ignition RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals Siemens Injection User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 329, PDF Size: 1.71 MB

Page 38 of 329

13B-38

MR-372-J84-13B050$390.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No. 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

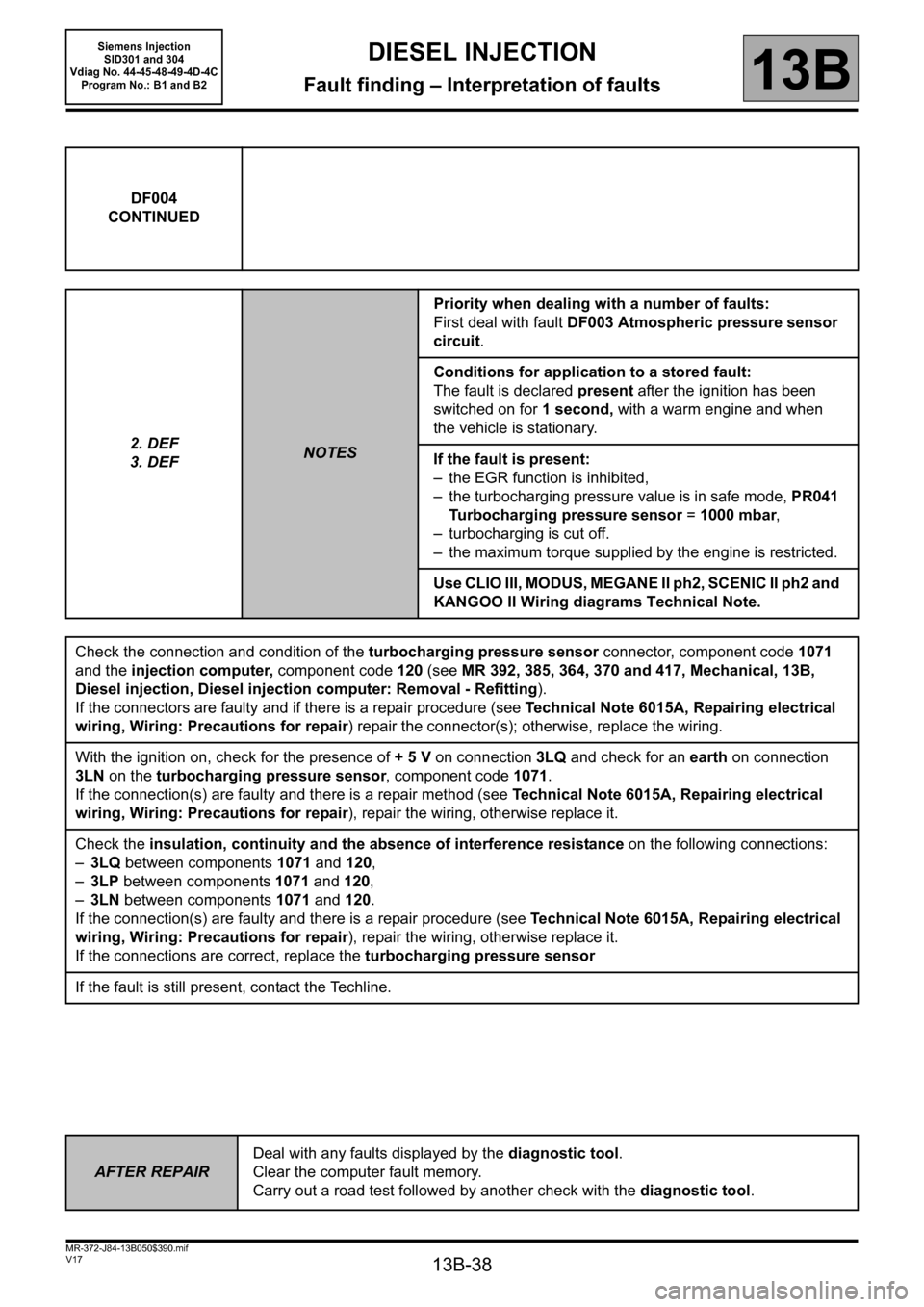

DF004

CONTINUED

2. DEF

3. DEF

NOTESPriority when dealing with a number of faults:

First deal with fault DF003 Atmospheric pressure sensor

circuit.

Conditions for application to a stored fault:

The fault is declared present after the ignition has been

switched on for 1 second, with a warm engine and when

the vehicle is stationary.

If the fault is present:

– the EGR function is inhibited,

– the turbocharging pressure value is in safe mode, PR041

Turbocharging pressure sensor = 1000 mbar,

– turbocharging is cut off.

– the maximum torque supplied by the engine is restricted.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and

KANGOO II Wiring diagrams Technical Note.

Check the connection and condition of the turbocharging pressure sensor connector, component code1071

and the injection computer, component code120 (see MR 392, 385, 364, 370 and 417, Mechanical, 13B,

Diesel injection, Diesel injection computer: Removal - Refitting).

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair) repair the connector(s); otherwise, replace the wiring.

With the ignition on, check for the presence of + 5 V on connection 3LQ and check for an earth on connection

3LN on the turbocharging pressure sensor, component code 1071.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the insulation, continuity and the absence of interference resistance on the following connections:

–3LQ between components 1071 and 120,

–3LP between components 1071 and 120,

–3LN between components 1071 and 120.

If the connection(s) are faulty and there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the connections are correct, replace the turbocharging pressure sensor

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

Page 40 of 329

13B-40

MR-372-J84-13B050$390.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No. 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

