ESP RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 365, PDF Size: 2.11 MB

Page 283 of 365

13B-283

MR-372-J84-13B200$684.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of parameters

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

PR672

DAMPER VALVE POSITION SETPOINT

PARAMETER

DEFINITIONThis parameter indicates the damper valve position setpoint as a %.

NOTESSpecial notes:

Only perform these tests if the parameters do not correspond with the system

operation programming.

Conformity check with the engine stopped and the ignition on, or with the engine running and the engine

coolant temperature > 80°C

PR672 < 5%

In the event of a fault, refer to the interpretation for DF226 Damper valve circuit.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

EDC16_V50_PR672/EDC16_V58_PR672/EDC16_V5C_PR672/EDC16_V18_PR672/EDC16_V1C_PR672/EDC16_V20_PR672

Page 293 of 365

13B-293

MR-372-J84-13B200$756.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of commands

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

SC002

ENTER INJECTOR CODES

NOTESrun this command after replacing the injectors but only if the vehicle is configured with

ima.

(ET104 Injector code use to YES).

If this command is not run, fault DF276 Injection code programming will be present.

WARNING

The letters J and Q, and figures 0 and 9 are not used in IMA coding.

If these characters are used the entry will be invalid.

Cylinder no. 1 is the cylinder located on the engine flywheel end.

Procedure to be followed:

– Make a note of the 6-character alphanumeric codes engraved on the upper section of the injector bodies.

– Use command SC002.

– Select the cylinder number for the cylinder concerned in the Desired, column, then confirm.

– enter the injector code displayed for the cylinder.

– Enter the new codes for each cylinder, then confirm.

– When the command is completed, the modified codes appear in the Current column.

– Check that the codes correspond to those read earlier.

– If the codes entered do not appear in either the Current column or the Desired column, check the codes read

and make sure that the data has been entered correctly.

The possible confusions are:

digit "1" with the letter "i"

figure 8 with the letter b

figure 5 with the letter s

- Exit fault finding mode.

- Switch off the ignition and wait for 1 min. Switch the ignition back on and check for faults.

-DF276 Injector code programming should be stored.

If fault DF276 Injector code programming is present, the command has not run correctly.

Start the procedure again and follow the instructions.

If the codes are still not accepted, check that the computer has been put on standby correctly:

Switch off the ignition and wait for 1 minute.

if the warning light flashes when the ignition is switched off, the computer has not been put on standby and the

command will be ignored.

If all these checks still do not enable the command to be confirmed, contact the Techline.

EDC16_V50_SC002/EDC16_V58_SC002/EDC16_V5C_SC002/EDC16_V18_SC002/EDC16_V1C_SC002/EDC16_V20_SC002

Page 294 of 365

13B-294

MR-372-J84-13B200$756.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of commands

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

SC003

SAVE COMPUTER DATA

NOTESperform this backup before computer reprogramming or before replacing the

computer

Select scenario SC003 on the CLIP tool.

If the following message appears:

"a saved file exists, do you want to overwrite this data?":

(this file corresponds to the last save carried out on the tool)

select "YES".

Confirming this command saves the following vehicle-specific data:

– injector codes,

– the egr valve data programming;

– options available on the vehicle and managed by the computer (e.g.. air conditioning);

– specific data related to the operation of the particle filter.

This information will be saved in the CLIP diagnostic tool.

After saving has finished, use the command SC001 Enter saved data to be able to set the new computer

parameters, after programming and reprogramming.

