warning RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16 Manual PDF

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 365, PDF Size: 2.11 MB

Page 192 of 365

13B-192

MR-372-J84-13B200$504.mif

V13

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Interpretation of statuses13B

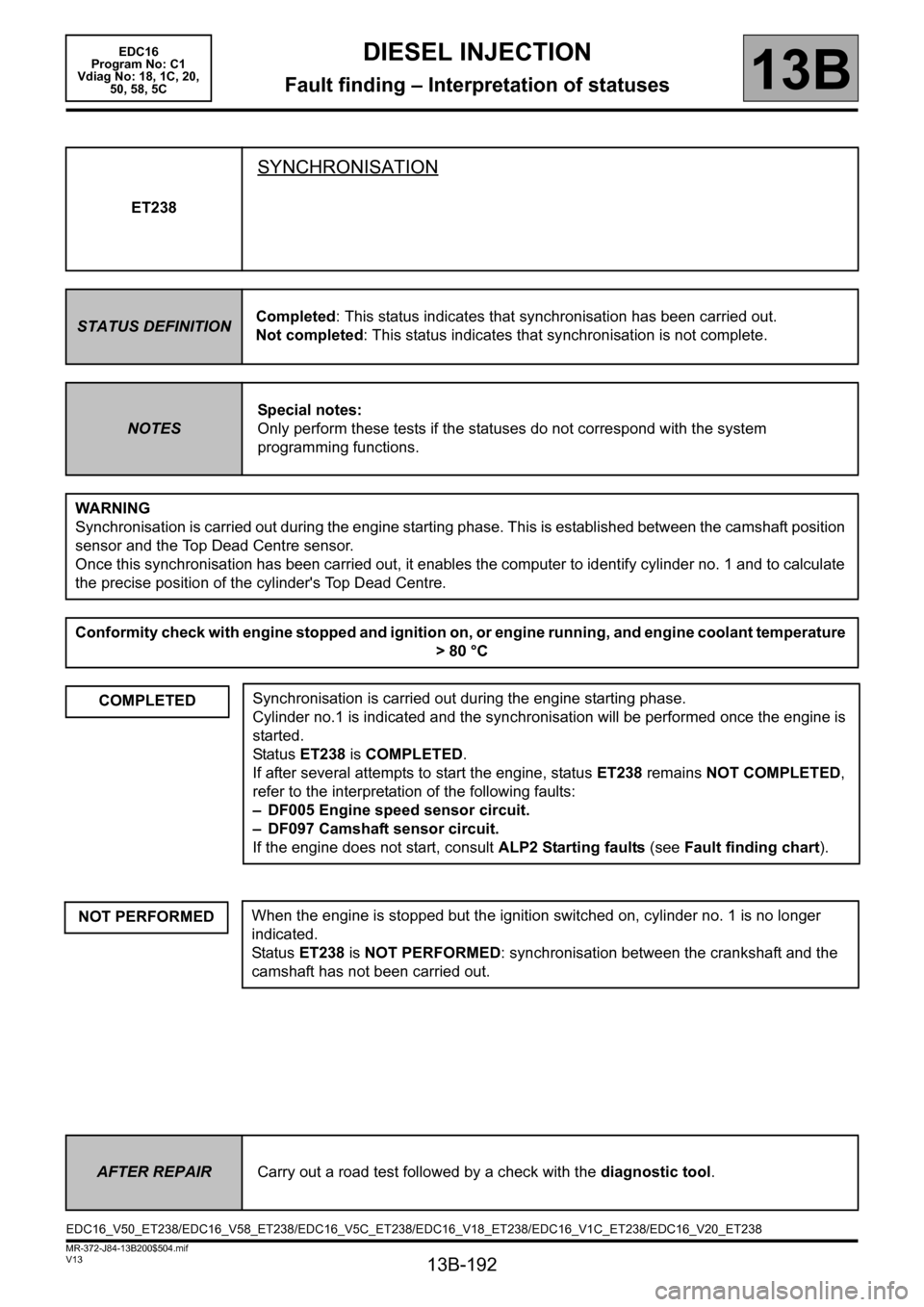

ET238

SYNCHRONISATION

STATUS DEFINITIONCompleted: This status indicates that synchronisation has been carried out.

Not completed: This status indicates that synchronisation is not complete.

NOTESSpecial notes:

Only perform these tests if the statuses do not correspond with the system

programming functions.

WARNING

Synchronisation is carried out during the engine starting phase. This is established between the camshaft position

sensor and the Top Dead Centre sensor.

Once this synchronisation has been carried out, it enables the computer to identify cylinder no. 1 and to calculate

the precise position of the cylinder's Top Dead Centre.

Conformity check with engine stopped and ignition on, or engine running, and engine coolant temperature

>80 °C

COMPLETED

Synchronisation is carried out during the engine starting phase.

Cylinder no.1 is indicated and the synchronisation will be performed once the engine is

started.

Status ET238 is COMPLETED.

If after several attempts to start the engine, status ET238 remains NOT COMPLETED,

refer to the interpretation of the following faults:

– DF005 Engine speed sensor circuit.

– DF097 Camshaft sensor circuit.

If the engine does not start, consult ALP2 Starting faults (see Fault finding chart).

NOT PERFORMEDWhen the engine is stopped but the ignition switched on, cylinder no. 1 is no longer

indicated.

Status ET238 is NOT PERFORMED: synchronisation between the crankshaft and the

camshaft has not been carried out.

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

EDC16_V50_ET238/EDC16_V58_ET238/EDC16_V5C_ET238/EDC16_V18_ET238/EDC16_V1C_ET238/EDC16_V20_ET238

Page 208 of 365

13B-208

MR-372-J84-13B200$540.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of statuses