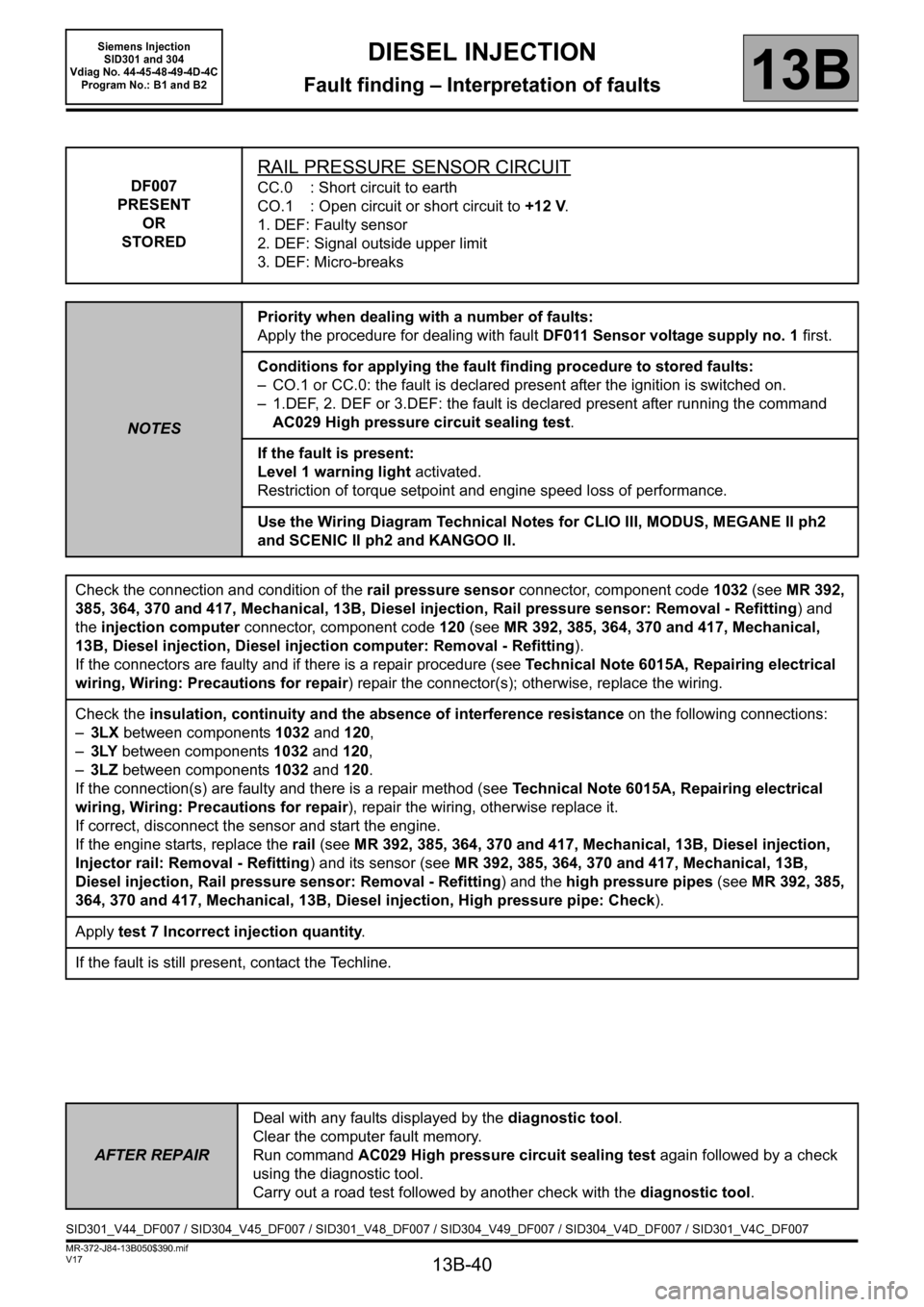

DF007

PRESENT

OR

STORED

RAIL PRESSURE SENSOR CIRCUIT

CC.0 : Short circuit to earth

CO.1 : Open circuit or short circuit to +12 V.

1. DEF: Faulty sensor

2. DEF: Signal outside upper limit

3. DEF: Micro-breaks

NOTESPriority when dealing with a number of faults:

Apply the procedure for dealing with fault DF011 Sensor voltage supply no. 1 first.

Conditions for applying the fault finding procedure to stored faults:

– CO.1 or CC.0: the fault is declared present after the ignition is switched on.

– 1.DEF, 2. DEF or 3.DEF: the fault is declared present after running the command

AC029 High pressure circuit sealing test.

If the fault is present:

Level 1 warning light activated.

Restriction of torque setpoint and engine speed loss of performance.

Use the Wiring Diagram Technical Notes for CLIO III, MODUS, MEGANE II ph2

and SCENIC II ph2 and KANGOO II.

Check the connection and condition of the rail pressure sensor connector, component code1032 (see MR 392,

385, 364, 370 and 417, Mechanical, 13B, Diesel injection, Rail pressure sensor: Removal - Refitting) and

the injection computer connector, component code120 (see MR 392, 385, 364, 370 and 417, Mechanical,

13B, Diesel injection, Diesel injection computer: Removal - Refitting).

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair) repair the connector(s); otherwise, replace the wiring.

Check the insulation, continuity and the absence of interference resistance on the following connections:

–3LX between components 1032 and 120,

–3LY between components 1032 and 120,

–3LZ between components 1032 and 120.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If correct, disconnect the sensor and start the engine.

If the engine starts, replace the rail (see MR 392, 385, 364, 370 and 417, Mechanical, 13B, Diesel injection,

Injector rail: Removal - Refitting) and its sensor (see MR 392, 385, 364, 370 and 417, Mechanical, 13B,

Diesel injection, Rail pressure sensor: Removal - Refitting) and the high pressure pipes (see MR 392, 385,

364, 370 and 417, Mechanical, 13B, Diesel injection, High pressure pipe: Check).

Apply test 7 Incorrect injection quantity

.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Run command AC029 High pressure circuit sealing test again followed by a check

using the diagnostic tool.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF007 / SID304_V45_DF007 / SID301_V48_DF007 / SID304_V49_DF007 / SID304_V4D_DF007 / SID301_V4C_DF007

Page 41 of 329

13B-41

MR-372-J84-13B050$390.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No. 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

