engine RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 365, PDF Size: 2.11 MB

Page 17 of 365

13B-17

MR-372-J84-13B200$108.mif

V13

DIESEL INJECTION

Fault finding – System operation

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

If regeneration whilst driving has not been possible, the driver should request After-Sales regeneration in the

following cases:

– the soot weight is greater than 56 g for Vdiag 18.

– the soot weight is greater than 59 g or the number of failed regenerations is greater than 10 for Vdiag 1C

and 20.

This regeneration is carried out in the workshop. It is essential to follow the instructions described in the

interpretation of commands SC017 Particle filter regeneration. To carry out regeneration safely (see Te c h n i c a l

Note 5040A, Recommendations for particle filter regeneration).

Warning light management:

Instrument panel display

The computer manages the data display on the instrument panel relating to engine operation. This involves six

functions:

– the pre-postheating warning light,

– the coolant temperature warning light or warning message;

– the level 1 fault warning light (non-critical fault),

– the level 2 fault warning light (emergency stop),

– the OBD warning light (European On Board Diagnostic),

– particle filter warning message or light.

These six functions are represented by 4 or 5 warning lights and/or messages displayed by the trip computer.

In addition, for vehicles fitted with a voice synthesiser the illumination of some warning lights may be accompanied

by a spoken message (refer to the Driver's Handbook for the vehicle concerned).

A 3 second visual inspection (automatic test procedure managed by the instrument panel) is carried out by the

injection computer when the ignition is switched on.

Orange pre-post heating/non-critical fault SERVICE warning light (level 1)

This light is used both as an in-operation indicator light and as a system fault indicator:

– Continuously lit with + after ignition feed:

Indicates plug preheating (this light goes out when preheating is complete and the engine is able to start).

– Continuously lit accompanied by the message Check injection or Electronic fault:

Indicates a level 1 fault (involving operation of the injection system in defect mode).

The driver should carry out repairs as soon as possible. IMPORTANT

The particle filter must be replaced after a period of time which largely depends on the grade of engine oil used.

This information is provided in the vehicle's Driver's handbook.

After replacing the particle filter, it is essential to reconfigure certain parameters in the computer (see SC036

Reinitialise programming).

Page 18 of 365

13B-18

MR-372-J84-13B200$108.mif

V13

DIESEL INJECTION

Fault finding – System operation

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

Temperature warning light/red EMERGENCY STOP (level 2)

This indicator light is used both as an in-operation indicator light and as a system fault warning light. It lights up for

3 seconds after the ignition is switched on (automatic test procedure managed by the instrument panel):

– Continuously or intermittently lit, accompanied by the message Engine overheating:

Indicates engine overheating (the driver is free to choose whether or not to stop the vehicle).

–For Vdiag 50, 58 and 5C: continuously lit, accompanied by the message faulty injection:

Indicates a level 2 fault (in this case, the injection is automatically cut after a few seconds).

The driver should carry out repairs as soon as possible.

–For Vdiag 18, 1C and 20: continuously lit, accompanied by the message Injection fault: stop the engine and by

a bleep, this indicates a level 2 fault.

In that case, the vehicle must be stopped immediately (when traffic conditions allow).

The driver should carry out repairs as soon as possible.

ORANGE OBD excess pollution warning light

An engine symbol accompanied by the message Check emission control.

This warning light comes on if the system has one or more OBD faults.

This warning light is used to alert the driver of any injection faults that could lead to excessive pollution, or if the

EOBD system has been deactivated.

The injection computer requests illumination of the OBD warning light for a present fault only after three consecutive

driving cycles.

If it flashes, reduce the engine speed until the flashing stops.

The driver should carry out repairs as soon as possible.

The 3 second visual inspection when the ignition is switched on (automatic test procedure managed by the

instrument panel) is carried out by the injection computer.

