check engine RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 365, PDF Size: 2.11 MB

Page 340 of 365

13B-340

MR-372-J84-13B200$900.mif

V13

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Tests13B

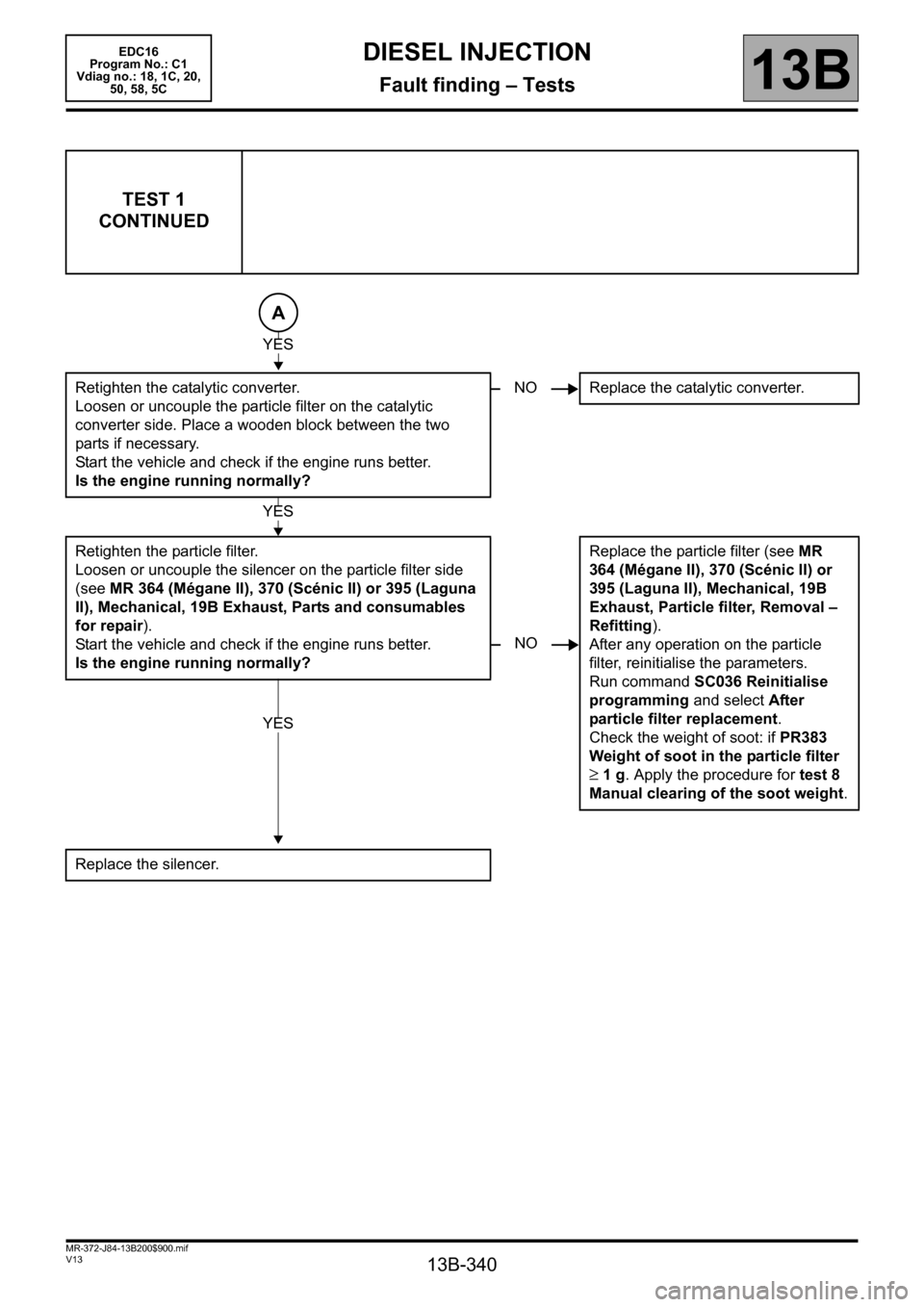

TEST 1

CONTINUED

Retighten the catalytic converter.

Loosen or uncouple the particle filter on the catalytic

converter side. Place a wooden block between the two

parts if necessary.

Start the vehicle and check if the engine runs better.

Is the engine running normally?Replace the catalytic converter.

Retighten the particle filter.

Loosen or uncouple the silencer on the particle filter side

(see MR 364 (Mégane II), 370 (Scénic II) or 395 (Laguna

II), Mechanical, 19B Exhaust, Parts and consumables

for repair).

