wiring RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 163 of 431

13B-163

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

*temp: temperature

DF309

PRESENT

OR

STOREDPARTICLE FILTER DOWNSTREAM TEMP.* SENSOR

CO.1: Open circuit or short circuit to +12 V

CC.0: Short circuit to earth

NOTESConditions for applying fault finding procedures to stored faults:

The fault becomes present if:

– ignition is on (CC.0),

– following a road test, engine warm (CO.1).

IMPORTANT

The particle filter downstream temperature sensor only measures temperatures

greater than 50°C.

Use the Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

CC.0

NOTESNone.

Check the condition of the particle filter downstream temperature sensor connector.

Check the condition of the engine management computer connector.

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation from earth of the following connections:

– connection code3TG,

– connection code3XU,

between components 120 and 1288.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the particle filter downstream temperature sensor.

EDC16C36_V48_DF309/EDC16C36_V58_DF309EDC16 C36

Program No.: 91

Vdiag No.: 48, 58

Page 164 of 431

13B-164

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF309

CONTINUED

CO.1NOTESNone.

Check the condition of the particle filter downstream temperature sensor connector.

Check the condition of the engine management computer connector.

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the continuity and insulation from + 12 V of the following connections:

– connection code3TG,

– connection code3XU,

between components 120 and 1288.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the particle filter downstream temperature sensor.

EDC16 C36

Program No.: 91

Vdiag No.: 48, 58

Page 165 of 431

13B-165

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF310

PRESENT

OR

STOREDPARTICLE FILTER UPSTREAM TEMP.* SENSOR

CO.1: Open circuit or short circuit to +12 V

CC.0: Short circuit to earth

NOTESConditions for applying fault finding procedures to stored faults:

The fault becomes present if:

– ignition is on (CC.0),

– following a road test, engine warm (CO.1).

Special notes:

If the fault is present:

– particle filter regeneration is inhibited,

–the level 1 warning light is lit,

–the OBD warning light comes on after three consecutive driving cycles (start

+5 seconds, switch off the ignition and wait 1 minute).

IMPORTANT

The particle filter upstream temperature sensor only measures temperatures

above 50°C.

Use the Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

EDC16C36_V48_DF310/EDC16C36_V50_DF310/EDC16C36_V58_DF310EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 166 of 431

13B-166

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

*temp: temperature

DF310

CONTINUED 1

CC.0NOTESNone.

Check the condition of the particle filter upstream temperature sensor connector.

Check the condition of the engine management computer connector.

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation from earth of the following connections:

– connection code3XT,

– connection code3TD,

between components 120 and 1287.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the wiring of the particle filter downstream temperature sensor, component code 1288, is present (with or without

the sensor being present), check the electrical insulation in relation to + 12 V between the following connections:

•3XU between components 120 and 1288,

•3TG between components 120 and 1288.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the particle filter upstream temperature sensor.

EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 167 of 431

13B-167

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$103.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF310

CONTINUED 2

CO.1NOTESNone.

Check the condition of the particle filter upstream temperature sensor connector.

Check the condition of the engine management computer connector.

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the continuity and insulation from + 12 V of the following connections:

– connection code3XT,

– connection code3TD,

between components 120 and 1287.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the particle filter upstream temperature sensor.

EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 175 of 431

13B-175

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

* diff: differential

DF315

PRESENT

OR

STOREDPARTICLE FILTER DIFF* PRESSURE SENSOR

CO: Open circuit

CC.1: Open circuit or short-circuit on + 12 volts

C0.0: Open circuit or short circuit to earth

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present after the engine is started or following a road test.

Special notes:

If the fault is present:

–the level 1 warning light is lit,

–the OBD warning light will come on after three consecutive driving cycles (start

+ 5 seconds + switch off the ignition switched and wait 1 minute),

– the particle filter fault finding procedure is inhibited,

– particle filter regeneration is inhibited.

Priorities when dealing with a number of faults:

– DF315 if it is present.

– DF308 "Particle filter clogged" if DF315 is stored and DF308 is present.