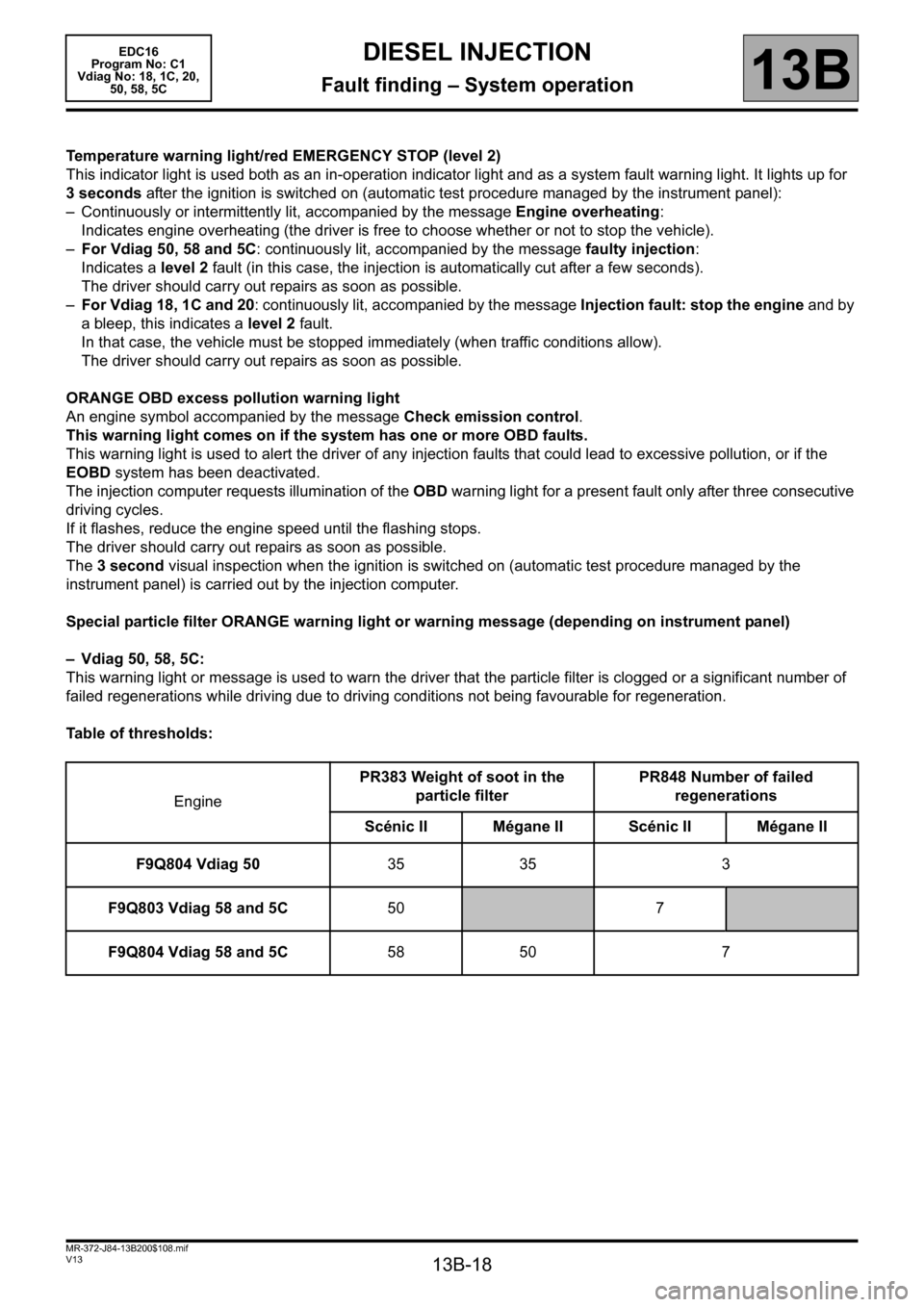

Special particle filter ORANGE warning light or warning message (depending on instrument panel)

– Vdiag 50, 58, 5C:

This warning light or message is used to warn the driver that the particle filter is clogged or a significant number of

failed regenerations while driving due to driving conditions not being favourable for regeneration.

Table of thresholds:

EnginePR383 Weight of soot in the

particle filterPR848 Number of failed

regenerations

Scénic II Mégane IIScénic II Mégane II

F9Q804 Vdiag 5035 35 3

F9Q803 Vdiag 58 and 5C50

7

F9Q804 Vdiag 58 and 5C58 50 7

Page 19 of 365

13B-19

MR-372-J84-13B200$108.mif

V13

DIESEL INJECTION

Fault finding – System operation

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

– Vdiag 18, 1C, 20:

This warning light or message is used to warn the driver that the particle filter is loaded with particles. This happens

when the soot weight is greater than 46 g or the number of failed regenerations is greater than:

– 8 for Vdiag 18.

– 6 for Vdiag 1C and 20.

The driver must then drive as soon as possible at an average speed of 48 mph (80 km/h) subject to the road

conditions and authorised speed limits.

EOBD management. (European On Board Diagnostic):

The OBD (On Board Diagnostic) system permits the detection of any faults relating to the vehicle emission control

system (OBD EURO IV emission control standards being exceeded).

This system should be active for the entire life of the vehicle.

1. OBD fault display conditions

An OBD fault will be detected after 3 driving cycles and the following parameters will be saved in the computer:

– engine load,

– vehicle speed

– air temperature

– coolant temperature,

– turbocharging pressure,

– rail pressure,

– air flow,

– distance travelled in miles by the vehicle since activation of the OBD warning light.

It allows the driver to know whether the vehicle has a fault directly linked to the emission control system.

Page 20 of 365

13B-20

MR-372-J84-13B200$108.mif

V13

DIESEL INJECTION

Fault finding – System operation

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

2. System faults displayed by the OBD

Only a few faults are displayed by the OBD system:

– DF001 Coolant temperature sensor circuit.

– DF003 Atmospheric pressure sensor circuit.

– DF011 Sensor supply voltage no. 1.

– DF012 Sensor supply voltage no. 2.

– DF013 Sensor supply voltage no. 3.

– DF038 Computer in 6.DEF EEPROM fault.

– DF040 Cylinder 1 injector circuit in CO Open circuit.

– DF041 Cylinder 2 injector circuit in CO Open circuit.

– DF042 Cylinder 3 injector circuit in CO Open circuit.

– DF043 Cylinder 4 injector circuit in CO Open circuit.

– DF054 Turbocharging solenoid valve control circuit in CC.0 Short circuit to earth.

– DF056 Air flowmeter circuit.

– DF209 EGR valve position sensor circuit.

– DF310 Particle filter upstream temp.* sensor.

– DF315 Particle filter diff.* pressure sensor.

– DF504 Automatic transmission.

– DF621 EGR valve jammed open.

– DF717 Particle filter upstream pressure.

– DF953 Particle filter absent.

Some repair operations require programming to ensure that certain engine components function correctly.

Follow the programming procedures (see Replacement of components), if replacing the exhaust gas

recirculation valve or an injector.

3. OBD fault clearing conditions

An OBD fault is cleared in several steps.

The fault present in the diagnostic tool will only be stored (after a repair operation) after the vehicle has been

driven 3 times.

The OBD warning light will only go out after these 3 trips.

The instrument panel warning light coming on does not automatically mean that the system has a fault.

In order for the OBD fault and display parameters to be cleared from the computer, the system requires

40 engine heating cycles.

An engine heating cycle is a driving cycle during which:

– the engine coolant temperature reaches at least 71.1°C,

– the engine coolant temperature varies by 22.2°C in relation to the engine starting temperature.

If one of these conditions is not fulfilled, the OBD fault will still be present or stored on the injection

computer.