Start the vehicle and check if the engine runs better.

Is the engine running normally?Replace the particle filter (see MR

364 (Mégane II), 370 (Scénic II) or

395 (Laguna II), Mechanical, 19B

Exhaust, Particle filter, Removal –

Refitting).

After any operation on the particle

filter, reinitialise the parameters.

Run command SC036 Reinitialise

programming and select After

particle filter replacement.

Check the weight of soot: if PR383

Weight of soot in the particle filter

≥ 1 g. Apply the procedure for test 8

Manual clearing of the soot weight.

Replace the silencer.

A

YES

NO

YES

NO

YES

Page 342 of 365

13B-342

MR-372-J84-13B200$900.mif

V13

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Tests13B

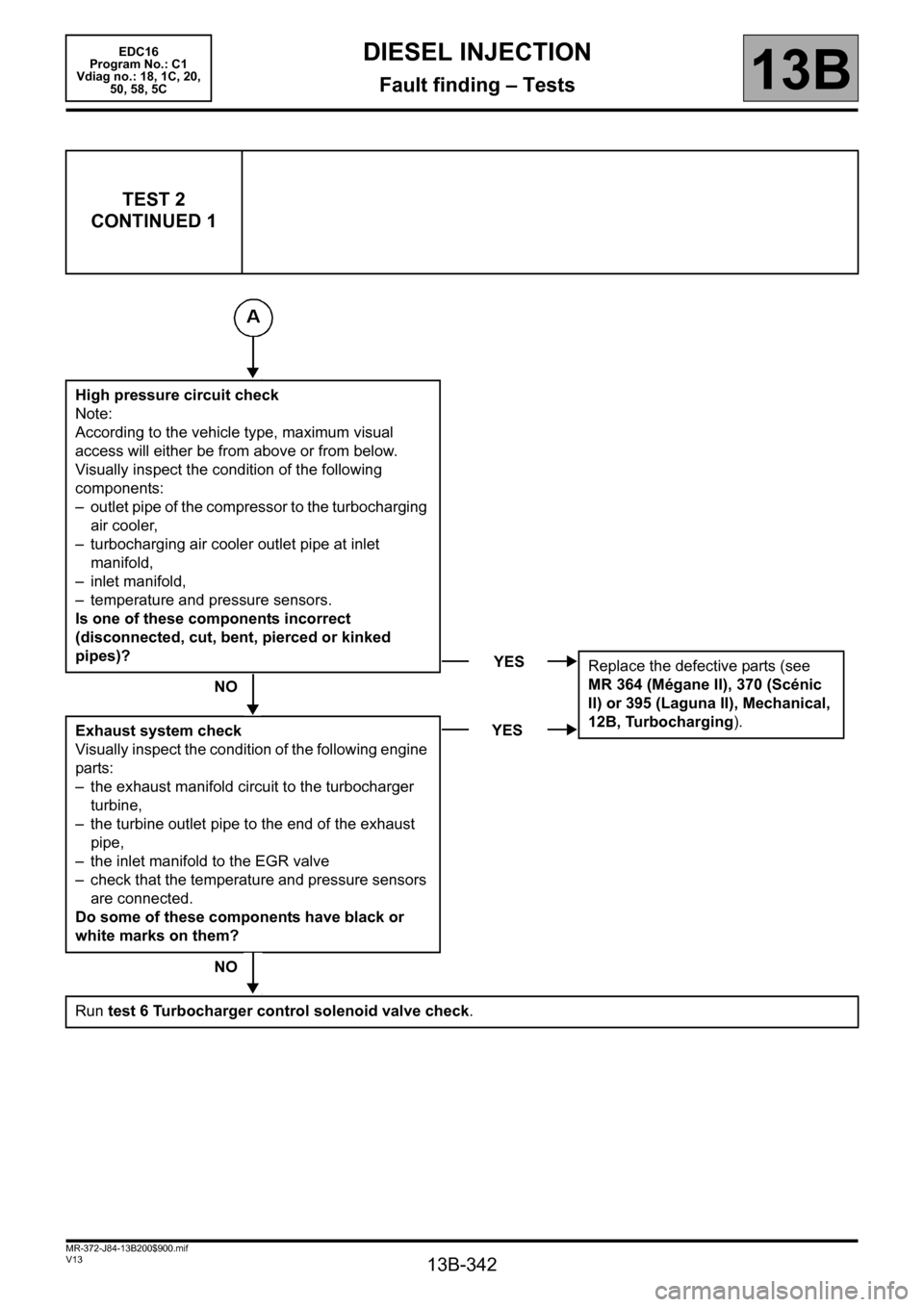

TEST 2

CONTINUED 1

High pressure circuit check

Note:

According to the vehicle type, maximum visual

access will either be from above or from below.