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

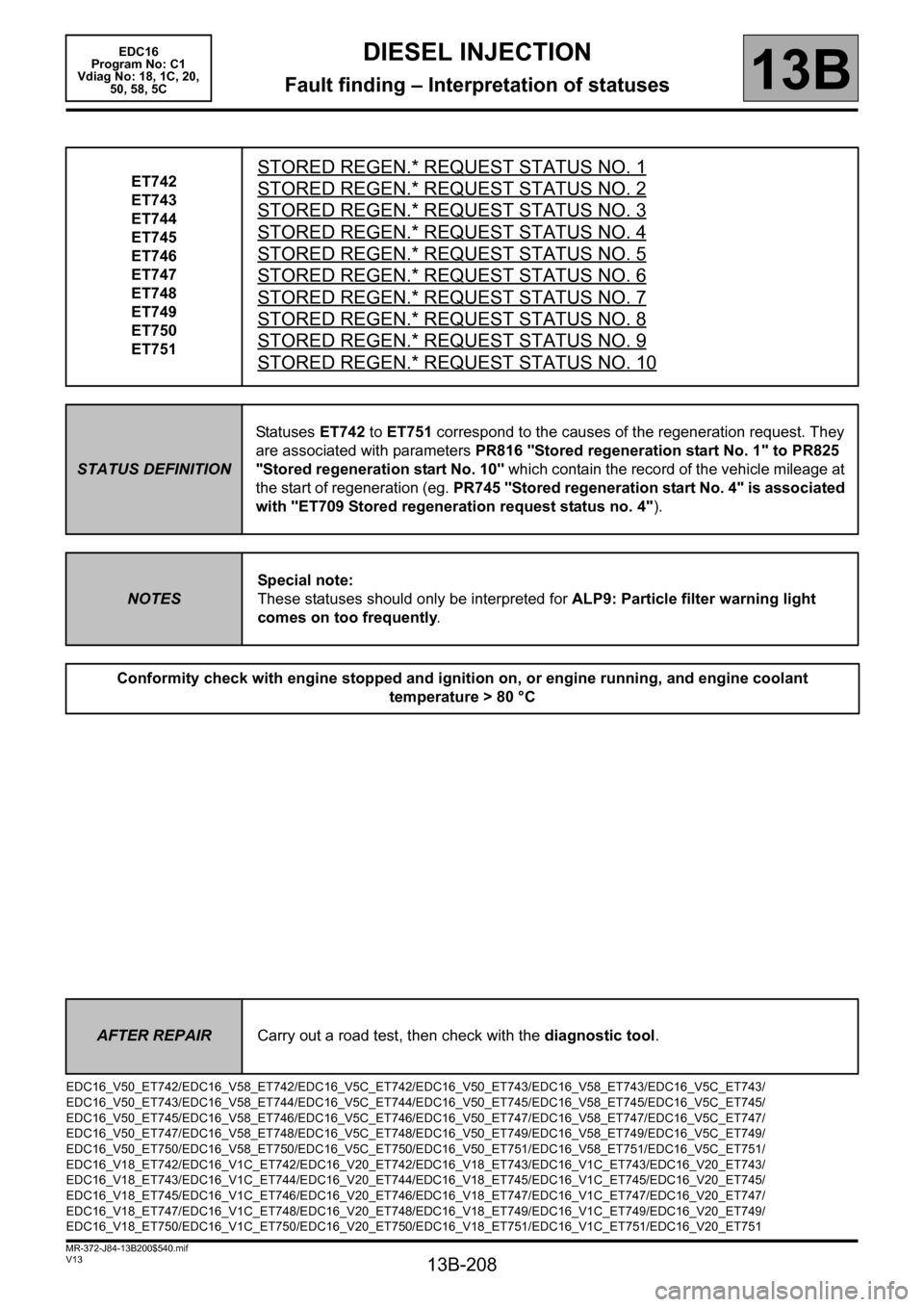

ET742

ET743

ET744

ET745

ET746

ET747

ET748

ET749

ET750

ET751STORED REGEN.* REQUEST STATUS NO. 1

STORED REGEN.* REQUEST STATUS NO. 2

STORED REGEN.* REQUEST STATUS NO. 3

STORED REGEN.* REQUEST STATUS NO. 4

STORED REGEN.* REQUEST STATUS NO. 5

STORED REGEN.* REQUEST STATUS NO. 6

STORED REGEN.* REQUEST STATUS NO. 7

STORED REGEN.* REQUEST STATUS NO. 8

STORED REGEN.* REQUEST STATUS NO. 9

STORED REGEN.* REQUEST STATUS NO. 10

STATUS DEFINITIONStatuses ET742 to ET751 correspond to the causes of the regeneration request. They

are associated with parameters PR816 "Stored regeneration start No. 1" to PR825

"Stored regeneration start No. 10" which contain the record of the vehicle mileage at

the start of regeneration (eg. PR745 "Stored regeneration start No. 4" is associated

with "ET709 Stored regeneration request status no. 4").

NOTESSpecial note:

These statuses should only be interpreted for ALP9: Particle filter warning light

comes on too frequently.

Conformity check with engine stopped and ignition on, or engine running, and engine coolant

temperature > 80 °C

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

EDC16_V50_ET742/EDC16_V58_ET742/EDC16_V5C_ET742/EDC16_V50_ET743/EDC16_V58_ET743/EDC16_V5C_ET743/

EDC16_V50_ET743/EDC16_V58_ET744/EDC16_V5C_ET744/EDC16_V50_ET745/EDC16_V58_ET745/EDC16_V5C_ET745/

EDC16_V50_ET745/EDC16_V58_ET746/EDC16_V5C_ET746/EDC16_V50_ET747/EDC16_V58_ET747/EDC16_V5C_ET747/

EDC16_V50_ET747/EDC16_V58_ET748/EDC16_V5C_ET748/EDC16_V50_ET749/EDC16_V58_ET749/EDC16_V5C_ET749/

EDC16_V50_ET750/EDC16_V58_ET750/EDC16_V5C_ET750/EDC16_V50_ET751/EDC16_V58_ET751/EDC16_V5C_ET751/

EDC16_V18_ET742/EDC16_V1C_ET742/EDC16_V20_ET742/EDC16_V18_ET743/EDC16_V1C_ET743/EDC16_V20_ET743/

EDC16_V18_ET743/EDC16_V1C_ET744/EDC16_V20_ET744/EDC16_V18_ET745/EDC16_V1C_ET745/EDC16_V20_ET745/

EDC16_V18_ET745/EDC16_V1C_ET746/EDC16_V20_ET746/EDC16_V18_ET747/EDC16_V1C_ET747/EDC16_V20_ET747/

EDC16_V18_ET747/EDC16_V1C_ET748/EDC16_V20_ET748/EDC16_V18_ET749/EDC16_V1C_ET749/EDC16_V20_ET749/

EDC16_V18_ET750/EDC16_V1C_ET750/EDC16_V20_ET750/EDC16_V18_ET751/EDC16_V1C_ET751/EDC16_V20_ET751

Page 209 of 365

13B-209

MR-372-J84-13B200$540.mif

V13

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Interpretation of statuses13B