EDC16_V50_SC003/EDC16_V58_SC003/EDC16_V5C_SC003/EDC16_V18_SC003/EDC16_V1C_SC003/EDC16_V20_SC003

Page 317 of 365

13B-317

MR-372-J84-13B200$792.mif

V13

13B

DIESEL INJECTION

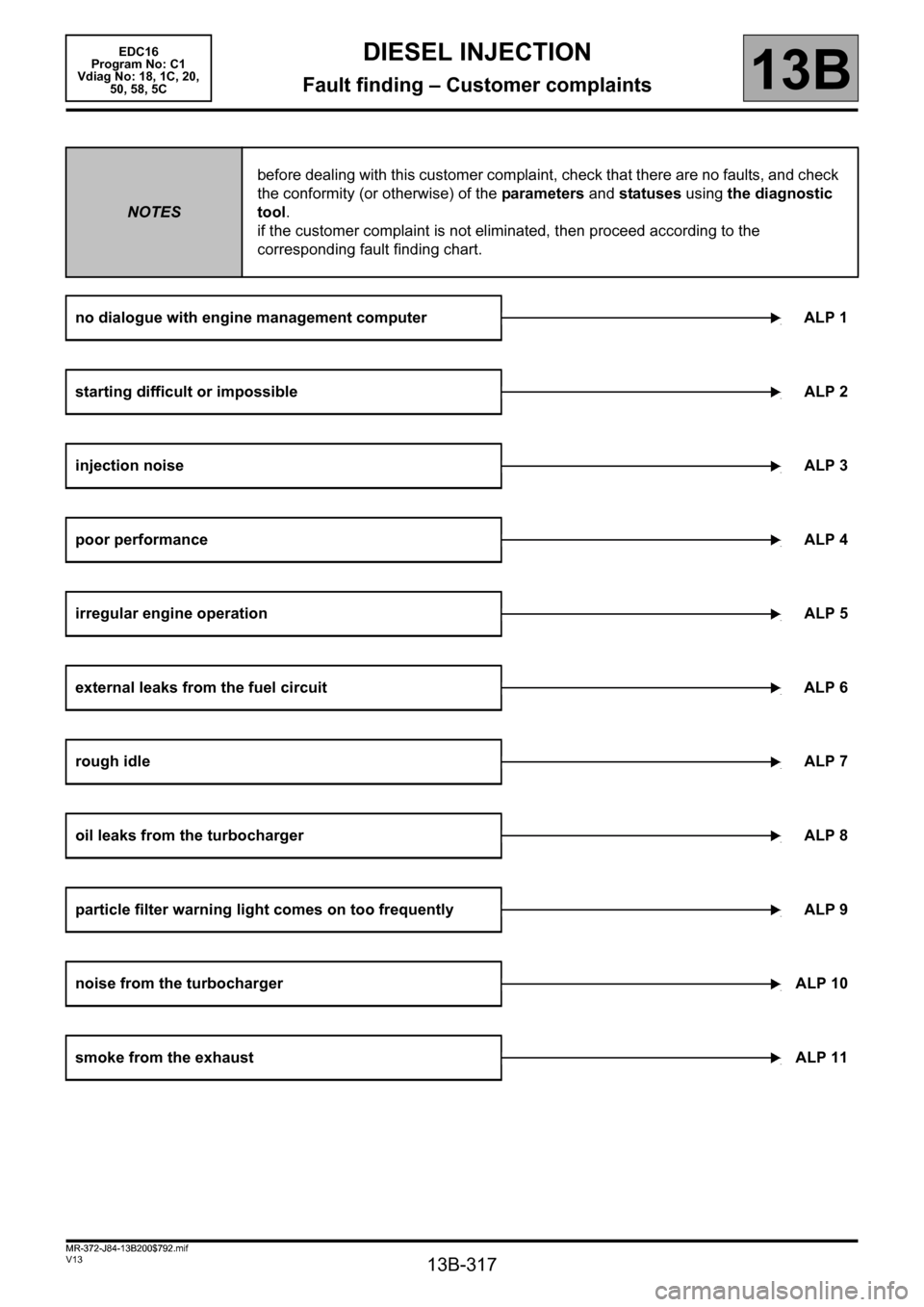

Fault finding – Customer complaints

NOTESbefore dealing with this customer complaint, check that there are no faults, and check

the conformity (or otherwise) of the parameters and statuses using the diagnostic

tool.

if the customer complaint is not eliminated, then proceed according to the

corresponding fault finding chart.