Visually inspect the condition of the following

components:

– outlet pipe of the compressor to the turbocharging

air cooler,

– turbocharging air cooler outlet pipe at inlet

manifold,

– inlet manifold,

– temperature and pressure sensors.

Is one of these components incorrect

(disconnected, cut, bent, pierced or kinked

pipes)?

NO

Exhaust system check

Visually inspect the condition of the following engine

parts:

– the exhaust manifold circuit to the turbocharger

turbine,

– the turbine outlet pipe to the end of the exhaust

pipe,

– the inlet manifold to the EGR valve

– check that the temperature and pressure sensors

are connected.

Do some of these components have black or

white marks on them?

NO

Run test 6 Turbocharger control solenoid valve check.

YES

Replace the defective parts (see

MR 364 (Mégane II), 370 (Scénic

II) or 395 (Laguna II), Mechanical,

12B, Turbocharging).

YES

Page 343 of 365

13B-343

MR-372-J84-13B200$900.mif

V13

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Tests13B

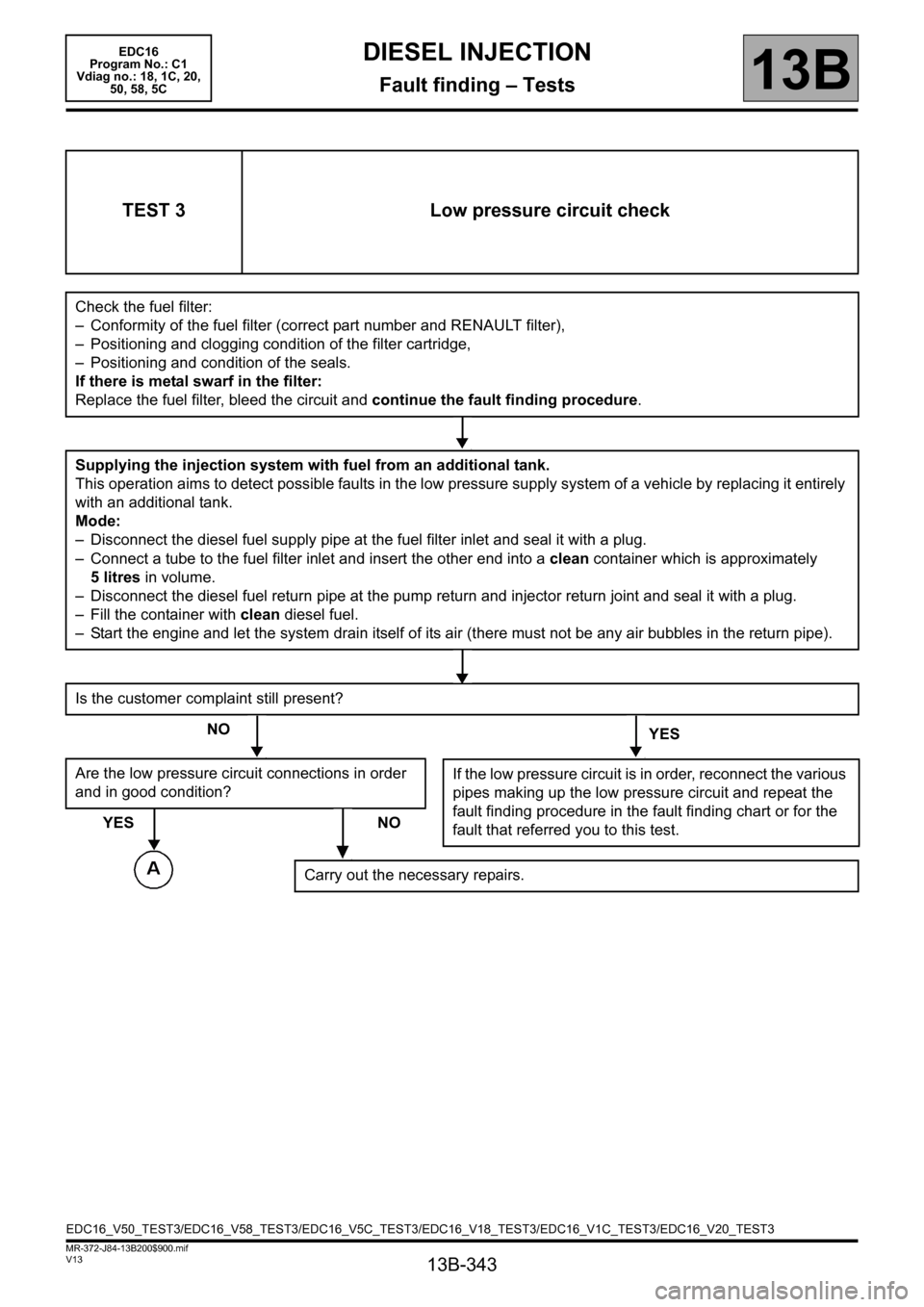

TEST 3 Low pressure circuit check

Check the fuel filter:

– Conformity of the fuel filter (correct part number and RENAULT filter),

– Positioning and clogging condition of the filter cartridge,

– Positioning and condition of the seals.

If there is metal swarf in the filter:

Replace the fuel filter, bleed the circuit and continue the fault finding procedure.

Supplying the injection system with fuel from an additional tank.

This operation aims to detect possible faults in the low pressure supply system of a vehicle by replacing it entirely

with an additional tank.

Mode:

– Disconnect the diesel fuel supply pipe at the fuel filter inlet and seal it with a plug.

– Connect a tube to the fuel filter inlet and insert the other end into a clean container which is approximately

5 litres in volume.

– Disconnect the diesel fuel return pipe at the pump return and injector return joint and seal it with a plug.

– Fill the container with clean diesel fuel.

– Start the engine and let the system drain itself of its air (there must not be any air bubbles in the return pipe).

Is the customer complaint still present?

NO

YES

Are the low pressure circuit connections in order

and in good condition?

YES NO

If the low pressure circuit is in order, reconnect the various

pipes making up the low pressure circuit and repeat the

fault finding procedure in the fault finding chart or for the

fault that referred you to this test.

Carry out the necessary repairs.

