check engine RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals Siemens Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 329, PDF Size: 1.71 MB

Page 313 of 329

13B-313

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

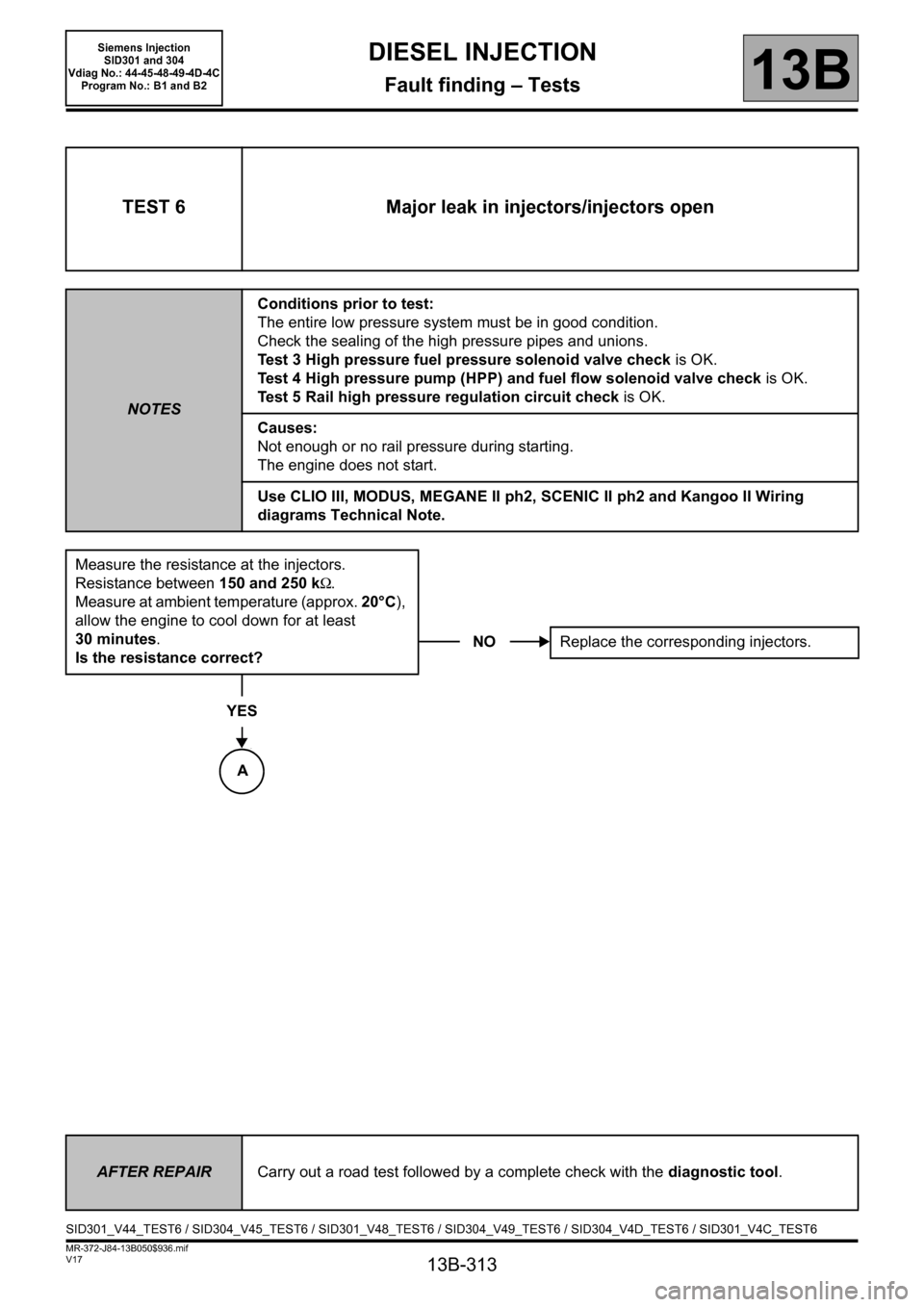

TEST 6 Major leak in injectors/injectors open

NOTESConditions prior to test:

The entire low pressure system must be in good condition.

Check the sealing of the high pressure pipes and unions.

Te s t 3 High pressure fuel pressure solenoid valve check is OK.

Test 4 High pressure pump (HPP) and fuel flow solenoid valve check is OK.

Te s t 5 Rail high pressure regulation circuit check is OK.

Causes:

Not enough or no rail pressure during starting.

The engine does not start.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and Kangoo II Wiring

diagrams Technical Note.

Measure the resistance at the injectors.

Resistance between 150 and 250 kΩ.

Measure at ambient temperature (approx. 20°C),

allow the engine to cool down for at least

30 minutes.

Is the resistance correct?