no dialogue with engine management computer ALP 1

starting difficult or impossibleALP 2

injection noiseALP 3

poor performanceALP 4

irregular engine operationALP 5

external leaks from the fuel circuit ALP 6

rough idleALP 7

oil leaks from the turbochargerALP 8

particle filter warning light comes on too frequently ALP 9

noise from the turbochargerALP 10

smoke from the exhaustALP 11

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

MR-372-J84-13B200$792.mif

Page 318 of 365

13B-318

MR-372-J84-13B200$828.mif

V13

13B

DIESEL INJECTION

Fault finding – Fault Finding Chart

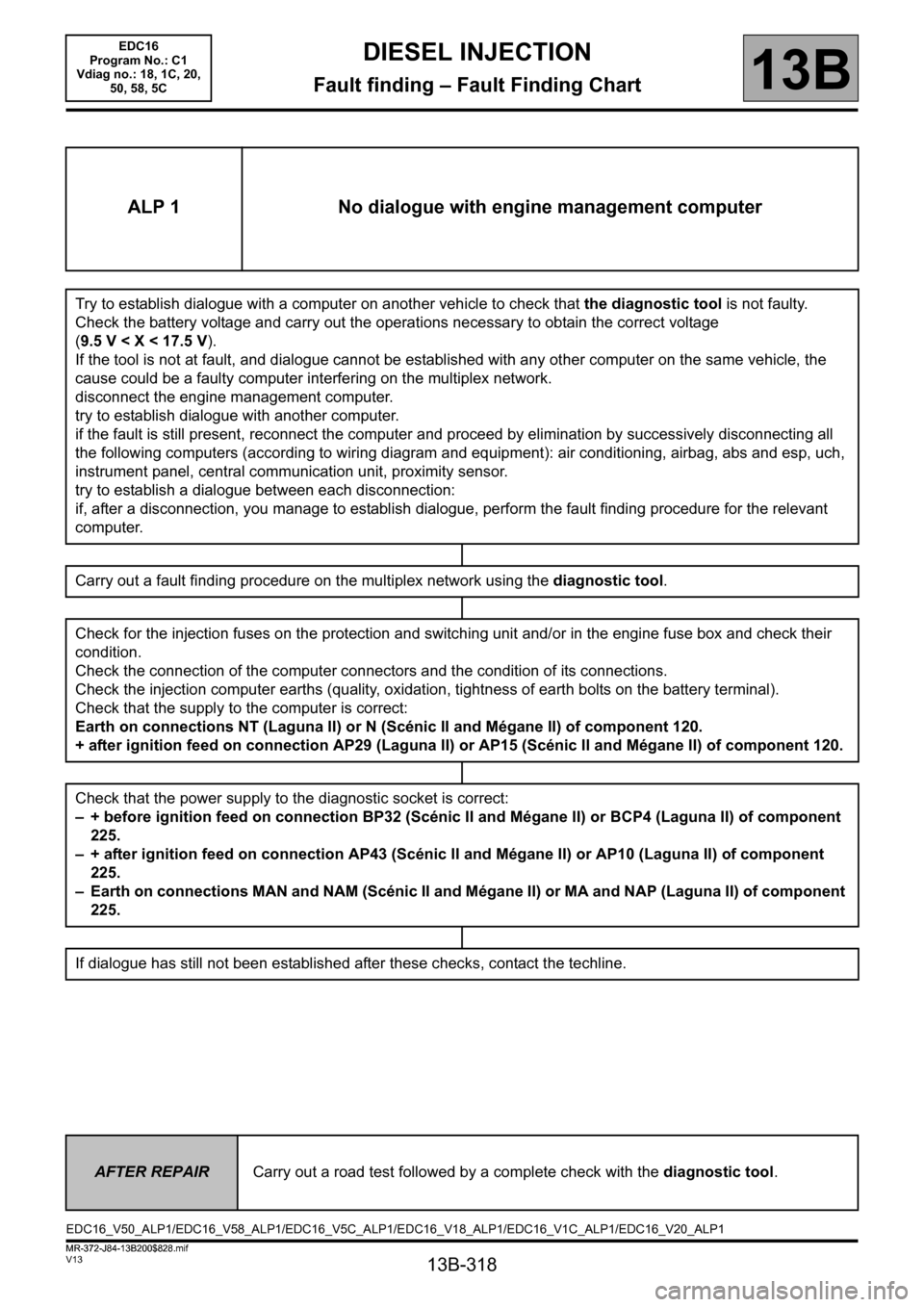

ALP 1 No dialogue with engine management computer

Try to establish dialogue with a computer on another vehicle to check that the diagnostic tool is not faulty.

Check the battery voltage and carry out the operations necessary to obtain the correct voltage

(9.5V

cause could be a faulty computer interfering on the multiplex network.

disconnect the engine management computer.

try to establish dialogue with another computer.

if the fault is still present, reconnect the computer and proceed by elimination by successively disconnecting all

the following computers (according to wiring diagram and equipment): air conditioning, airbag, abs and esp, uch,

instrument panel, central communication unit, proximity sensor.

try to establish a dialogue between each disconnection:

if, after a disconnection, you manage to establish dialogue, perform the fault finding procedure for the relevant

computer.