– DF011 Sensor supply voltage no. 1 if it is present or stored.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

EDC16C36_V48_DF315/EDC16C36_V50_DF315/EDC16C36_V58_DF315EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 176 of 431

13B-176

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF315

CONTINUED 1

CC.1NOTESNone.

Check the condition of the connector of the differential pressure sensor.

Check the condition of the connector of the engine management computer.

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation in relation to + 12 V on the following connections:

– connection code3TL,

– connection code3TM,

between components 120 and 1290.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the differential pressure sensor.

EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 177 of 431

13B-177

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF315

CONTINUED 2

CO.0

CONOTESNone.

Check the condition of the connector of the differential pressure sensor (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, Component code 1290).

Check the condition of the connector of the engine management computer (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, Component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the continuity and insulation to earth of the following connections:

– connection code3TL,

– connection code3TM,

between components 120 and 1290.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the wiring of the particle filter downstream temperature sensor, component code 1288, is present (with or without

the sensor being present), check the electrical insulation in relation to + 12 V between the following connections:

• 3XU between components 120 and 1288,

• 3TG between components 120 and 1288.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the differential pressure sensor.

EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 178 of 431

13B-178

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

* diff: differential

DF316

PRESENT

OR

STOREDPARTICLE FILTER DIFF* PRESSURE

1.DEF: Signal incoherent

2.DEF: Below minimum threshold

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

– the ignition is switched on.

– the engine is started.

Special notes:

If the fault is present:

– the particle filter fault finding procedure is inhibited,

–the Level 1 and OBD warning lights are lit.

Use bornier Ele. 1681 for all operations on the engine management computer

connector.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

Check the condition of the pressure pipes on the differential pressure sensor.

Check that they are sealed and in the correct position.

Replace if necessary.

Check the condition of the connectors on the differential pressure sensor and the injection computer.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

Check the continuity, insulation and the absence of interference resistance on the following connections:

– Connection code3AAQ,

– Connection code3TM,

– Connection code 3TL,

between components 1290 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the Techline.

EDC16C36_V48_DF316/EDC16C36_V50_DF316/EDC16C36_V58_DF316EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 179 of 431

13B-179

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check using the diagnostic tool.

