coolant level RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals Siemens Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 329, PDF Size: 1.71 MB

Page 13 of 329

13B-13

MR-372-J84-13B050$195.mif

V17

13B

DIESEL INJECTION

Fault finding – Function

SYSTEM FLOWCHART

The high pressure injection system is designed to deliver a precise quantity of diesel fuel to the engine at a set

moment.

The Siemens VDO piezo Common Rail system used on the K9K Step 2 engine is a second generation Common Rail

injection system. Fuel pressure in the rail can reach a maximum of 1650 bar.

The Siemens VDO piezo Common Rail system uses injectors which are controlled by piezoelectric actuators.

The fuel is pressurised by means of a high pressure pump then sent to a rail which supplies the four injectors.

The system includes two subsystems, which have different fuel pressure levels:

●the low pressure system which includes the tank, diesel fuel filter, internal fuel transfer pump and injector

return pipes,

●the high pressure system which includes the high pressure pump, rail, injectors and high pressure pipes.

There are a number of sensors and regulating actuators for controlling and monitoring the entire system.

It is fitted with a 112- track (or 128- track for Kangoo II) SIEMENS computer (SID 301 and SID 304).

The system comprises:

– a priming bulb,

– a diesel filter,

– a high pressure pump (HPP) with a fuel pressure solenoid valve (PCV), a fuel flow solenoid valve (VCV) and an

internal fuel transfer pump (ITP, low pressure pump),

– an injector rail,

– a rail pressure sensor,

– four piezoelectric injectors,

– a fuel temperature sensor,

– a coolant temperature sensor,

– a camshaft sensor,

– a TDC sensor,

– a turbocharger pressure sensor,

– an exhaust gas recirculation solenoid valve with integrated position sensor (EGR),

– an accelerator pedal potentiometer,

– an atmospheric pressure sensor integrated into the injection computer,

– an air mass flowmeter with integrated air temperature sensor,

– an air damper valve (Vdiag 44, 45, 48, 49 and 4D only),

– a temperature sensor upstream of the turbine,

– an antipollution system:

●a temperature sensor upstream of the particle filter (Vdiag 45, 49, 4D only),

●a temperature sensor downstream of the particle filter (Vdiag 45, 49, 4D only),

●a particle filter differential pressure sensor (Vdiag 45, 49, 4D only),

●a particle filter injector (Vdiag 45, 49, 4D only),

●a particle filter (Vdiag 45, 49, 4D only),

– a temperature sensor downstream of the catalytic converter,

– an electric fuel pump,

– an electric coolant pump (Vdiag 45, 49, 4D only),

– four heating elements and their control unit (Vdiag 45, 49, 4D only),

– four heater plugs,

– a water in the fuel detection sensor (optional).

MR-372-J84-13B050$195.mif

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

Page 19 of 329

13B-19

MR-372-J84-13B050$195.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Function13B

INTERSYSTEM EXCHANGES

The inter-system connections concerning the particular requirements of engine management are as follows:

●Request for injection computer to switch on the OBD warning light to warn of an OBD related pollution fault.

●Request to switch on the Level 1 warning light to warn of an operational safety fault with the engine

management system which may restrict performance.

●Request to switch on the Level 2 warning light to warn of an operational safety fault with the engine

management system which may result in the engine stopping.

●Request to switch on the Particle Filter and Service warning light to warn of an operational safety fault of the

particle filter system which may result in reduced performance or engine stoppage.

●Request to switch on the Engine overheating warning light to warn of an engine overheating fault or a fault

in the coolant temperature sensor.

●Request to switch on the Particle filter warning light to warn the driver that the particle filter is loaded with

particles (weight of soot more than 30.8 g). As soon as possible, the driver must drive at a speed of more than

25 mph (40 km/h) for 2 minutes to activate regeneration.

The driver must maintain a speed of more than 25 mph (40 km/h) until the particle filter warning light goes out

(Vdiag 45 and 49 only).

●Request to start the fan assembly for engine cooling and also for air conditioning purposes,

●Request to switch off the air conditioning compressor for engine programming requirements such as pulling

away, performance, anti-stalling, overspeed, etc.

●Request to switch off electrical consumers (passenger compartment heating resistor (if fitted), heated rear

screen, etc.) for engine operation purposes such as: pulling away, performance, anti-stalling,

overspeed, etc.

●Formulation of requests to engage electrical consumers and limit power as a function of rail conditions.

