engine oil RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 365, PDF Size: 2.11 MB

Page 296 of 365

13B-296

MR-372-J84-13B200$756.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of commands

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

SC017

CONTINUED 1

DESCRIPTION OF THE PROCESS

particle filter regeneration takes place in 3 stages (values given as a guide only):

–Warm-up phase: the engine speed is fixed or varies between 1000 rpm and 1650 rpm.

This phase lasts at least 3 minutes, until the coolant temperature exceeds 80°C.

–Regeneration phase: the engine speed is fixed or varies between 1000 rpm and 1650 rpm. Engine injection

is retarded. The exhaust fumes rise in temperature and burn the soot retained in the particle filter. The particle

filter downstream temperature starts to rise after the particle filter upstream temperature due to the

volume of the particle filter. Then the combustion of the soot stored in the particle filter causes the particle filter

downstream temperature to increase, possibly reaching more than 700°C depending on the amount of soot in

the filter (with a particle filter upstream temperature of approximately 600°C). This phase lasts between 20

and 25 minutes.

–Cooling phase: the engine speed is fixed or varies between 1000 rpm and 1650 rpm.

Engine injection returns to normal and the exhaust gases cool the particle filter.

This phase lasts 3 minutes. At the end of this period, the engine speed returns to idle speed or remains fixed at

1500 rpm.

The process lasts at least 30 minutes (regeneration time will be increased depending on how long it takes for

the coolant temperature to reach 80°C).

CONFIRMING THE REGENERATION PROCESS:

At the end of regeneration, a message appears to announce whether the regeneration was successful:

●Particle filter regeneration finished:

Consult PR1012 Weight of soot after regeneration. If PR1012 is less than 15 g, the particle filter regeneration

completed correctly. If PR1012 is greater than 15 g, a second particle filter regeneration must be performed using

the command in the diagnostic tool and choose command SC017.

IMPORTANT:

Before performing a second After-Sales regeneration of the particle filter, the engine must be allowed to cool

down for 2 hours with the bonnet open.

Do not systematically change the engine oil before a second After-Sales regeneration.

Consult PR848 Number of regeneration failures. If PR848 is greater than 3, change the engine oil.

●Particle filter too full – replace the particle filter: regeneration has failed. The weight of soot in the particle

filter is so great that it is creating back-pressure. Deal with any faults that appear or replace the particle filter.

Run command SC036 Reinitialise programming and select After particle filter replacement.

Check the weight of soot: PR383 Weight of soot in the particle filter.

If PR383

≥ 1 g. Apply the procedure for test 8 Manual clearing of the soot weight.

Page 297 of 365

13B-297

MR-372-J84-13B200$756.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of commands

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

SC017

CONTINUED 2

–Consult PR848 Number of regeneration failures. If this parameter is greater than 3, it is essential to change

the engine oil.

– Explain to the customer the procedure for regeneration when driving to avoid unnecessary repairs: see PART D

in the interpretation of DF312 Speed request.

●Particle filter regeneration failed – run test "Temperature upstream of turbine too low": regeneration

has failed because the temperature upstream of the turbine is too low. Run test 10 Temperature upstream

of turbine too low.

In all cases, carry out the following operations:

– switch off the ignition and wait for the diagnostic tool message (maximum wait 8 minutes): Loss of dialogue

with the computer: EDC16, check the tool connection and the computer supply.

– switch on the ignition and establish dialogue with the injection computer,

– run command SC036 Reinitialise programming,

– depending on the operation performed, select After particle filter regeneration with diag tool, or After

particle filter replacement

– switch off the ignition and wait for the diagnostic tool message (maximum wait 8 minutes): Loss of dialogue

with the computer: EDC16, check the tool connection and the computer supply.

–Then switch on the ignition again, clear the present or stored faults from the computer memory (operation

to be carried out within 3 minutes of switching on the ignition).

Check the weight of soot: PR383 Weight of soot in the particle filter.

If PR383

≥ 1 g. Apply the procedure for test 8 Manual clearing of the soot weight.

If DF308 Clogged particle filter or DF312 Speed request is still present, contact the Techline.