Carry out a fault finding procedure on the multiplex network using the diagnostic tool.

Check for the injection fuses on the protection and switching unit and/or in the engine fuse box and check their

condition.

Check the connection of the computer connectors and the condition of its connections.

Check the injection computer earths (quality, oxidation, tightness of earth bolts on the battery terminal).

Check that the supply to the computer is correct:

Earth on connections NT (Laguna II) or N (Scénic II and Mégane II) of component 120.

+ after ignition feed on connection AP29 (Laguna II) or AP15 (Scénic II and Mégane II) of component 120.

Check that the power supply to the diagnostic socket is correct:

– + before ignition feed on connection BP32 (Scénic II and Mégane II) or BCP4 (Laguna II) of component

225.

– + after ignition feed on connection AP43 (Scénic II and Mégane II) or AP10 (Laguna II) of component

225.

– Earth on connections MAN and NAM (Scénic II and Mégane II) or MA and NAP (Laguna II) of component

225.

If dialogue has still not been established after these checks, contact the techline.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16_V50_ALP1/EDC16_V58_ALP1/EDC16_V5C_ALP1/EDC16_V18_ALP1/EDC16_V1C_ALP1/EDC16_V20_ALP1 EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5C

MR-372-J84-13B200$828.mif

Page 328 of 365

13B-328

MR-372-J84-13B200$828.mif

V13

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Fault Finding Chart13B

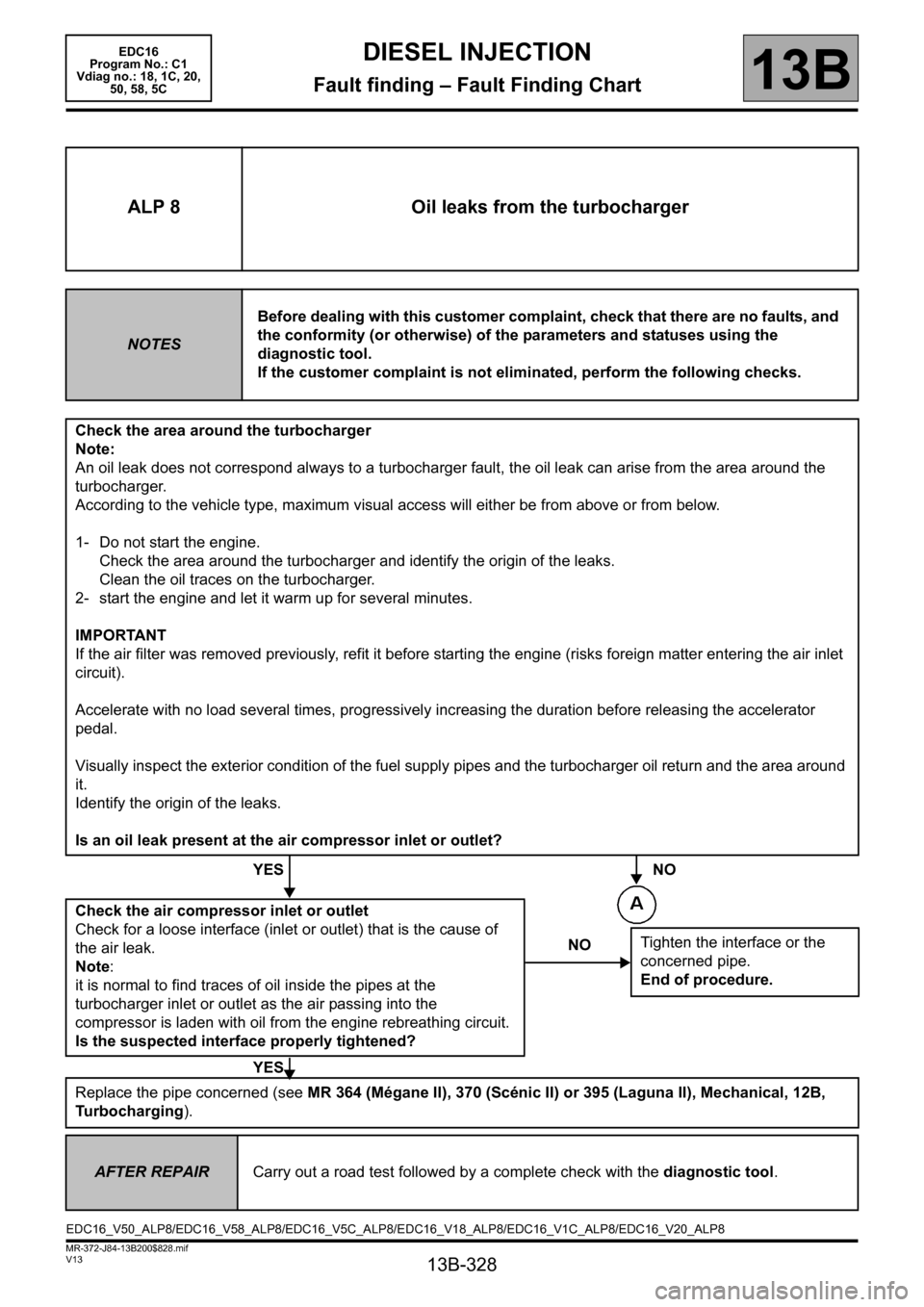

ALP 8 Oil leaks from the turbocharger

NOTESBefore dealing with this customer complaint, check that there are no faults, and

the conformity (or otherwise) of the parameters and statuses using the

diagnostic tool.