This last function is made possible with the introduction of alternator control. Formulation of requests enables

the smooth running of the engine to be improved in the critical operating phases, mainly at idle speed and

when pulling away. These requests pass via the multiplex network to the Protection and Switching Unit where

they are converted before being sent to the alternator.

In comparison to the version without a particle filter (K9K Step 2), the K9K Step 2 particle filter technical

specifications also include:

●Four temperature sensors spread along the exhaust system.

●One differential pressure sensor.

●One fuel injector with a dedicated electric fuel pump.

●An electric water pump (in addition to the mechanical pump) controlled by a relay to cool the turbocharger when

the engine is stopped (only for Clio III, Modus and Mégane II/Scénic II).

●Four heating elements and their control unit.

Oil Control System (OCS) (except Vdiag 44, 45 and 49)

This program takes into account the driving style of the user to warn him of the need for an oil change. This program

counts the number of miles since the last oil change, corrected by a factor which depends on the oil temperature.

When the number of miles exceeds a threshold, the customer is warned by a message to the instrument panel that

the drain must be performed.

After the oil change, the user must reset the oil change interval on the instrument panel.

Page 24 of 329

13B-24

MR-372-J84-13B050$195.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Function13B

Cruise control/speed limiter on/off switch:

This switch turns the cruise control/speed limiter on or off.

Water in diesel fuel sensor (optional):

This sensor indicates if water is present in the diesel.

Fan unit relay:

This relay actuates the motor-driven fan assemblies when a temperature threshold has been exceeded.

Accelerator potentiometer:

The accelerator potentiometer informs the computer about the position of the accelerator pedal (engine load).

Brake pedal switch:

The brake pedal switch informs the computer about the pedal status.

Clutch pedal switch:

The clutch pedal switch informs the computer about the pedal status.

Particle filter injector:

The particle filter injector is a low pressure injector. This injector allows the temperature of the second catalytic

converter to be raised to assist with regeneration of the particle filter (Vdiag 45, 49, 4D only).

Only on Kangoo 2: an evaporator plate is present at the particle filter injector outlet, at the level of the bracket

between the exhaust pipe and the catalytic converter.

Heating elements:

The heating elements heat the engine coolant to enhance user comfort (Vdiag 45, 49, 4D only).

Heater plugs:

The heater plugs preheat the combustion chamber so that the explosion of the fuel mixture occurs under the best

conditions to start the engine.