EDC16_V50_TEST3/EDC16_V58_TEST3/EDC16_V5C_TEST3/EDC16_V18_TEST3/EDC16_V1C_TEST3/EDC16_V20_TEST3

Page 345 of 365

13B-345

MR-372-J84-13B200$900.mif

V13

DIESEL INJECTION

Fault finding – Tests

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5C

13B

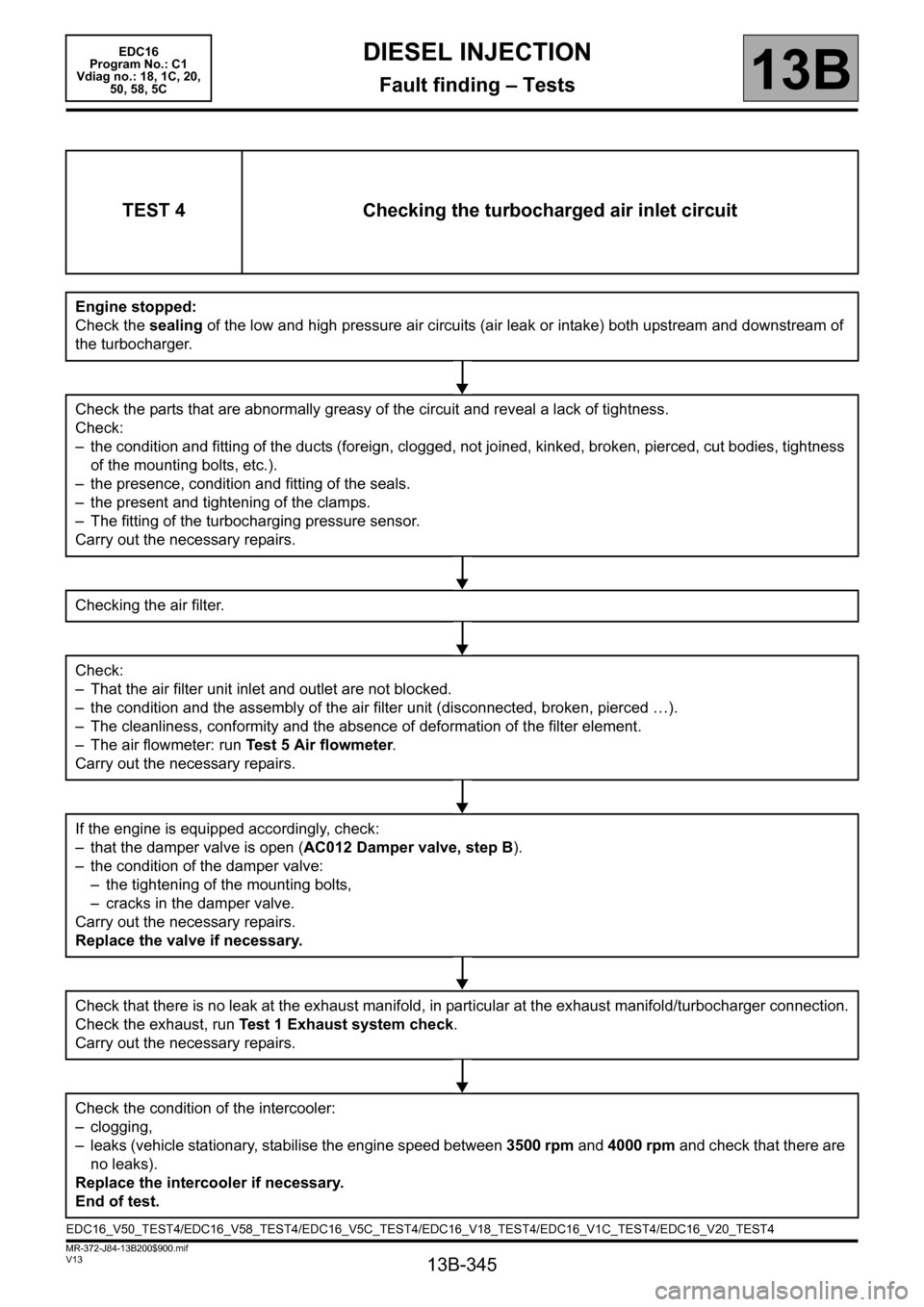

TEST 4 Checking the turbocharged air inlet circuit

Engine stopped:

Check the sealing of the low and high pressure air circuits (air leak or intake) both upstream and downstream of

the turbocharger.

Check the parts that are abnormally greasy of the circuit and reveal a lack of tightness.

Check:

– the condition and fitting of the ducts (foreign, clogged, not joined, kinked, broken, pierced, cut bodies, tightness

of the mounting bolts, etc.).

– the presence, condition and fitting of the seals.

– the present and tightening of the clamps.

– The fitting of the turbocharging pressure sensor.

Carry out the necessary repairs.

Checking the air filter.

Check:

– That the air filter unit inlet and outlet are not blocked.

– the condition and the assembly of the air filter unit (disconnected, broken, pierced …).

– The cleanliness, conformity and the absence of deformation of the filter element.

– The air flowmeter: run Test 5 Air flowmeter.

Carry out the necessary repairs.

If the engine is equipped accordingly, check:

– that the damper valve is open (AC012 Damper valve, step B).

– the condition of the damper valve:

– the tightening of the mounting bolts,

– cracks in the damper valve.

