weight RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 258 of 431

13B-258V9 MR-372-J84-13B450$132.mif

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

* Regen: regeneration

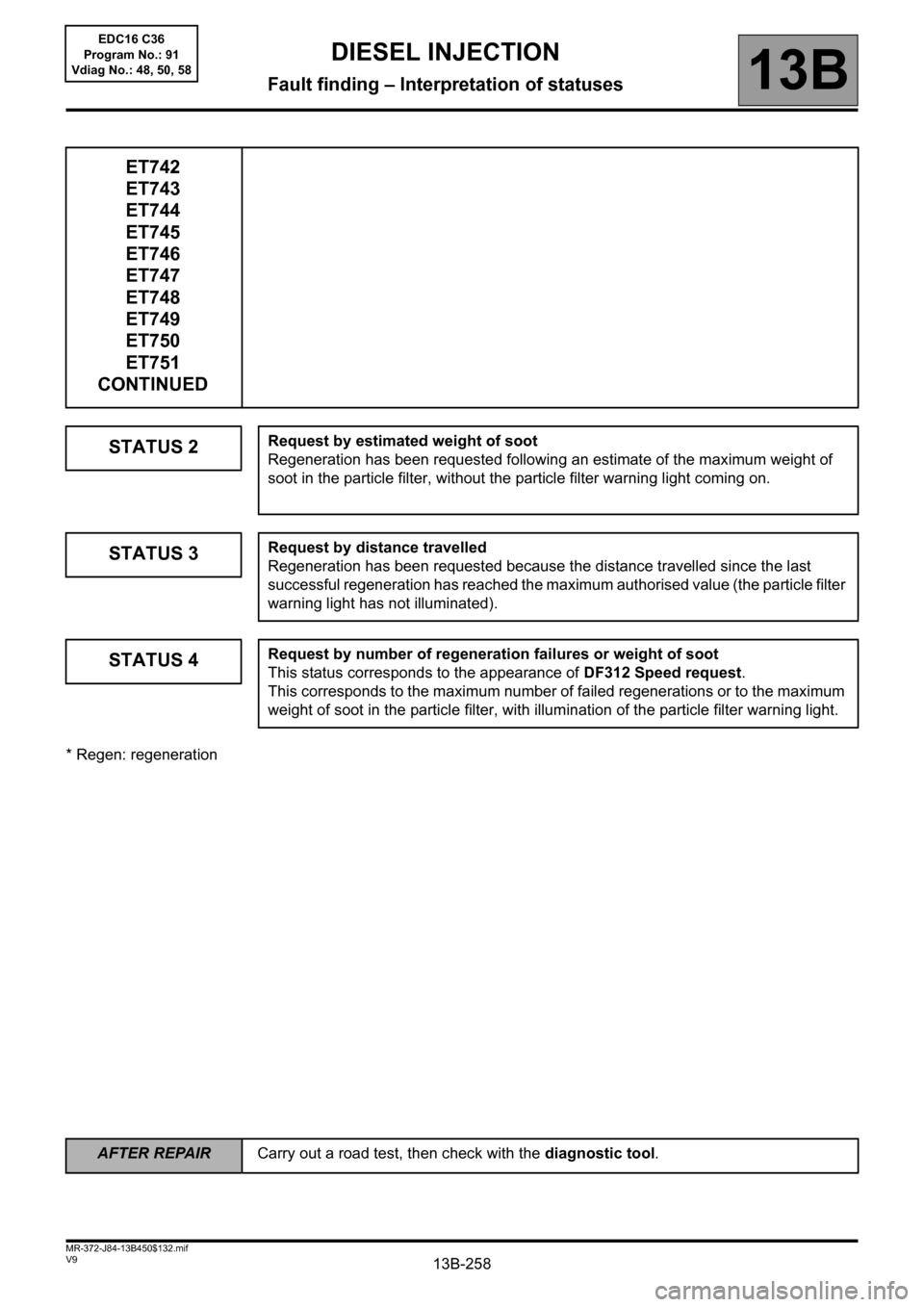

ET742

ET743

ET744

ET745

ET746

ET747

ET748

ET749

ET750

ET751

CONTINUED

STATUS 2

Request by estimated weight of soot

Regeneration has been requested following an estimate of the maximum weight of

soot in the particle filter, without the particle filter warning light coming on.

STATUS 3Request by distance travelled

Regeneration has been requested because the distance travelled since the last

successful regeneration has reached the maximum authorised value (the particle filter

warning light has not illuminated).