Page 31 of 329

13B-31

MR-372-J84-13B050$351.mif

V17

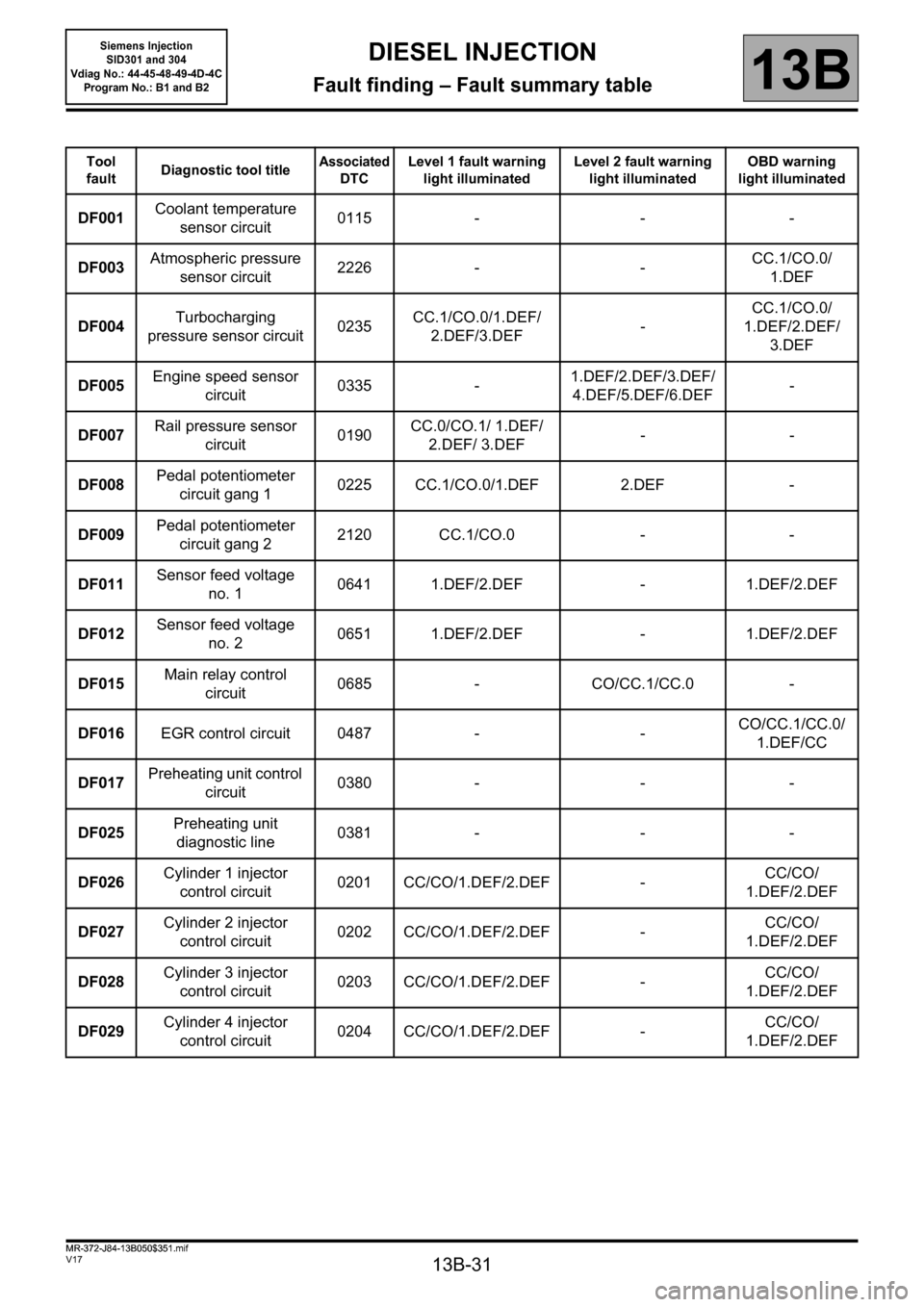

13B

DIESEL INJECTION

Fault finding – Fault summary table

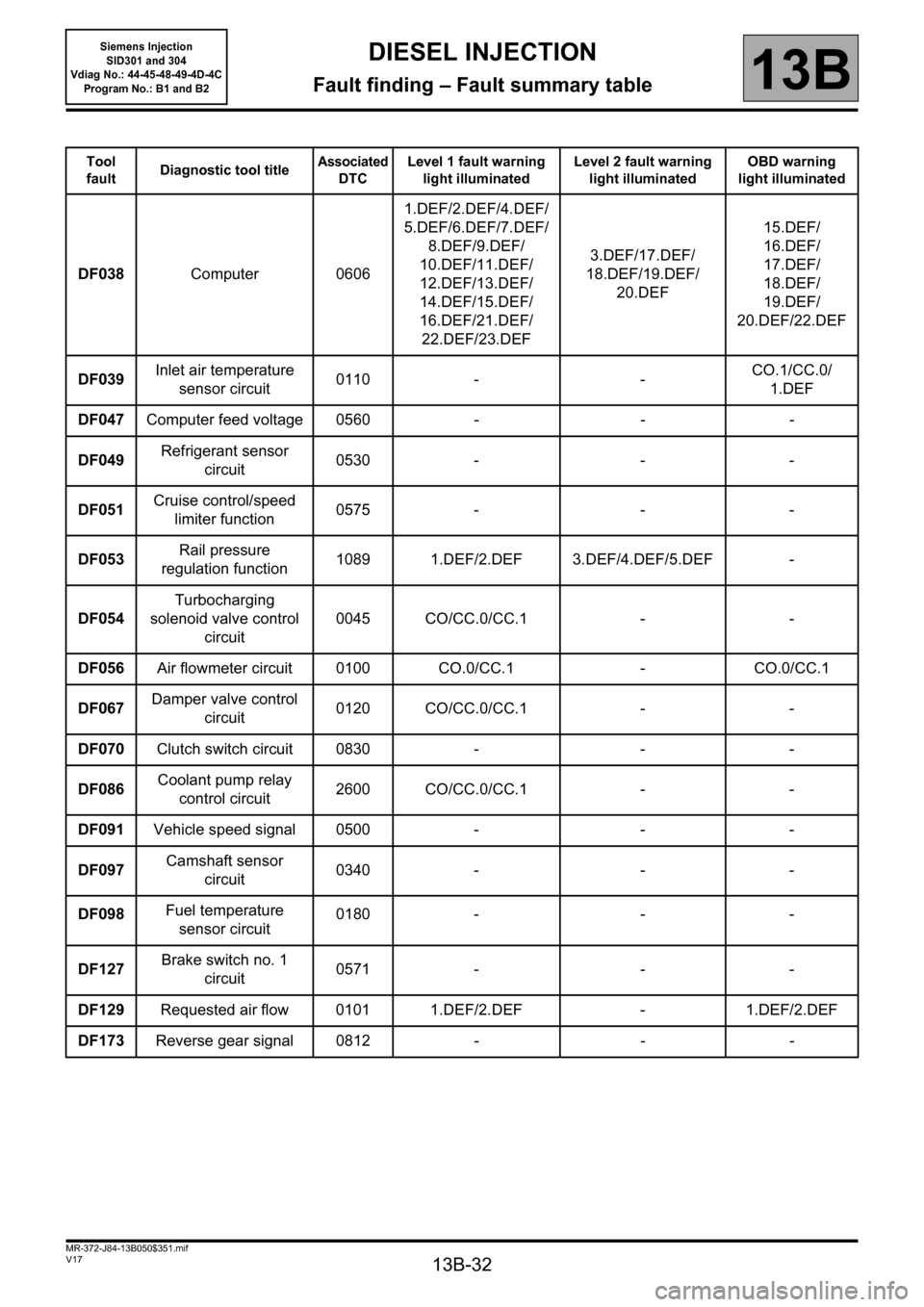

Tool

faultDiagnostic tool titleAssociated

DTCLevel 1 fault warning

light illuminatedLevel 2 fault warning

light illuminatedOBD warning

light illuminated

DF001Coolant temperature

sensor circuit0115 - - -

DF003Atmospheric pressure

sensor circuit2226 - -CC.1/CO.0/

1.DEF

DF004Turbocharging

pressure sensor circuit0235CC.1/CO.0/1.DEF/

2.DEF/3.DEF-CC.1/CO.0/

1.DEF/2.DEF/

3.DEF

DF005Engine speed sensor

circuit0335 -1.DEF/2.DEF/3.DEF/

4.DEF/5.DEF/6.DEF-

DF007Rail pressure sensor

circuit0190CC.0/CO.1/ 1.DEF/

2.DEF/ 3.DEF--

DF008Pedal potentiometer

circuit gang 10225 CC.1/CO.0/1.DEF 2.DEF -

DF009Pedal potentiometer

circuit gang 22120 CC.1/CO.0 - -

DF011Sensor feed voltage

no. 10641 1.DEF/2.DEF - 1.DEF/2.DEF

DF012Sensor feed voltage

no. 20651 1.DEF/2.DEF - 1.DEF/2.DEF

DF015Main relay control

circuit0685 - CO/CC.1/CC.0 -

DF016EGR control circuit 0487 - -CO/CC.1/CC.0/

1.DEF/CC

DF017Preheating unit control

circuit0380 - - -

DF025Preheating unit

diagnostic line0381 - - -

DF026Cylinder 1 injector

control circuit0201 CC/CO/1.DEF/2.DEF -CC/CO/

1.DEF/2.DEF

DF027Cylinder 2 injector

control circuit0202 CC/CO/1.DEF/2.DEF -CC/CO/

1.DEF/2.DEF

DF028Cylinder 3 injector

control circuit0203 CC/CO/1.DEF/2.DEF -CC/CO/

1.DEF/2.DEF

DF029Cylinder 4 injector

control circuit0204 CC/CO/1.DEF/2.DEF -CC/CO/

1.DEF/2.DEF

MR-372-J84-13B050$351.mif

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

Page 32 of 329

13B-32

MR-372-J84-13B050$351.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Fault summary table13B