* diff: differential

* temp: temperature

Page 21 of 365

13B-21

MR-372-J84-13B200$144.mif

V13

13B

DIESEL INJECTION

Fault finding – Replacement of components

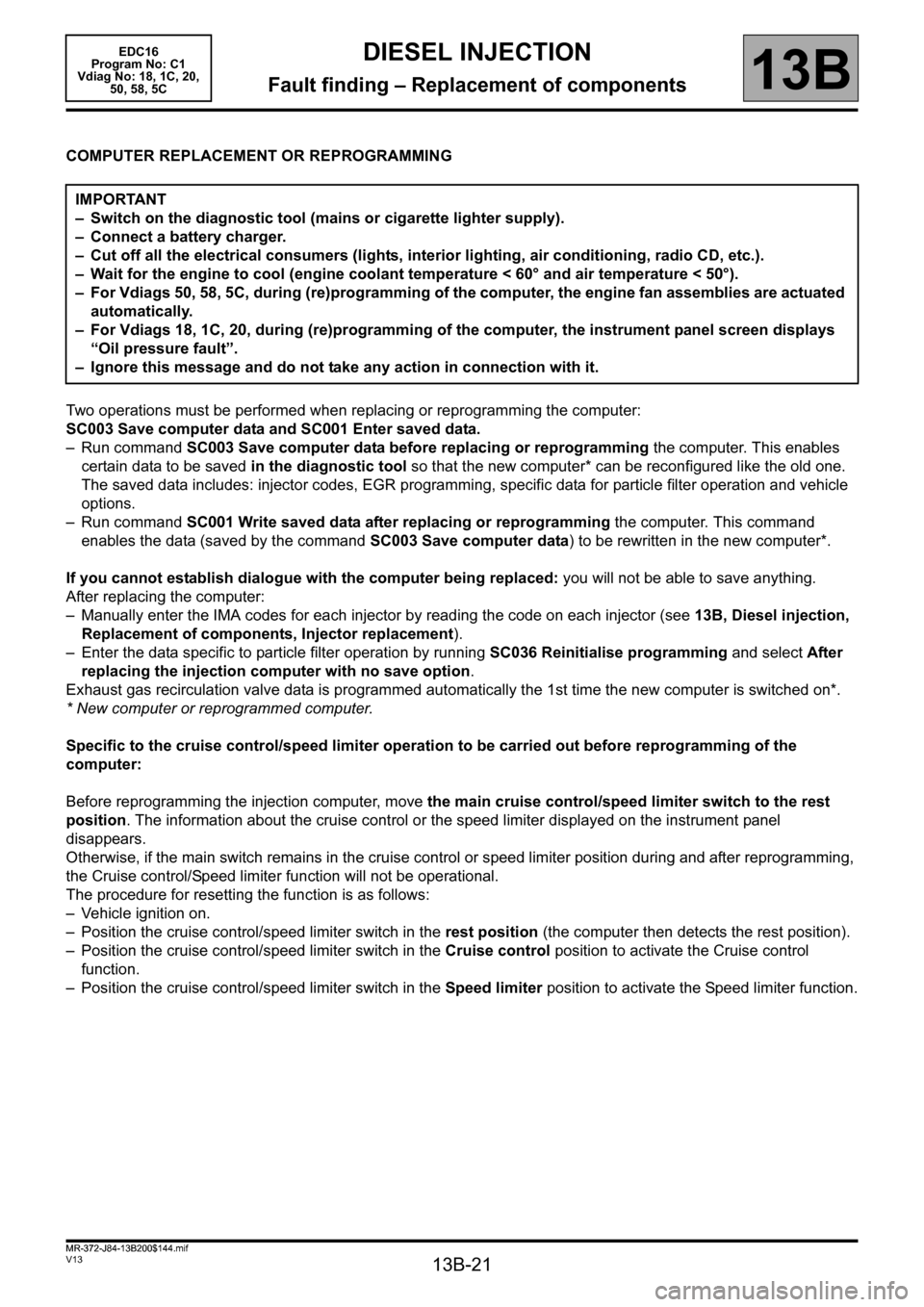

COMPUTER REPLACEMENT OR REPROGRAMMING

Two operations must be performed when replacing or reprogramming the computer:

SC003 Save computer data and SC001 Enter saved data.

– Run command SC003 Save computer data before replacing or reprogramming the computer. This enables

certain data to be saved in the diagnostic tool so that the new computer* can be reconfigured like the old one.

The saved data includes: injector codes, EGR programming, specific data for particle filter operation and vehicle

options.

– Run command SC001 Write saved data after replacing or reprogramming the computer. This command

enables the data (saved by the command SC003 Save computer data) to be rewritten in the new computer*.

If you cannot establish dialogue with the computer being replaced: you will not be able to save anything.

After replacing the computer:

– Manually enter the IMA codes for each injector by reading the code on each injector (see 13B, Diesel injection,

Replacement of components, Injector replacement).

– Enter the data specific to particle filter operation by running SC036 Reinitialise programming and select After

replacing the injection computer with no save option.

Exhaust gas recirculation valve data is programmed automatically the 1st time the new computer is switched on*.

* New computer or reprogrammed computer.

Specific to the cruise control/speed limiter operation to be carried out before reprogramming of the

computer:

Before reprogramming the injection computer, move the main cruise control/speed limiter switch to the rest

position. The information about the cruise control or the speed limiter displayed on the instrument panel

disappears.

Otherwise, if the main switch remains in the cruise control or speed limiter position during and after reprogramming,

the Cruise control/Speed limiter function will not be operational.

The procedure for resetting the function is as follows:

– Vehicle ignition on.

– Position the cruise control/speed limiter switch in the rest position (the computer then detects the rest position).

– Position the cruise control/speed limiter switch in the Cruise control position to activate the Cruise control

function.