STATUS 4Request by number of regeneration failures or weight of soot

This status corresponds to the appearance of DF312 Speed request.

This corresponds to the maximum number of failed regenerations or to the maximum

weight of soot in the particle filter, with illumination of the particle filter warning light.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 260 of 431

13B-260V9 MR-372-J84-13B450$140.mif

DIESEL INJECTION

Fault finding – Parameter summary table13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

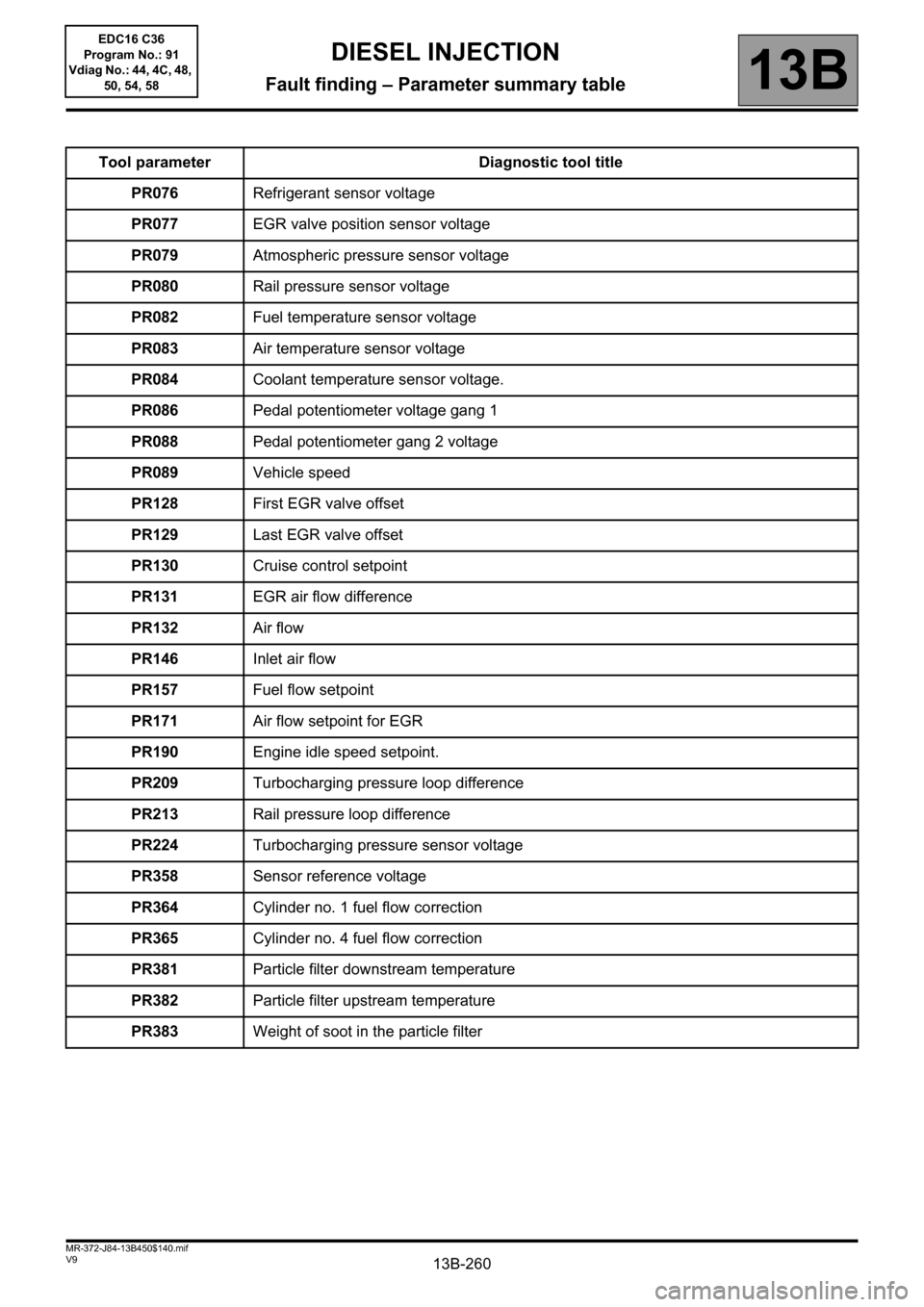

Tool parameter Diagnostic tool title

PR076Refrigerant sensor voltage

PR077EGR valve position sensor voltage

PR079Atmospheric pressure sensor voltage

PR080Rail pressure sensor voltage

PR082Fuel temperature sensor voltage

PR083Air temperature sensor voltage

PR084Coolant temperature sensor voltage.