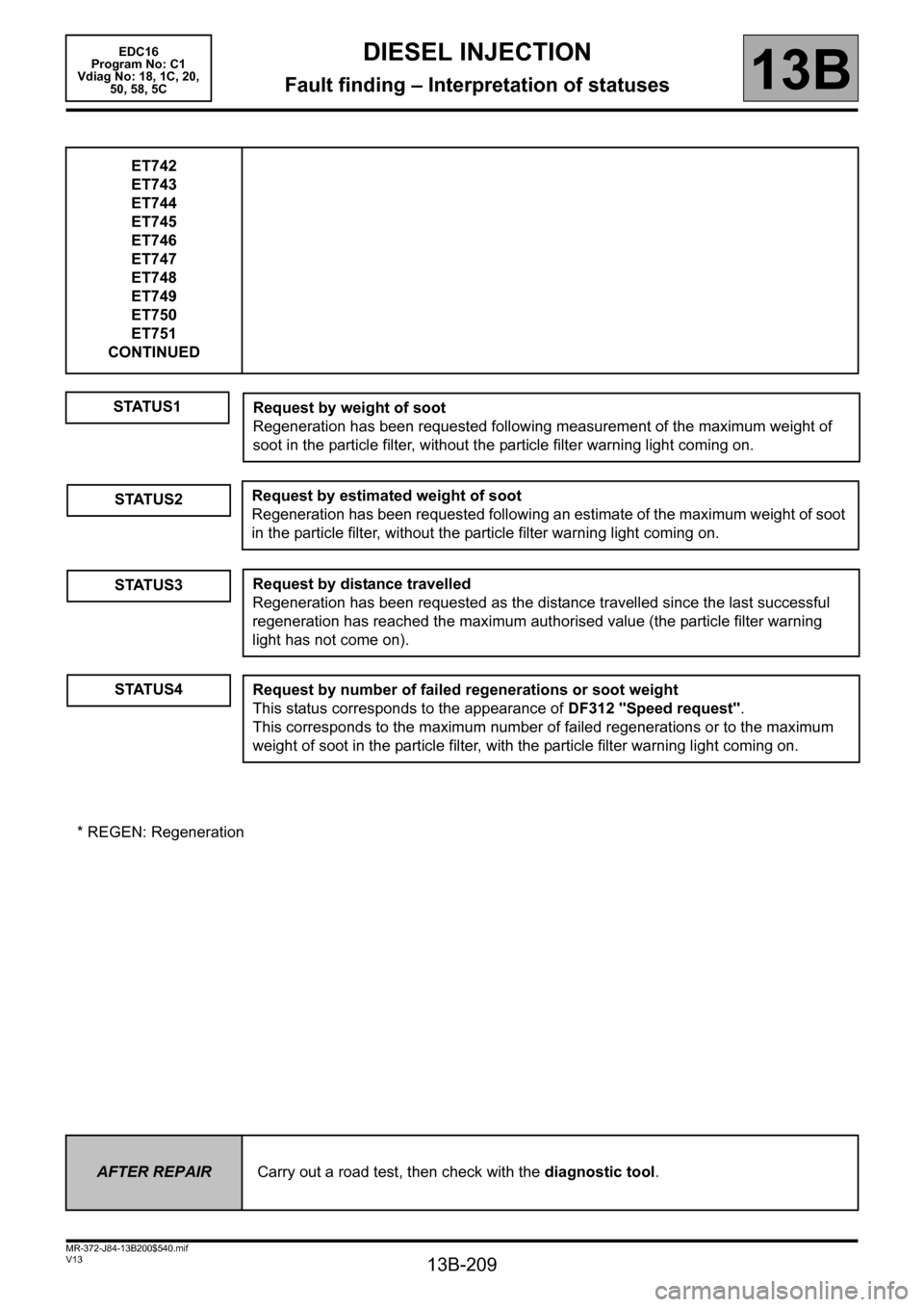

ET742

ET743

ET744

ET745

ET746

ET747

ET748

ET749

ET750

ET751

CONTINUED

STATUS1

Request by weight of soot

Regeneration has been requested following measurement of the maximum weight of

soot in the particle filter, without the particle filter warning light coming on.

STATUS2Request by estimated weight of soot

Regeneration has been requested following an estimate of the maximum weight of soot

in the particle filter, without the particle filter warning light coming on.

STATUS3Request by distance travelled

Regeneration has been requested as the distance travelled since the last successful

regeneration has reached the maximum authorised value (the particle filter warning

light has not come on).

STATUS4Request by number of failed regenerations or soot weight

This status corresponds to the appearance of DF312 "Speed request".

This corresponds to the maximum number of failed regenerations or to the maximum

weight of soot in the particle filter, with the particle filter warning light coming on.

* REGEN: Regeneration

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 285 of 365

13B-285

MR-372-J84-13B200$684.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of parameters

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

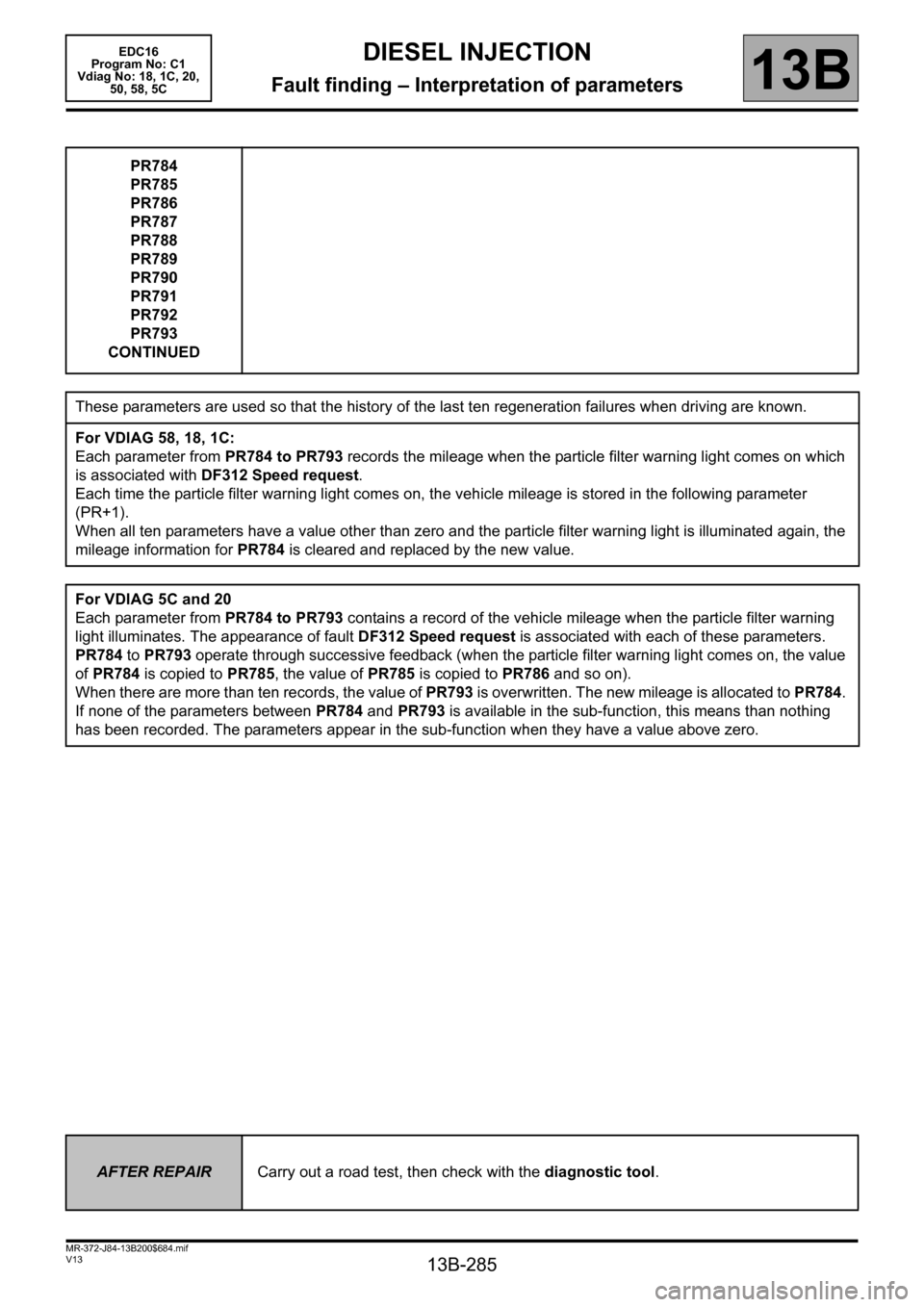

PR784

PR785

PR786

PR787

PR788

PR789

PR790

PR791

PR792

PR793

CONTINUED

These parameters are used so that the history of the last ten regeneration failures when driving are known.