Carry out the necessary repairs.

Replace the valve if necessary.

Check that there is no leak at the exhaust manifold, in particular at the exhaust manifold/turbocharger connection.

Check the exhaust, run Test 1 Exhaust system check.

Carry out the necessary repairs.

Check the condition of the intercooler:

– clogging,

– leaks (vehicle stationary, stabilise the engine speed between 3500 rpm and 4000 rpm and check that there are

no leaks).

Replace the intercooler if necessary.

End of test.

EDC16_V50_TEST4/EDC16_V58_TEST4/EDC16_V5C_TEST4/EDC16_V18_TEST4/EDC16_V1C_TEST4/EDC16_V20_TEST4

Page 346 of 365

13B-346

MR-372-J84-13B200$900.mif

V13

DIESEL INJECTION

Fault finding – Tests

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5C

13B

* OCR: Opening Cyclic Ratio

TEST 5 Air flowmeter

Impurities in the grilles:

Visual inspection: remove the flowmeter. There should be no foreign bodies on the grilles (see diagram 110734).

Do not clean the grilles using compressed air or any other procedure: this damages the sensors and

creates variations from the values displayed on the CLIP tool.

Check the sealing of the air circuit upstream of the air flowmeter:

disconnected or pierced pipes and air filter unit, seals present.

Replace the air flowmeter if necessary and clean upstream of this, if necessary.

Damage to electrical components:

Visual inspection:

– remove the flowmeter, the components should not be broken (see diagram no. 110736).

Replace the air flowmeter if necessary.