PR086Pedal potentiometer voltage gang 1

PR088Pedal potentiometer gang 2 voltage

PR089Vehicle speed

PR128First EGR valve offset

PR129Last EGR valve offset

PR130Cruise control setpoint

PR131EGR air flow difference

PR132Air flow

PR146Inlet air flow

PR157Fuel flow setpoint

PR171Air flow setpoint for EGR

PR190Engine idle speed setpoint.

PR209Turbocharging pressure loop difference

PR213Rail pressure loop difference

PR224Turbocharging pressure sensor voltage

PR358Sensor reference voltage

PR364Cylinder no. 1 fuel flow correction

PR365Cylinder no. 4 fuel flow correction

PR381Particle filter downstream temperature

PR382Particle filter upstream temperature

PR383Weight of soot in the particle filter

Page 322 of 431

13B-322V9 MR-372-J84-13B450$152.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

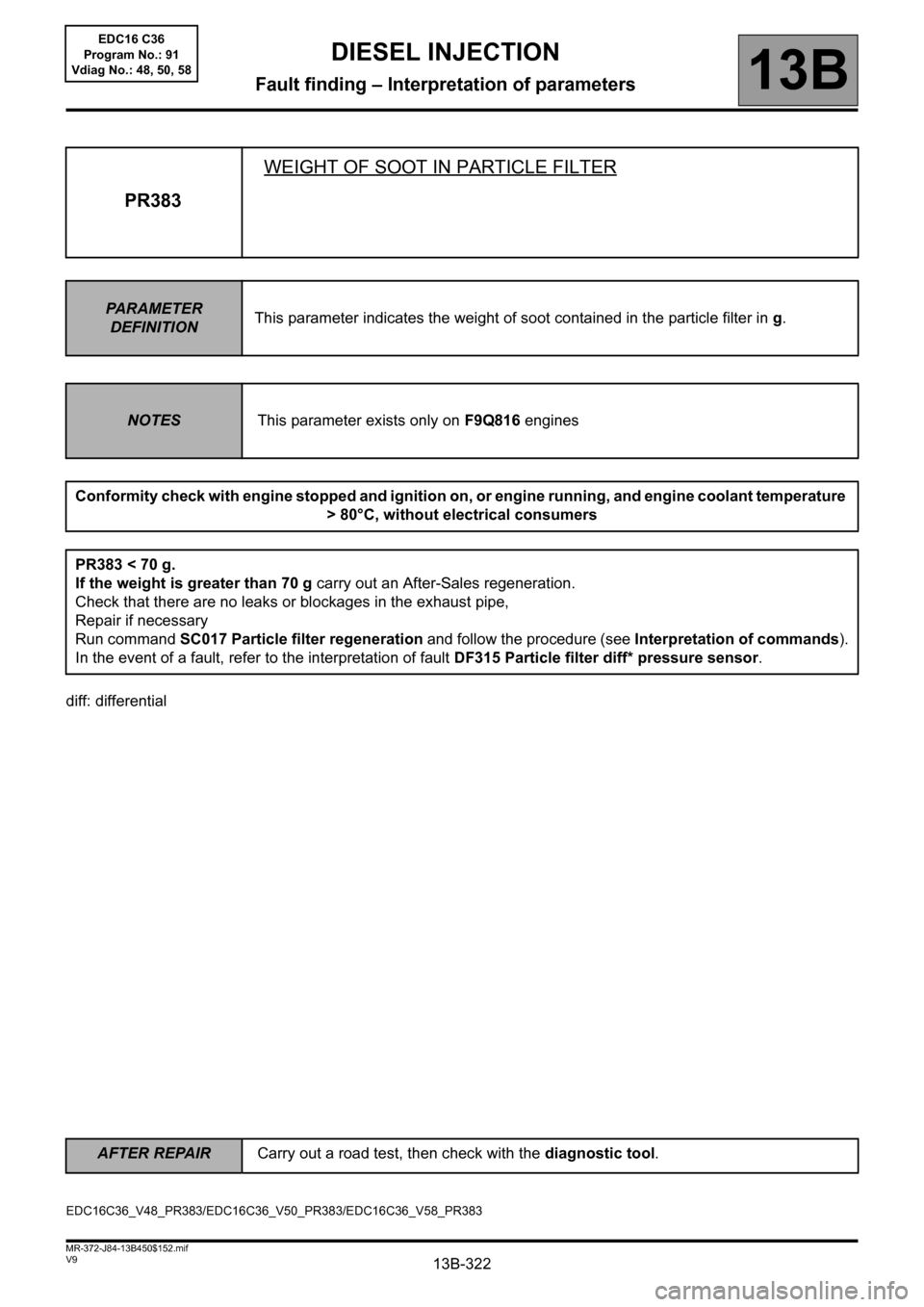

diff: differential

PR383WEIGHT OF SOOT IN PARTICLE FILTER

PARAMETER

DEFINITIONThis parameter indicates the weight of soot contained in the particle filter in g.

