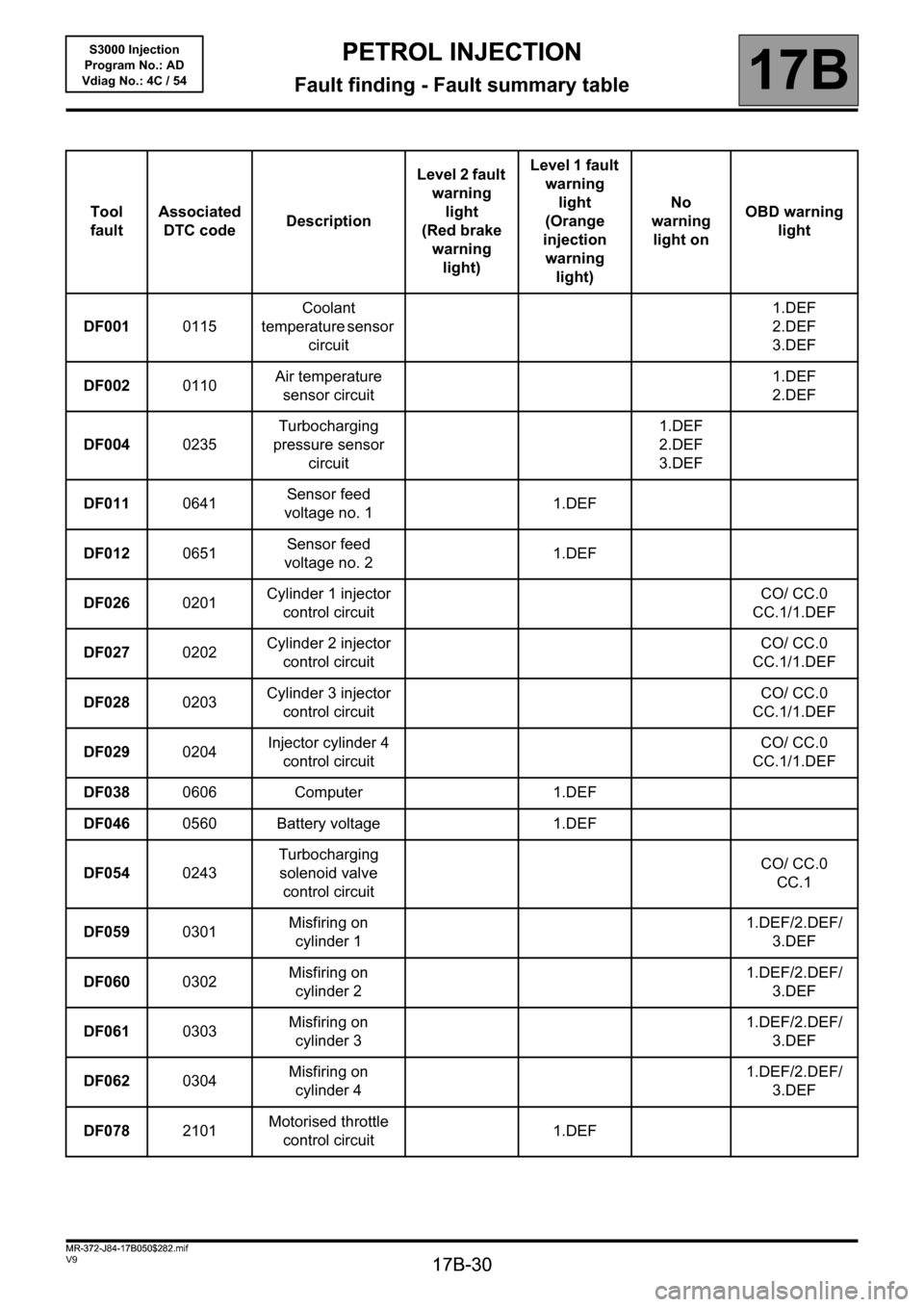

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54PETROL INJECTION

Fault finding - Fault summary table

Tool

faultAssociated

DTC codeDescriptionLevel 2 fault

warning

light

(Red brake

warning

light)Level 1 fault

warning

light

(Orange

injection

warning

light)No

warning

light onOBD warning

light

DF0010115Coolant

temperature sensor

circuit1.DEF

2.DEF

3.DEF

DF0020110Air temperature

sensor circuit1.DEF

2.DEF

DF0040235Turbocharging

pressure sensor

circuit1.DEF

2.DEF

3.DEF

DF0110641Sensor feed

voltage no. 11.DEF

DF0120651Sensor feed

voltage no. 21.DEF

DF0260201Cylinder 1 injector

control circuitCO/ CC.0

CC.1/1.DEF

DF0270202Cylinder 2 injector

control circuitCO/ CC.0

CC.1/1.DEF

DF0280203Cylinder 3 injector

control circuitCO/ CC.0

CC.1/1.DEF

DF0290204Injector cylinder 4

control circuitCO/ CC.0

CC.1/1.DEF

DF0380606 Computer 1.DEF

DF0460560 Battery voltage 1.DEF

DF0540243Turbocharging

solenoid valve

control circuitCO/ CC.0

CC.1

DF0590301Misfiring on

cylinder 11.DEF/2.DEF/

3.DEF

DF0600302Misfiring on

cylinder 21.DEF/2.DEF/

3.DEF

DF061

0303Misfiring on

cylinder 31.DEF/2.DEF/

3.DEF

DF0620304Misfiring on

cylinder 41.DEF/2.DEF/

3.DEF

DF0782101Motorised throttle

control circuit1.DEF

MR-372-J84-17B050$282.mif

Page 31 of 230

PETROL INJECTION

Fault finding - Fault summary table