Note:

It is essential to change the engine oil and the oil filter in the following cases:

– following an After-Sales regeneration only if a message on the CLIP diagnostic tool requests it,

– after particle filter replacement following DF311 Number of failed regenerations exceeded (present or stored

before regeneration),

– after a second regeneration (when two successive regenerations).

Page 309 of 365

13B-309

MR-372-J84-13B200$756.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of commands

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

AC031

CONTINUED

vdiag 18, 1C, 20:

If the additional heater no. 3 relay does not operate when running command AC031:

Check the additional heater no. 3 relay mounting.

check the engine management computer connections.

Repair if necessary.

if the fault is still present, check as follows that this relay is controlled by the engine management computer:

Disconnect the additional heater no. 3 relay, fit a 50 to 100Ω resistor on the mounting in place of the coil and

connect a voltmeter as follows:

Positive terminal to +12 V battery.

Negative terminal to connection 3JAB of the additional heater no. 3 relay mounting.

Clear the fault and actuate the relay using command AC031.

If the voltmeter shows the battery voltage (two, 2-second ON-OFF cycles), replace the additional heater no. 3

relay.

If the voltmeter does not show the battery voltage (two 2 second ON-OFF cycles), contact the Techline.

If the additional heater no. 3 relay is supplied by command AC031, but there is still a fault with the passenger

compartment heating and demisting, check using a wiring diagram:

– the conformity of the thermoplunger maxi-fuse,

– the presence of + 12 V battery on connection BP9 of the additional heater no. 3 relay mounting,

– the conformity of the additional heater relay 3;

– the continuity between connection 3JAC of the additional heater no. 3 relay mounting and the supply terminal

for thermoplunger no. 3.

– the conformity of the thermoplunger resistance: 0.4 Ω < X < 0.5 Ω at 20 °C,

– the presence of earth at the water chamber (thermoplunger mounting).

Also check the level of the cooling circuit and that there are no leaks.

Carry out the necessary repairs.

Page 310 of 365

13B-310

MR-372-J84-13B200$756.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of commands

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

AC038

LOW-SPEED FAN ASSEMBLY RELAY

NOTESThere must be no present or stored faults.

Perform this fault finding procedure if a malfunction appears on the command menu

or after an engine cooling system or air conditioning fault.

Refer to the Wiring diagrams Technical Note for the vehicle to locate the fuses and

relays concerned.

If the low-speed fan assembly relay does not operate when command AC038 is run:

Check the low speed fan relay mounting and the connections of the engine management computer.

Repair if necessary.

If the fault is still present, check that the relay is actuated by the engine management computer as follows:

Disconnect the low-speed fan assembly relay, fit a 50 Ω < X < 100 Ω resistor on the relay mounting in place of

the coil, and connect a voltmeter as follows:

Positive terminal to the +12 V battery.

Negative terminal to connection 3JN of the low-speed fan assembly relay mounting.

Clear the fault and run command AC038

If the voltmeter indicates the battery voltage (three 2-second ON-OFF cycles), replace the relay.

If the voltmeter does not show the battery voltage (three 2 second ON-OFF cycles), contact the techline.

If the low speed fan assembly relay operates when command AC038, is run, but there is still a fan assembly

activation fault, use the wiring diagram to check the following:

– the conformity of the fan assembly maxi-fuse.

– the conformity of the low-speed fan unit relay,

– the continuity of connection 49L between components 597 and 321.

– the continuity of connection 49B between components 321 and 262.

– the conformity of the fan assembly and the continuity of connection MAS of component 262.

Carry out the necessary repairs.

EDC16_V18_AC038/EDC16_V1C_AC038/EDC16_V20_AC038

Page 311 of 365

13B-311

MR-372-J84-13B200$756.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of commands

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

AC039

HIGH-SPEED FAN ASSEMBLY RELAY

NOTESThere must be no present or stored faults.

Perform this fault finding procedure if a malfunction appears on the command menu

or after an engine cooling system or air conditioning fault.

Refer to the Wiring Diagrams Technical Note for the vehicle to locate the fuses and

relays concerned.