NOTESThis parameter exists only on F9Q816 engines

Conformity check with engine stopped and ignition on, or engine running, and engine coolant temperature

> 80°C, without electrical consumers

PR383 < 70 g.

If the weight is greater than 70 g carry out an After-Sales regeneration.

Check that there are no leaks or blockages in the exhaust pipe,

Repair if necessary

Run command SC017 Particle filter regeneration and follow the procedure (see Interpretation of commands).

In the event of a fault, refer to the interpretation of fault DF315 Particle filter diff* pressure sensor.

EDC16C36_V48_PR383/EDC16C36_V50_PR383/EDC16C36_V58_PR383

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 349 of 431

13B-349V9 MR-372-J84-13B450$152.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

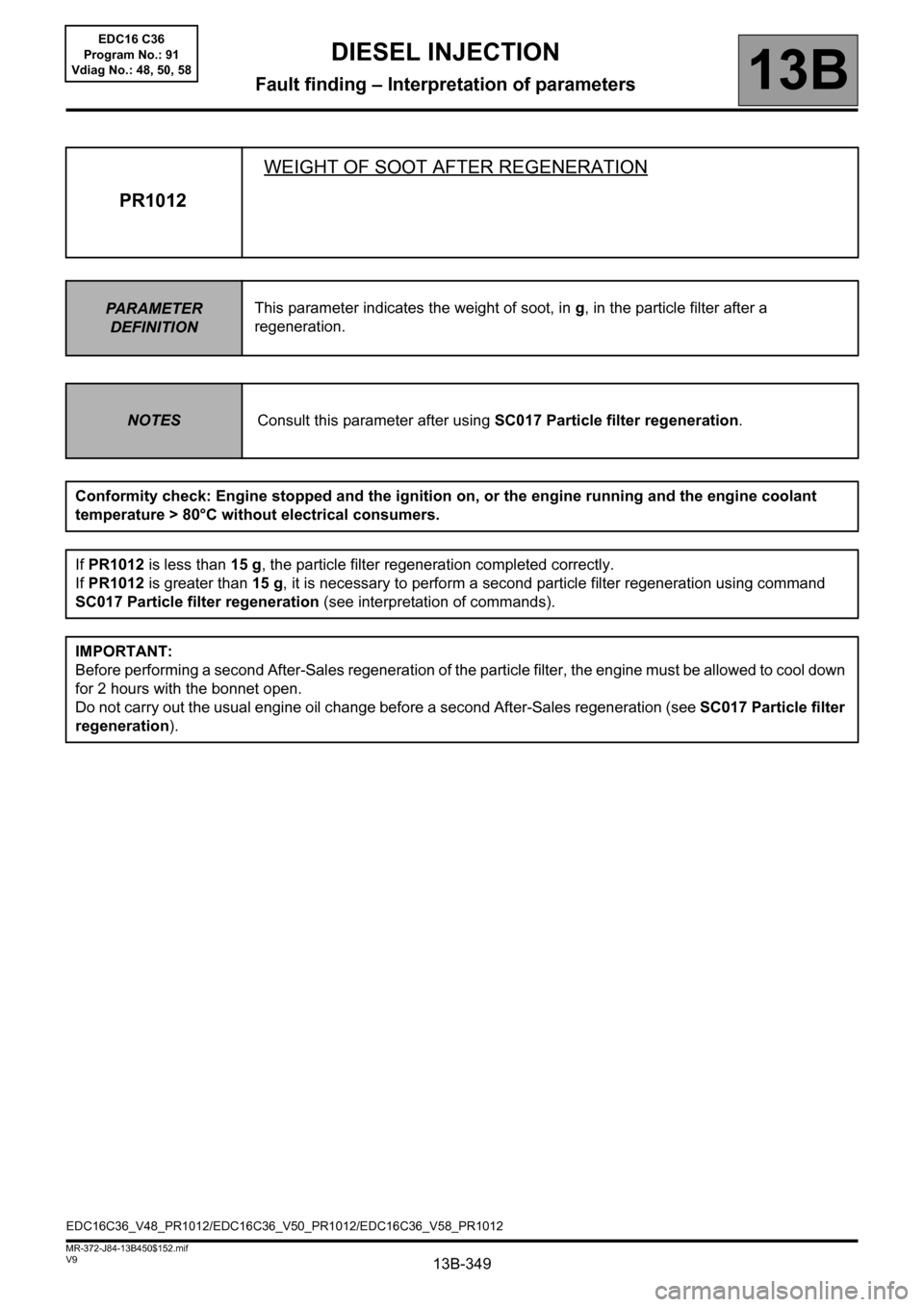

PR1012WEIGHT OF SOOT AFTER REGENERATION

PARAMETER

DEFINITIONThis parameter indicates the weight of soot, in g, in the particle filter after a

regeneration.

NOTESConsult this parameter after using SC017 Particle filter regeneration.

Conformity check: Engine stopped and the ignition on, or the engine running and the engine coolant

temperature > 80°C without electrical consumers.

If PR1012 is less than 15 g, the particle filter regeneration completed correctly.

If PR1012 is greater than 15 g, it is necessary to perform a second particle filter regeneration using command

SC017 Particle filter regeneration (see interpretation of commands).

IMPORTANT:

Before performing a second After-Sales regeneration of the particle filter, the engine must be allowed to cool down

for 2 hours with the bonnet open.

Do not carry out the usual engine oil change before a second After-Sales regeneration (see SC017 Particle filter

regeneration).

EDC16C36_V48_PR1012/EDC16C36_V50_PR1012/EDC16C36_V58_PR1012EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 356 of 431

13B-356

AFTER REPAIRRepeat the conformity check in the interpretation of statuses and parameters

V9 MR-372-J84-13B450$170.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

SC017

CONTINUED 1

DESCRIPTION OF THE PROCESS

Particle filter regeneration takes place in 3 stages (values given as a guide only):

–Heating phase: the engine speed is fixed or fluctuating around 2000 rpm.

This phase lasts between 8 and 14 minutes, until the coolant temperature exceeds 70°C.

–Regeneration phase: the speed is fixed or varies around 2000 rpm. Engine injection is retarded. The exhaust

fumes rise in temperature and burn the soot retained in the particle filter. Then the combustion of the soot stored

