fuel filter RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals EDC16C36 Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 431, PDF Size: 2.03 MB

Page 408 of 431

13B-408V9 MR-372-J84-13B450$200.mif

DIESEL INJECTION

Fault finding – Tests13B

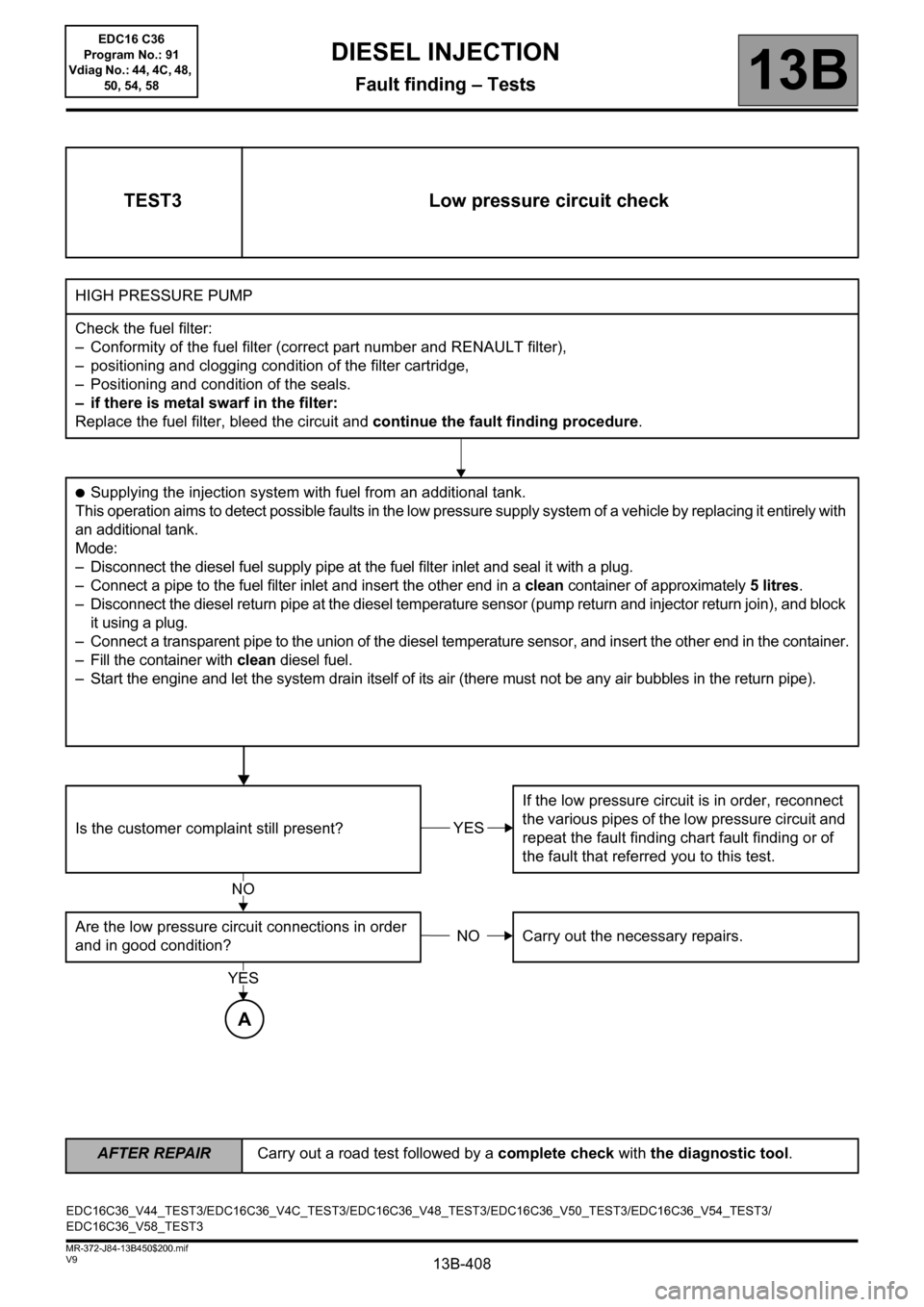

TEST3 Low pressure circuit check

HIGH PRESSURE PUMP

Check the fuel filter:

– Conformity of the fuel filter (correct part number and RENAULT filter),

– positioning and clogging condition of the filter cartridge,

– Positioning and condition of the seals.

– if there is metal swarf in the filter:

Replace the fuel filter, bleed the circuit and continue the fault finding procedure.