For VDIAG 58, 18, 1C:

Each parameter from PR784 to PR793 records the mileage when the particle filter warning light comes on which

is associated with DF312 Speed request.

Each time the particle filter warning light comes on, the vehicle mileage is stored in the following parameter

(PR+1).

When all ten parameters have a value other than zero and the particle filter warning light is illuminated again, the

mileage information for PR784 is cleared and replaced by the new value.

For VDIAG 5C and 20

Each parameter from PR784 to PR793 contains a record of the vehicle mileage when the particle filter warning

light illuminates. The appearance of fault DF312 Speed request is associated with each of these parameters.

PR784 to PR793 operate through successive feedback (when the particle filter warning light comes on, the value

of PR784 is copied to PR785, the value of PR785 is copied to PR786 and so on).

When there are more than ten records, the value of PR793 is overwritten. The new mileage is allocated to PR784.

If none of the parameters between PR784 and PR793 is available in the sub-function, this means than nothing

has been recorded. The parameters appear in the sub-function when they have a value above zero.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 288 of 365

13B-288

MR-372-J84-13B200$684.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of parameters

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

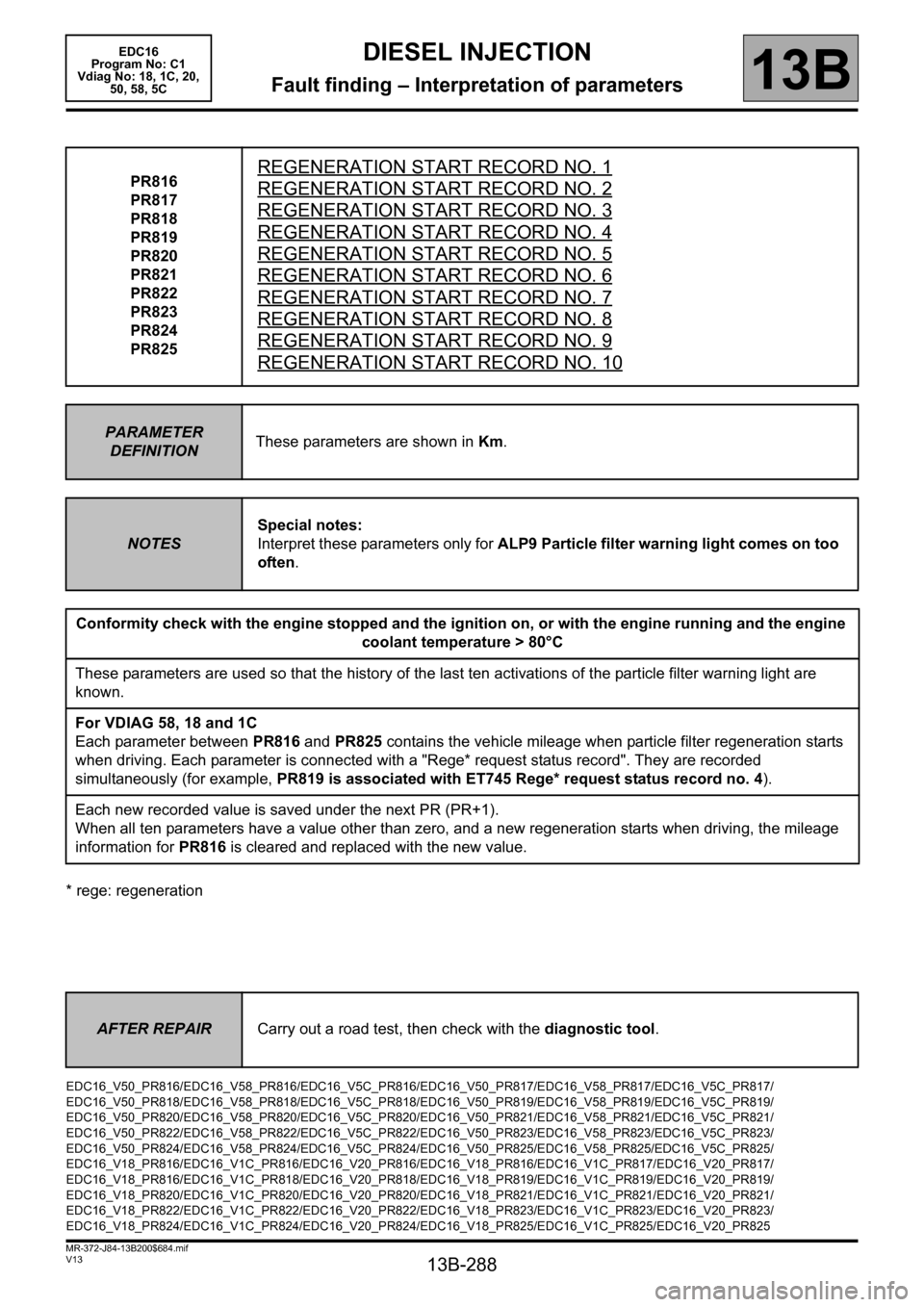

* rege: regenerationPR816

PR817

PR818

PR819

PR820

PR821

PR822

PR823

PR824

PR825

REGENERATION START RECORD NO. 1

REGENERATION START RECORD NO. 2

REGENERATION START RECORD NO. 3

REGENERATION START RECORD NO. 4

REGENERATION START RECORD NO. 5

REGENERATION START RECORD NO. 6

REGENERATION START RECORD NO. 7

REGENERATION START RECORD NO. 8

REGENERATION START RECORD NO. 9

REGENERATION START RECORD NO. 10

PARAMETER

DEFINITIONThese parameters are shown in Km.

NOTESSpecial notes:

Interpret these parameters only for ALP9 Particle filter warning light comes on too

often.

Conformity check with the engine stopped and the ignition on, or with the engine running and the engine

coolant temperature > 80°C

These parameters are used so that the history of the last ten activations of the particle filter warning light are

known.

For VDIAG 58, 18 and 1C

Each parameter between PR816 and PR825 contains the vehicle mileage when particle filter regeneration starts

when driving. Each parameter is connected with a "Rege* request status record". They are recorded

simultaneously (for example, PR819 is associated with ET745 Rege* request status record no. 4).

Each new recorded value is saved under the next PR (PR+1).