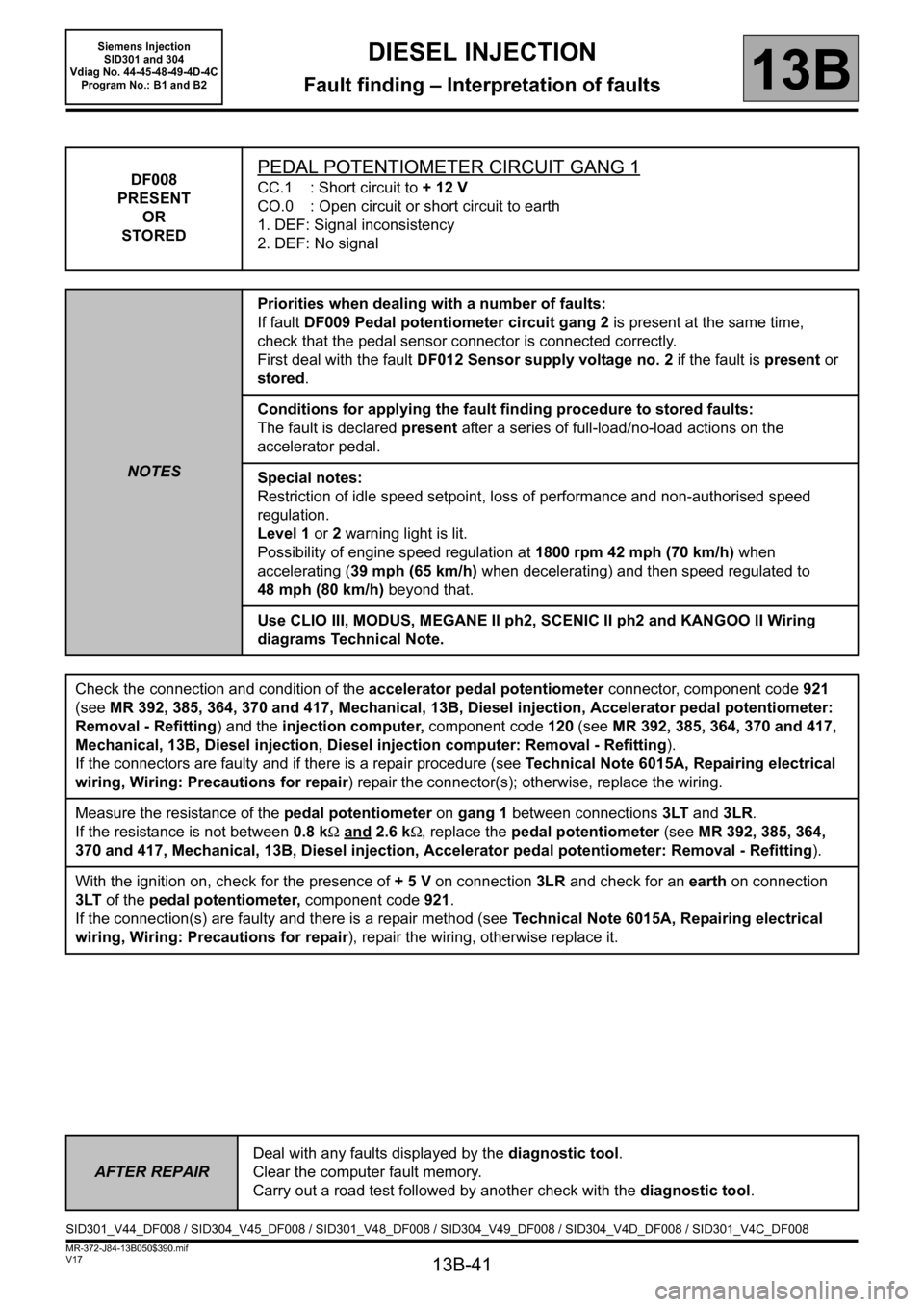

DF008

PRESENT

OR

STOREDPEDAL POTENTIOMETER CIRCUIT GANG 1

CC.1 : Short circuit to + 12 V

CO.0 : Open circuit or short circuit to earth

1. DEF: Signal inconsistency

2. DEF: No signal

NOTESPriorities when dealing with a number of faults:

If fault DF009 Pedal potentiometer circuit gang 2 is present at the same time,

check that the pedal sensor connector is connected correctly.

First deal with the fault DF012 Sensor supply voltage no. 2 if the fault is present or

stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after a series of full-load/no-load actions on the

accelerator pedal.

Special notes:

Restriction of idle speed setpoint, loss of performance and non-authorised speed

regulation.

Level 1 or 2 warning light is lit.

Possibility of engine speed regulation at 1800 rpm 42 mph (70 km/h) when

accelerating (39 mph (65 km/h) when decelerating) and then speed regulated to

48 mph (80 km/h) beyond that.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and KANGOO II Wiring

diagrams Technical Note.

Check the connection and condition of the accelerator pedal potentiometer connector, component code921

(see MR 392, 385, 364, 370 and 417, Mechanical, 13B, Diesel injection, Accelerator pedal potentiometer:

Removal - Refitting) and the injection computer, component code120 (see MR 392, 385, 364, 370 and 417,

Mechanical, 13B, Diesel injection, Diesel injection computer: Removal - Refitting).

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair) repair the connector(s); otherwise, replace the wiring.

Measure the resistance of the pedal potentiometer on gang 1 between connections3LT and 3LR.

If the resistance is not between 0.8 kΩ and

2.6 kΩ, replace the pedal potentiometer (see MR 392, 385, 364,

370 and 417, Mechanical, 13B, Diesel injection, Accelerator pedal potentiometer: Removal - Refitting).

With the ignition on, check for the presence of + 5 V on connection 3LR and check for an earth on connection

3LT of the pedal potentiometer, component code 921.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF008 / SID304_V45_DF008 / SID301_V48_DF008 / SID304_V49_DF008 / SID304_V4D_DF008 / SID301_V4C_DF008

Page 43 of 329

13B-43

MR-372-J84-13B050$390.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No. 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