If the customer complaint is not eliminated, perform the following checks.

Check the area around the turbocharger

Note:

An oil leak does not correspond always to a turbocharger fault, the oil leak can arise from the area around the

turbocharger.

According to the vehicle type, maximum visual access will either be from above or from below.

1- Do not start the engine.

Check the area around the turbocharger and identify the origin of the leaks.

Clean the oil traces on the turbocharger.

2- start the engine and let it warm up for several minutes.

IMPORTANT

If the air filter was removed previously, refit it before starting the engine (risks foreign matter entering the air inlet

circuit).

Accelerate with no load several times, progressively increasing the duration before releasing the accelerator

pedal.

Visually inspect the exterior condition of the fuel supply pipes and the turbocharger oil return and the area around

it.

Identify the origin of the leaks.

Is an oil leak present at the air compressor inlet or outlet?

YES NO

Check the air compressor inlet or outlet

Check for a loose interface (inlet or outlet) that is the cause of

the air leak.

Note:

it is normal to find traces of oil inside the pipes at the

turbocharger inlet or outlet as the air passing into the

compressor is laden with oil from the engine rebreathing circuit.

Is the suspected interface properly tightened?

YES

Replace the pipe concerned (see MR 364 (Mégane II), 370 (Scénic II) or 395 (Laguna II), Mechanical, 12B,

Turbocharging).

NOTighten the interface or the

concerned pipe.

End of procedure.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16_V50_ALP8/EDC16_V58_ALP8/EDC16_V5C_ALP8/EDC16_V18_ALP8/EDC16_V1C_ALP8/EDC16_V20_ALP8