Tool

faultDiagnostic tool titleAssociated

DTCLevel 1 fault warning

light illuminatedLevel 2 fault warning

light illuminatedOBD warning

light illuminated

DF038Computer 06061.DEF/2.DEF/4.DEF/

5.DEF/6.DEF/7.DEF/

8.DEF/9.DEF/

10.DEF/11.DEF/

12.DEF/13.DEF/

14.DEF/15.DEF/

16.DEF/21.DEF/

22.DEF/23.DEF3.DEF/17.DEF/

18.DEF/19.DEF/

20.DEF15.DEF/

16.DEF/

17.DEF/

18.DEF/

19.DEF/

20.DEF/22.DEF

DF039Inlet air temperature

sensor circuit0110 - -CO.1/CC.0/

1.DEF

DF047Computer feed voltage 0560 - - -

DF049Refrigerant sensor

circuit0530 - - -

DF051Cruise control/speed

limiter function0575 - - -

DF053Rail pressure

regulation function1089 1.DEF/2.DEF 3.DEF/4.DEF/5.DEF -

DF054Turbocharging

solenoid valve control

circuit0045 CO/CC.0/CC.1 - -

DF056Air flowmeter circuit 0100 CO.0/CC.1 - CO.0/CC.1

DF067Damper valve control

circuit0120 CO/CC.0/CC.1 - -

DF070Clutch switch circuit 0830 - - -

DF086Coolant pump relay

control circuit2600 CO/CC.0/CC.1 - -

DF091Vehicle speed signal 0500 - - -

DF097Camshaft sensor

circuit0340 - - -

DF098Fuel temperature

sensor circuit0180 - - -

DF127Brake switch no. 1

circuit0571 - - -

DF129Requested air flow 0101 1.DEF/2.DEF - 1.DEF/2.DEF

DF173Reverse gear signal 0812 - - -

Page 135 of 329

13B-135

MR-372-J84-13B050$585.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Interpretation of statuses13B