When all ten parameters have a value other than zero, and a new regeneration starts when driving, the mileage

information for PR816 is cleared and replaced with the new value.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

EDC16_V50_PR816/EDC16_V58_PR816/EDC16_V5C_PR816/EDC16_V50_PR817/EDC16_V58_PR817/EDC16_V5C_PR817/

EDC16_V50_PR818/EDC16_V58_PR818/EDC16_V5C_PR818/EDC16_V50_PR819/EDC16_V58_PR819/EDC16_V5C_PR819/

EDC16_V50_PR820/EDC16_V58_PR820/EDC16_V5C_PR820/EDC16_V50_PR821/EDC16_V58_PR821/EDC16_V5C_PR821/

EDC16_V50_PR822/EDC16_V58_PR822/EDC16_V5C_PR822/EDC16_V50_PR823/EDC16_V58_PR823/EDC16_V5C_PR823/

EDC16_V50_PR824/EDC16_V58_PR824/EDC16_V5C_PR824/EDC16_V50_PR825/EDC16_V58_PR825/EDC16_V5C_PR825/

EDC16_V18_PR816/EDC16_V1C_PR816/EDC16_V20_PR816/EDC16_V18_PR816/EDC16_V1C_PR817/EDC16_V20_PR817/

EDC16_V18_PR816/EDC16_V1C_PR818/EDC16_V20_PR818/EDC16_V18_PR819/EDC16_V1C_PR819/EDC16_V20_PR819/

EDC16_V18_PR820/EDC16_V1C_PR820/EDC16_V20_PR820/EDC16_V18_PR821/EDC16_V1C_PR821/EDC16_V20_PR821/

EDC16_V18_PR822/EDC16_V1C_PR822/EDC16_V20_PR822/EDC16_V18_PR823/EDC16_V1C_PR823/EDC16_V20_PR823/

EDC16_V18_PR824/EDC16_V1C_PR824/EDC16_V20_PR824/EDC16_V18_PR825/EDC16_V1C_PR825/EDC16_V20_PR825

Page 293 of 365

13B-293

MR-372-J84-13B200$756.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of commands

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

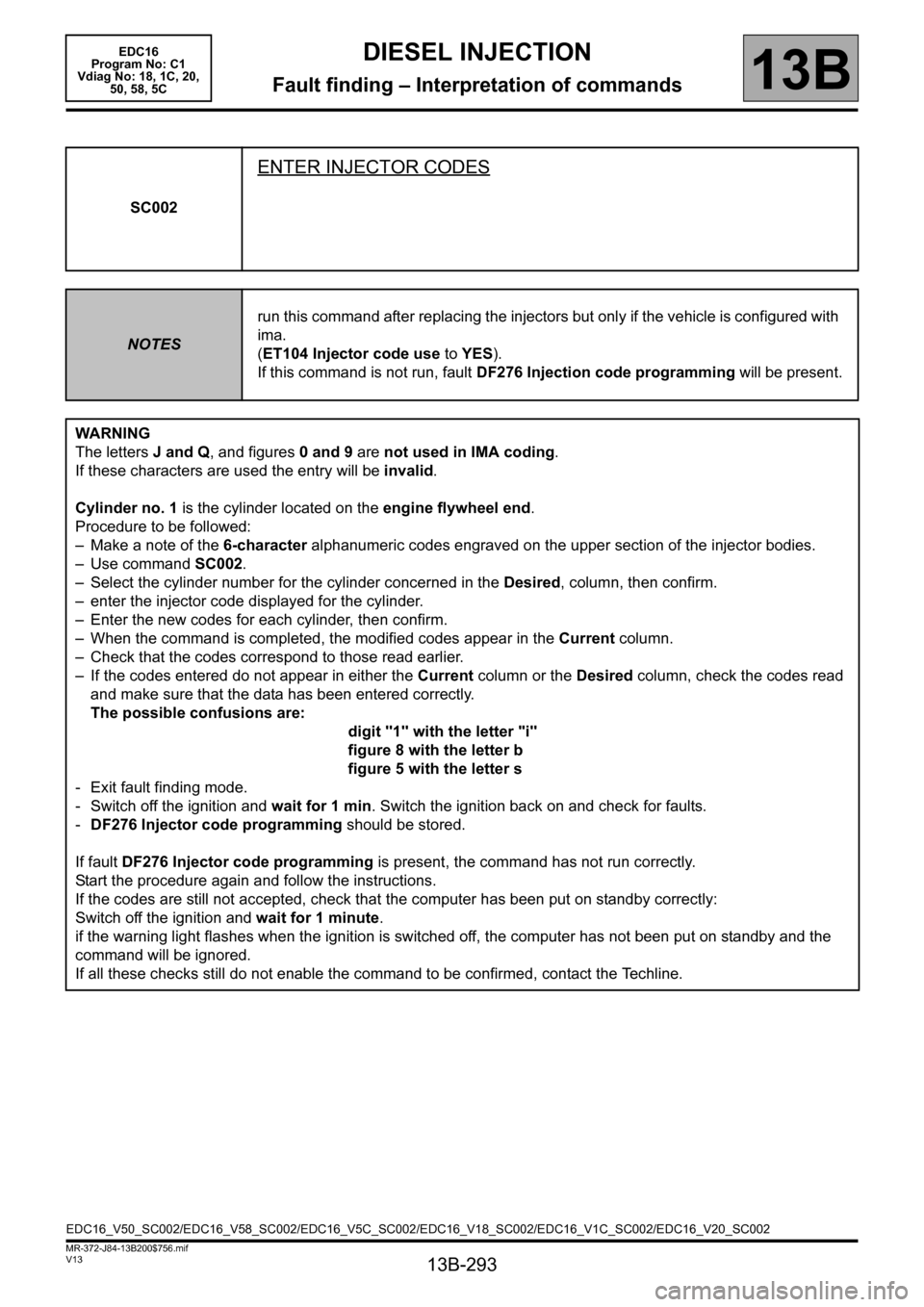

SC002

ENTER INJECTOR CODES

NOTESrun this command after replacing the injectors but only if the vehicle is configured with

ima.

(ET104 Injector code use to YES).

If this command is not run, fault DF276 Injection code programming will be present.

WARNING

The letters J and Q, and figures 0 and 9 are not used in IMA coding.

If these characters are used the entry will be invalid.

Cylinder no. 1 is the cylinder located on the engine flywheel end.

Procedure to be followed:

– Make a note of the 6-character alphanumeric codes engraved on the upper section of the injector bodies.

– Use command SC002.

– Select the cylinder number for the cylinder concerned in the Desired, column, then confirm.

– enter the injector code displayed for the cylinder.

– Enter the new codes for each cylinder, then confirm.

– When the command is completed, the modified codes appear in the Current column.

– Check that the codes correspond to those read earlier.

– If the codes entered do not appear in either the Current column or the Desired column, check the codes read

and make sure that the data has been entered correctly.

The possible confusions are:

digit "1" with the letter "i"

figure 8 with the letter b

figure 5 with the letter s

- Exit fault finding mode.

- Switch off the ignition and wait for 1 min. Switch the ignition back on and check for faults.

-DF276 Injector code programming should be stored.

If fault DF276 Injector code programming is present, the command has not run correctly.

Start the procedure again and follow the instructions.

If the codes are still not accepted, check that the computer has been put on standby correctly:

Switch off the ignition and wait for 1 minute.

if the warning light flashes when the ignition is switched off, the computer has not been put on standby and the

command will be ignored.

If all these checks still do not enable the command to be confirmed, contact the Techline.