– Position the cruise control/speed limiter switch in the Speed limiter position to activate the Speed limiter function. IMPORTANT

– Switch on the diagnostic tool (mains or cigarette lighter supply).

– Connect a battery charger.

– Cut off all the electrical consumers (lights, interior lighting, air conditioning, radio CD, etc.).

– Wait for the engine to cool (engine coolant temperature < 60° and air temperature < 50°).

– For Vdiags 50, 58, 5C, during (re)programming of the computer, the engine fan assemblies are actuated

automatically.

– For Vdiags 18, 1C, 20, during (re)programming of the computer, the instrument panel screen displays

“Oil pressure fault”.

– Ignore this message and do not take any action in connection with it.

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

MR-372-J84-13B200$144.mif

Page 23 of 365

13B-23

MR-372-J84-13B200$144.mif

V13

DIESEL INJECTION

Fault finding – Replacement of components

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

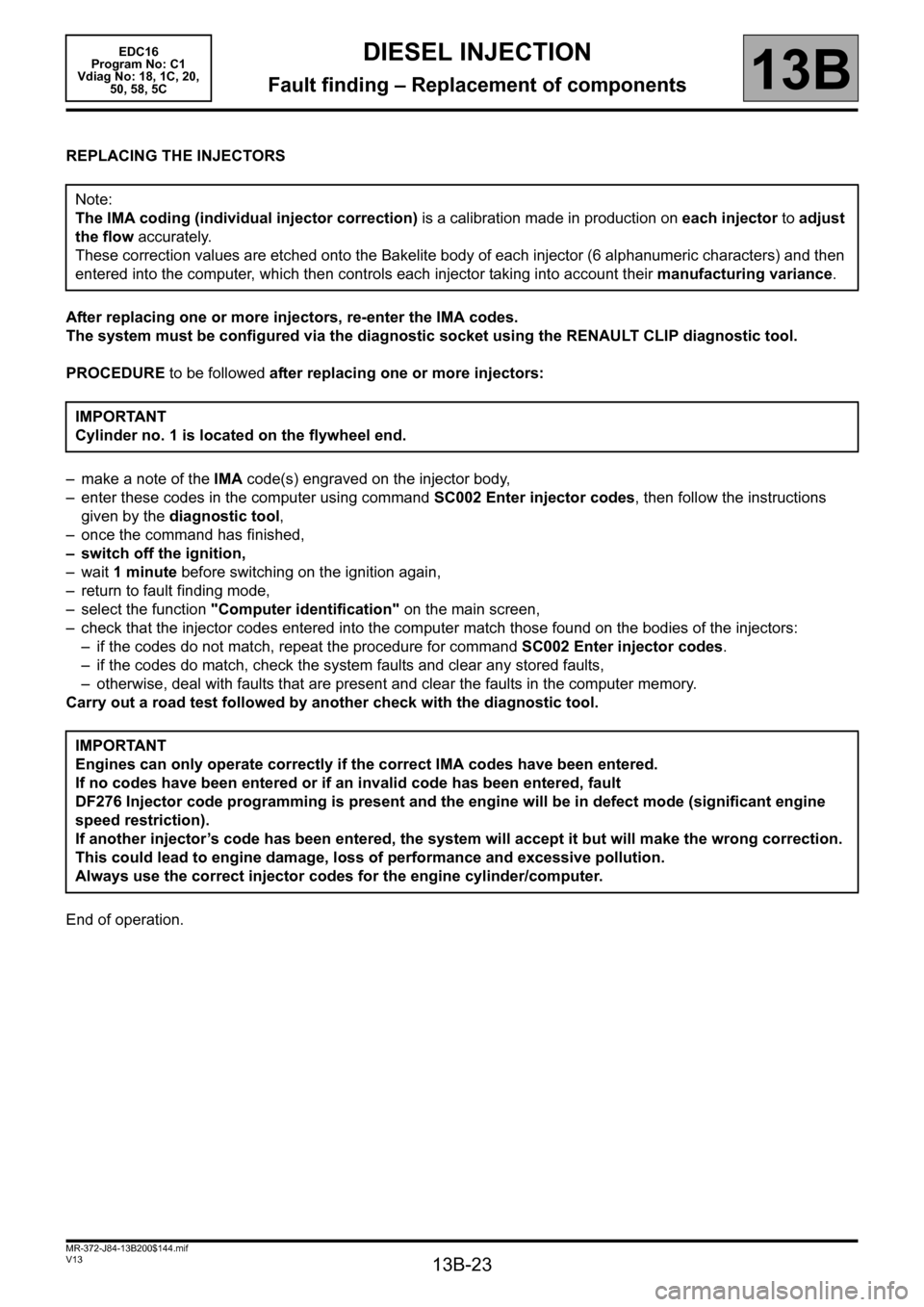

REPLACING THE INJECTORS

After replacing one or more injectors, re-enter the IMA codes.

The system must be configured via the diagnostic socket using the RENAULT CLIP diagnostic tool.

PROCEDURE to be followed after replacing one or more injectors:

– make a note of the IMA code(s) engraved on the injector body,

– enter these codes in the computer using command SC002 Enter injector codes, then follow the instructions

given by the diagnostic tool,

– once the command has finished,

– switch off the ignition,

–wait 1 minute before switching on the ignition again,

– return to fault finding mode,

– select the function "Computer identification" on the main screen,

– check that the injector codes entered into the computer match those found on the bodies of the injectors:

– if the codes do not match, repeat the procedure for command SC002 Enter injector codes.

– if the codes do match, check the system faults and clear any stored faults,

– otherwise, deal with faults that are present and clear the faults in the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

End of operation.Note:

The IMA coding (individual injector correction) is a calibration made in production on each injector to adjust

the flow accurately.

These correction values are etched onto the Bakelite body of each injector (6 alphanumeric characters) and then

entered into the computer, which then controls each injector taking into account their manufacturing variance.