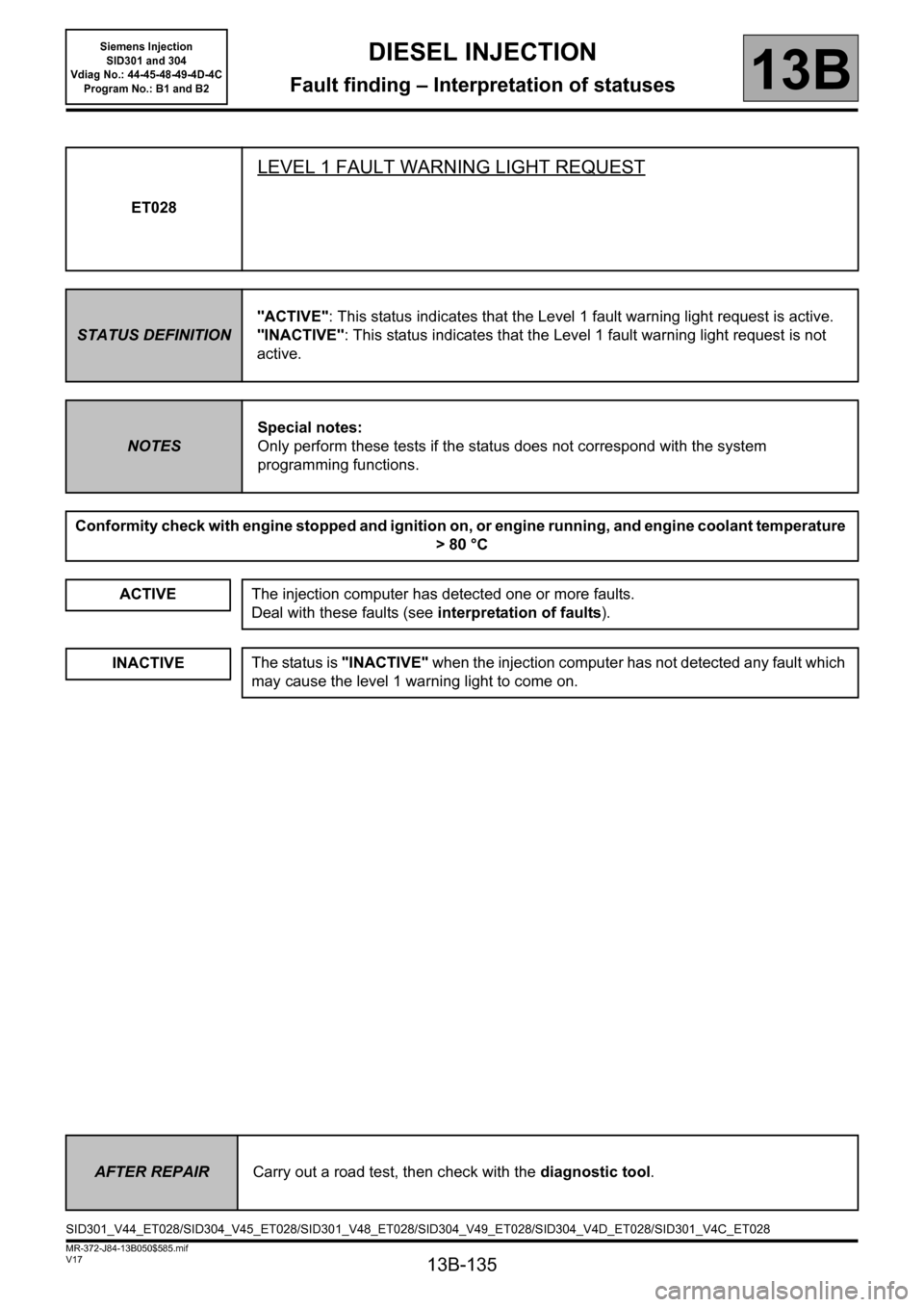

ET028

LEVEL 1 FAULT WARNING LIGHT REQUEST

STATUS DEFINITION"ACTIVE": This status indicates that the Level 1 fault warning light request is active.

"INACTIVE": This status indicates that the Level 1 fault warning light request is not

active.

NOTESSpecial notes:

Only perform these tests if the status does not correspond with the system

programming functions.

Conformity check with engine stopped and ignition on, or engine running, and engine coolant temperature

>80 °C

ACTIVE

The injection computer has detected one or more faults.

Deal with these faults (see interpretation of faults).

INACTIVEThe status is "INACTIVE" when the injection computer has not detected any fault which

may cause the level 1 warning light to come on.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

SID301_V44_ET028/SID304_V45_ET028/SID301_V48_ET028/SID304_V49_ET028/SID304_V4D_ET028/SID301_V4C_ET028

Page 136 of 329

13B-136

MR-372-J84-13B050$585.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Interpretation of statuses13B