V9 MR-372-J84-13B450$104.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

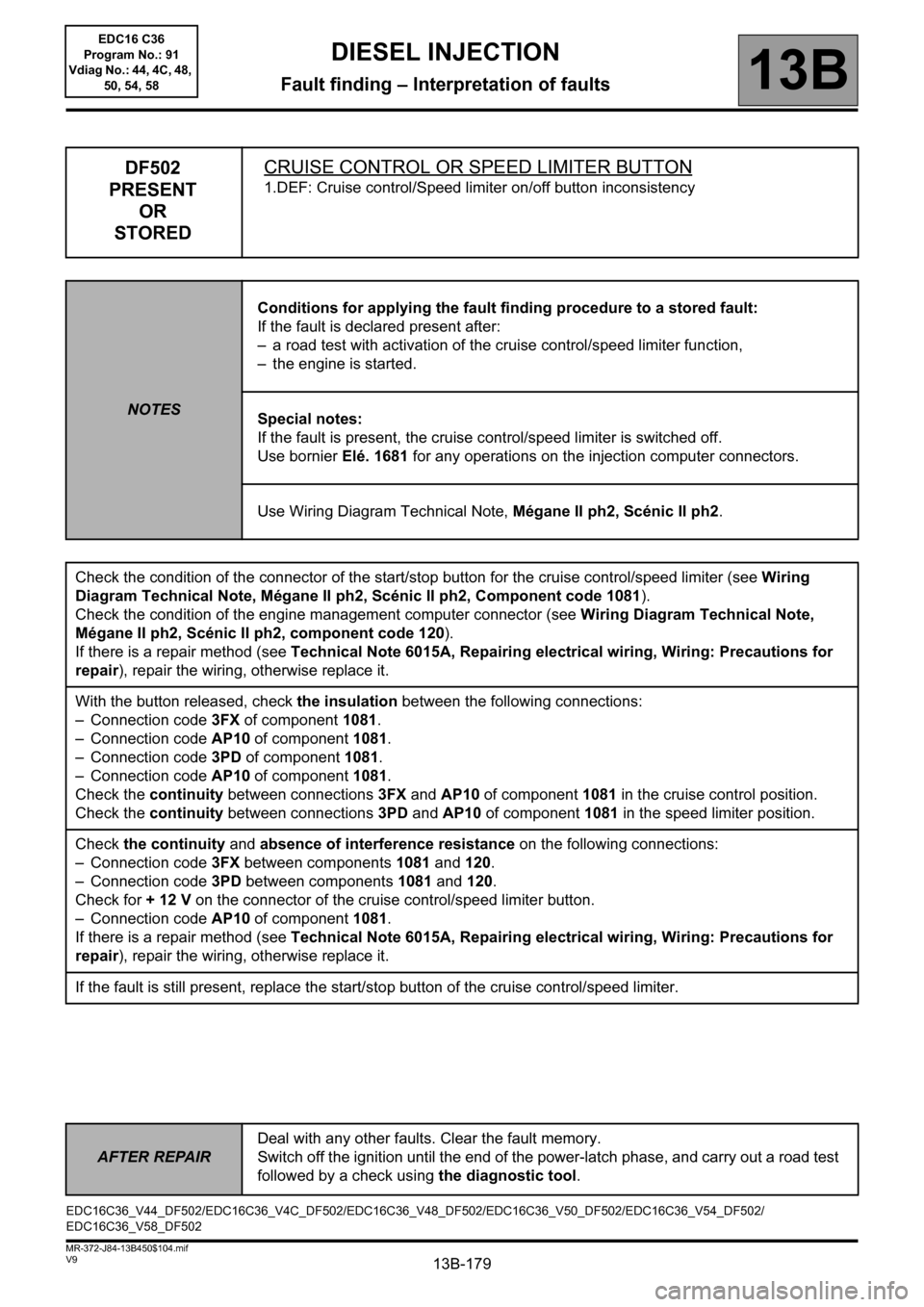

DF502

PRESENT

OR

STOREDCRUISE CONTROL OR SPEED LIMITER BUTTON

1.DEF: Cruise control/Speed limiter on/off button inconsistency

NOTESConditions for applying the fault finding procedure to a stored fault:

If the fault is declared present after:

– a road test with activation of the cruise control/speed limiter function,

– the engine is started.

Special notes:

If the fault is present, the cruise control/speed limiter is switched off.

Use bornier Elé. 1681 for any operations on the injection computer connectors.

Use Wiring Diagram Technical Note, Mégane II ph2, Scénic II ph2.

Check the condition of the connector of the start/stop button for the cruise control/speed limiter (see Wiring

Diagram Technical Note, Mégane II ph2, Scénic II ph2, Component code 1081).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, component code 120).

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the wiring, otherwise replace it.

With the button released, check the insulation between the following connections:

– Connection code 3FX of component 1081.

– Connection code AP10 of component 1081.

– Connection code 3PD of component 1081.

– Connection code AP10 of component 1081.

Check the continuity between connections 3FX and AP10 of component 1081 in the cruise control position.

Check the continuity between connections 3PD and AP10 of component 1081 in the speed limiter position.

Check the continuity and absence of interference resistance on the following connections:

– Connection code 3FX between components 1081 and 120.

– Connection code 3PD between components 1081 and 120.

Check for + 12 V on the connector of the cruise control/speed limiter button.

– Connection code AP10 of component 1081.

If there is a repair method (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair

), repair the wiring, otherwise replace it.

If the fault is still present, replace the start/stop button of the cruise control/speed limiter.

EDC16C36_V44_DF502/EDC16C36_V4C_DF502/EDC16C36_V48_DF502/EDC16C36_V50_DF502/EDC16C36_V54_DF502/

EDC16C36_V58_DF502EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58