EDC16_V50_SC002/EDC16_V58_SC002/EDC16_V5C_SC002/EDC16_V18_SC002/EDC16_V1C_SC002/EDC16_V20_SC002

Page 295 of 365

13B-295

MR-372-J84-13B200$756.mif

V13

DIESEL INJECTION

Fault finding – Interpretation of commands

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

13B

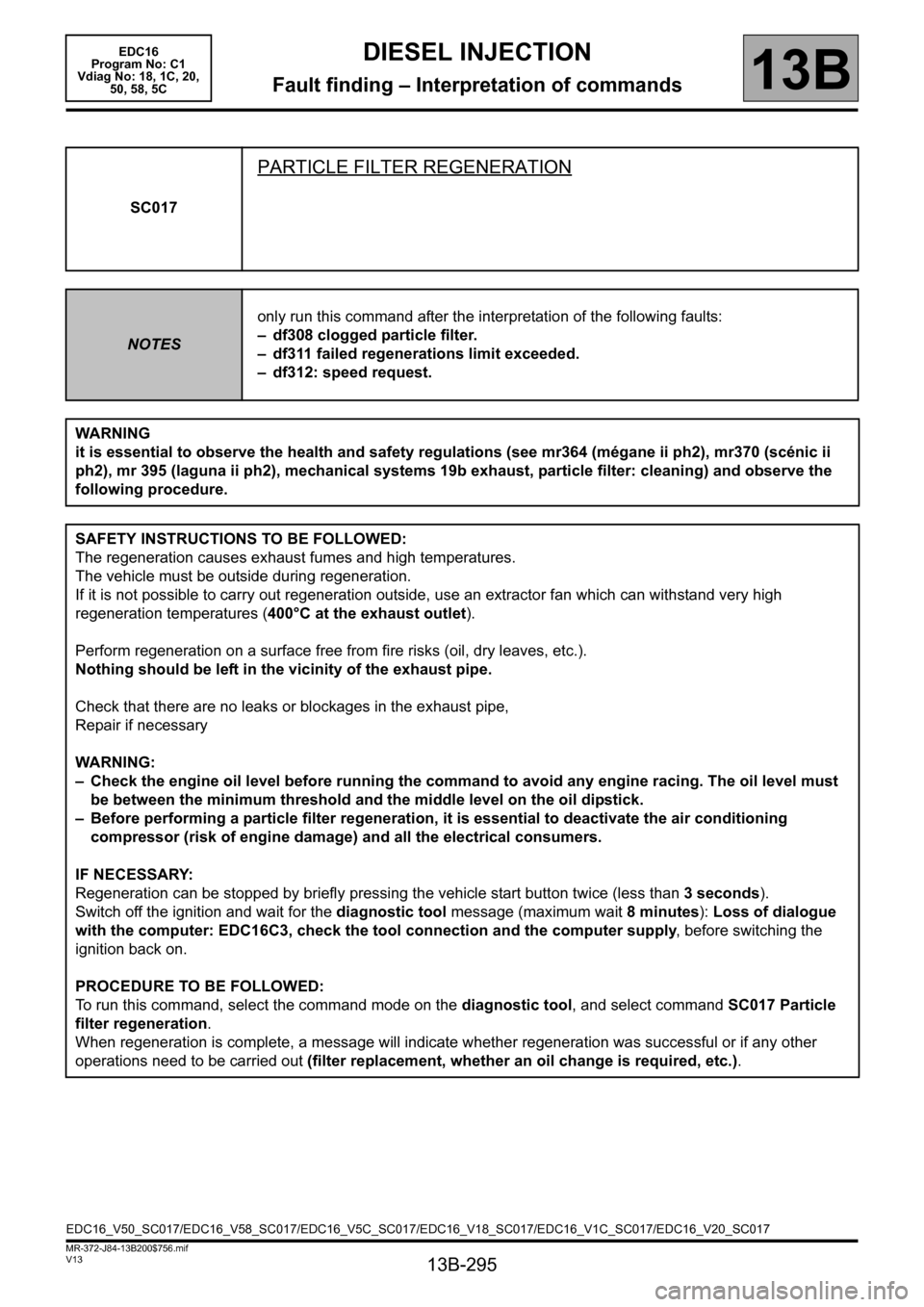

SC017

PARTICLE FILTER REGENERATION

NOTESonly run this command after the interpretation of the following faults:

– df308 clogged particle filter.

– df311 failed regenerations limit exceeded.

– df312: speed request.

WARNING

it is essential to observe the health and safety regulations (see mr364 (mégane ii ph2), mr370 (scénic ii

ph2), mr 395 (laguna ii ph2), mechanical systems 19b exhaust, particle filter: cleaning) and observe the

following procedure.

SAFETY INSTRUCTIONS TO BE FOLLOWED:

The regeneration causes exhaust fumes and high temperatures.

The vehicle must be outside during regeneration.

If it is not possible to carry out regeneration outside, use an extractor fan which can withstand very high

regeneration temperatures (400°C at the exhaust outlet).

Perform regeneration on a surface free from fire risks (oil, dry leaves, etc.).

Nothing should be left in the vicinity of the exhaust pipe.

Check that there are no leaks or blockages in the exhaust pipe,

Repair if necessary

WARNING:

– Check the engine oil level before running the command to avoid any engine racing. The oil level must

be between the minimum threshold and the middle level on the oil dipstick.

– Before performing a particle filter regeneration, it is essential to deactivate the air conditioning

compressor (risk of engine damage) and all the electrical consumers.

IF NECESSARY:

Regeneration can be stopped by briefly pressing the vehicle start button twice (less than 3 seconds).

Switch off the ignition and wait for the diagnostic tool message (maximum wait 8 minutes): Loss of dialogue

with the computer: EDC16C3, check the tool connection and the computer supply, before switching the

ignition back on.

PROCEDURE TO BE FOLLOWED:

To run this command, select the command mode on the diagnostic tool, and select command SC017 Particle

filter regeneration.

When regeneration is complete, a message will indicate whether regeneration was successful or if any other

operations need to be carried out (filter replacement, whether an oil change is required, etc.).

