engine overheat RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 383 of 431

13B-383

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

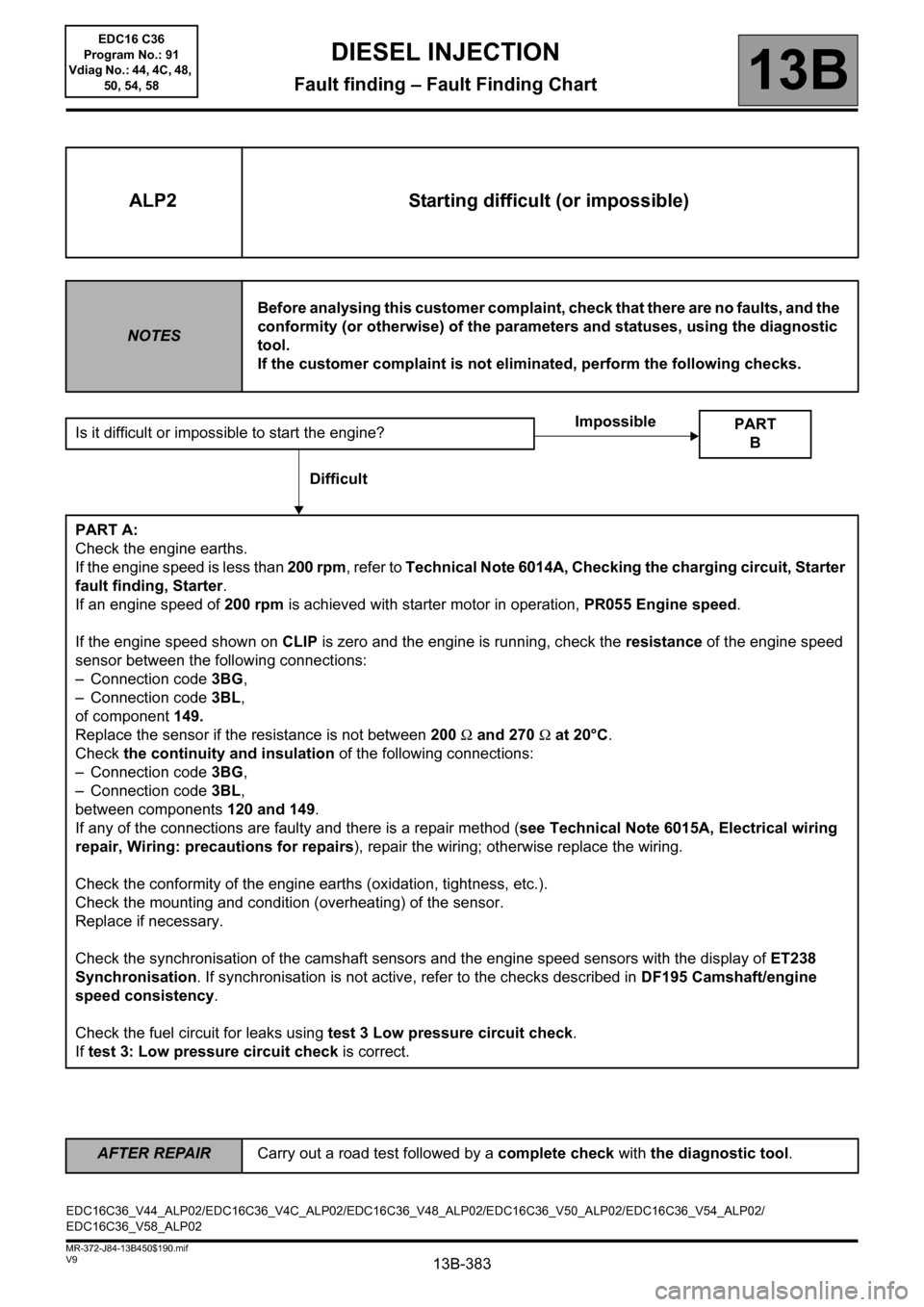

ALP2 Starting difficult (or impossible)

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not eliminated, perform the following checks.

Is it difficult or impossible to start the engine?

PART A:

Check the engine earths.

If the engine speed is less than 200 rpm, refer to Technical Note 6014A, Checking the charging circuit, Starter

fault finding, Starter.

If an engine speed of 200 rpm is achieved with starter motor in operation, PR055 Engine speed.