in the particle filter causes the particle filter upstream temperature to increase, possibly reaching 600°C

depending on the amount of soot in the particle filter. This phase lasts 28 minutes.

–Cooling phase: the engine speed decreases to 1250 rpm then increases to 1750 rpm.

Engine injection returns to normal and the exhaust gases cool the particle filter.

This phase lasts 3 minutes.

The procedure lasts at least 40 minutes, and varies depending on the time taken to reach a coolant temperature

of 70°C.

VALIDATING THE REGENERATION PROCESS:

At the end of regeneration, a message appears to announce whether the regeneration was successful:

●Particle filter regeneration finished:

Consult PR1012 Weight of soot after regeneration. If PR1012 is less than 15 g, the particle filter regeneration

completed correctly. If PR1012 is greater than 15 g, a second particle filter regeneration must be performed using

the command in the diagnostic tool and choose command SC017.

EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 357 of 431

13B-357

AFTER REPAIRRepeat the conformity check in the interpretation of statuses and parameters

V9 MR-372-J84-13B450$170.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

SC017

CONTINUED 2

IMPORTANT:

Before performing a second After-Sales regeneration of the particle filter, the engine must be allowed to cool down

for 2 hours with the bonnet open.

Do not carry out the usual engine oil change before a second After-Sales regeneration.

Only for Vdiag 50:

– Change the engine oil if a message on the instrument panel requests it.

For the other VDiag:

–Consult PR848 Number of regeneration failures. If PR848 is greater than 3, change the engine oil.

●Particle filter too full - replace the particle filter: regeneration has failed. The weight of soot in the particle

filter is so great that it is creating back-pressure. Deal with any faults that appear or replace the particle filter.

Run command SC036 Reinitialise programming and select After particle filter replacement.

– Switch off the ignition and wait for the diagnostic tool message (maximum time 8 minutes): Communication

lost with computer: EDC16C36, check the tool connection and computer power supply.

–Then switch on the ignition again, clear the present or stored faults from the computer memory (operation

to be carried out within 3 minutes of switching on the ignition).

– Check the weight of soot: PR383 Weight of soot in the particle filter.

– If PR383

≥ 1 g. Apply the procedure of test 12 Manual clearing of the weight of soot.