If the high-speed fan assembly relay does not operate when command AC039 is run:

Check the high-speed fan assembly relay mounting and the connections of the engine management computer.

Repair if necessary.

If the fault is still present, check that the relay is actuated by the engine management computer as follows:

Disconnect the high-speed fan assembly relay, fit a 50 Ω < X < 100 Ω resistor on its mounting in place of the

coil, and connect a voltmeter as follows:

Positive terminal to the +12 V battery.

Negative terminal to connection 3JP of the high-speed fan assembly relay mounting.

Clear the fault and run command AC039.

If the voltmeter indicates the battery voltage (three 2-second ON-OFF cycles), replace the relay.

If the voltmeter does not show the battery voltage (three 2 second ON-OFF cycles), contact the techline.

If the high-speed fan assembly relay is supplied by command AC039, but there remains a fault with the

triggering the fan assembly. Check using the wiring diagram:

– the conformity of the fan assembly maxi-fuse.

– + battery feed on connection BP71 of the high-speed fan assembly relay mounting,

– the conformity of the high-speed fan assembly relay,

– the continuity of connection 49B between components 597 and 262,

– the conformity of the fan assembly,

– the continuity of connection MAS of component 262.

Carry out the necessary repairs.

EDC16_V18_AC039/EDC16_V1C_AC039/EDC16_V20_AC039

Page 313 of 365

13B-313

MR-372-J84-13B200$756.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of commands

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

AC063

CONTINUED

vdiag 18, 1C, 20:

If the additional heater no. 1 relay does not operate when running command AC063:

Check the additional heater no. 1 relay mounting.

Check the engine management computer connectors.

Repair if necessary.

if the fault is still present, check as follows that this relay is controlled by the engine management computer:

Disconnect the additional heater no. 1 relay, fit a 50 Ω < X < 100 Ω resistor on the relay mounting in place of the

coil, and connect a voltmeter as follows:

Positive terminal to the +12 V battery.

Negative terminal to connection 3JA of component 597.

Clear the fault and actuate the relay using command AC063.

If the voltmeter shows the battery voltage (two, 2-second ON-OFF cycles), replace the additional heater no. 1

relay.

If the voltmeter does not show the battery voltage (two, 2-second ON-OFF cycles), contact the Techline.

If the additional heater no. 1 relay is supplied by command AC063, but there is still a fault with the passenger

compartment heating and demisting, check the following using a wiring diagram:

– the conformity of the thermoplunger maxi-fuse,

–+12V battery on connection 3FB of component 597.

– the conformity of the additional heater no. 1 relay,

– the continuity between connection 3JB of component 597 and connection 3JB of component 898,

– the conformity of the thermoplunger resistance: 0.40 Ω < X < 0.50 Ω at 20°C,

– the presence of earth at the water chamber (thermoplunger mounting).

Also check the level of the cooling circuit and that there are no leaks.

Carry out the necessary repairs.

Page 315 of 365

13B-315

MR-372-J84-13B200$756.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of commands

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

AC064

CONTINUED

vdiag 18, 1c, 20:

If the additional heater no. 2 relay does not operate when running command AC064,

check the additional heater no. 2 relay mounting,

check the connectors on the engine management computer.

Repair if necessary.

if the fault is still present, check as follows that this relay is controlled by the engine management computer:

Disconnect the additional heater no. 2 relay, fit a 50 Ω < X < 100 Ω resistor on the mounting in place of the coil,

and connect a voltmeter as follows:

Positive terminal to the +12 V battery.

Negative terminal to connection 3JAA of component 597.

Clear the fault and actuate the relay via command AC064.

If the voltmeter shows the battery voltage (two 2-second ON-OFF cycles), replace the additional heater 1 relay.

If the voltmeter does not show the battery voltage (two 2 second ON-OFF cycles), contact the Techline.

If the additional heater no. 2 relay is supplied by command AC064, but there is still a fault with the passenger

compartment heating and demisting, use the wiring diagram to check the following:

– the conformity of the thermoplunger maxi-fuse,

–+12V battery on connection BP91 of component 597,

– the conformity of the additional heater no. 2 relay,

– the continuity of connection 3JAD between components 597 and 1072.