If the engine speed shown on CLIP is zero and the engine is running, check the resistance of the engine speed

sensor between the following connections:

– Connection code 3BG,

– Connection code 3BL,

of component 149.

Replace the sensor if the resistance is not between 200 Ω and 270 Ω at 20°C.

Check the continuity and insulation of the following connections:

– Connection code 3BG,

– Connection code 3BL,

between components 120 and 149.

If any of the connections are faulty and there is a repair method (see Technical Note 6015A, Electrical wiring

repair, Wiring: precautions for repairs), repair the wiring; otherwise replace the wiring.

Check the conformity of the engine earths (oxidation, tightness, etc.).

Check the mounting and condition (overheating) of the sensor.

Replace if necessary.

Check the synchronisation of the camshaft sensors and the engine speed sensors with the display of ET238

Synchronisation. If synchronisation is not active, refer to the checks described in DF195 Camshaft/engine

speed consistency.

Check the fuel circuit for leaks using test 3 Low pressure circuit check.

If test 3: Low pressure circuit check is correct.

PART

B

Impossible

Difficult

EDC16C36_V44_ALP02/EDC16C36_V4C_ALP02/EDC16C36_V48_ALP02/EDC16C36_V50_ALP02/EDC16C36_V54_ALP02/

EDC16C36_V58_ALP02EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 386 of 431