●Supplying the injection system with fuel from an additional tank.

This operation aims to detect possible faults in the low pressure supply system of a vehicle by replacing it entirely with

an additional tank.

Mode:

– Disconnect the diesel fuel supply pipe at the fuel filter inlet and seal it with a plug.

– Connect a pipe to the fuel filter inlet and insert the other end in a clean container of approximately 5litres.

– Disconnect the diesel return pipe at the diesel temperature sensor (pump return and injector return join), and block

it using a plug.

– Connect a transparent pipe to the union of the diesel temperature sensor, and insert the other end in the container.

– Fill the container with clean diesel fuel.

– Start the engine and let the system drain itself of its air (there must not be any air bubbles in the return pipe).

Is the customer complaint still present?If the low pressure circuit is in order, reconnect

the various pipes of the low pressure circuit and

repeat the fault finding chart fault finding or of

the fault that referred you to this test.

Are the low pressure circuit connections in order

and in good condition?Carry out the necessary repairs.

YES

NO

NO

YES

A

EDC16C36_V44_TEST3/EDC16C36_V4C_TEST3/EDC16C36_V48_TEST3/EDC16C36_V50_TEST3/EDC16C36_V54_TEST3/

EDC16C36_V58_TEST3

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 409 of 431

13B-409V9 MR-372-J84-13B450$200.mif

DIESEL INJECTION

Fault finding – Tests13B

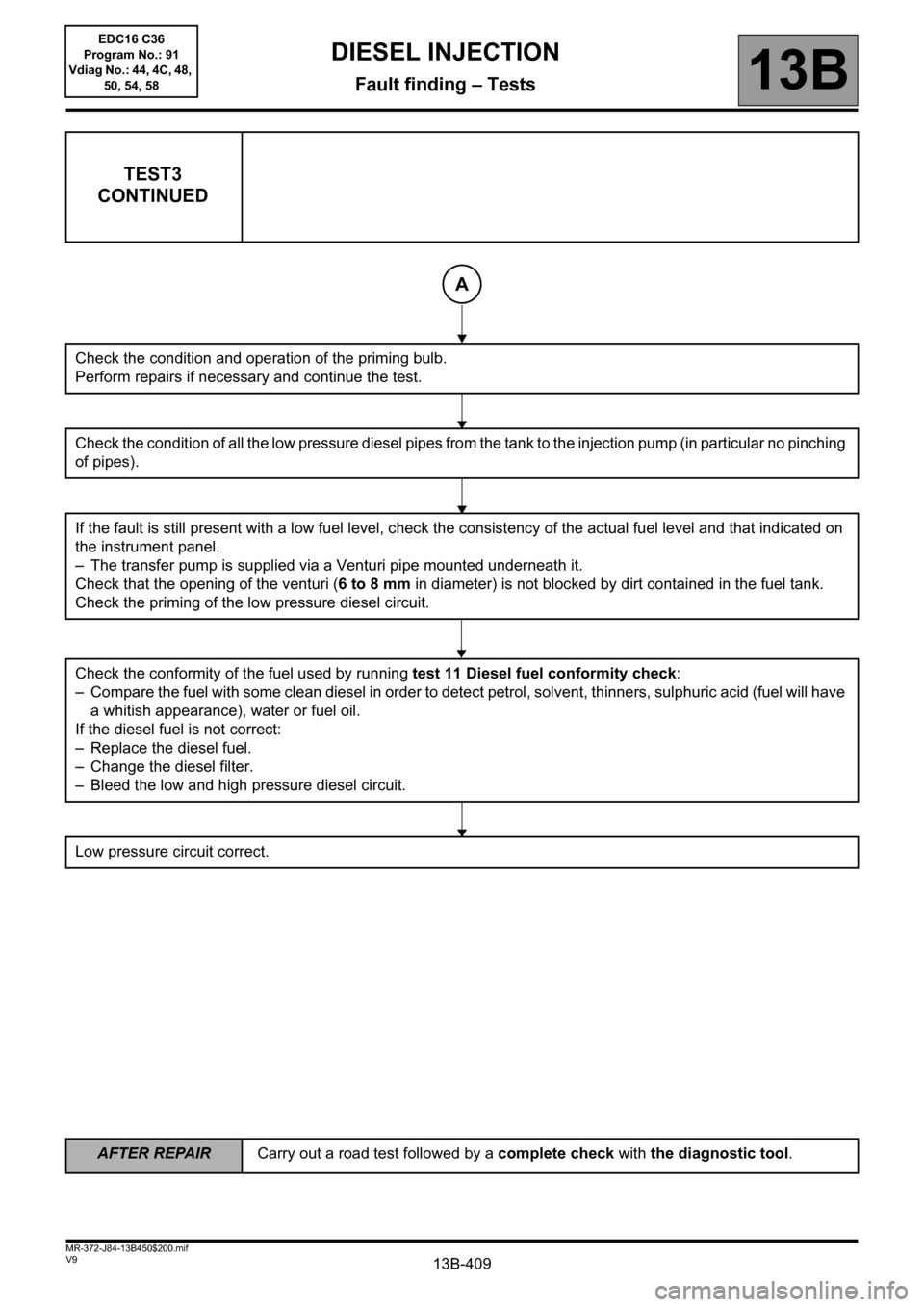

TEST3

CONTINUED

Check the condition and operation of the priming bulb.

Perform repairs if necessary and continue the test.

Check the condition of all the low pressure diesel pipes from the tank to the injection pump (in particular no pinching

of pipes).

If the fault is still present with a low fuel level, check the consistency of the actual fuel level and that indicated on

the instrument panel.

– The transfer pump is supplied via a Venturi pipe mounted underneath it.

Check that the opening of the venturi (6 to 8 mm in diameter) is not blocked by dirt contained in the fuel tank.

Check the priming of the low pressure diesel circuit.

Check the conformity of the fuel used by running test 11 Diesel fuel conformity check:

– Compare the fuel with some clean diesel in order to detect petrol, solvent, thinners, sulphuric acid (fuel will have

a whitish appearance), water or fuel oil.

If the diesel fuel is not correct:

– Replace the diesel fuel.

– Change the diesel filter.

– Bleed the low and high pressure diesel circuit.

Low pressure circuit correct.