YES

NOReplace the corresponding injectors.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

SID301_V44_TEST6 / SID304_V45_TEST6 / SID301_V48_TEST6 / SID304_V49_TEST6 / SID304_V4D_TEST6 / SID301_V4C_TEST6

A

Page 314 of 329

13B-314

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

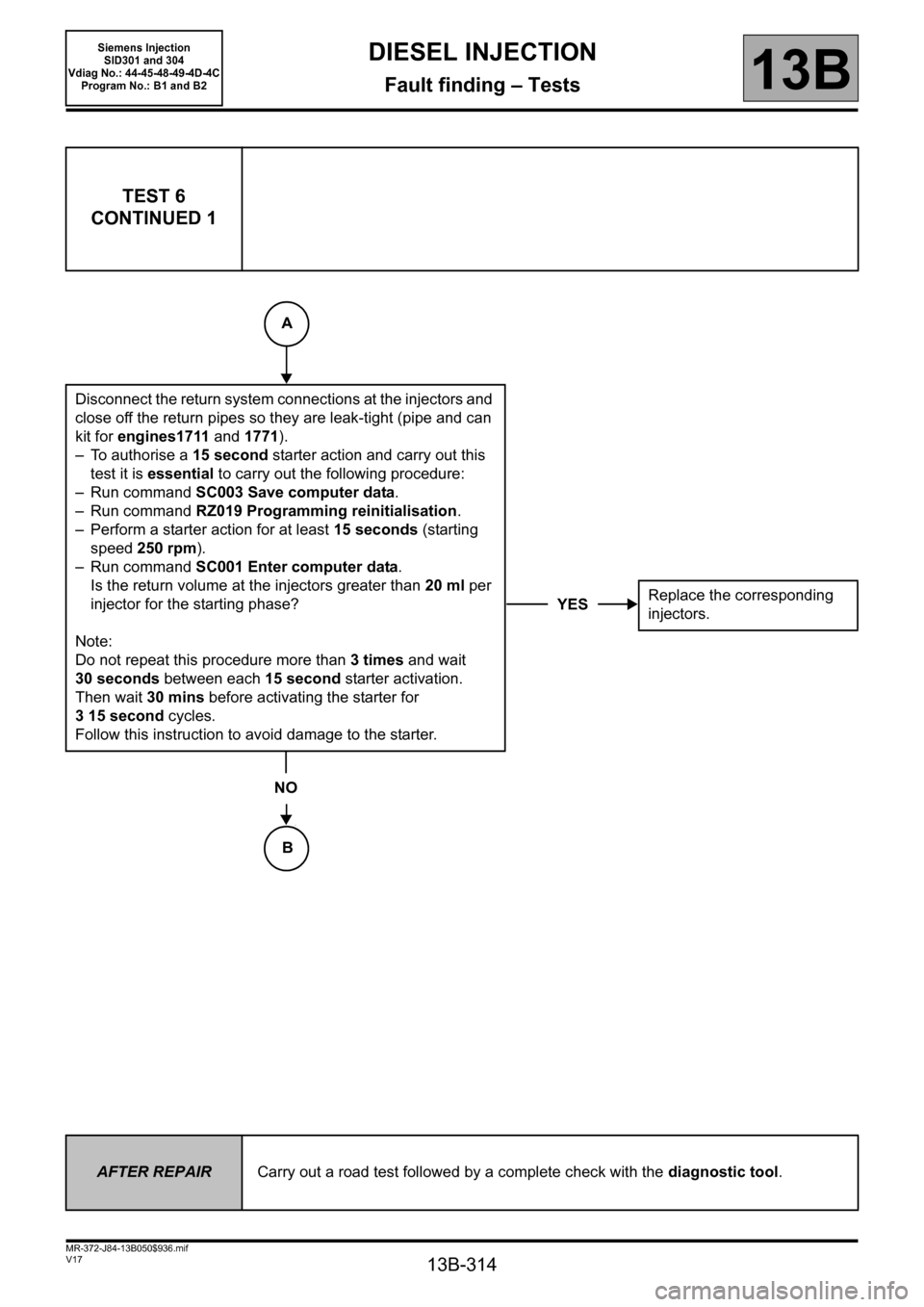

TEST 6

CONTINUED 1

Disconnect the return system connections at the injectors and

close off the return pipes so they are leak-tight (pipe and can

kit for engines1711 and 1771).

– To authorise a 15 second starter action and carry out this

test it is essential to carry out the following procedure:

– Run command SC003 Save computer data.

– Run command RZ019 Programming reinitialisation.

– Perform a starter action for at least 15 seconds (starting

speed 250 rpm).

– Run command SC001 Enter computer data.

Is the return volume at the injectors greater than 20 ml per

injector for the starting phase?

Note:

Do not repeat this procedure more than 3times and wait

30 seconds between each 15 second starter activation.

Then wait 30 mins before activating the starter for

315second cycles.

Follow this instruction to avoid damage to the starter.