– the conformity of the thermoplunger resistance: 0.40 Ω < X < 0.50 Ω at 20°C,

– the presence of earth at the water chamber (thermoplunger mounting).

Also check the level of the cooling circuit and that there are no leaks.

Carry out the necessary repairs.

Page 317 of 365

13B-317

MR-372-J84-13B200$792.mif

V13

13B

DIESEL INJECTION

Fault finding – Customer complaints

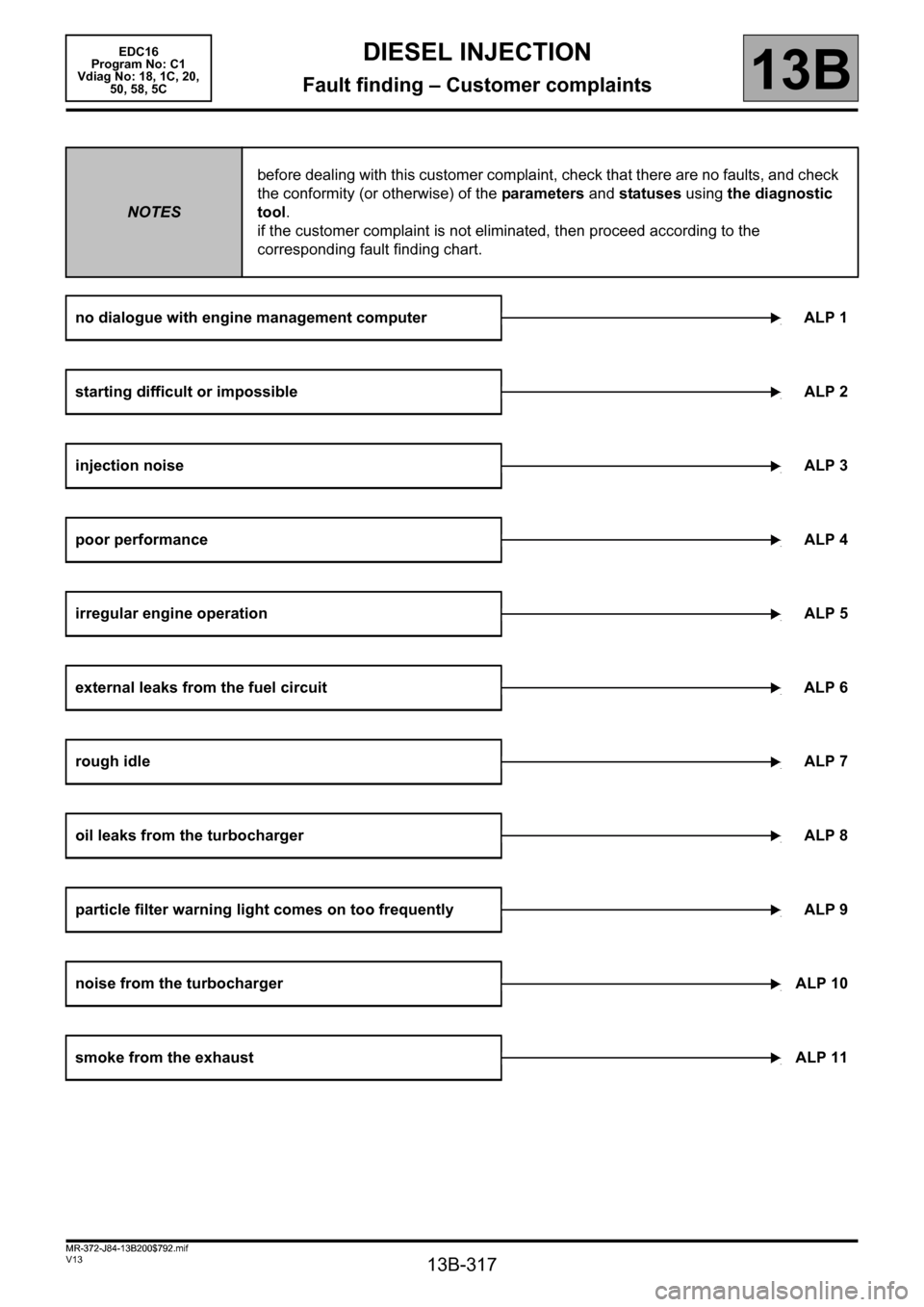

NOTESbefore dealing with this customer complaint, check that there are no faults, and check

the conformity (or otherwise) of the parameters and statuses using the diagnostic

tool.