EDC16_V50_SC017/EDC16_V58_SC017/EDC16_V5C_SC017/EDC16_V18_SC017/EDC16_V1C_SC017/EDC16_V20_SC017

Page 317 of 365

13B-317

MR-372-J84-13B200$792.mif

V13

13B

DIESEL INJECTION

Fault finding – Customer complaints

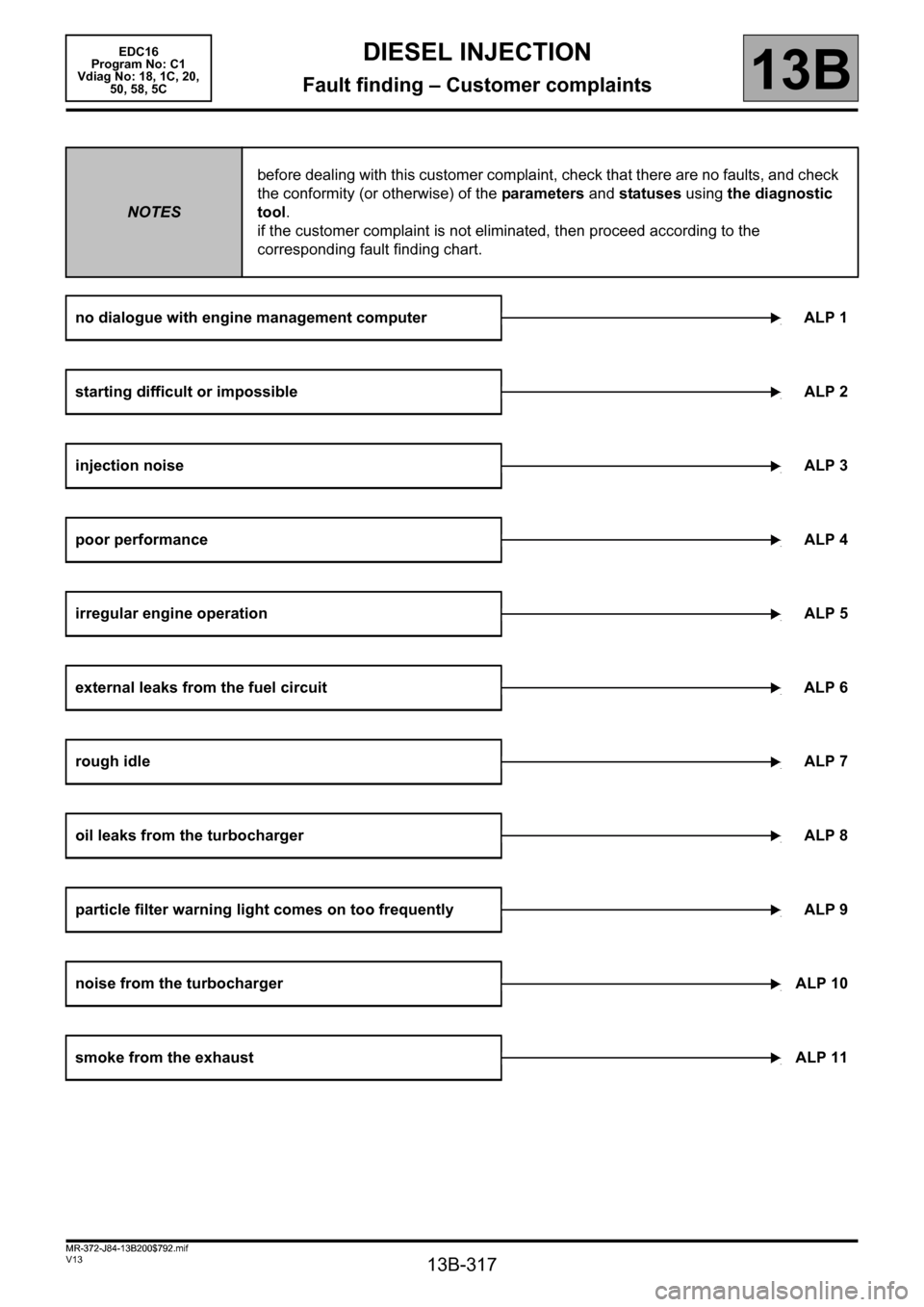

NOTESbefore dealing with this customer complaint, check that there are no faults, and check

the conformity (or otherwise) of the parameters and statuses using the diagnostic

tool.

if the customer complaint is not eliminated, then proceed according to the

corresponding fault finding chart.

no dialogue with engine management computer ALP 1

starting difficult or impossibleALP 2

injection noiseALP 3

poor performanceALP 4

irregular engine operationALP 5

external leaks from the fuel circuit ALP 6

rough idleALP 7

oil leaks from the turbochargerALP 8

particle filter warning light comes on too frequently ALP 9

noise from the turbochargerALP 10

smoke from the exhaustALP 11

EDC16

Program No: C1

Vdiag No: 18, 1C, 20,

50, 58, 5C

MR-372-J84-13B200$792.mif

Page 320 of 365

13B-320

MR-372-J84-13B200$828.mif

V13

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Fault Finding Chart13B

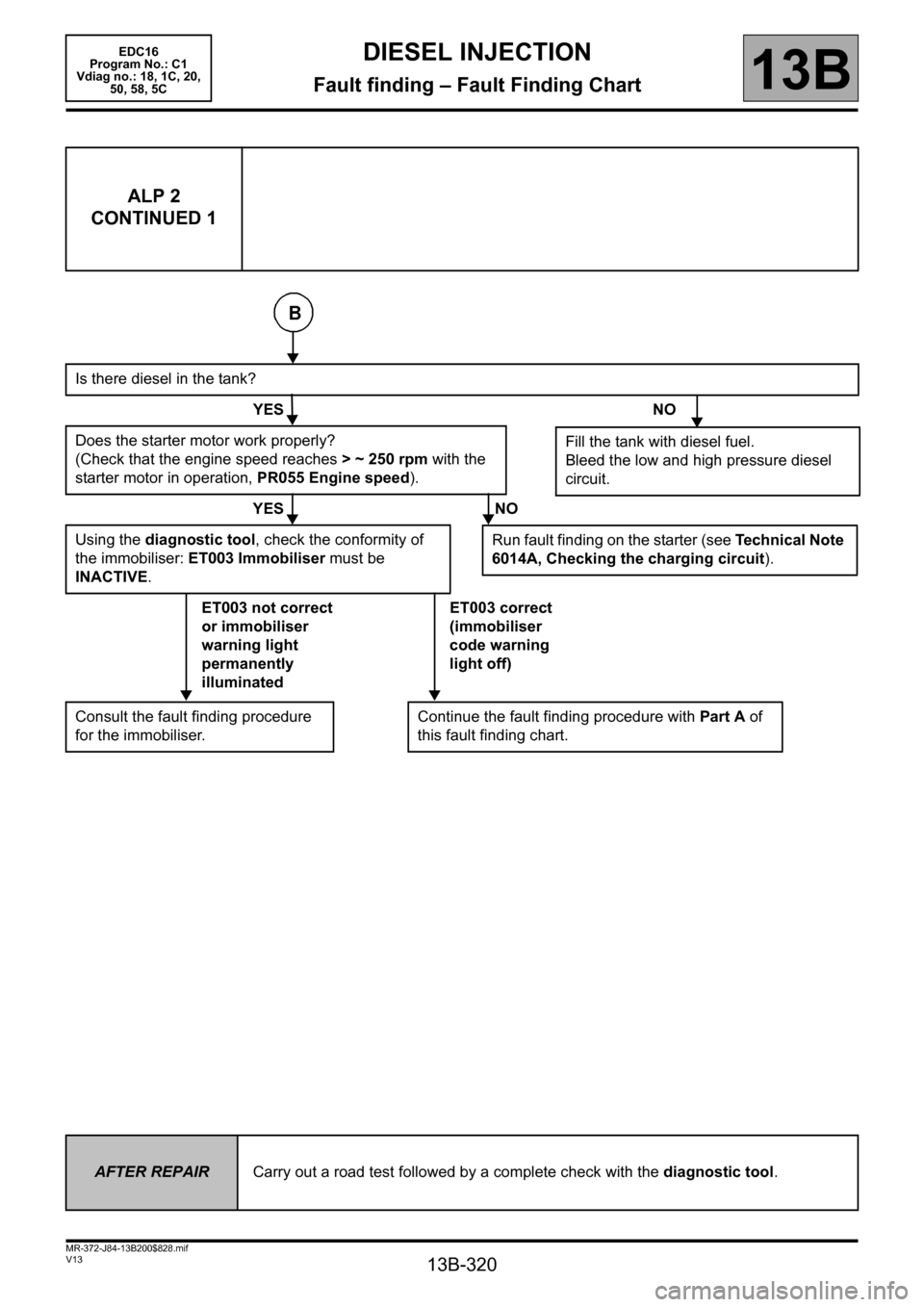

ALP 2

CONTINUED 1

Is there diesel in the tank?