NO

YESReplace the corresponding

injectors.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

B

A

Page 316 of 329

13B-316

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

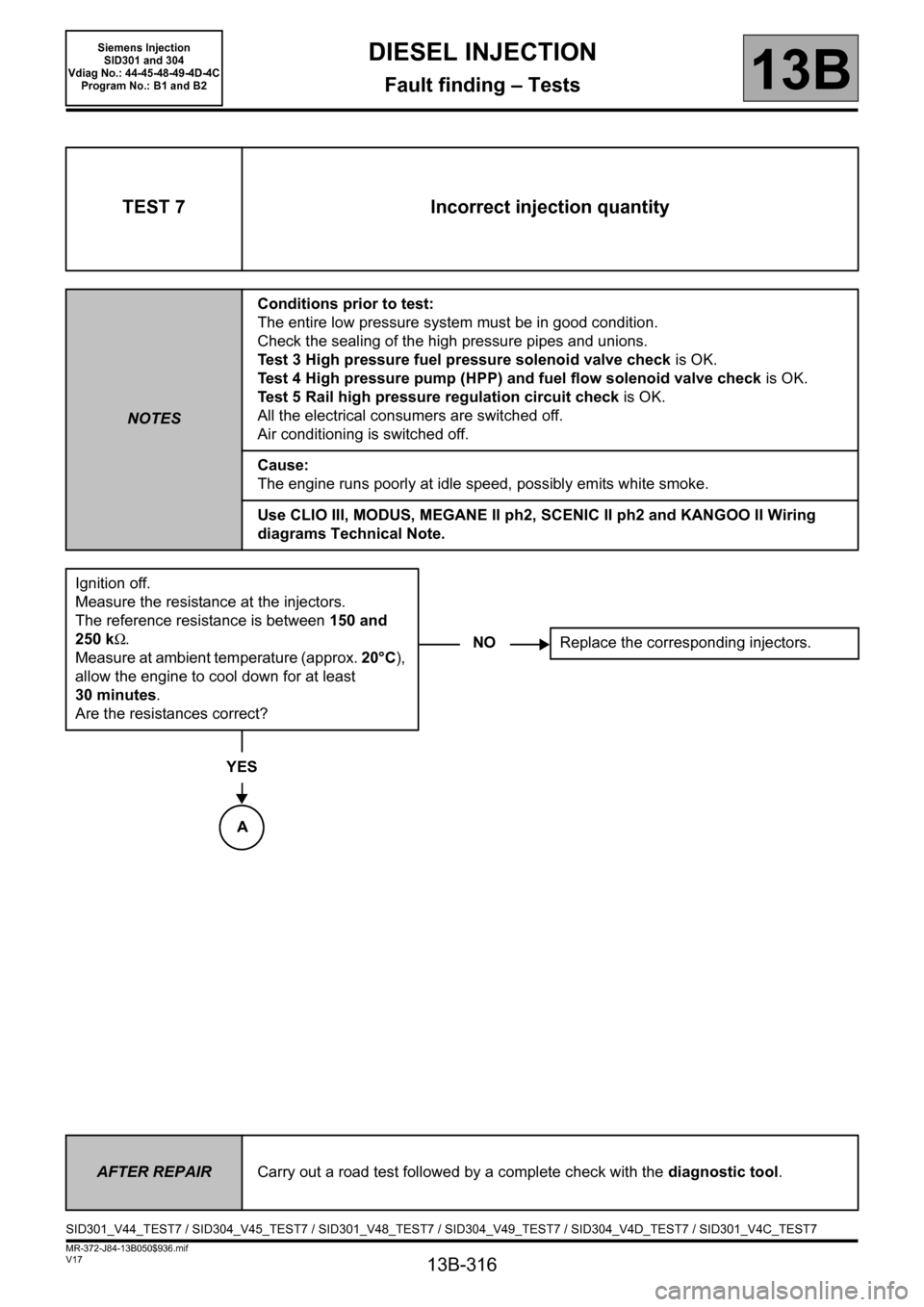

TEST 7 Incorrect injection quantity

NOTESConditions prior to test:

The entire low pressure system must be in good condition.

Check the sealing of the high pressure pipes and unions.

Te s t 3 High pressure fuel pressure solenoid valve check is OK.

Test 4 High pressure pump (HPP) and fuel flow solenoid valve check is OK.

Te s t 5 Rail high pressure regulation circuit check is OK.

All the electrical consumers are switched off.

Air conditioning is switched off.

Cause:

The engine runs poorly at idle speed, possibly emits white smoke.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and KANGOO II Wiring

diagrams Technical Note.

Ignition off.

Measure the resistance at the injectors.

The reference resistance is between 150 and

250 kΩ.

Measure at ambient temperature (approx. 20°C),

allow the engine to cool down for at least

30 minutes.

Are the resistances correct?

YES

NOReplace the corresponding injectors.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