Oxidation of the electrical components:

Visual inspection:

– remove the air flowmeter, there must not be any green deposits on the electrical components.

Replace the air flowmeter if necessary.

Clogging of the air flowmeter:

Te s t :

– Check the values for conformity:

* During the first 5 seconds after starting:

– Coolant temperature: 80°C.

– Engine speed: at idle speed (750 rpm < PR055 < 850 rpm).

– Air flow measurement: 37 kg/h < PR132 < 57 kg/h.

– EGR valve OCR*: between - 10% and 0%.

* After the starting phase:

– Coolant temperature: 80°C,

– Engine speed: at idle speed (750 rpm < PR055 < 850 rpm).

– Air flow measurement: 25 kg/h < PR132 < 35 kg/h.

– EGR valve OCR*: between 10% and 40%.

– Refer to the interpretation of DF056 Air flow sensor circuit 2.DEF, for the air flowmeter checks.

Replace the air flowmeter if necessary.

EDC16_V50_TEST5/EDC16_V58_TEST5/EDC16_V5C_TEST5/EDC16_V18_TEST5/EDC16_V1C_TEST5/EDC16_V20_TEST5

Page 348 of 365

13B-348

MR-372-J84-13B200$900.mif

V13

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Tests13B

TEST8 Manual clearing of the soot weight

Note: In certain cases, this procedure is to be carried out only after replacement of the particle filter or after an

After-sales regeneration of the particle filter.

– Start the engine.

– Raise the engine coolant temperature.

– Read the coolant temperature with PR064 Coolant temperature until a value greater than 65ºC is obtained.

– Accelerate the engine to 4000 rpm and maintain this speed for 5 minutes.

–After 5 minutes, release the accelerator and stop the engine.

– Switch on the ignition.

– Run command SC036 Reinitialise programming and select After particle filter replacement or After

particle filter regeneration (as appropriate).

– Switch off the ignition and wait for the diagnostic tool message (maximum time 8 minutes): Communication

lost with computer: EDC16C36, check the tool connection and computer power supply.

–Then switch on the ignition again, clear the present or stored faults from the computer memory (operation

to be carried out within 3 minutes of switching on the ignition).

EDC16_V50_TEST8/EDC16_V58_TEST8/EDC16_V5C_TEST8/EDC16_V18_TEST8/EDC16_V1C_TEST8/EDC16_V20_TEST8

Page 350 of 365

13B-350

MR-372-J84-13B200$936.mif

V13

DIESEL INJECTION

Fault finding – Tests

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

TEST 9 Incorrect injector operation

Section A: Fuel regulation balance check for each injector (individual correction):

– In the CLIP diagnostic tool, choose the Fuel circuit subfunction.

– With the engine idling and the fuel temperature > 50°C, display the flow correction values for each injector

(individual correction), i.e.:

– PR364 Cylinder no. 1 fuel flow correction.

– PR405 Cylinder no. 2 fuel flow correction.

– PR406 Cylinder no. 3 fuel flow correction.

– PR365 Cylinder no. 4 fuel flow correction.

The flow correction range per injector is between - 5 mg/stroke and + 5 mg/stroke without reaching these

values.

– If this has not already been carried out, check the injector connections and wiring.

– Check the connections and wiring of the engine management computer to the injectors.

– Repair if necessary.

– Check the IMA injector codes, comparing the IMA codes on the injectors (the IMA codes must be read from left

to right) and the IMA codes read in the CLIP diagnostic tool.

– If the IMA codes are correct, continue the fault finding procedure,

– If not, modify the incorrect IMA codes using command SC002 Enter injector codes (see Interpretation of

commands).

To confirm the repair, consult part B of test 9.

CASE No. 1: If at least one of these values is equal to or greater than + 5 mg/st

– Check the valve clearance.

– Check the condition of the engine and the compressions (using the Clip diagnostic tool or a compression

gauge).

– If the compression test reveals a cylinder fault, carry out the necessary repairs.

– If the compression is correct, check that the injector is fitted correctly (see MR 364 (Mégane II), 370 (Scénic II)

or 395 (Laguna II), Mechanical, 13B, Diesel injection, Diesel injector: Removal - Refitting)

In particular, check that each injector has one compression washer.

Check the fuel regulation again for each injector (individual correction).

– If not, replace the injector and check for the sealing washer. Modify the IMA code using command SC002 Enter

injector codes (see Interpretation of commands).

–Apply Part B of this test to confirm the fault finding.