A

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

Page 426 of 431

13B-426V9 MR-372-J84-13B450$200.mif

DIESEL INJECTION

Fault finding – Tests13B

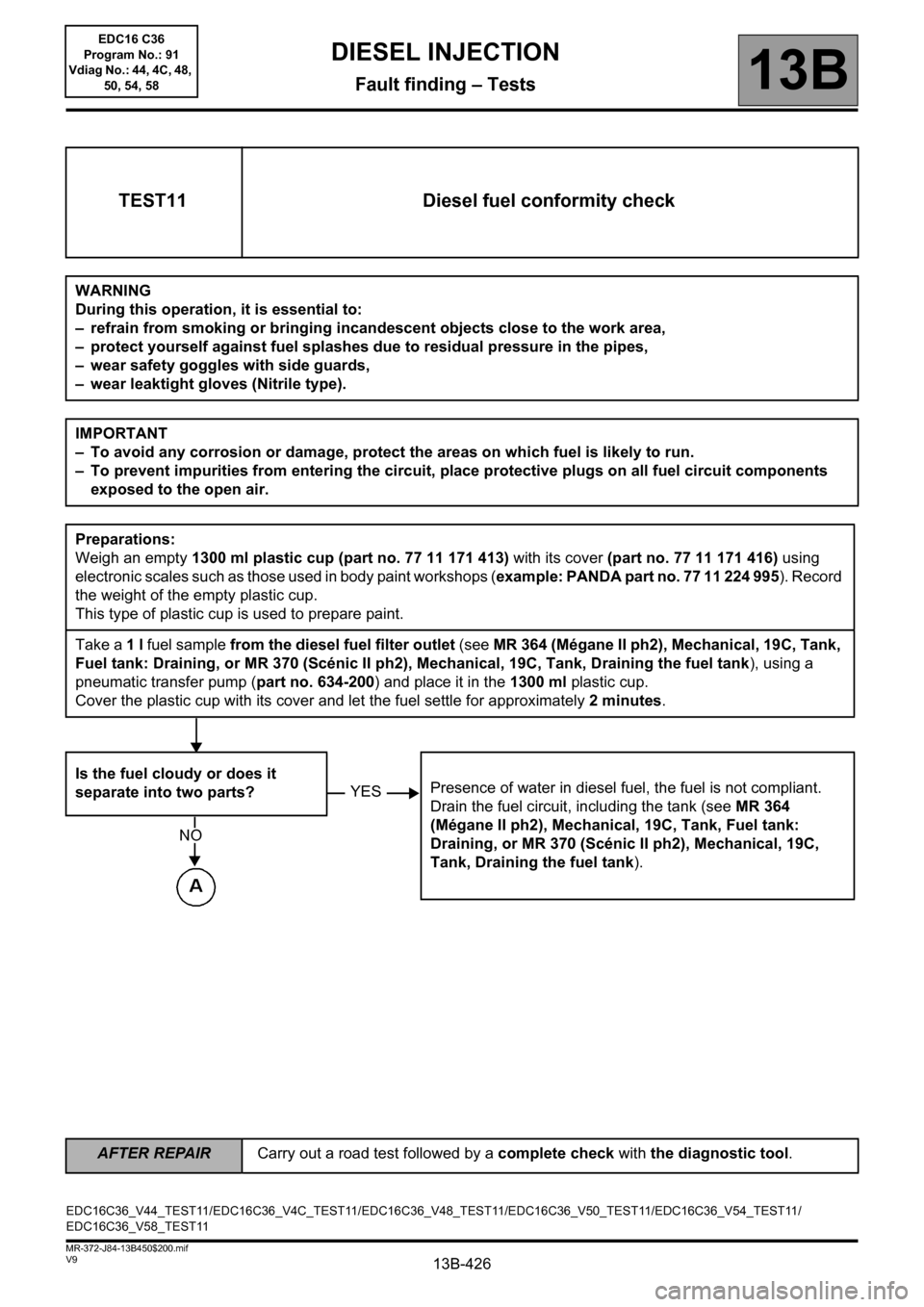

TEST11 Diesel fuel conformity check

WARNING

During this operation, it is essential to:

– refrain from smoking or bringing incandescent objects close to the work area,

– protect yourself against fuel splashes due to residual pressure in the pipes,

– wear safety goggles with side guards,

– wear leaktight gloves (Nitrile type).

IMPORTANT

– To avoid any corrosion or damage, protect the areas on which fuel is likely to run.

– To prevent impurities from entering the circuit, place protective plugs on all fuel circuit components

exposed to the open air.

Preparations:

Weigh an empty 1300 ml plastic cup (part no. 77 11 171 413) with its cover (part no. 77 11 171 416) using

electronic scales such as those used in body paint workshops (example: PANDA part no. 77 11 224 995). Record

the weight of the empty plastic cup.

This type of plastic cup is used to prepare paint.

Take a 1 l fuel sample from the diesel fuel filter outlet (see MR 364 (Mégane II ph2), Mechanical, 19C, Tank,

Fuel tank: Draining, or MR 370 (Scénic II ph2), Mechanical, 19C, Tank, Draining the fuel tank), using a

pneumatic transfer pump (part no. 634-200) and place it in the 1300 ml plastic cup.

Cover the plastic cup with its cover and let the fuel settle for approximately 2 minutes.

Is the fuel cloudy or does it

separate into two parts?Presence of water in diesel fuel, the fuel is not compliant.

Drain the fuel circuit, including the tank (see MR 364

(Mégane II ph2), Mechanical, 19C, Tank, Fuel tank:

Draining, or MR 370 (Scénic II ph2), Mechanical, 19C,

Tank, Draining the fuel tank).