SID301_V44_TEST7 / SID304_V45_TEST7 / SID301_V48_TEST7 / SID304_V49_TEST7 / SID304_V4D_TEST7 / SID301_V4C_TEST7

A

Page 317 of 329

13B-317

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

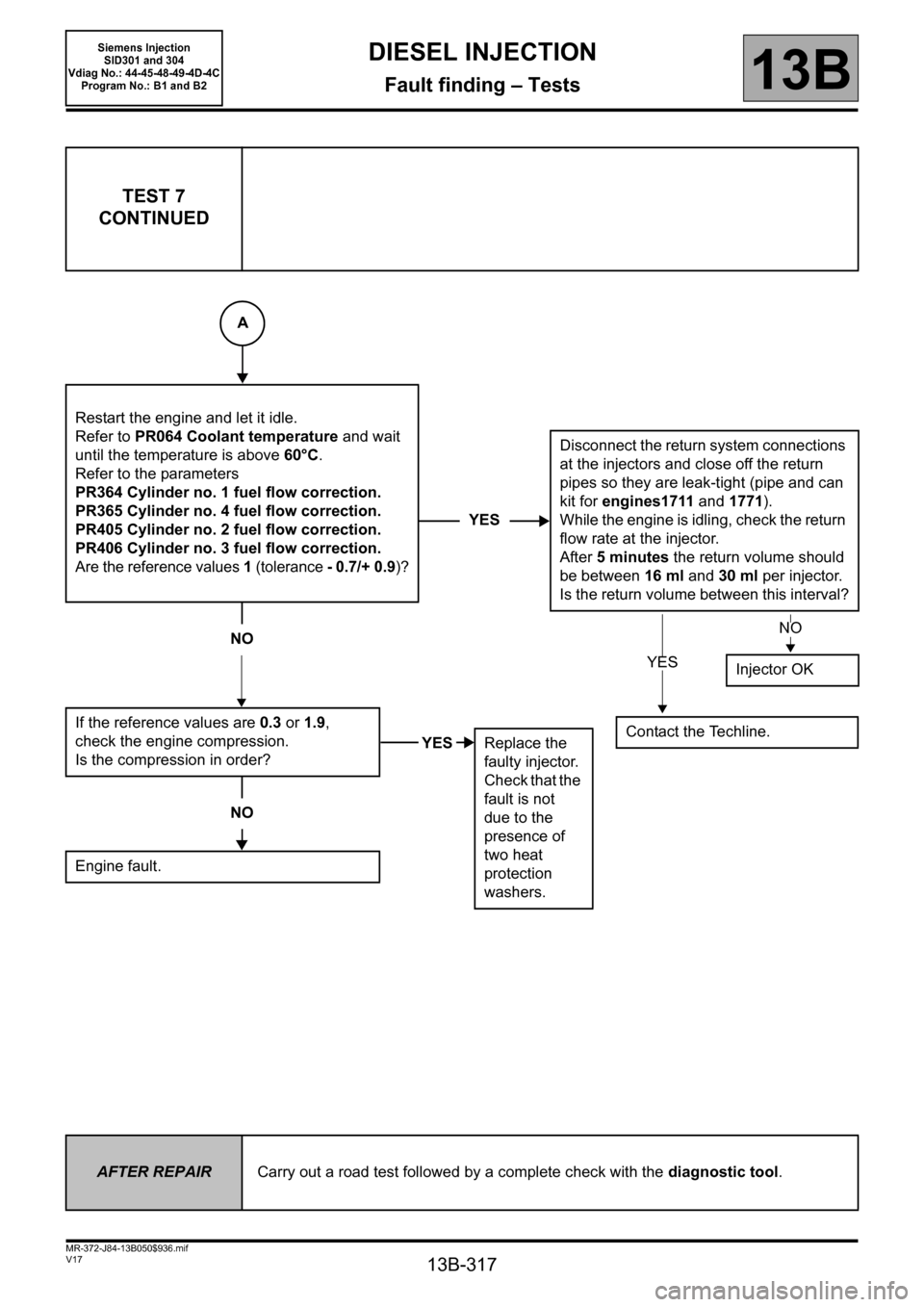

TEST 7

CONTINUED

Restart the engine and let it idle.

Refer to PR064 Coolant temperature and wait

until the temperature is above 60°C.

Refer to the parameters

PR364 Cylinder no. 1 fuel flow correction.

PR365 Cylinder no. 4 fuel flow correction.

PR405 Cylinder no. 2 fuel flow correction.

PR406 Cylinder no. 3 fuel flow correction.

Are the reference values 1 (tolerance - 0.7/+ 0.9)?

NO

If the reference values are 0.3 or 1.9,

check the engine compression.

Is the compression in order?

NO

Engine fault.

YESDisconnect the return system connections

at the injectors and close off the return

pipes so they are leak-tight (pipe and can

kit for engines1711 and 1771).

While the engine is idling, check the return

flow rate at the injector.

After 5minutes the return volume should

be between 16 ml and 30 ml per injector.

Is the return volume between this interval?

Injector OK

Contact the Techline.

NO

YES

YESReplace the

faulty injector.