EDC16_V50_TEST9/EDC16_V58_TEST9/EDC16_V5C_TEST9/EDC16_V18_TEST9/EDC16_V1C_TEST9/EDC16_V20_TEST9

Page 351 of 365

13B-351

MR-372-J84-13B200$936.mif

V13

DIESEL INJECTION

Fault finding – Tests

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

TEST 9

CONTINUED 1

CASE No. 2: If at least one of these values is equal to or less than - 5 mg/st

– Check the valve clearance.

– Check the level and condition of the engine oil.

– Remove the injector with the largest correction.

– If there is diesel fuel contamination, check the condition of the cylinder concerned (cylinder, piston, valves).

Use an endoscope if possible.

– Only replace the removed injector, and modify the IMA code using command SC002 Enter injector codes

(see Interpretation of commands).

–Apply Part B of this test to confirm the fault finding.

CASE No. 3: If at least one of these values does not stabilise (20 seconds after starting)

– Check the low pressure circuit using Test 4 Low pressure circuit check.

– Check the conformity of the fuel by applying Test 11 Diesel fuel conformity check.

–Apply Part B of this test to confirm the fault finding procedure

CASE No. 4: If all the fuel flow correction values are correct (between - 5 mg/st and + 5 mg/st)

–Apply Part C of this test (Fuel return flow measurement).

IMPORTANT

When removing or refitting injectors, follow the cleanliness and safety instructions (see MR 364 (Mégane II), 370

(Scénic II) or 395 (Laguna II), Mechanical, 13B, Diesel injection, Diesel injector: Removal - Refitting).

Page 352 of 365

13B-352

MR-372-J84-13B200$936.mif

V13

DIESEL INJECTION

Fault finding – Tests

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

TEST 9

CONTINUED 2

Section B: Confirmation of flow correction fault finding for each injector (individual correction):

Clear the faults and perform a test with the engine idling for at least 5 minutes and fuel temperature > 50°C.

Check that no fault appears on the CLIP diagnostic tool and that the corrective values do not reach ±5mg/

stroke to confirm the repair.

If the customer complaint is still present and the fuel flow correction values are between

-5 mg/stroke and + 5mg/stroke, apply Part A Fuel regulation balance check for each injector (individual)

of this test (Case no.4).

If one or more cylinders has an injector flow correction value in excess of ± 5 mg/stroke, apply Part A Fuel

regulation balance check for each injector (individual) of this test, as one or more injectors may be defective.

Part C: Measuring fuel return flow

1 – Fitting the tool:

This section is only to be carried out if PR063 "Fuel temperature" is higher than 50°C (see step 2 of

section C for this test).

Remove the engine undertray

Disconnect the entire fuel return pipe in accordance with the following procedure (do not remove the clips):

– press the clip,

– pull vertically on the end piece (see arrow in the diagram below) of the fuel return pipe.

IMPORTANT

The end piece is fragile. Be careful not to break it by pulling it too hard. Replace all removed clips