IMPORTANT

Cylinder no. 1 is located on the flywheel end.

IMPORTANT

Engines can only operate correctly if the correct IMA codes have been entered.

If no codes have been entered or if an invalid code has been entered, fault

DF276 Injector code programming is present and the engine will be in defect mode (significant engine

speed restriction).

If another injector’s code has been entered, the system will accept it but will make the wrong correction.

This could lead to engine damage, loss of performance and excessive pollution.

Always use the correct injector codes for the engine cylinder/computer.

Page 27 of 365

13B-27

MR-372-J84-13B200$216.mif

V13

13B

DIESEL INJECTION

Fault finding – Fault summary table

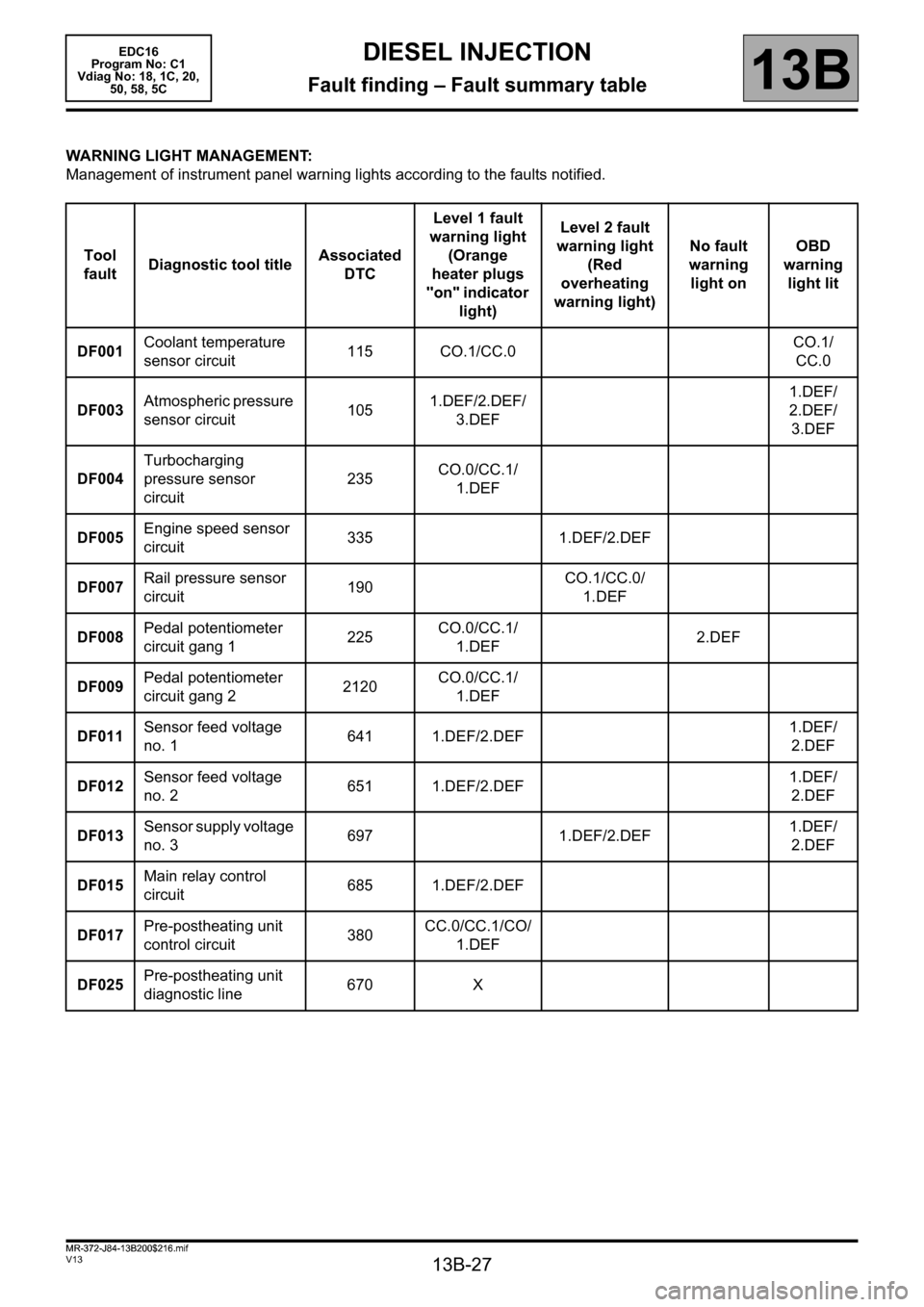

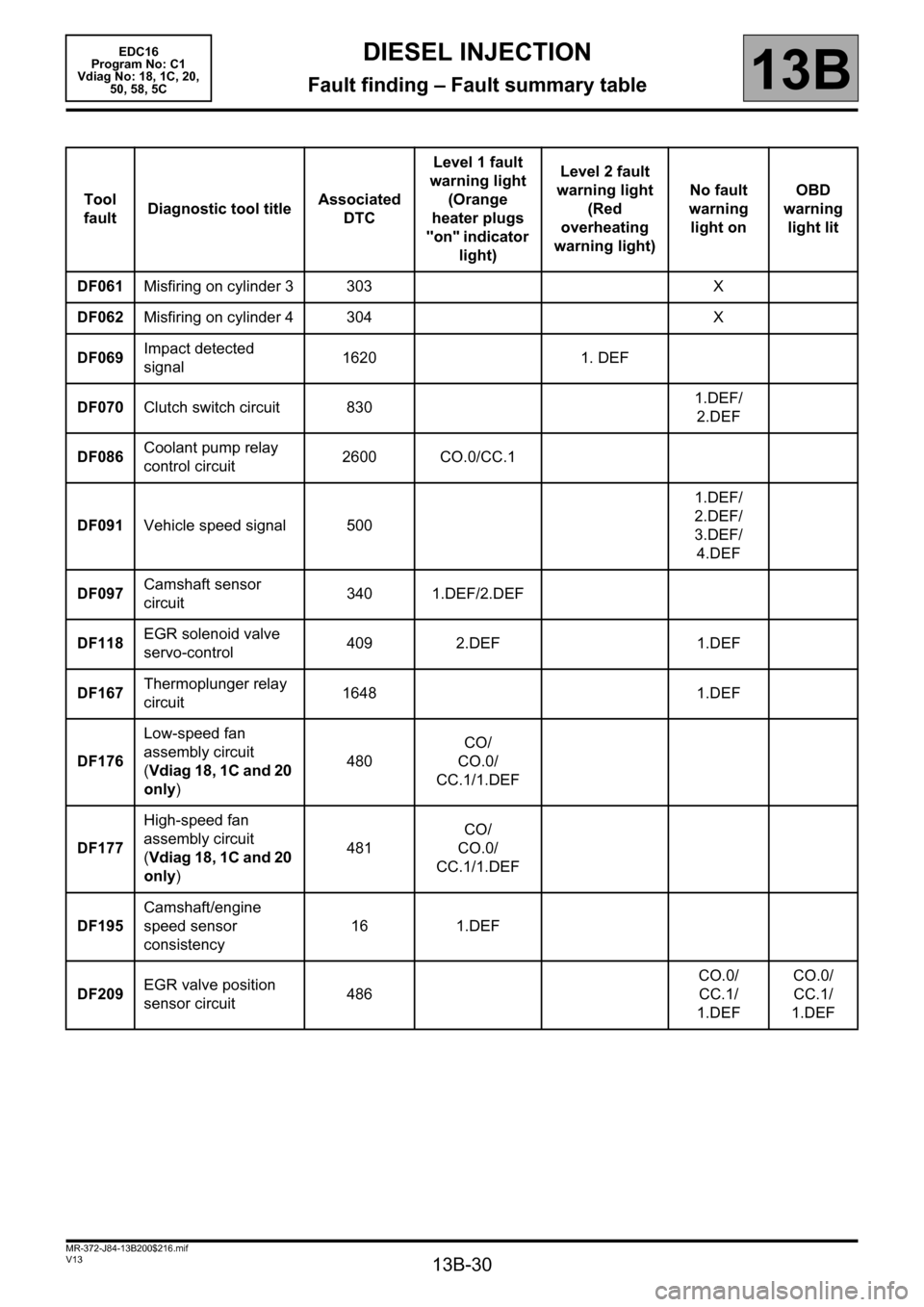

WARNING LIGHT MANAGEMENT:

Management of instrument panel warning lights according to the faults notified.