Page 332 of 365

13B-332

MR-372-J84-13B200$828.mif

V13

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Fault Finding Chart13B

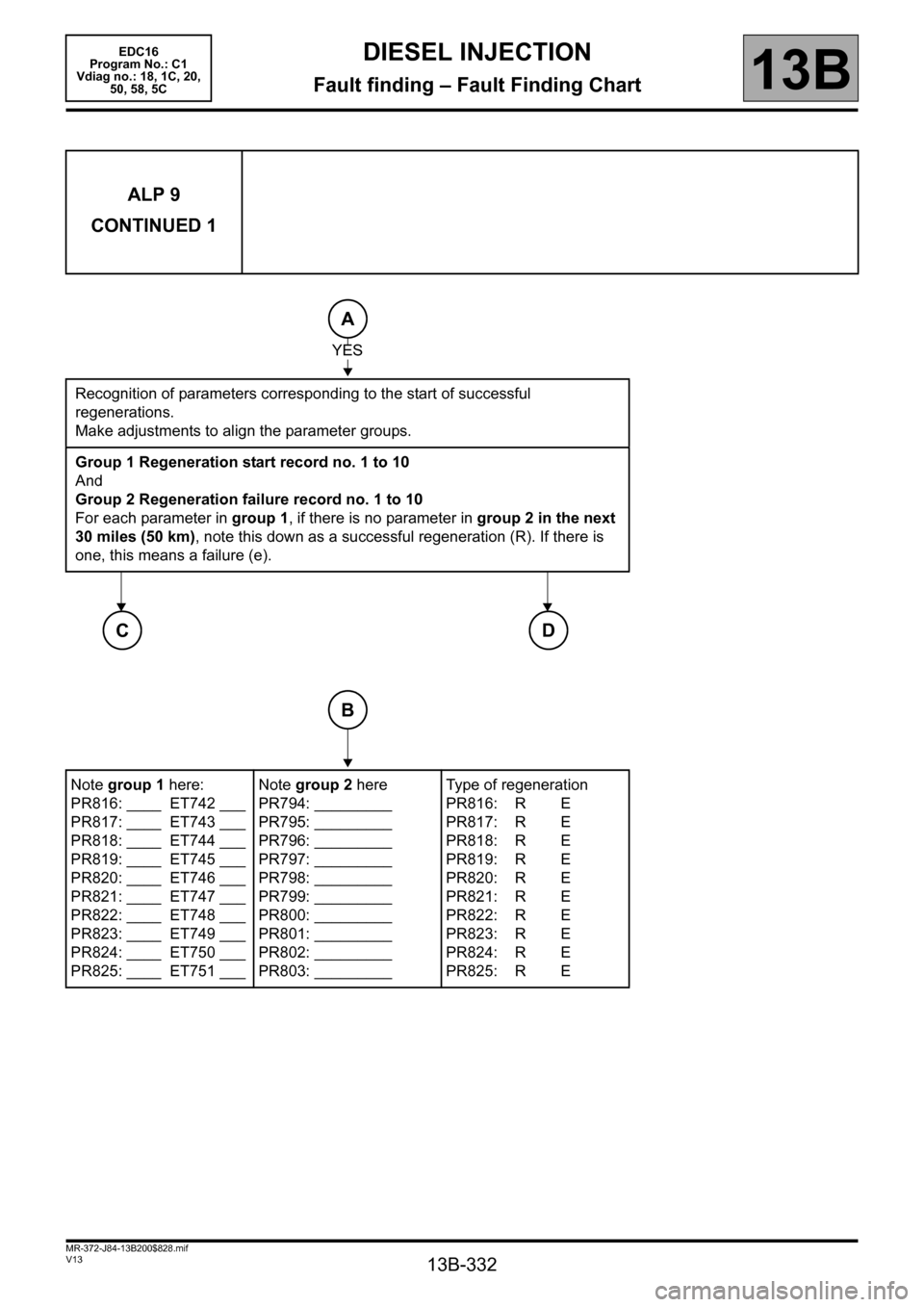

ALP 9

CONTINUED 1

Recognition of parameters corresponding to the start of successful

regenerations.

Make adjustments to align the parameter groups.

Group 1 Regeneration start record no. 1 to 10

And

Group 2 Regeneration failure record no. 1 to 10

For each parameter in group 1, if there is no parameter in group 2 in the next

30 miles (50 km), note this down as a successful regeneration (R). If there is

one, this means a failure (e).

Note group 1 here:

PR816: ____ ET742 ___

PR817: ____ ET743 ___

PR818: ____ ET744 ___

PR819: ____ ET745 ___

PR820: ____ ET746 ___

PR821: ____ ET747 ___

PR822: ____ ET748 ___

PR823: ____ ET749 ___

PR824: ____ ET750 ___

PR825: ____ ET751 ___Note group 2 here

PR794: _________

PR795: _________

PR796: _________

PR797: _________

PR798: _________

PR799: _________

PR800: _________

PR801: _________

PR802: _________

PR803: _________Type of regeneration

PR816: R E

PR817: R E

PR818: R E

PR819: R E

PR820: R E

PR821: R E

PR822: R E

PR823: R E

PR824: R E

PR825: R E

A

YES

CD

B

Page 337 of 365

13B-337

MR-372-J84-13B200$828.mif

V13

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Fault Finding Chart13B

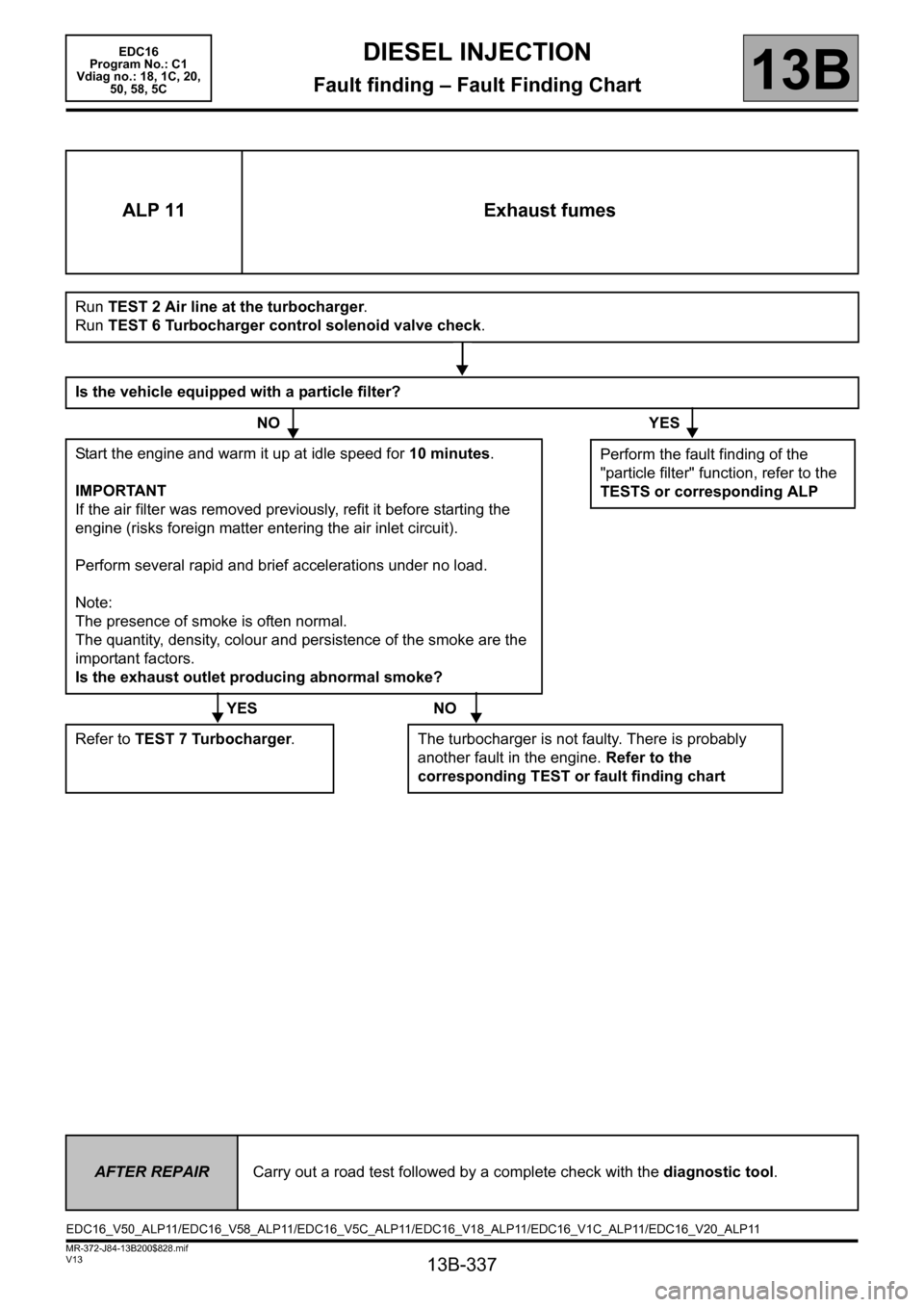

ALP 11 Exhaust fumes

Run TEST 2 Air line at the turbocharger.

Run TEST 6 Turbocharger control solenoid valve check.

Is the vehicle equipped with a particle filter?

NO YES

Start the engine and warm it up at idle speed for 10 minutes.

IMPORTANT

If the air filter was removed previously, refit it before starting the

engine (risks foreign matter entering the air inlet circuit).

Perform several rapid and brief accelerations under no load.

Note:

The presence of smoke is often normal.

The quantity, density, colour and persistence of the smoke are the

important factors.

Is the exhaust outlet producing abnormal smoke?

YES NO

Refer to TEST 7 Turbocharger. The turbocharger is not faulty. There is probably

another fault in the engine. Refer to the

corresponding TEST or fault finding chart

Perform the fault finding of the

"particle filter" function, refer to the

TESTS or corresponding ALP

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16_V50_ALP11/EDC16_V58_ALP11/EDC16_V5C_ALP11/EDC16_V18_ALP11/EDC16_V1C_ALP11/EDC16_V20_ALP11