17B

17B-31

PETROL INJECTION

Fault finding - Fault summary table

17B

17B-31V9 MR-372-J84-17B050$282.mif

S3000 Injection

Program No.: AD

Vdiag No.: 4C / 54

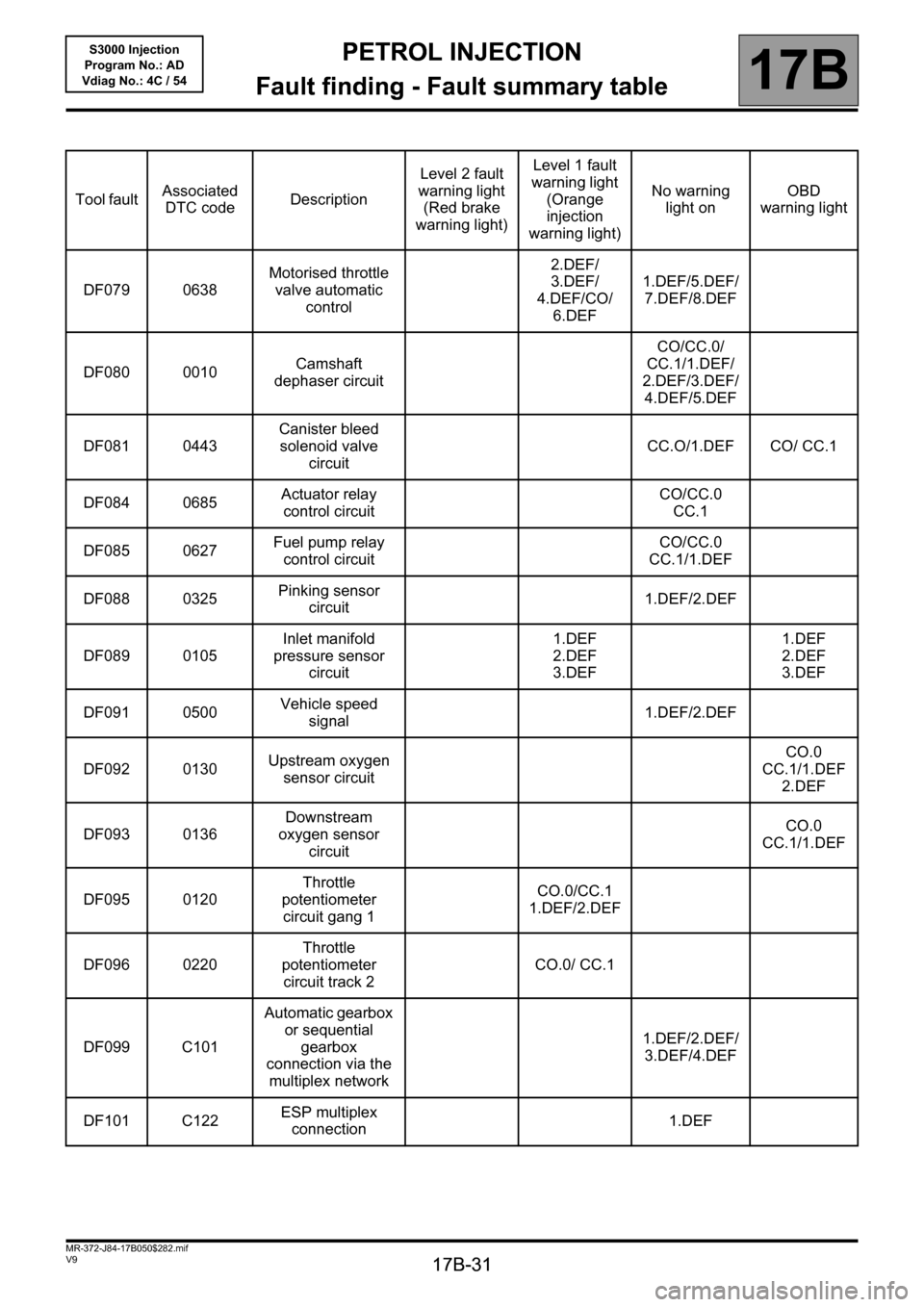

Tool faultAssociated

DTC codeDescriptionLevel 2 fault

warning light

(Red brake

warning light)Level 1 fault

warning light

(Orange

injection

warning light)No warning

light onOBD

warning light

DF079 0638Motorised throttle

valve automatic

control2.DEF/

3.DEF/

4.DEF/CO/

6.DEF1.DEF/5.DEF/

7.DEF/8.DEF

DF080 0010Camshaft

dephaser circuitCO/CC.0/

CC.1/1.DEF/

2.DEF/3.DEF/

4.DEF/5.DEF

DF081 0443Canister bleed

solenoid valve

circuitCC.O/1.DEF CO/ CC.1

DF084 0685Actuator relay

control circuitCO/CC.0

CC.1

DF085 0627Fuel pump relay

control circuitCO/CC.0

CC.1/1.DEF

DF088 0325Pinking sensor

circuit1.DEF/2.DEF

DF089 0105Inlet manifold

pressure sensor

circuit1.DEF

2.DEF

3.DEF1.DEF

2.DEF

3.DEF

DF091 0500Vehicle speed

signal1.DEF/2.DEF

DF092 0130Upstream oxygen

sensor circuitCO.0

CC.1/1.DEF

2.DEF

DF093 0136Downstream

oxygen sensor

circuitCO.0

CC.1/1.DEF

DF095 0120Throttle

potentiometer

circuit gang 1CO.0/CC.1

1.DEF/2.DEF

DF096 0220Throttle

potentiometer

circuit track 2CO.0/ CC.1

DF099 C101Automatic gearbox

or sequential

gearbox

connection via the

multiplex network1.DEF/2.DEF/

3.DEF/4.DEF

DF101 C122ESP multiplex

connection1.DEF