Tool

faultDiagnostic tool titleAssociated

DTCLevel 1 fault

warning light

(Orange

heater plugs

"on" indicator

light)Level 2 fault

warning light

(Red

overheating

warning light)No fault

warning

light onOBD

warning

light lit

DF001Coolant temperature

sensor circuit115 CO.1/CC.0CO.1/

CC.0

DF003Atmospheric pressure

sensor circuit1051.DEF/2.DEF/

3.DEF1.DEF/

2.DEF/

3.DEF

DF004Turbocharging

pressure sensor

circuit235CO.0/CC.1/

1.DEF

DF005Engine speed sensor

circuit335 1.DEF/2.DEF

DF007Rail pressure sensor

circuit190CO.1/CC.0/

1.DEF

DF008Pedal potentiometer

circuit gang 1225CO.0/CC.1/

1.DEF2.DEF

DF009Pedal potentiometer

circuit gang 22120CO.0/CC.1/

1.DEF

DF011Sensor feed voltage

no. 1641 1.DEF/2.DEF1.DEF/

2.DEF

DF012Sensor feed voltage

no. 2651 1.DEF/2.DEF1.DEF/

2.DEF

DF013Sensor supply voltage

no. 3697 1.DEF/2.DEF1.DEF/

2.DEF

DF015Main relay control

circuit685 1.DEF/2.DEF

DF017Pre-postheating unit

control circuit380CC.0/CC.1/CO/

1.DEF

DF025Pre-postheating unit

diagnostic line670 X

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

MR-372-J84-13B200$216.mif

Page 28 of 365

13B-28

MR-372-J84-13B200$216.mif

V13

DIESEL INJECTION

Fault finding – Fault summary table

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

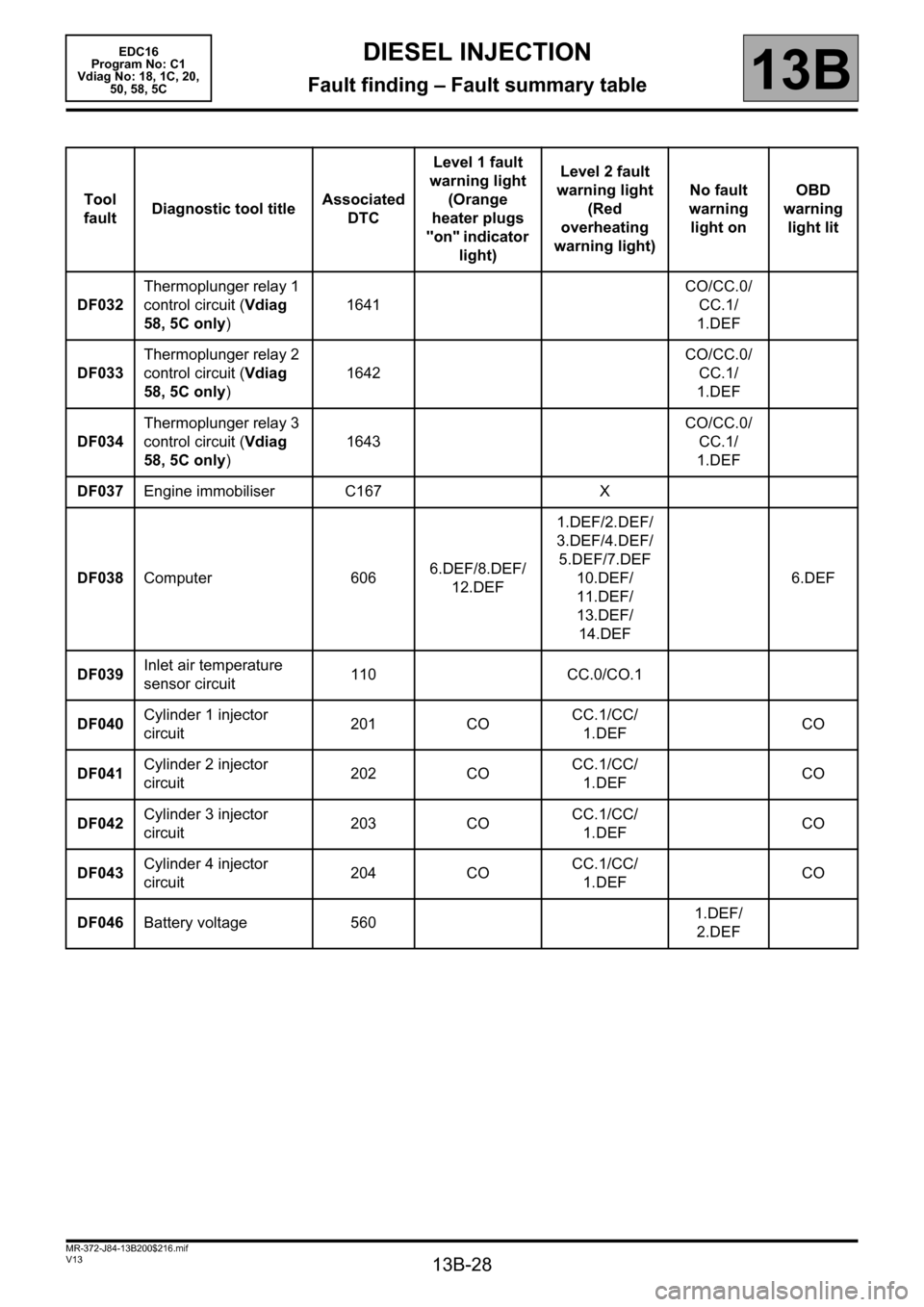

Tool

faultDiagnostic tool titleAssociated

DTCLevel 1 fault

warning light

(Orange

heater plugs

"on" indicator

light)Level 2 fault

warning light

(Red

overheating

warning light)No fault

warning

light onOBD

warning

light lit

DF032Thermoplunger relay 1

control circuit (Vdiag

58, 5C only)1641CO/CC.0/

CC.1/

1.DEF

DF033Thermoplunger relay 2

control circuit (Vdiag

58, 5C only)1642CO/CC.0/

CC.1/

1.DEF

DF034Thermoplunger relay 3

control circuit (Vdiag

58, 5C only)1643CO/CC.0/

CC.1/

1.DEF

DF037Engine immobiliser C167 X