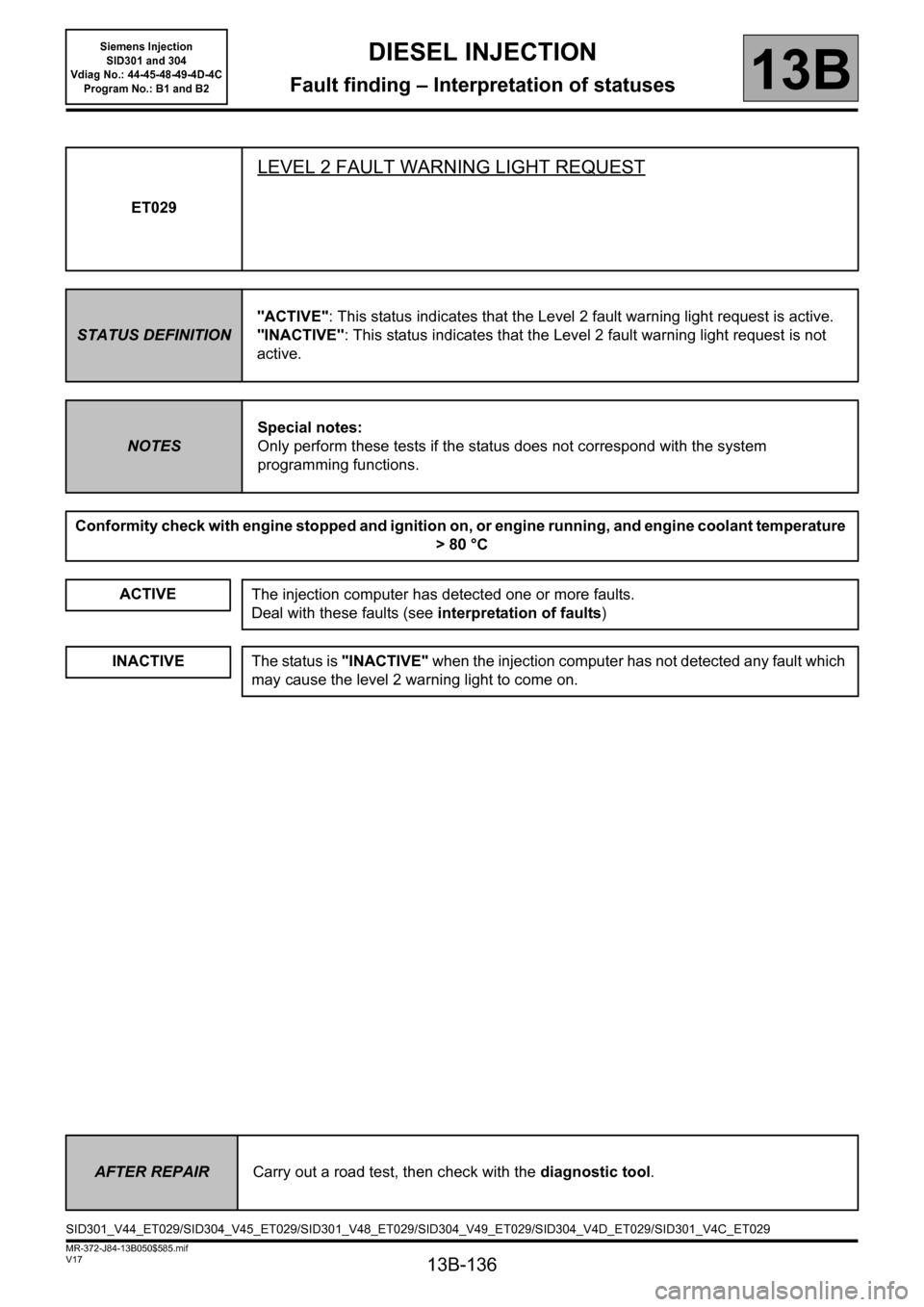

ET029

LEVEL 2 FAULT WARNING LIGHT REQUEST

STATUS DEFINITION"ACTIVE": This status indicates that the Level 2 fault warning light request is active.

"INACTIVE": This status indicates that the Level 2 fault warning light request is not

active.

NOTESSpecial notes:

Only perform these tests if the status does not correspond with the system

programming functions.

Conformity check with engine stopped and ignition on, or engine running, and engine coolant temperature

>80 °C

ACTIVE

The injection computer has detected one or more faults.

Deal with these faults (see interpretation of faults)

INACTIVEThe status is "INACTIVE" when the injection computer has not detected any fault which

may cause the level 2 warning light to come on.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

SID301_V44_ET029/SID304_V45_ET029/SID301_V48_ET029/SID304_V49_ET029/SID304_V4D_ET029/SID301_V4C_ET029

Page 151 of 329

13B-151

MR-372-J84-13B050$585.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of statuses