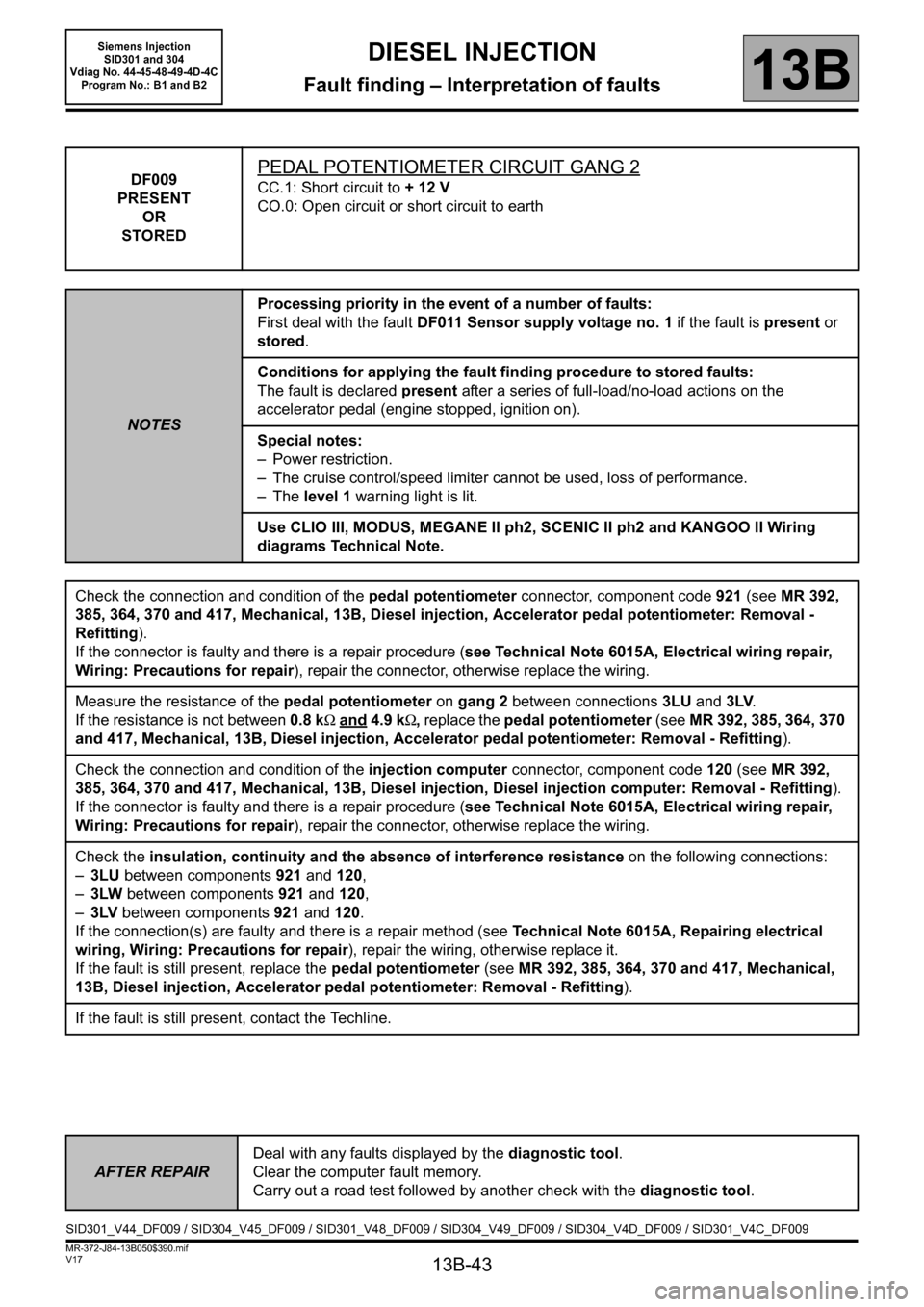

DF009

PRESENT

OR

STOREDPEDAL POTENTIOMETER CIRCUIT GANG 2

CC.1: Short circuit to + 12 V

CO.0: Open circuit or short circuit to earth

NOTESProcessing priority in the event of a number of faults:

First deal with the fault DF011 Sensor supply voltage no. 1 if the fault is present or

stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after a series of full-load/no-load actions on the

accelerator pedal (engine stopped, ignition on).

Special notes:

– Power restriction.

– The cruise control/speed limiter cannot be used, loss of performance.

–The level 1 warning light is lit.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and KANGOO II Wiring

diagrams Technical Note.

Check the connection and condition of the pedal potentiometer connector, component code921 (see MR 392,

385, 364, 370 and 417, Mechanical, 13B, Diesel injection, Accelerator pedal potentiometer: Removal -

Refitting).

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Measure the resistance of the pedal potentiometer on gang 2 between connections 3LU and 3LV.

If the resistance is not between 0.8 kΩ and

4.9 kΩ, replace the pedal potentiometer (see MR 392, 385, 364, 370

and 417, Mechanical, 13B, Diesel injection, Accelerator pedal potentiometer: Removal - Refitting).

Check the connection and condition of the injection computer connector, component code 120 (see MR 392,

385, 364, 370 and 417, Mechanical, 13B, Diesel injection, Diesel injection computer: Removal - Refitting).

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation, continuity and the absence of interference resistance on the following connections:

–3LU between components921 and 120,

–3LW between components 921 and 120,

–3LV between components 921 and 120.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the pedal potentiometer (see MR 392, 385, 364, 370 and 417, Mechanical,

13B, Diesel injection, Accelerator pedal potentiometer: Removal - Refitting).

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF009 / SID304_V45_DF009 / SID301_V48_DF009 / SID304_V49_DF009 / SID304_V4D_DF009 / SID301_V4C_DF009

Page 44 of 329

13B-44

MR-372-J84-13B050$390.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No. 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