YES

NO

EDC16C36_V44_TEST11/EDC16C36_V4C_TEST11/EDC16C36_V48_TEST11/EDC16C36_V50_TEST11/EDC16C36_V54_TEST11/

EDC16C36_V58_TEST11EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

Page 431 of 431

13B-431V9 MR-372-J84-13B450$210.mif

DIESEL INJECTION

Fault finding – Glossary13B

EDC16 C36

Program No.: 91

Vdiag No.: 44, 4C, 48,

50, 54, 58

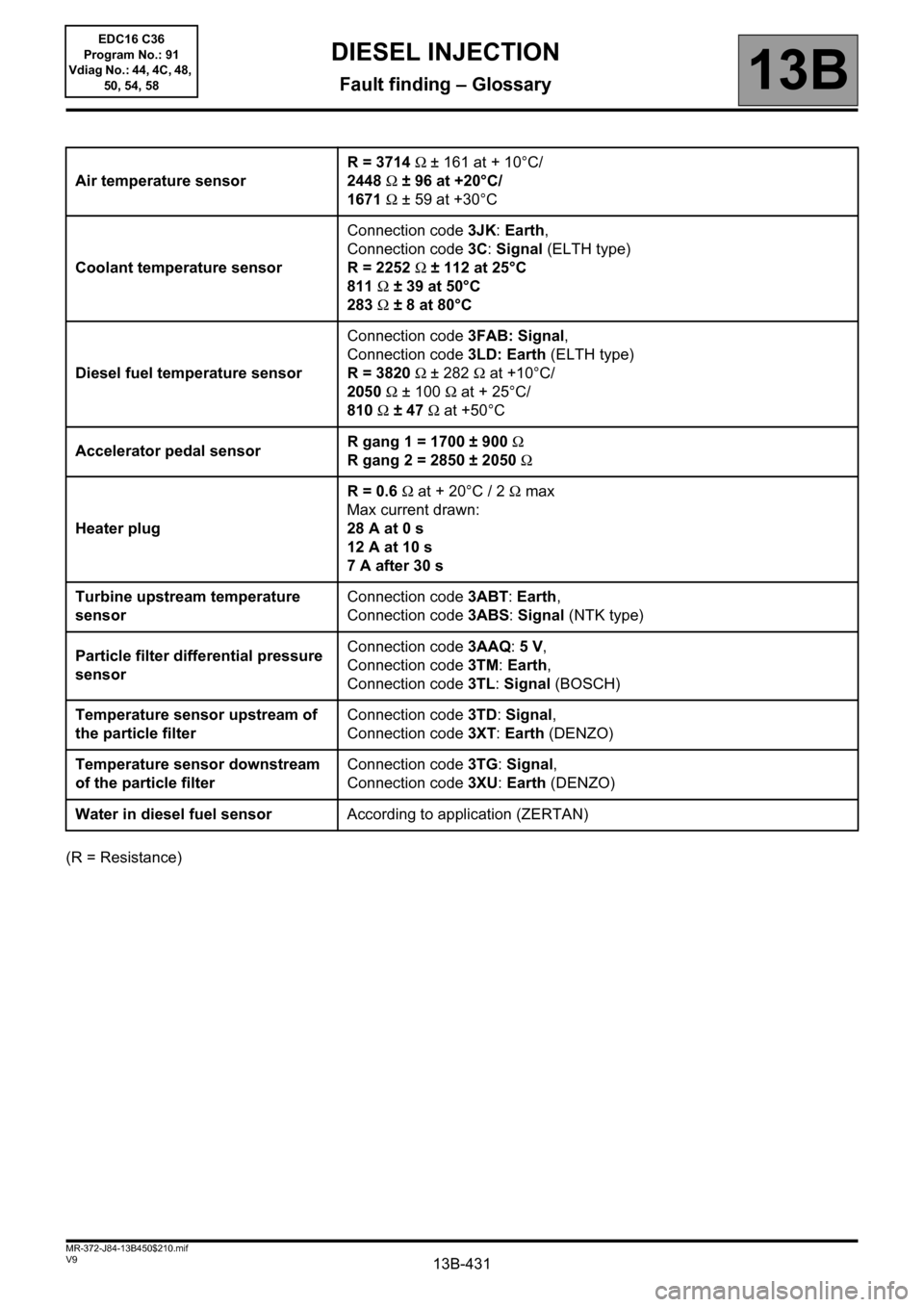

(R = Resistance)Air temperature sensorR = 3714 Ω ± 161 at + 10°C/

2448 Ω ± 96 at +20°C/

1671 Ω ± 59 at +30°C

Coolant temperature sensorConnection code3JK: Earth,

Connection code 3C: Signal (ELTH type)

R = 2252 Ω ± 112 at 25°C

811 Ω ± 39 at 50°C

283 Ω ± 8 at 80°C

Diesel fuel temperature sensorConnection code 3FAB: Signal,

Connection code 3LD: Earth (ELTH type)

R = 3820 Ω ± 282 Ω at +10°C/

2050 Ω ± 100 Ω at + 25°C/

810 Ω ± 47 Ω at +50°C

Accelerator pedal sensorR gang 1 = 1700 ± 900Ω

R gang 2 = 2850 ± 2050Ω

Heater plugR = 0.6 Ω at + 20°C / 2 Ω max

Max current drawn:

28 A at 0 s

12 A at 10 s

7 A after 30 s

Turbine upstream temperature

sensorConnection code 3ABT: Earth,

Connection code 3ABS: Signal (NTK type)

Particle filter differential pressure

sensorConnection code 3AAQ: 5 V,

Connection code 3TM: Earth,

Connection code 3TL: Signal

(BOSCH)

Temperature sensor upstream of

the particle filterConnection code 3TD: Signal,

Connection code 3XT: Earth (DENZO)

Temperature sensor downstream

of the particle filterConnection code 3TG: Signal,

Connection code 3XU: Earth (DENZO)

Water in diesel fuel sensorAccording to application (ZERTAN)