YES NO

Does the starter motor work properly?

(Check that the engine speed reaches >~250rpm with the

starter motor in operation, PR055 Engine speed).

YES NO

Using the diagnostic tool, check the conformity of

the immobiliser: ET003 Immobiliser must be

INACTIVE.

ET003 not correct

or immobiliser

warning light

permanently

illuminatedET003 correct

(immobiliser

code warning

light off)

Consult the fault finding procedure

for the immobiliser.Continue the fault finding procedure with Part A of

this fault finding chart.

Fill the tank with diesel fuel.

Bleed the low and high pressure diesel

circuit.

Run fault finding on the starter (see Technical Note

6014A, Checking the charging circuit).

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

Page 322 of 365

13B-322

MR-372-J84-13B200$828.mif

V13

EDC16

Program No.: C1

Vdiag no.: 18, 1C, 20,

50, 58, 5CDIESEL INJECTION

Fault finding – Fault Finding Chart13B

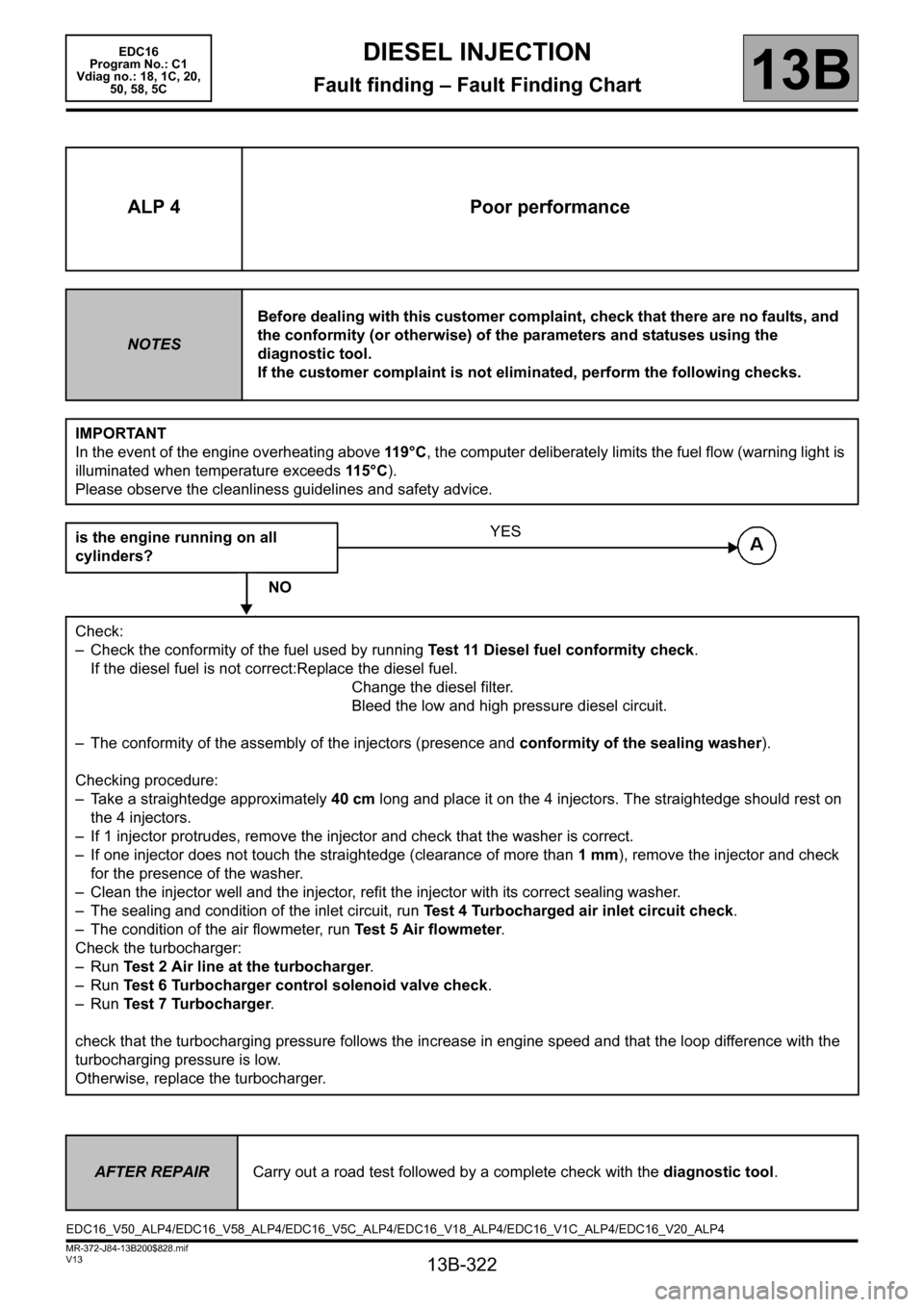

ALP 4 Poor performance

NOTESBefore dealing with this customer complaint, check that there are no faults, and

the conformity (or otherwise) of the parameters and statuses using the

diagnostic tool.

If the customer complaint is not eliminated, perform the following checks.

IMPORTANT

In the event of the engine overheating above 119°C, the computer deliberately limits the fuel flow (warning light is

illuminated when temperature exceeds 115 ° C).

Please observe the cleanliness guidelines and safety advice.

is the engine running on all

cylinders?

NO

Check:

– Check the conformity of the fuel used by running Test 11 Diesel fuel conformity check.

If the diesel fuel is not correct:Replace the diesel fuel.

Change the diesel filter.

Bleed the low and high pressure diesel circuit.

– The conformity of the assembly of the injectors (presence and conformity of the sealing washer).

Checking procedure:

– Take a straightedge approximately 40 cm long and place it on the 4 injectors. The straightedge should rest on

the 4 injectors.

– If 1 injector protrudes, remove the injector and check that the washer is correct.

– If one injector does not touch the straightedge (clearance of more than 1 mm), remove the injector and check

for the presence of the washer.

– Clean the injector well and the injector, refit the injector with its correct sealing washer.

– The sealing and condition of the inlet circuit, run Test 4 Turbocharged air inlet circuit check.

– The condition of the air flowmeter, run Test 5 Air flowmeter.

Check the turbocharger:

–Run Test 2 Air line at the turbocharger.

–Run Test 6 Turbocharger control solenoid valve check.

–Run Test 7 Turbocharger.

check that the turbocharging pressure follows the increase in engine speed and that the loop difference with the

turbocharging pressure is low.

Otherwise, replace the turbocharger.

YES

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16_V50_ALP4/EDC16_V58_ALP4/EDC16_V5C_ALP4/EDC16_V18_ALP4/EDC16_V1C_ALP4/EDC16_V20_ALP4