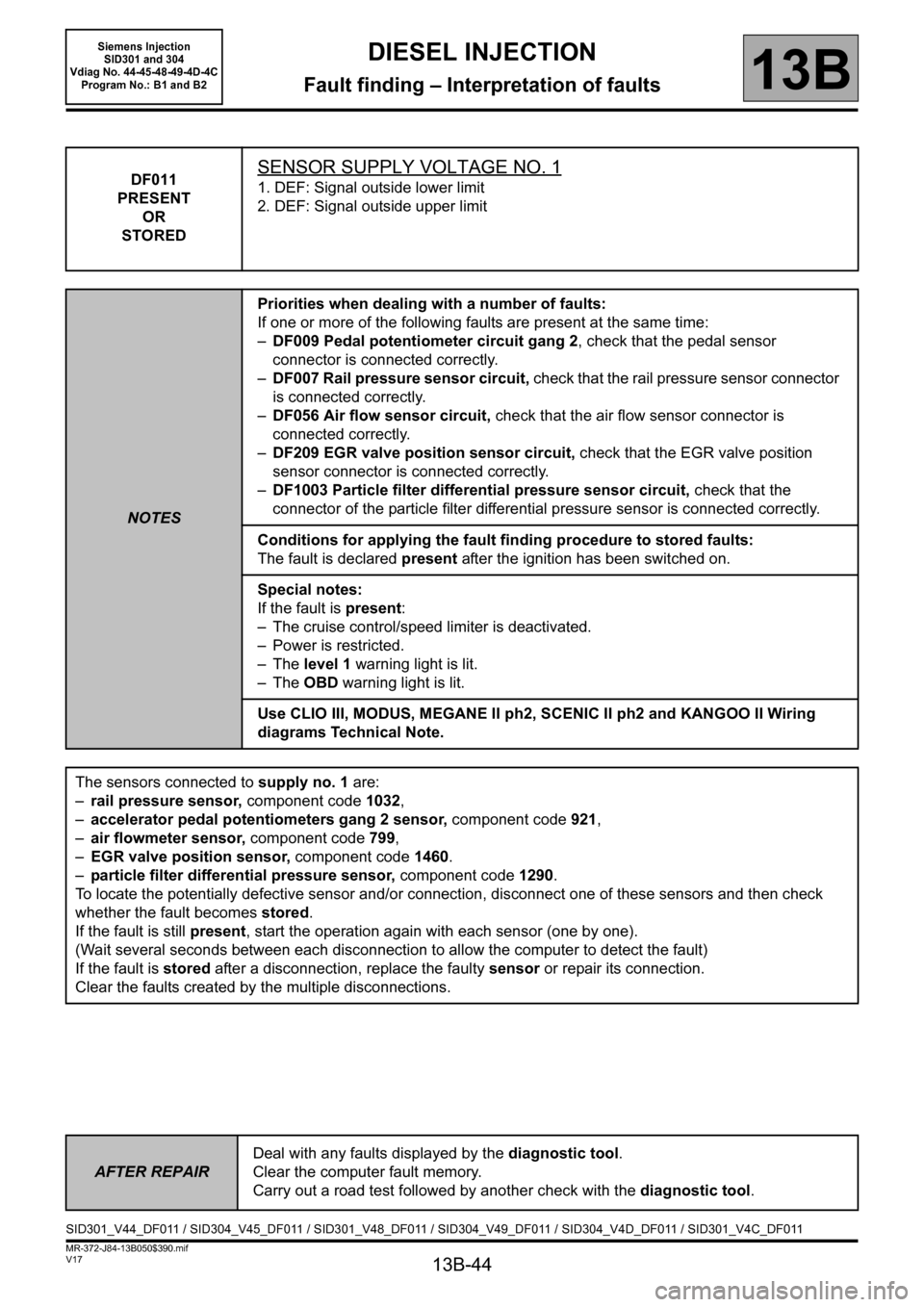

DF011

PRESENT

OR

STOREDSENSOR SUPPLY VOLTAGE NO. 1

1. DEF: Signal outside lower limit

2. DEF: Signal outside upper limit

NOTESPriorities when dealing with a number of faults:

If one or more of the following faults are present at the same time:

–DF009 Pedal potentiometer circuit gang 2, check that the pedal sensor

connector is connected correctly.

–DF007 Rail pressure sensor circuit, check that the rail pressure sensor connector

is connected correctly.

–DF056 Air flow sensor circuit, check that the air flow sensor connector is

connected correctly.

–DF209 EGR valve position sensor circuit, check that the EGR valve position

sensor connector is connected correctly.

–DF1003 Particle filter differential pressure sensor circuit, check that the

connector of the particle filter differential pressure sensor is connected correctly.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the ignition has been switched on.

Special notes:

If the fault is present:

– The cruise control/speed limiter is deactivated.

– Power is restricted.

–The level 1 warning light is lit.

–The OBD warning light is lit.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and KANGOO II Wiring

diagrams Technical Note.

The sensors connected to supply no. 1 are:

–rail pressure sensor, component code1032,

–accelerator pedal potentiometers gang 2 sensor, component code921,

–air flowmeter sensor, component code799,

–EGR valve position sensor, component code 1460.

–particle filter differential pressure sensor, component code 1290.

To locate the potentially defective sensor and/or connection, disconnect one of these sensors and then check

whether the fault becomes stored.

If the fault is still present, start the operation again with each sensor (one by one).

(Wait several seconds between each disconnection to allow the computer to detect the fault)

If the fault is stored after a disconnection, replace the faulty sensor or repair its connection.

Clear the faults created by the multiple disconnections.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF011 / SID304_V45_DF011 / SID301_V48_DF011 / SID304_V49_DF011 / SID304_V4D_DF011 / SID301_V4C_DF011

Page 46 of 329

13B-46

MR-372-J84-13B050$390.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No. 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