DF038Computer 6066.DEF/8.DEF/

12.DEF1.DEF/2.DEF/

3.DEF/4.DEF/

5.DEF/7.DEF

10.DEF/

11.DEF/

13.DEF/

14.DEF6.DEF

DF039Inlet air temperature

sensor circuit110 CC.0/CO.1

DF040Cylinder 1 injector

circuit201 COCC.1/CC/

1.DEFCO

DF041Cylinder 2 injector

circuit202 COCC.1/CC/

1.DEFCO

DF042Cylinder 3 injector

circuit203 COCC.1/CC/

1.DEFCO

DF043Cylinder 4 injector

circuit204 COCC.1/CC/

1.DEFCO

DF046Battery voltage 5601.DEF/

2.DEF

Page 30 of 365

13B-30

MR-372-J84-13B200$216.mif

V13

DIESEL INJECTION

Fault finding – Fault summary table

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

Tool

faultDiagnostic tool titleAssociated

DTCLevel 1 fault

warning light

(Orange

heater plugs

"on" indicator

light)Level 2 fault

warning light

(Red

overheating

warning light)No fault

warning

light onOBD

warning

light lit

DF061Misfiring on cylinder 3 303 X

DF062Misfiring on cylinder 4 304 X

DF069Impact detected

signal1620 1. DEF

DF070Clutch switch circuit 8301.DEF/

2.DEF

DF086Coolant pump relay

control circuit2600 CO.0/CC.1

DF091Vehicle speed signal 5001.DEF/

2.DEF/

3.DEF/

4.DEF

DF097Camshaft sensor

circuit340 1.DEF/2.DEF

DF118EGR solenoid valve

servo-control409 2.DEF 1.DEF

DF167Thermoplunger relay

circuit1648 1.DEF

DF176 Low-speed fan

assembly circuit

(Vdiag 18, 1C and 20

only)480CO/

CO.0/

CC.1/1.DEF

DF177 High-speed fan

assembly circuit

(Vdiag 18, 1C and 20

only)481CO/

CO.0/

CC.1/1.DEF

DF195Camshaft/engine

speed sensor

consistency16 1.DEF

DF209EGR valve position

sensor circuit486CO.0/

CC.1/

1.DEFCO.0/

CC.1/

1.DEF

Page 33 of 365

13B-33

MR-372-J84-13B200$252.mif

V13

13B

DIESEL INJECTION

Fault finding – Interpretation of faults

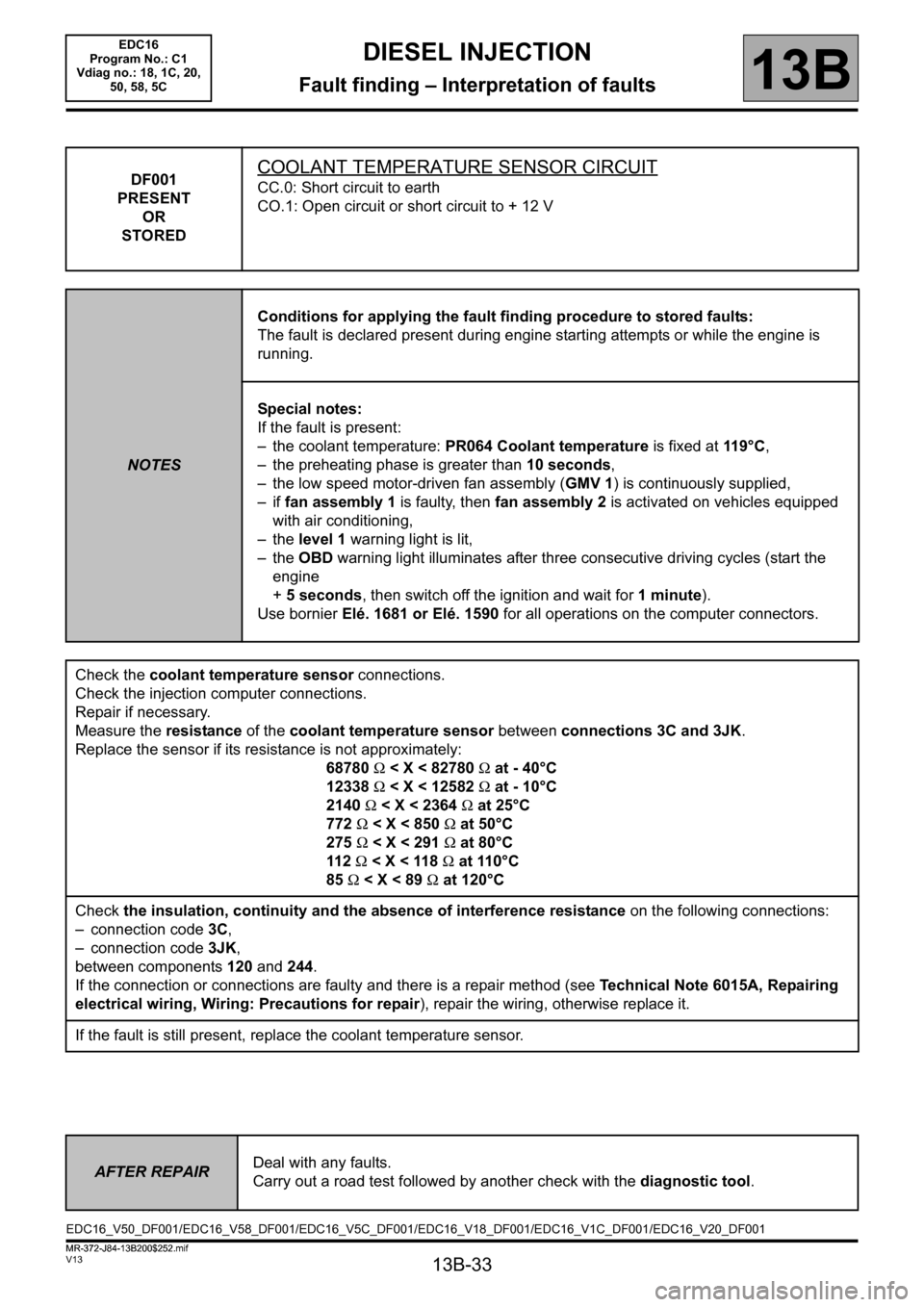

DF001

PRESENT

OR

STOREDCOOLANT TEMPERATURE SENSOR CIRCUIT

CC.0: Short circuit to earth

CO.1: Open circuit or short circuit to + 12 V