if the customer complaint is not eliminated, then proceed according to the

corresponding fault finding chart.

no dialogue with engine management computer ALP 1

starting difficult or impossibleALP 2

injection noiseALP 3

poor performanceALP 4

irregular engine operationALP 5

external leaks from the fuel circuit ALP 6

rough idleALP 7

oil leaks from the turbochargerALP 8

particle filter warning light comes on too frequently ALP 9

noise from the turbochargerALP 10

smoke from the exhaustALP 11

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

MR-372-J84-13B200$792.mif

Page 323 of 365

13B-323

MR-372-J84-13B200$828.mif

V13

DIESEL INJECTION

Fault finding – Fault Finding Chart

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5C

13B

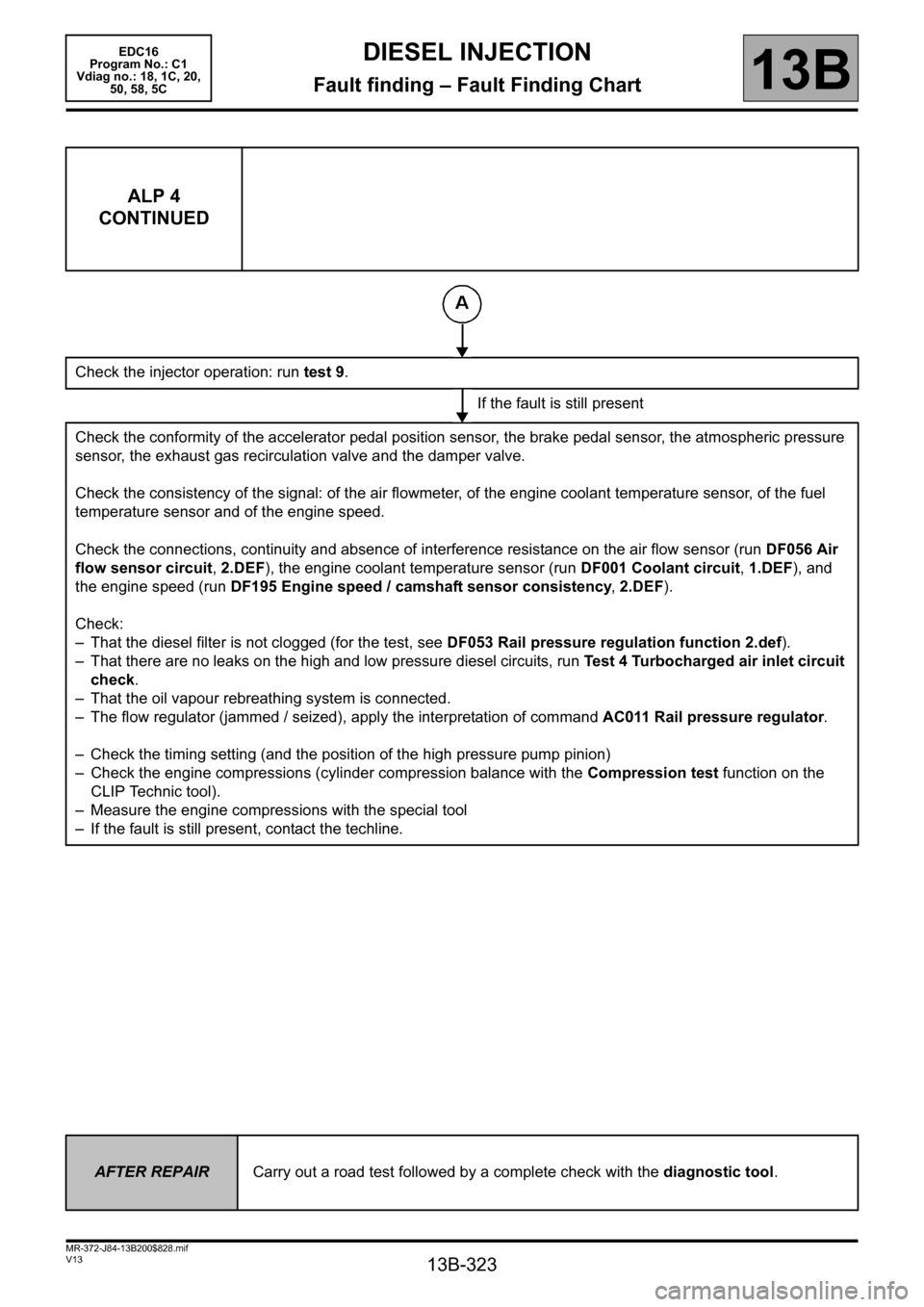

ALP 4

CONTINUED

Check the injector operation: run test 9.

If the fault is still present

Check the conformity of the accelerator pedal position sensor, the brake pedal sensor, the atmospheric pressure

sensor, the exhaust gas recirculation valve and the damper valve.

Check the consistency of the signal: of the air flowmeter, of the engine coolant temperature sensor, of the fuel

temperature sensor and of the engine speed.

Check the connections, continuity and absence of interference resistance on the air flow sensor (run DF056 Air

flow sensor circuit, 2.DEF), the engine coolant temperature sensor (run DF001 Coolant circuit, 1.DEF), and

the engine speed (run DF195 Engine speed / camshaft sensor consistency, 2.DEF).

Check:

– That the diesel filter is not clogged (for the test, see DF053 Rail pressure regulation function 2.def).

– That there are no leaks on the high and low pressure diesel circuits, run Test 4 Turbocharged air inlet circuit

check.

– That the oil vapour rebreathing system is connected.

– The flow regulator (jammed / seized), apply the interpretation of command AC011 Rail pressure regulator.

– Check the timing setting (and the position of the high pressure pump pinion)

– Check the engine compressions (cylinder compression balance with the Compression test function on the

CLIP Technic tool).

– Measure the engine compressions with the special tool

– If the fault is still present, contact the techline.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