13B-386

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

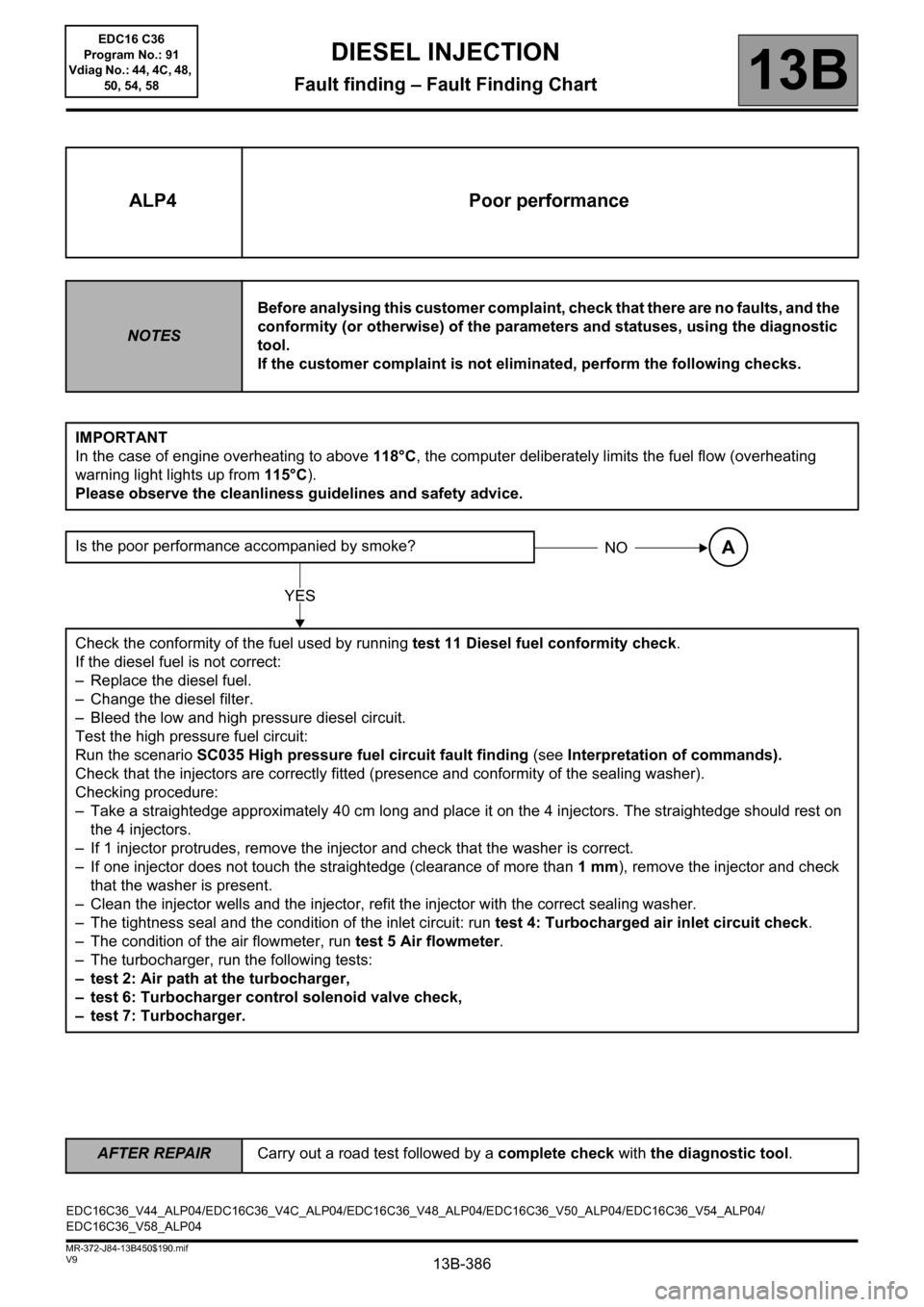

ALP4 Poor performance

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not eliminated, perform the following checks.

IMPORTANT

In the case of engine overheating to above 118°C, the computer deliberately limits the fuel flow (overheating

warning light lights up from 115°C).

Please observe the cleanliness guidelines and safety advice.

Is the poor performance accompanied by smoke?

Check the conformity of the fuel used by running test 11 Diesel fuel conformity check.

If the diesel fuel is not correct:

– Replace the diesel fuel.

– Change the diesel filter.

– Bleed the low and high pressure diesel circuit.

Test the high pressure fuel circuit:

Run the scenario SC035 High pressure fuel circuit fault finding (see Interpretation of commands).

Check that the injectors are correctly fitted (presence and conformity of the sealing washer).

Checking procedure:

– Take a straightedge approximately 40 cm long and place it on the 4 injectors. The straightedge should rest on

the 4 injectors.

– If 1 injector protrudes, remove the injector and check that the washer is correct.

– If one injector does not touch the straightedge (clearance of more than 1 mm), remove the injector and check

that the washer is present.

– Clean the injector wells and the injector, refit the injector with the correct sealing washer.

– The tightness seal and the condition of the inlet circuit: run test 4: Turbocharged air inlet circuit check.

– The condition of the air flowmeter, run test 5 Air flowmeter.

– The turbocharger, run the following tests:

– test 2: Air path at the turbocharger,

– test 6: Turbocharger control solenoid valve check,

– test 7: Turbocharger.

NOA

YES

EDC16C36_V44_ALP04/EDC16C36_V4C_ALP04/EDC16C36_V48_ALP04/EDC16C36_V50_ALP04/EDC16C36_V54_ALP04/

EDC16C36_V58_ALP04EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 388 of 431

13B-388

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

V9 MR-372-J84-13B450$190.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

ALP5 Irregular engine operation

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic

tool.

If the customer complaint is not eliminated, perform the following checks.

If the engine races during gear changes, if there is a floor carpet, check that this is not blocking the accelerator

pedal, the brake pedal and the clutch pedal, then check the conformity of the clutch switch and the conformity of

the accelerator pedal sensor when the pedal is released.

Measure the resistance of the engine speed sensor between the following connections:

– Connection code 3BG,

– Connection code 3BL,

of component 149.

Replace the sensor if the resistance is not 200 Ω to 270 Ω at +20°C

Check the continuity of the following connections:

– Connection code 3BG,

– Connection code 3BL,

between components120 and 149.

Check the conformity of the engine earths (oxidation, tightness, etc.).

Check the mounting and condition (overheating) of the sensor.

Replace if necessary.

Check the low pressure circuit, run test 3 Low pressure circuit check.

Apply the air flow test procedure (see Interpretation of statuses and Interpretation of parameters).

Check the turbocharger, apply the following tests:

– test 2: Air path at the turbocharger,

– test 6: Turbocharger control solenoid valve check,

– test 7: Turbocharger.

Test the high pressure fuel circuit:

Run scenario SC035 High pressure fuel circuit fault finding (see Interpretation of commands).

If the customer complaint is still present, contact Techline.

EDC16C36_V44_ALP05/EDC16C36_V4C_ALP05/EDC16C36_V48_ALP05/EDC16C36_V50_ALP05/EDC16C36_V54_ALP05/

EDC16C36_V58_ALP05EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58