Check that the

fault is not

due to the

presence of

two heat

protection

washers.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

A

Page 319 of 329

13B-319

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

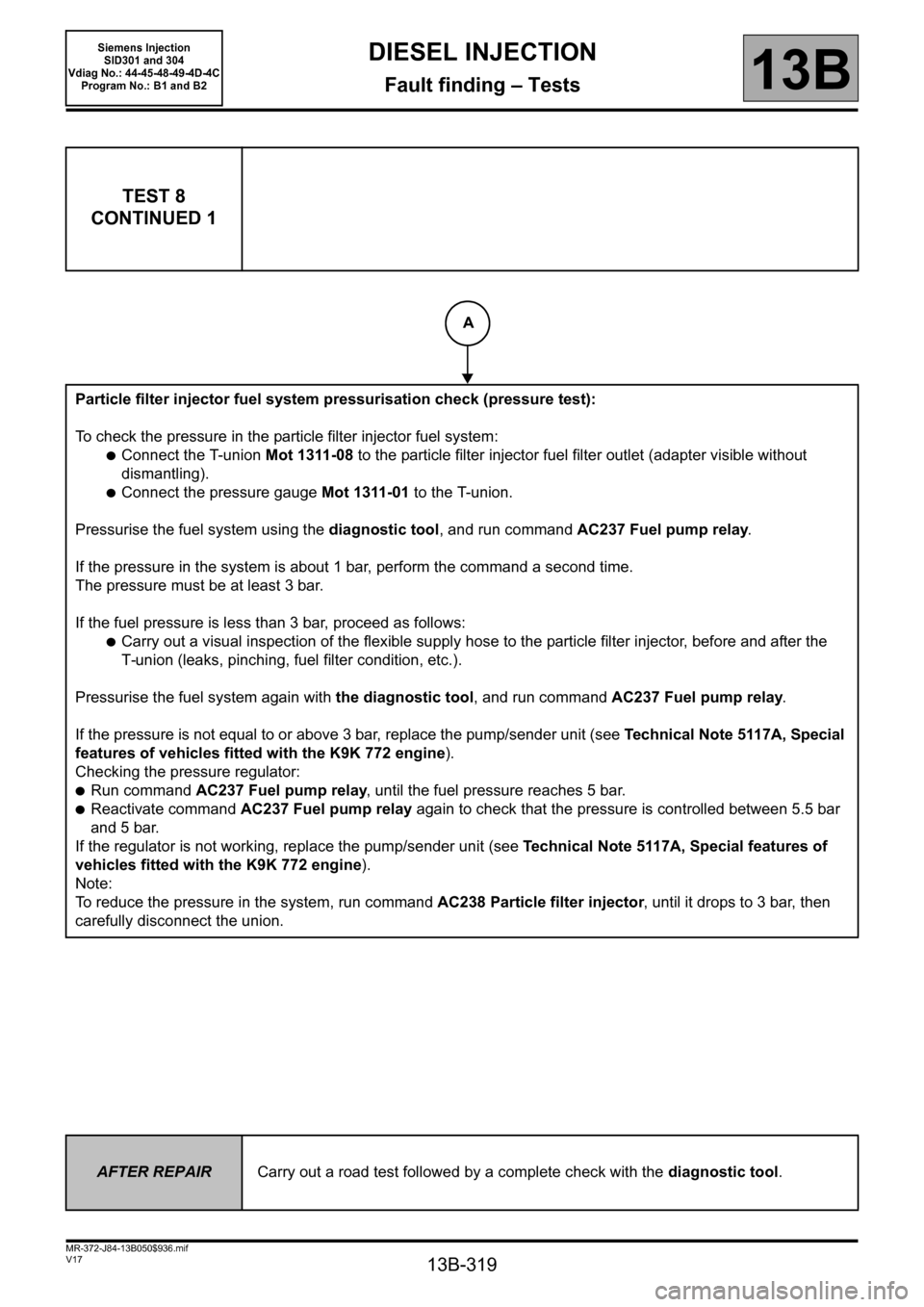

TEST 8

CONTINUED 1

Particle filter injector fuel system pressurisation check (pressure test):

To check the pressure in the particle filter injector fuel system:

●Connect the T-union Mot 1311-08 to the particle filter injector fuel filter outlet (adapter visible without

dismantling).

●Connect the pressure gauge Mot 1311-01 to the T-union.

Pressurise the fuel system using the diagnostic tool, and run command AC237 Fuel pump relay.

If the pressure in the system is about 1 bar, perform the command a second time.

The pressure must be at least 3 bar.

If the fuel pressure is less than 3 bar, proceed as follows:

●Carry out a visual inspection of the flexible supply hose to the particle filter injector, before and after the

T-union (leaks, pinching, fuel filter condition, etc.).

Pressurise the fuel system again with the diagnostic tool, and run command AC237 Fuel pump relay.

If the pressure is not equal to or above 3 bar, replace the pump/sender unit (see Technical Note 5117A, Special

features of vehicles fitted with the K9K 772 engine).

Checking the pressure regulator:

●Run command AC237 Fuel pump relay, until the fuel pressure reaches 5 bar.

●Reactivate command AC237 Fuel pump relay again to check that the pressure is controlled between 5.5 bar

and 5 bar.

If the regulator is not working, replace the pump/sender unit (see Technical Note 5117A, Special features of

vehicles fitted with the K9K 772 engine).