Only for Vdiag 50:

– Change the engine oil if a message on the instrument panel requests it.

– For the other Vdiags:

–Consult PR848 Number of regeneration failures. If this parameter is greater than 3, it is essential to change

the engine oil.

– Explain to the customer the procedure for regeneration when driving to avoid unnecessary repairs: see PART D

in the interpretation of DF312 Speed request.

EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 358 of 431

13B-358

AFTER REPAIRRepeat the conformity check in the interpretation of statuses and parameters

V9 MR-372-J84-13B450$170.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

SC017

CONTINUED 3

●Particle filter regeneration failed - run test Temperature upstream of turbine too low: regeneration has

failed because the temperature upstream of the turbine is too low. Run Test 8 Temperature upstream of

turbine too low.

In all cases, carry out the following operations:

– switch off the ignition and wait for the diagnostic tool message (maximum time 8 minutes): Communication

lost with computer: EDC16C36, check the tool connection and the computer supply.

– switch on the ignition and establish dialogue with the injection computer,

– run command SC036 Reinitialise programming,

– depending on the operation performed, select After particle filter regeneration with diagnostic tool, or After

particle filter replacement

– switch off the ignition and wait for the diagnostic tool message (maximum time 8 minutes): Communication

lost with computer: EDC16C36, check the tool connection and the computer supply.

–Then switch on the ignition again, clear the present or stored faults from the computer memory (operation

to be carried out within 3 minutes of switching on the ignition).

– Check the weight of soot: PR383 Weight of soot in the particle filter.

– If PR383

≥ 1 g. Apply test procedure 12 Manual clearing of the weight of soot.

If DF308 Particle filter clogged or DF312 Speed request is still present, contact Techline.

Note:

It is essential to change the engine oil and the oil filter in the following cases:

– following an After-Sales regeneration only if a message on the CLIP diagnostic tool requests it,

– following particle filter replacement,

after a second regeneration (when two successive regenerations).

EDC16 C36

Program No.: 91

Vdiag No.: 48, 50, 58

Page 364 of 431

13B-364

AFTER REPAIRRepeat the conformity check in the interpretation of statuses and parameters

V9 MR-372-J84-13B450$170.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

SC036

CONTINUED

Features of the selections: After particle filter regeneration with diagnostic tool and After replacement of the

particle filter:

After using one of these 2 commands:

– switch off the ignition and wait for the diagnostic tool message (maximum time 8 minutes): Communication

lost with computer: EDC16C36, check the tool connection and computer power supply.

–Then switch on the ignition again and clear the present or stored faults from the computer memory

(operation to be carried out within 3 minutes of switching on the ignition).

– Check the weight of soot: PR383 Weight of soot in the particle filter.

– If PR383

≥ 1 g. Apply test procedure 12 Manual clearing of the weight of soot.

IMPORTANT

When reinitialising injectors, do not forget that cylinder no. 1 is located at the flywheel end.