Page 328 of 365

13B-328

MR-372-J84-13B200$828.mif

V13

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Fault Finding Chart13B

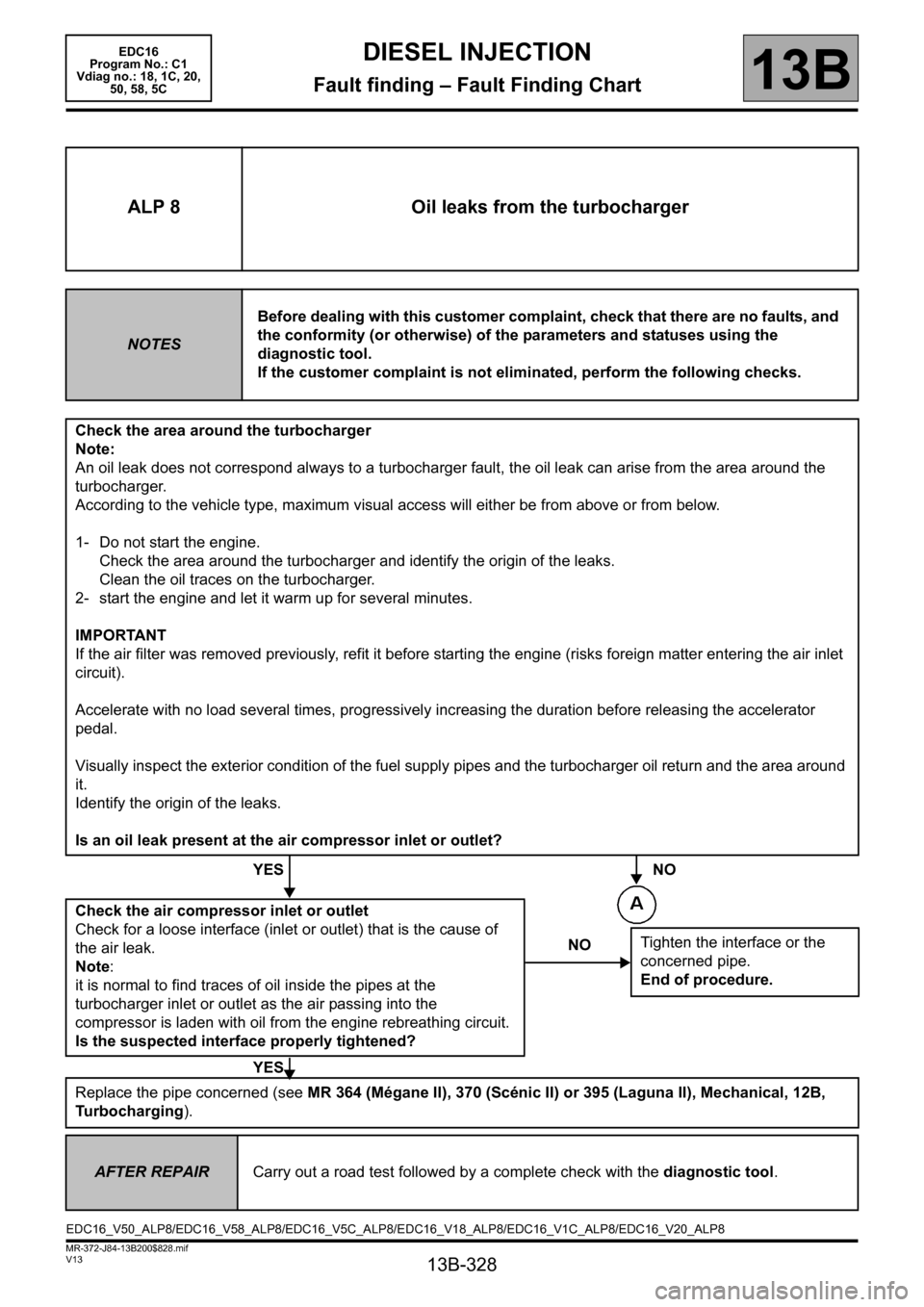

ALP 8 Oil leaks from the turbocharger

NOTESBefore dealing with this customer complaint, check that there are no faults, and

the conformity (or otherwise) of the parameters and statuses using the

diagnostic tool.

If the customer complaint is not eliminated, perform the following checks.

Check the area around the turbocharger

Note:

An oil leak does not correspond always to a turbocharger fault, the oil leak can arise from the area around the

turbocharger.

According to the vehicle type, maximum visual access will either be from above or from below.

1- Do not start the engine.

Check the area around the turbocharger and identify the origin of the leaks.

Clean the oil traces on the turbocharger.

2- start the engine and let it warm up for several minutes.

IMPORTANT

If the air filter was removed previously, refit it before starting the engine (risks foreign matter entering the air inlet

circuit).

Accelerate with no load several times, progressively increasing the duration before releasing the accelerator

pedal.

Visually inspect the exterior condition of the fuel supply pipes and the turbocharger oil return and the area around

it.

Identify the origin of the leaks.

Is an oil leak present at the air compressor inlet or outlet?

YES NO

Check the air compressor inlet or outlet

Check for a loose interface (inlet or outlet) that is the cause of

the air leak.

Note:

it is normal to find traces of oil inside the pipes at the

turbocharger inlet or outlet as the air passing into the

compressor is laden with oil from the engine rebreathing circuit.

Is the suspected interface properly tightened?

YES

Replace the pipe concerned (see MR 364 (Mégane II), 370 (Scénic II) or 395 (Laguna II), Mechanical, 12B,

Turbocharging).

NOTighten the interface or the

concerned pipe.

End of procedure.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16_V50_ALP8/EDC16_V58_ALP8/EDC16_V5C_ALP8/EDC16_V18_ALP8/EDC16_V1C_ALP8/EDC16_V20_ALP8