Note:

To reduce the pressure in the system, run command AC238 Particle filter injector, until it drops to 3 bar, then

carefully disconnect the union.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

A

Page 322 of 329

13B-322

MR-372-J84-13B050$936.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Tests13B

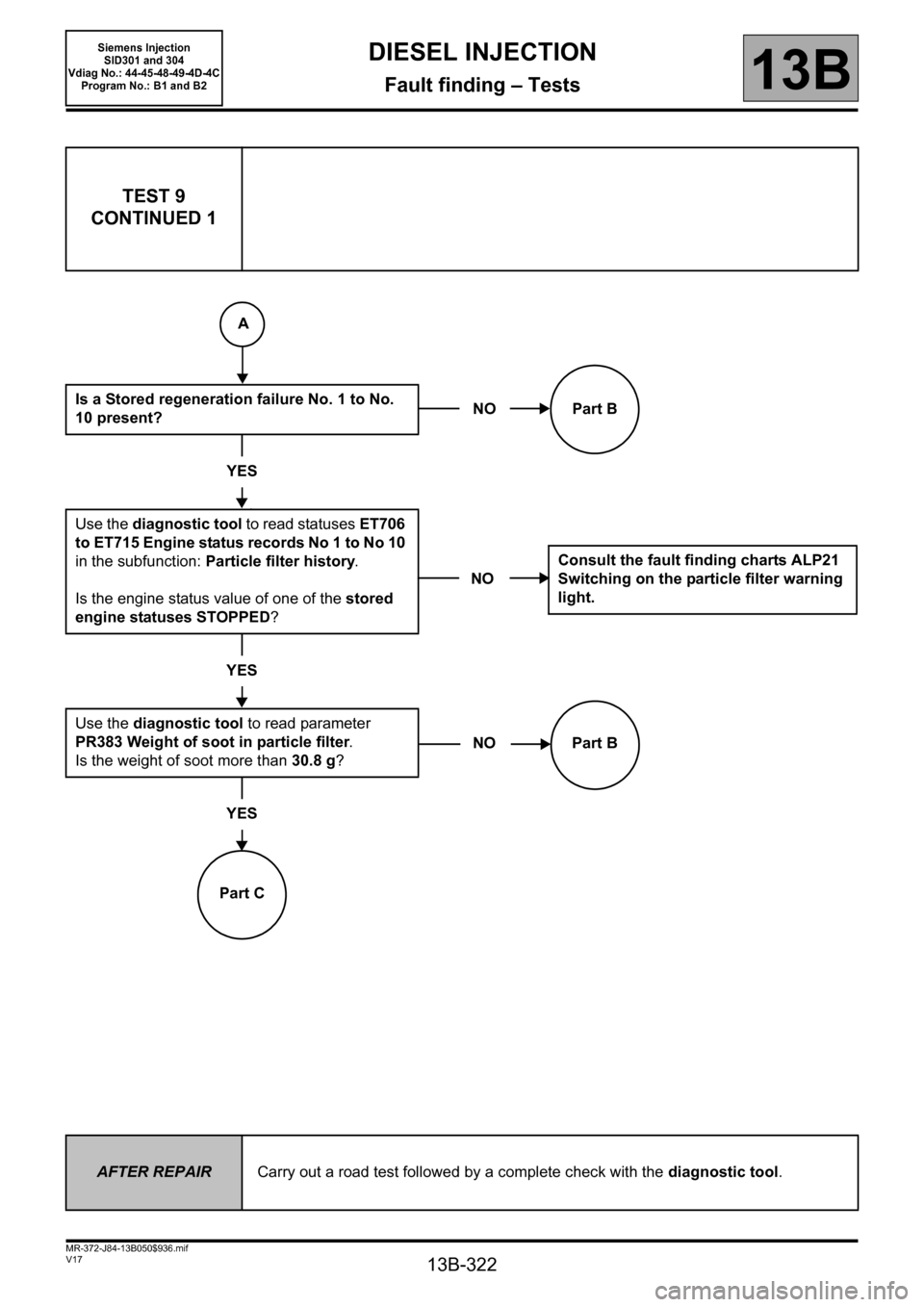

TEST 9

CONTINUED 1

Is a Stored regeneration failure No. 1 to No.

10 present?

YES

Use the diagnostic tool to read statuses ET706

to ET715 Engine status records No 1 to No 10

in the subfunction: Particle filter history.

Is the engine status value of one of the stored

engine statuses STOPPED?

YES

Use the diagnostic tool to read parameter

PR383 Weight of soot in particle filter.

Is the weight of soot more than 30.8 g?

YES

Part CNO Part B

NOConsult the fault finding charts ALP21

Switching on the particle filter warning

light.

NO Part B

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

A

Page 323 of 329

13B-323

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

TEST 9

CONTINUED 2

PA R T B

1 - NO particle filter regeneration.

2 - Write on the repair order: the parameter and status relating to the last failure:

– Mileage of last Particle filter warning light record

– Mileage of last Failed regeneration records

– Engine statuses for last Engine status records

Example: PR837 = 2794 miles (4657 km); PR801 = 2760 miles (4600 km); engine status = STOPPED

3 - Interpretation of the values written on the repair order by the service advisor for the customer:

Before the last time the warning light or Particle Filter message came on (appeared at the mileage of the last

Stored particle filter warning light) the customer did not follow the driving instructions: the failure which

occurred at the Mileage of the last failure was due to the engine being switched off.

4 - Service advisor explains to the customer the procedure to turn off the warning light, backed up by the

parameters written in the repair order: see PA R T D.

PA R T C

1 - Carry out a regeneration in the Renault dealership with the approval of the Techline.

Follow the procedure for command SC017 Particle filter regeneration.

Note: Do not carry out an engine oil change following an After-Sales regeneration.