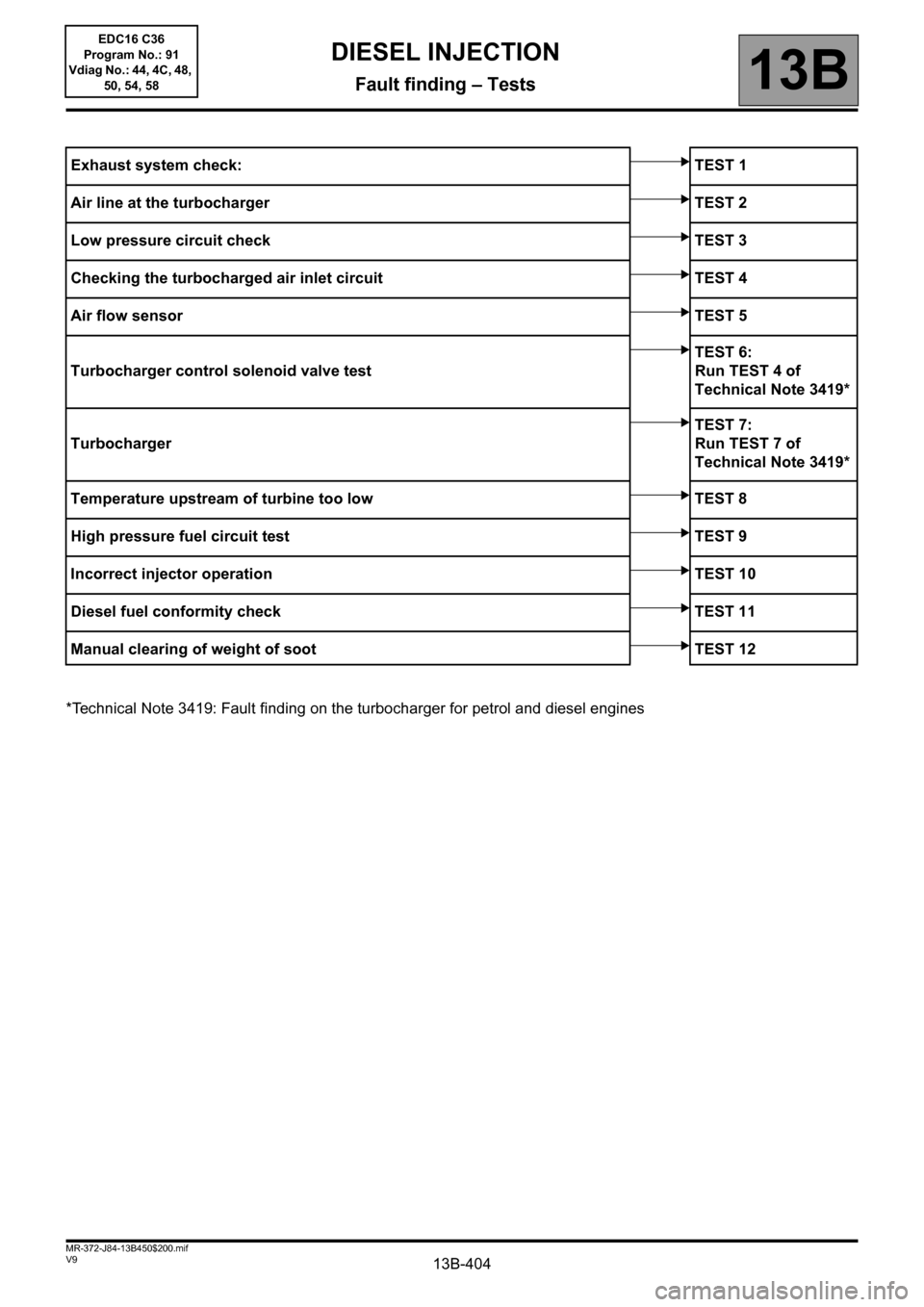

Page 404 of 431

13B-404V9 MR-372-J84-13B450$200.mif

13B

*Technical Note 3419: Fault finding on the turbocharger for petrol and diesel enginesExhaust system check: TEST 1

Air line at the turbocharger TEST 2

Low pressure circuit check TEST 3

Checking the turbocharged air inlet circuit TEST 4

Air flow sensorTEST 5

Turbocharger control solenoid valve testTEST 6:

Run TEST 4 of

Technical Note 3419*

TurbochargerTEST 7:

Run TEST 7 of

Technical Note 3419*

Temperature upstream of turbine too low TEST 8

High pressure fuel circuit test TEST 9

Incorrect injector operation TEST 10

Diesel fuel conformity check TEST 11

Manual clearing of weight of soot TEST 12

DIESEL INJECTION

Fault finding – Tests

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

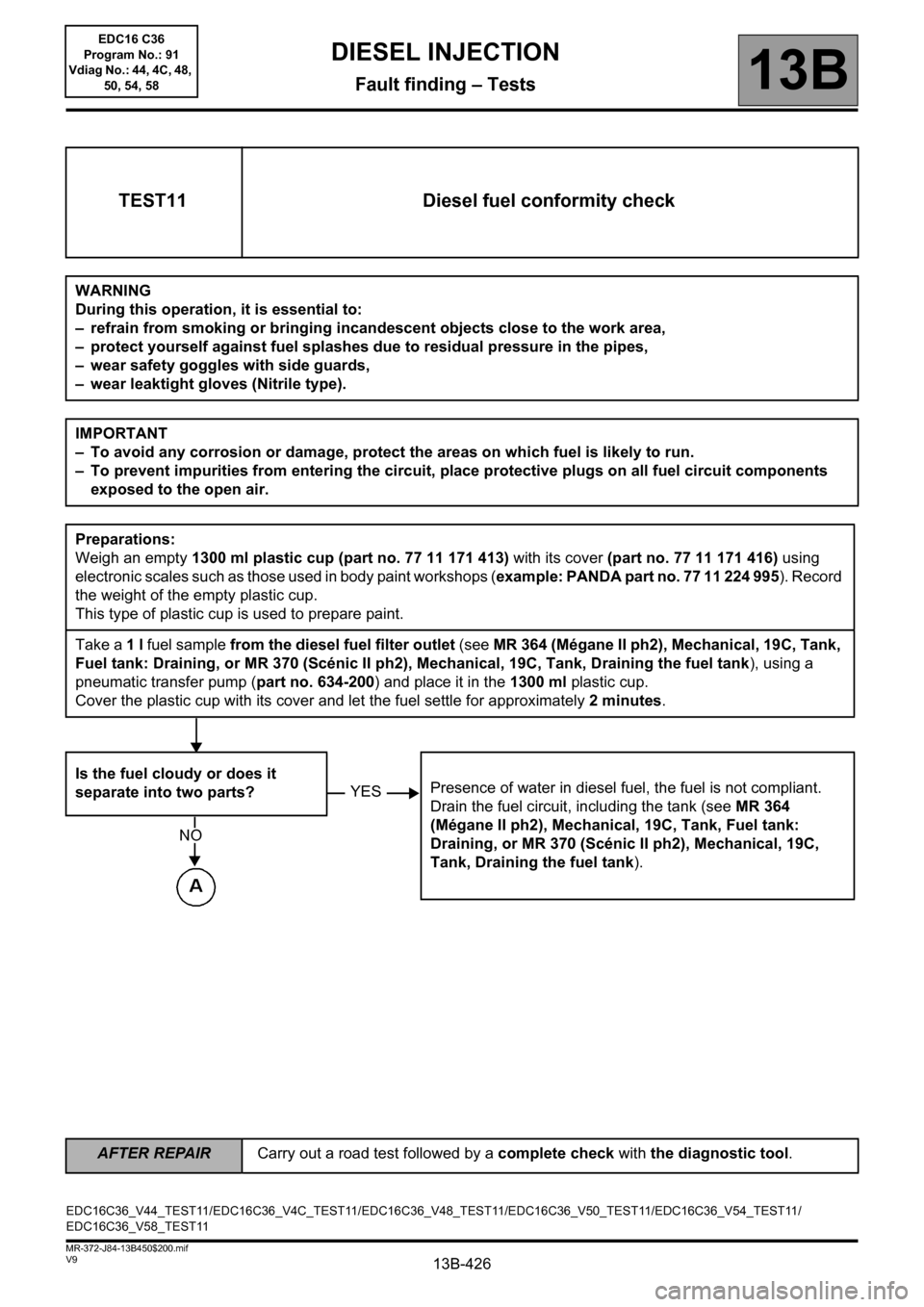

Page 426 of 431

13B-426V9 MR-372-J84-13B450$200.mif

DIESEL INJECTION

Fault finding – Tests13B

TEST11 Diesel fuel conformity check

WARNING

During this operation, it is essential to:

– refrain from smoking or bringing incandescent objects close to the work area,

– protect yourself against fuel splashes due to residual pressure in the pipes,

– wear safety goggles with side guards,

– wear leaktight gloves (Nitrile type).

IMPORTANT

– To avoid any corrosion or damage, protect the areas on which fuel is likely to run.

– To prevent impurities from entering the circuit, place protective plugs on all fuel circuit components

exposed to the open air.

Preparations:

Weigh an empty 1300 ml plastic cup (part no. 77 11 171 413) with its cover (part no. 77 11 171 416) using

electronic scales such as those used in body paint workshops (example: PANDA part no. 77 11 224 995). Record

the weight of the empty plastic cup.

This type of plastic cup is used to prepare paint.

Take a 1 l fuel sample from the diesel fuel filter outlet (see MR 364 (Mégane II ph2), Mechanical, 19C, Tank,

Fuel tank: Draining, or MR 370 (Scénic II ph2), Mechanical, 19C, Tank, Draining the fuel tank), using a

pneumatic transfer pump (part no. 634-200) and place it in the 1300 ml plastic cup.

Cover the plastic cup with its cover and let the fuel settle for approximately 2 minutes.

Is the fuel cloudy or does it

separate into two parts?Presence of water in diesel fuel, the fuel is not compliant.

Drain the fuel circuit, including the tank (see MR 364

(Mégane II ph2), Mechanical, 19C, Tank, Fuel tank:

Draining, or MR 370 (Scénic II ph2), Mechanical, 19C,

Tank, Draining the fuel tank).

YES

NO

EDC16C36_V44_TEST11/EDC16C36_V4C_TEST11/EDC16C36_V48_TEST11/EDC16C36_V50_TEST11/EDC16C36_V54_TEST11/

EDC16C36_V58_TEST11EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.