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

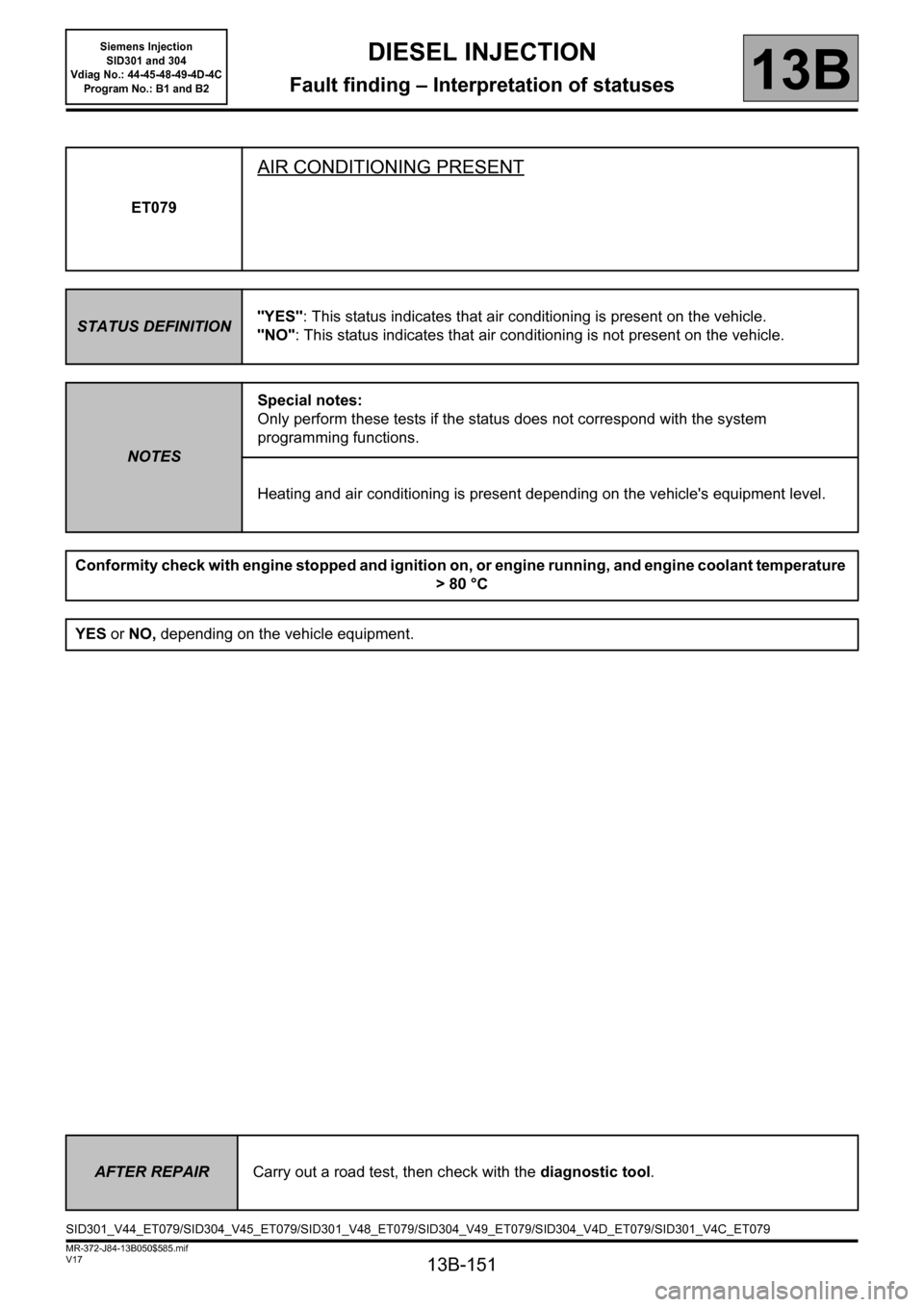

ET079

AIR CONDITIONING PRESENT

STATUS DEFINITION"YES": This status indicates that air conditioning is present on the vehicle.

"NO": This status indicates that air conditioning is not present on the vehicle.

NOTESSpecial notes:

Only perform these tests if the status does not correspond with the system

programming functions.

Heating and air conditioning is present depending on the vehicle's equipment level.

Conformity check with engine stopped and ignition on, or engine running, and engine coolant temperature

>80 °C

YES or NO, depending on the vehicle equipment.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

SID301_V44_ET079/SID304_V45_ET079/SID301_V48_ET079/SID304_V49_ET079/SID304_V4D_ET079/SID301_V4C_ET079

Page 239 of 329

13B-239

MR-372-J84-13B050$780.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of parameters

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

PR513

LEVEL 1 WARNING LIGHT DISTANCE COUNTER

PARAMETER

DEFINITIONThis parameter indicates the number of miles (km) travelled since the Level 1 warning

light was last activated.

NOTESSpecial notes:

Only perform these tests if the parameters do not correspond with the system

operation programming.

Conformity check with the engine stopped and the ignition on, or the engine running and the engine

coolant temperature > 80°C

PR513 = X km

Check the consistency of this parameter with the first appearance of possible faults associated with the Level 1

warning light.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_PR513/SID304_V45_PR513/SID301_V48_PR513/SID304_V49_PR513/SID304_V4D_PR513/SID301_V4C_PR513

Page 240 of 329

13B-240

MR-372-J84-13B050$780.mif

V17

DIESEL INJECTION

Fault finding – Interpretation of parameters

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

PR514

LEVEL 2 WARNING LIGHT DISTANCE COUNTER

PARAMETER

DEFINITIONThis parameter indicates the number of miles (km) travelled since the Level 2 warning

light was last activated.

NOTESSpecial notes:

Only perform these tests if the parameters do not correspond with the system

operation programming.

Conformity check with the engine stopped and the ignition on, or the engine running and the engine

coolant temperature > 80°C

PR514 = X miles (km)

Check the consistency of this parameter with the first appearance of any faults related to the Level 2 warning

light.

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

SID301_V44_PR514/SID304_V45_PR514/SID301_V48_PR514/SID304_V49_PR514/SID304_V4D_PR514/SID301_V4C_PR514