2 - Explain the procedure for regeneration while driving to the customer to reduce returns to the garage:

see SECTION D:

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

Page 324 of 329

13B-324

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

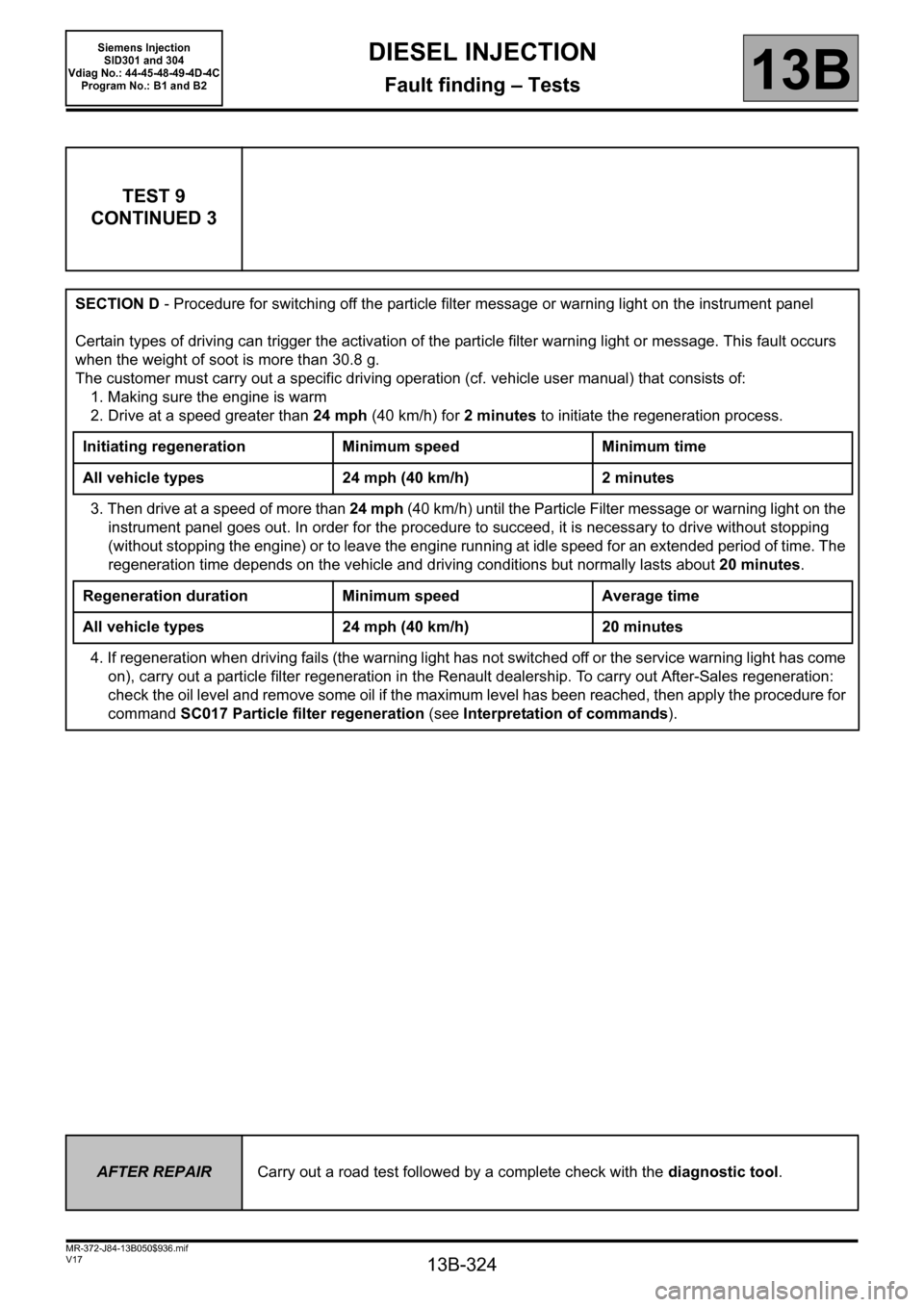

TEST 9

CONTINUED 3

SECTION D - Procedure for switching off the particle filter message or warning light on the instrument panel

Certain types of driving can trigger the activation of the particle filter warning light or message. This fault occurs

when the weight of soot is more than 30.8 g.

The customer must carry out a specific driving operation (cf. vehicle user manual) that consists of:

1. Making sure the engine is warm

2. Drive at a speed greater than 24 mph (40 km/h) for 2 minutes to initiate the regeneration process.

Initiating regeneration Minimum speed Minimum time

All vehicle types 24 mph (40 km/h) 2 minutes

3. Then drive at a speed of more than 24 mph (40 km/h) until the Particle Filter message or warning light on the

instrument panel goes out. In order for the procedure to succeed, it is necessary to drive without stopping

(without stopping the engine) or to leave the engine running at idle speed for an extended period of time. The

regeneration time depends on the vehicle and driving conditions but normally lasts about 20 minutes.

Regeneration duration Minimum speed Average time

All vehicle types 24 mph (40 km/h) 20 minutes

4. If regeneration when driving fails (the warning light has not switched off or the service warning light has come

on), carry out a particle filter regeneration in the Renault dealership. To carry out After-Sales regeneration:

check the oil level and remove some oil if the maximum level has been reached, then apply the procedure for

command SC017 Particle filter regeneration (see Interpretation of commands).