Page 355 of 365

13B-355

MR-372-J84-13B200$936.mif

V13

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Tests13B

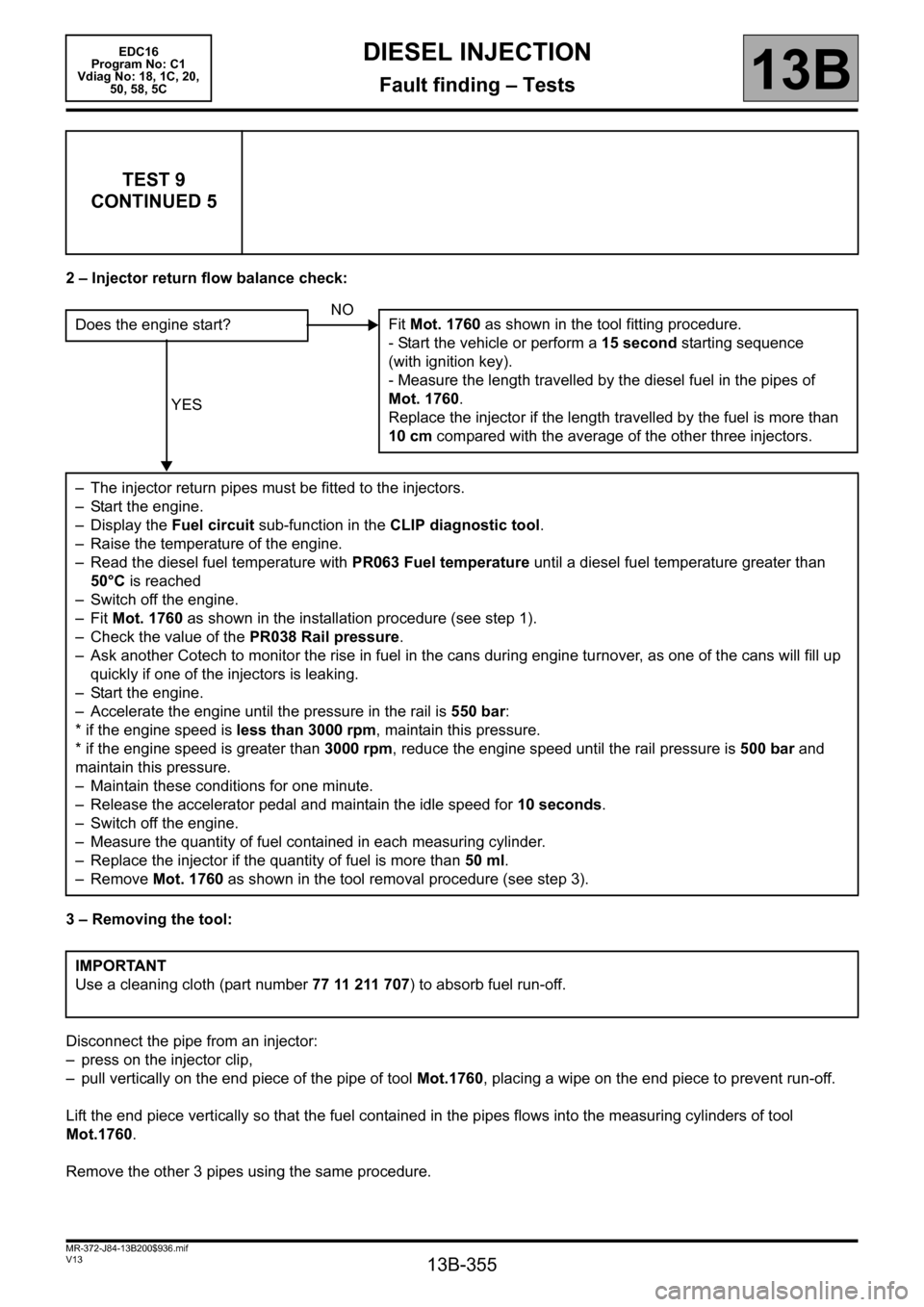

2 – Injector return flow balance check:

3 – Removing the tool:

Disconnect the pipe from an injector:

– press on the injector clip,

– pull vertically on the end piece of the pipe of tool Mot.1760, placing a wipe on the end piece to prevent run-off.

Lift the end piece vertically so that the fuel contained in the pipes flows into the measuring cylinders of tool

Mot.1760.

Remove the other 3 pipes using the same procedure.

TEST 9

CONTINUED 5

Does the engine start?

YES

– The injector return pipes must be fitted to the injectors.

– Start the engine.

– Display the Fuel circuit sub-function in the CLIP diagnostic tool.

– Raise the temperature of the engine.

– Read the diesel fuel temperature with PR063 Fuel temperature until a diesel fuel temperature greater than

50°C is reached

– Switch off the engine.

–Fit Mot. 1760 as shown in the installation procedure (see step 1).

– Check the value of the PR038 Rail pressure.

– Ask another Cotech to monitor the rise in fuel in the cans during engine turnover, as one of the cans will fill up

quickly if one of the injectors is leaking.

– Start the engine.

– Accelerate the engine until the pressure in the rail is 550 bar:

* if the engine speed is less than 3000 rpm, maintain this pressure.

* if the engine speed is greater than 3000 rpm, reduce the engine speed until the rail pressure is 500 bar and

maintain this pressure.

– Maintain these conditions for one minute.

– Release the accelerator pedal and maintain the idle speed for 10 seconds.

– Switch off the engine.

– Measure the quantity of fuel contained in each measuring cylinder.

– Replace the injector if the quantity of fuel is more than 50 ml.

– Remove Mot. 1760 as shown in the tool removal procedure (see step 3).

IMPORTANT

Use a cleaning cloth (part number 77 11 211 707) to absorb fuel run-off.NO

Fit Mot. 1760 as shown in the tool fitting procedure.

- Start the vehicle or perform a 15 second starting sequence

(with ignition key).

- Measure the length travelled by the diesel fuel in the pipes of

Mot. 1760.

Replace the injector if the length travelled by the fuel is more than

10 cm compared with the average of the other three injectors.