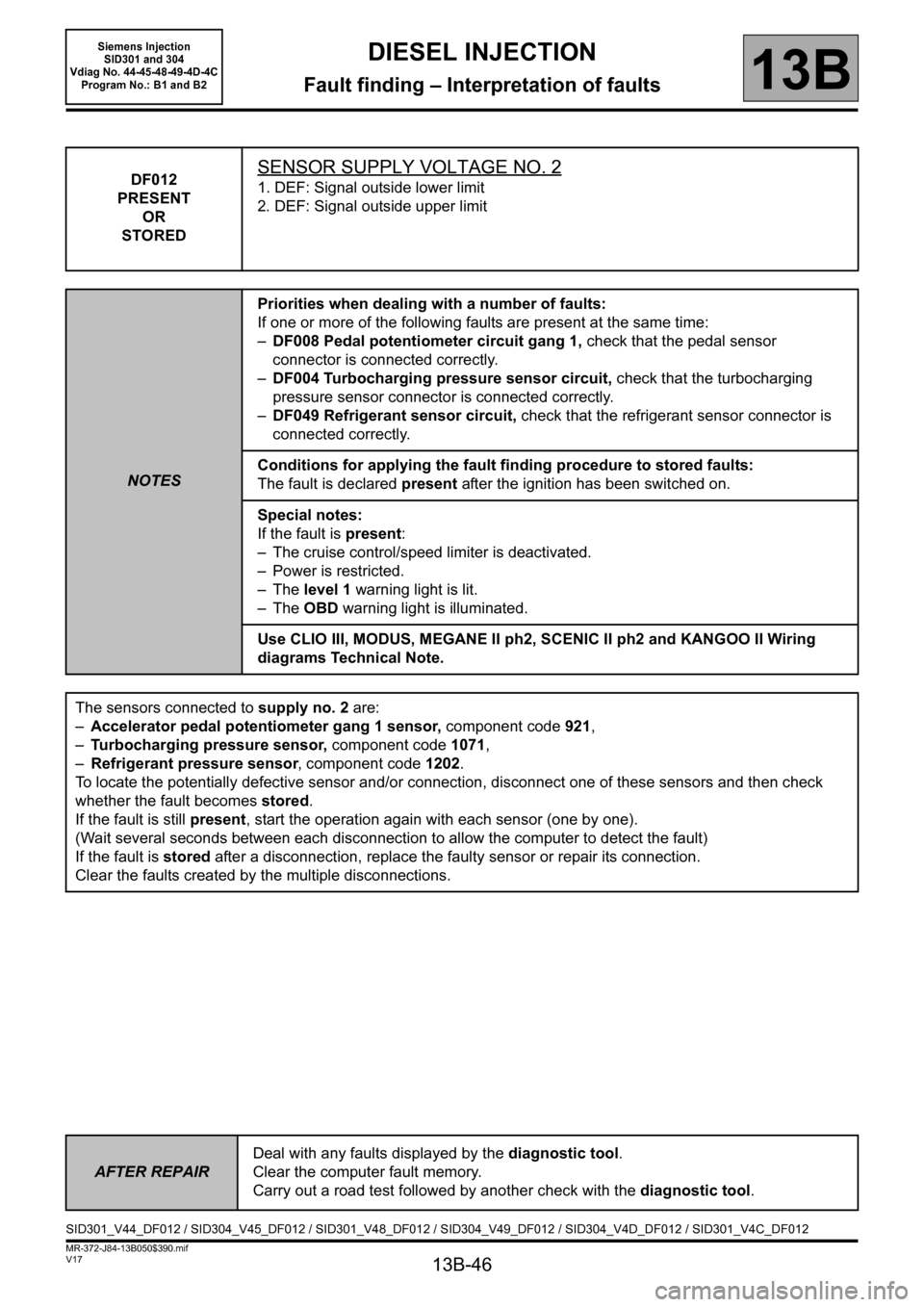

DF012

PRESENT

OR

STOREDSENSOR SUPPLY VOLTAGE NO. 2

1. DEF: Signal outside lower limit

2. DEF: Signal outside upper limit

NOTESPriorities when dealing with a number of faults:

If one or more of the following faults are present at the same time:

–DF008 Pedal potentiometer circuit gang 1, check that the pedal sensor

connector is connected correctly.

–DF004 Turbocharging pressure sensor circuit, check that the turbocharging

pressure sensor connector is connected correctly.

–DF049 Refrigerant sensor circuit, check that the refrigerant sensor connector is

connected correctly.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the ignition has been switched on.

Special notes:

If the fault is present:

– The cruise control/speed limiter is deactivated.

– Power is restricted.

–The level 1 warning light is lit.

–The OBD warning light is illuminated.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and KANGOO II Wiring

diagrams Technical Note.

The sensors connected to supply no. 2 are:

–Accelerator pedal potentiometer gang 1 sensor, component code 921,

–Turbocharging pressure sensor, component code 1071,

–Refrigerant pressure sensor, component code 1202.

To locate the potentially defective sensor and/or connection, disconnect one of these sensors and then check

whether the fault becomes stored.

If the fault is still present, start the operation again with each sensor (one by one).

(Wait several seconds between each disconnection to allow the computer to detect the fault)

If the fault is stored after a disconnection, replace the faulty sensor or repair its connection.

Clear the faults created by the multiple disconnections.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF012 / SID304_V45_DF012 / SID301_V48_DF012 / SID304_V49_DF012 / SID304_V4D_DF012 / SID301_V4C_DF012

Page 48 of 329

13B-48

MR-372-J84-13B050$390.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No. 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