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

Page 326 of 329

13B-326

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

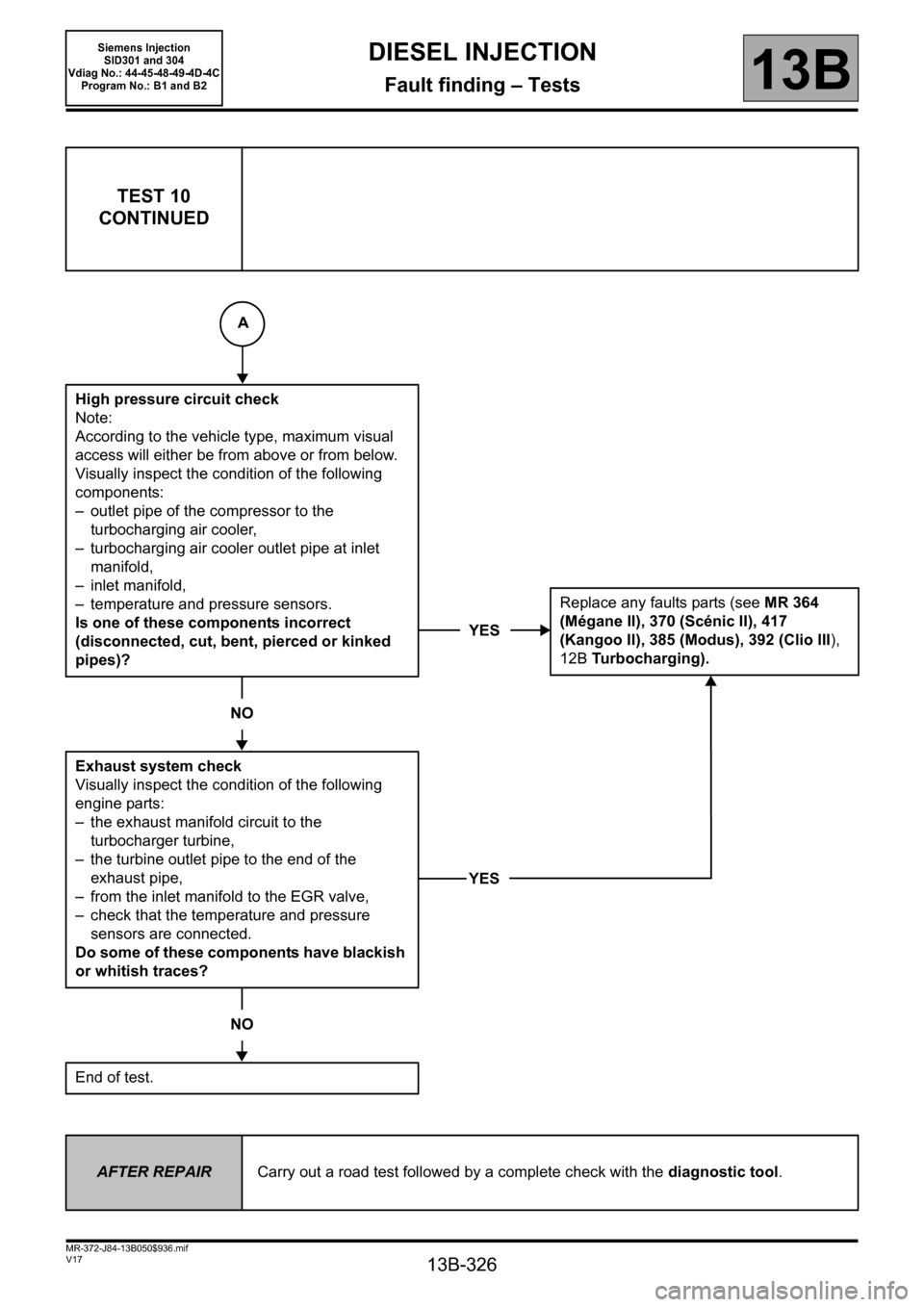

TEST 10

CONTINUED

High pressure circuit check

Note:

According to the vehicle type, maximum visual

access will either be from above or from below.

Visually inspect the condition of the following

components:

– outlet pipe of the compressor to the

turbocharging air cooler,

– turbocharging air cooler outlet pipe at inlet

manifold,

– inlet manifold,

– temperature and pressure sensors.

Is one of these components incorrect

(disconnected, cut, bent, pierced or kinked

pipes)?

NO

Exhaust system check

Visually inspect the condition of the following

engine parts:

– the exhaust manifold circuit to the

turbocharger turbine,

– the turbine outlet pipe to the end of the

exhaust pipe,

– from the inlet manifold to the EGR valve,

– check that the temperature and pressure

sensors are connected.

Do some of these components have blackish

or whitish traces?

NO

End of test.

YESReplace any faults parts (see MR 364

(Mégane II), 370 (Scénic II), 417

(Kangoo II), 385 (Modus), 392 (Clio III),

12B Turbocharging).

YES

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

A