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present during engine starting attempts or while the engine is

running.

Special notes:

If the fault is present:

– the coolant temperature: PR064 Coolant temperature is fixed at 11 9 ° C,

– the preheating phase is greater than 10 seconds,

– the low speed motor-driven fan assembly (GMV 1) is continuously supplied,

–if fan assembly 1 is faulty, then fan assembly 2 is activated on vehicles equipped

with air conditioning,

– the level 1 warning light is lit,

– the OBD warning light illuminates after three consecutive driving cycles (start the

engine

+ 5 seconds, then switch off the ignition and wait for 1 minute).

Use bornier Elé. 1681 or Elé. 1590 for all operations on the computer connectors.

Check the coolant temperature sensor connections.

Check the injection computer connections.

Repair if necessary.

Measure the resistance of the coolant temperature sensor between connections 3C and 3JK.

Replace the sensor if its resistance is not approximately:

68780 Ω < X < 82780 Ω at - 40°C

12338 Ω < X < 12582 Ω at - 10°C

2140 Ω < X < 2364 Ω at 25°C

772 Ω < X < 850 Ω at 50°C

275 Ω < X < 291 Ω at 80°C

11 2 Ω < X < 118 Ω at 110°C

85 Ω < X < 89 Ω at 120°C

Check the insulation, continuity and the absence of interference resistance on the following connections:

– connection code3C,

– connection code 3JK,

between components 120 and 244.

If the connection or connections are faulty and there is a repair method (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the coolant temperature sensor.

AFTER REPAIRDeal with any faults.

Carry out a road test followed by another check with the diagnostic tool.

EDC16_V50_DF001/EDC16_V58_DF001/EDC16_V5C_DF001/EDC16_V18_DF001/EDC16_V1C_DF001/EDC16_V20_DF001EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5C

MR-372-J84-13B200$252.mif