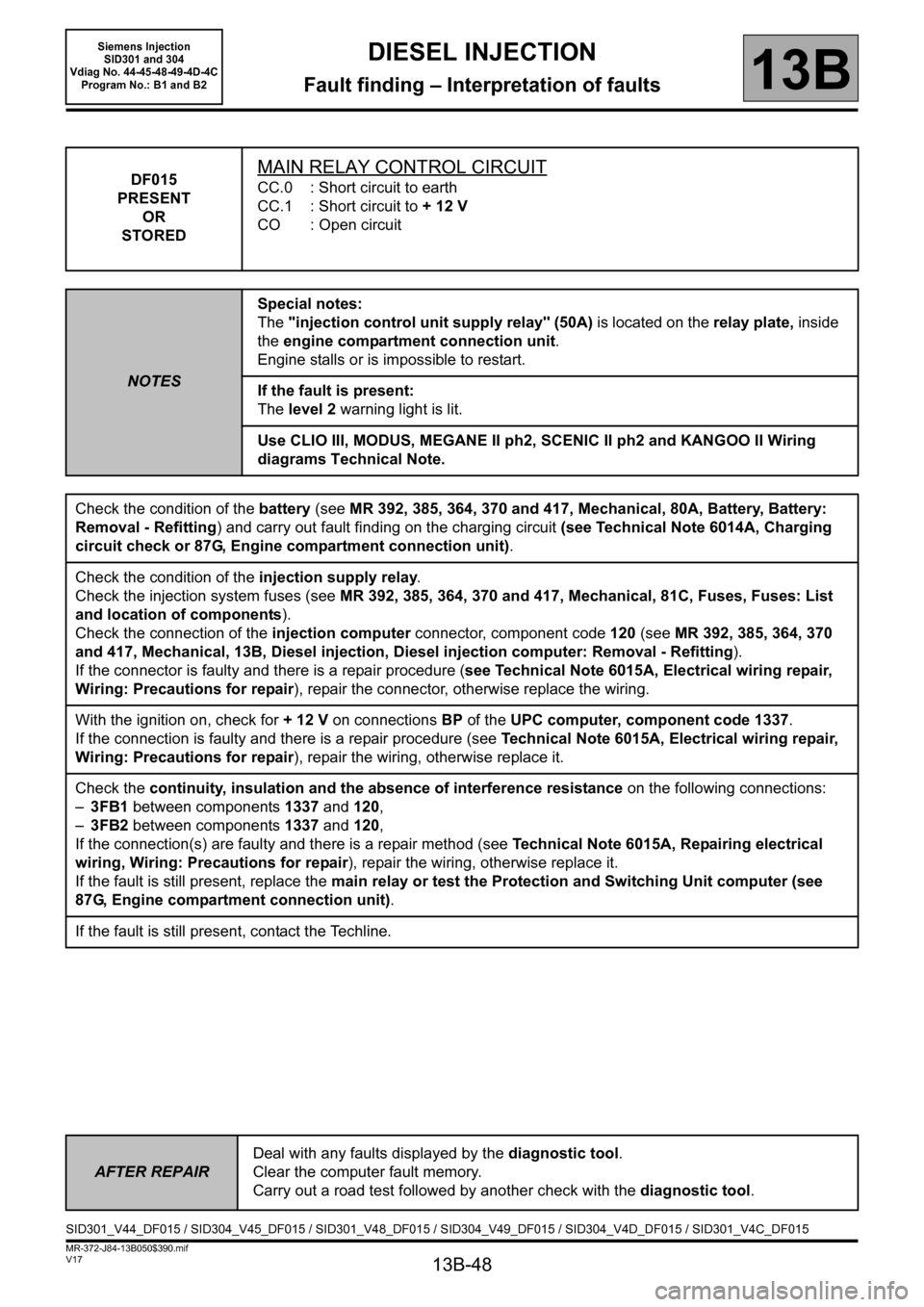

DF015

PRESENT

OR

STOREDMAIN RELAY CONTROL CIRCUIT

CC.0 : Short circuit to earth

CC.1 : Short circuit to + 12 V

CO : Open circuit

NOTESSpecial notes:

The "injection control unit supply relay" (50A) is located on the relay plate, inside

the engine compartment connection unit.

Engine stalls or is impossible to restart.

If the fault is present:

The level 2 warning light is lit.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and KANGOO II Wiring

diagrams Technical Note.

Check the condition of the battery (see MR 392, 385, 364, 370 and 417, Mechanical, 80A, Battery, Battery:

Removal - Refitting) and carry out fault finding on the charging circuit (see Technical Note 6014A, Charging

circuit check or 87G, Engine compartment connection unit).

Check the condition of the injection supply relay.

Check the injection system fuses (see MR 392, 385, 364, 370 and 417, Mechanical, 81C, Fuses, Fuses: List

and location of components).

Check the connection of the injection computer connector, component code120 (see MR 392, 385, 364, 370

and 417, Mechanical, 13B, Diesel injection, Diesel injection computer: Removal - Refitting).

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

With the ignition on, check for + 12 V on connections BP of the UPC computer, component code 1337.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the continuity, insulation and the absence of interference resistance on the following connections:

–3FB1 between components 1337 and 120,

–3FB2 between components 1337 and 120,

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the main relay or test the Protection and Switching Unit computer (see

87G, Engine compartment connection unit).

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF015 / SID304_V45_DF015 / SID301_V48_DF015 / SID304_V49_DF015 / SID304_V4D_DF015 / SID301_V4C_DF015

Page 49 of 329

13B-49

MR-372-J84-13B050$390.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No. 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

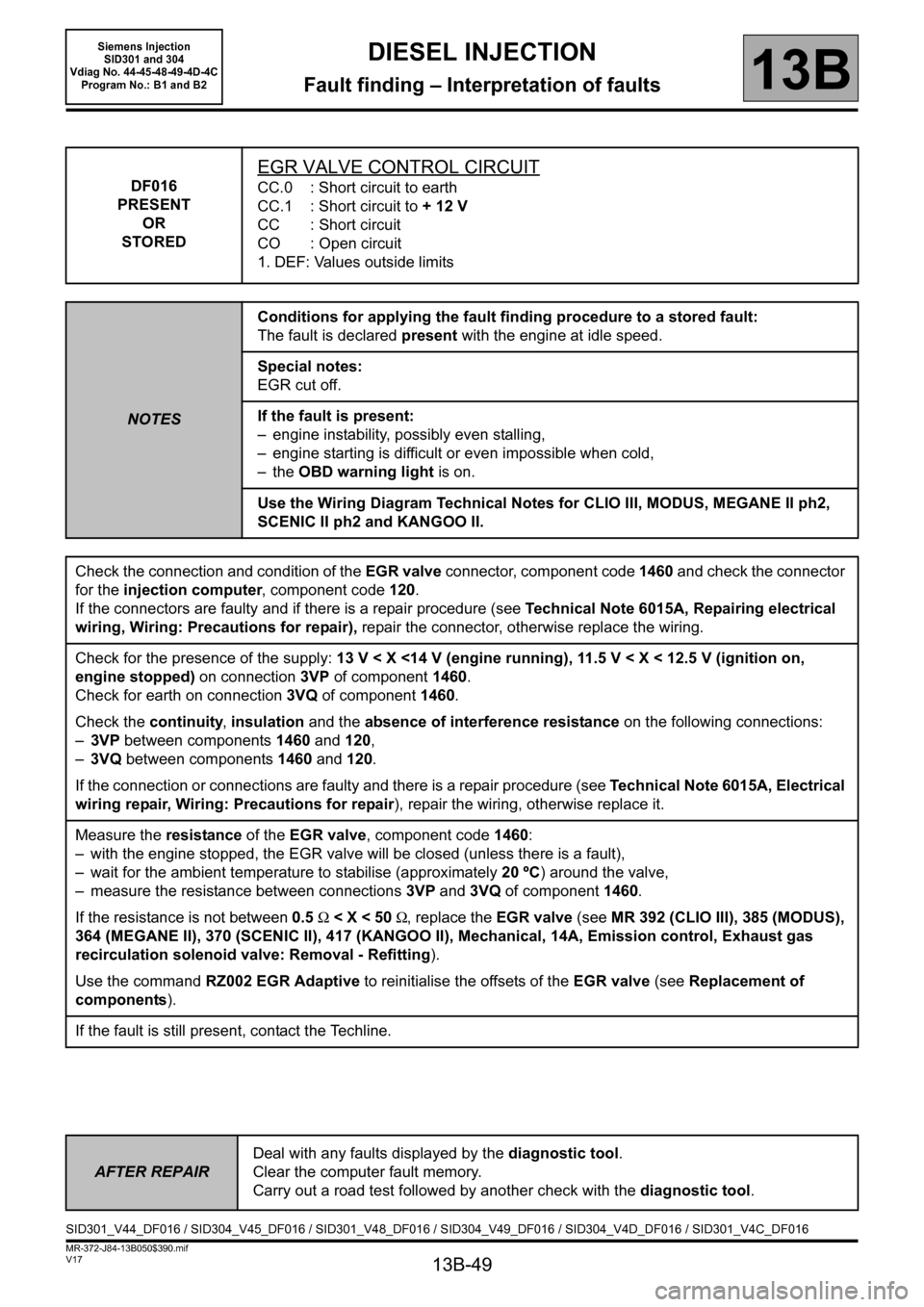

DF016

PRESENT

OR

STORED

EGR VALVE CONTROL CIRCUIT

CC.0 : Short circuit to earth

CC.1 : Short circuit to + 12 V

CC : Short circuit

CO : Open circuit

1. DEF: Values outside limits

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present with the engine at idle speed.

Special notes:

EGR cut off.

If the fault is present:

– engine instability, possibly even stalling,

– engine starting is difficult or even impossible when cold,

– the OBD warning light is on.

Use the Wiring Diagram Technical Notes for CLIO III, MODUS, MEGANE II ph2,

SCENIC II ph2 and KANGOO II.

Check the connection and condition of the EGR valve connector, component code 1460 and check the connector

for the injection computer, component code 120.

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check for the presence of the supply: 13 V < X <14 V (engine running), 11.5 V < X < 12.5 V (ignition on,

engine stopped) on connection 3VP of component 1460.

Check for earth on connection3VQ of component1460.

Check the continuity, insulation and the absence of interference resistance on the following connections:

–3VP between components 1460 and 120,

–3VQ between components 1460 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Measure the resistance of the EGR valve, component code 1460:

– with the engine stopped, the EGR valve will be closed (unless there is a fault),

– wait for the ambient temperature to stabilise (approximately 20 ºC) around the valve,

– measure the resistance between connections3VP and 3VQ of component1460.

If the resistance is not between 0.5 Ω < X < 50 Ω, replace the EGR valve (see MR 392 (CLIO III), 385 (MODUS),

364 (MEGANE II), 370 (SCENIC II), 417 (KANGOO II), Mechanical, 14A, Emission control, Exhaust gas

recirculation solenoid valve: Removal - Refitting

).

Use the command RZ002 EGR Adaptive to reinitialise the offsets of the EGR valve (see Replacement of

components).

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF016 / SID304_V45_DF016 / SID301_V48_DF016 / SID304_V49_DF016 / SID304_V4D_DF016 / SID301_V4C_DF016

Page 58 of 329

13B-58

MR-372-J84-13B050$390.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No. 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

DF039

PRESENT

OR

STOREDINLET AIR TEMPERATURE SENSOR CIRCUIT

CC.0 : Short circuit to earth

CO.1 : Open circuit or short circuit to +12 V.

1. DEF: Micro-breaks

NOTESProcessing priority in the event of a number of faults:

Deal with fault DF011 Sensor supply voltage no. 1 first if it is present or stored.

Conditions for applying the fault finding procedure to a stored fault:

The fault is declared present after the ignition has been switched on for at least

10 seconds.

If the fault is present:

The air temperature has a default value, which is PR059 Inlet air temperature =

40°C.

Illumination of OBD fault warning light on the instrument panel.

Special notes:

The inlet air temperature sensor is integrated into the air flowmeter.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and KANGOO II Wiring

diagrams Technical Note.

Check the connection and condition of the connector for the flowmeter, component code799 (see MR 392, 364,

370 and 417, Mechanical, 12A, Fuel mixture, Air flowmeter: Removal - Refitting).

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the connection and condition of the injection computer connector, component code 120 (see MR 392,

385, 364, 370 and 417, Mechanical, 13B, Diesel injection, Diesel injection computer: Removal - Refitting).

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Measure the resistance of the air temperature sensor between connections 3ABQ and 3DW of the air

flowmeter component code 799.

If the resistance measured is not:

3553Ω

flowmeter: Removal - Refitting)

Check the insulation, continuity and the absence of interference resistance on the following connections:

–3ABQ

, between components799 and 120,

–3DW between components 799 and 120.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF039 / SID304_V45_DF039 / SID301_V48_DF039 / SID304_V49_DF039 / SID304_V4D_DF039 / SID301_V4C_DF039

Page 59 of 329

13B-59

MR-372-J84-13B050$390.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of faults

Siemens Injection

SID301 and 304

Vdiag No. 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

DF047

PRESENT

OR

STOREDCOMPUTER SUPPLY VOLTAGE

1. DEF: Signal outside lower limit

2. DEF: Signal outside upper limit

NOTESProcessing priority in the event of a number of faults:

Deal with fault DF532 Alternator charge signal first if the fault is present or stored.

Conditions for applying the fault finding procedure to a stored fault:

– The fault is declared present with the engine running.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and KANGOO II Wiring

diagrams Technical Note.

Check the battery and run fault finding on the charging circuit (see Technical Note 6014A, Checking the

charging circuit or 87G, Engine compartment connection unit).

Check the connection and condition of the injection computer connectors, component code 120 (see MR 392,

385, 364, 370 and 417, Mechanical, 13B, Diesel injection, Diesel injection computer: Removal - Refitting).

If the connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair) repair the connector(s); otherwise, replace the wiring.

Check the engine and chassis earths.

Check the condition of the relay support plate as well as the positioning and condition of the injection supply

relay, component code 983.

Replace the relay if necessary (see Replacement of components).

With the ignition on, check for the presence of +12 V on the connectionsBP of the main relay support plate,

component code 983 or the Protection and Switching Unit computer, component code 1337.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the insulation, continuity and the absence of interference resistance on the following connections:

–3FB between components983 and 120,

–M between components120 and ME (Bodywork electrical earth).

Or (for Kangoo II):

–3FB1 between components 1337 and 120,

–3FB2 between components 1337 and 120,

–N between component 120 and the earth.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_DF047 / SID304_V45_DF047 / SID301_V48_DF047 / SID304_V49_DF047 / SID304_V4D_DF047 / SID301_V4C_DF047