Starter engine RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 198, PDF Size: 0.85 MB

Page 18 of 198

13B-18V4 MR-372-J84-13B000$030.mif

13B

DDCR INJECTION

Vdiag No.: 44, 48

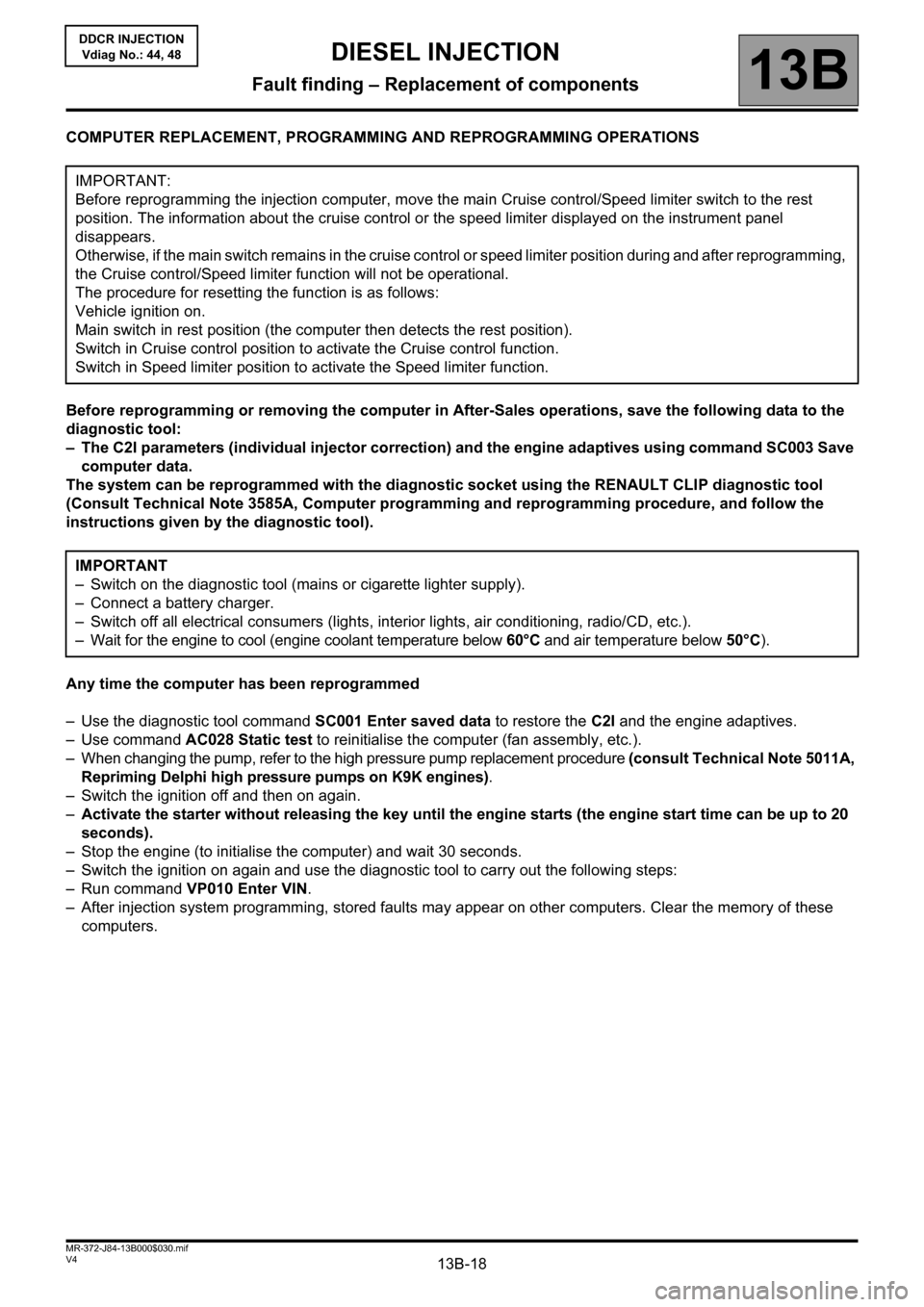

COMPUTER REPLACEMENT, PROGRAMMING AND REPROGRAMMING OPERATIONS

Before reprogramming or removing the computer in After-Sales operations, save the following data to the

diagnostic tool:

– The C2I parameters (individual injector correction) and the engine adaptives using command SC003 Save

computer data.

The system can be reprogrammed with the diagnostic socket using the RENAULT CLIP diagnostic tool

(Consult Technical Note 3585A, Computer programming and reprogramming procedure, and follow the

instructions given by the diagnostic tool).

Any time the computer has been reprogrammed

– Use the diagnostic tool command SC001 Enter saved data to restore the C2I and the engine adaptives.

– Use command AC028 Static test to reinitialise the computer (fan assembly, etc.).

– When changing the pump, refer to the high pressure pump replacement procedure (consult Technical Note 5011A,

Repriming Delphi high pressure pumps on K9K engines).

– Switch the ignition off and then on again.

–Activate the starter without releasing the key until the engine starts (the engine start time can be up to 20

seconds).

– Stop the engine (to initialise the computer) and wait 30 seconds.

– Switch the ignition on again and use the diagnostic tool to carry out the following steps:

– Run command VP010 Enter VIN.

– After injection system programming, stored faults may appear on other computers. Clear the memory of these

computers. IMPORTANT:

Before reprogramming the injection computer, move the main Cruise control/Speed limiter switch to the rest

position. The information about the cruise control or the speed limiter displayed on the instrument panel

disappears.

Otherwise, if the main switch remains in the cruise control or speed limiter position during and after reprogramming,

the Cruise control/Speed limiter function will not be operational.

The procedure for resetting the function is as follows:

Vehicle ignition on.

Main switch in rest position (the computer then detects the rest position).

Switch in Cruise control position to activate the Cruise control function.

Switch in Speed limiter position to activate the Speed limiter function.

IMPORTANT

– Switch on the diagnostic tool (mains or cigarette lighter supply).

– Connect a battery charger.

– Switch off all electrical consumers (lights, interior lights, air conditioning, radio/CD, etc.).

– Wait for the engine to cool (engine coolant temperature below 60°C and air temperature below 50°C).

DIESEL INJECTION

Fault finding – Replacement of components

Page 27 of 198

13B-27

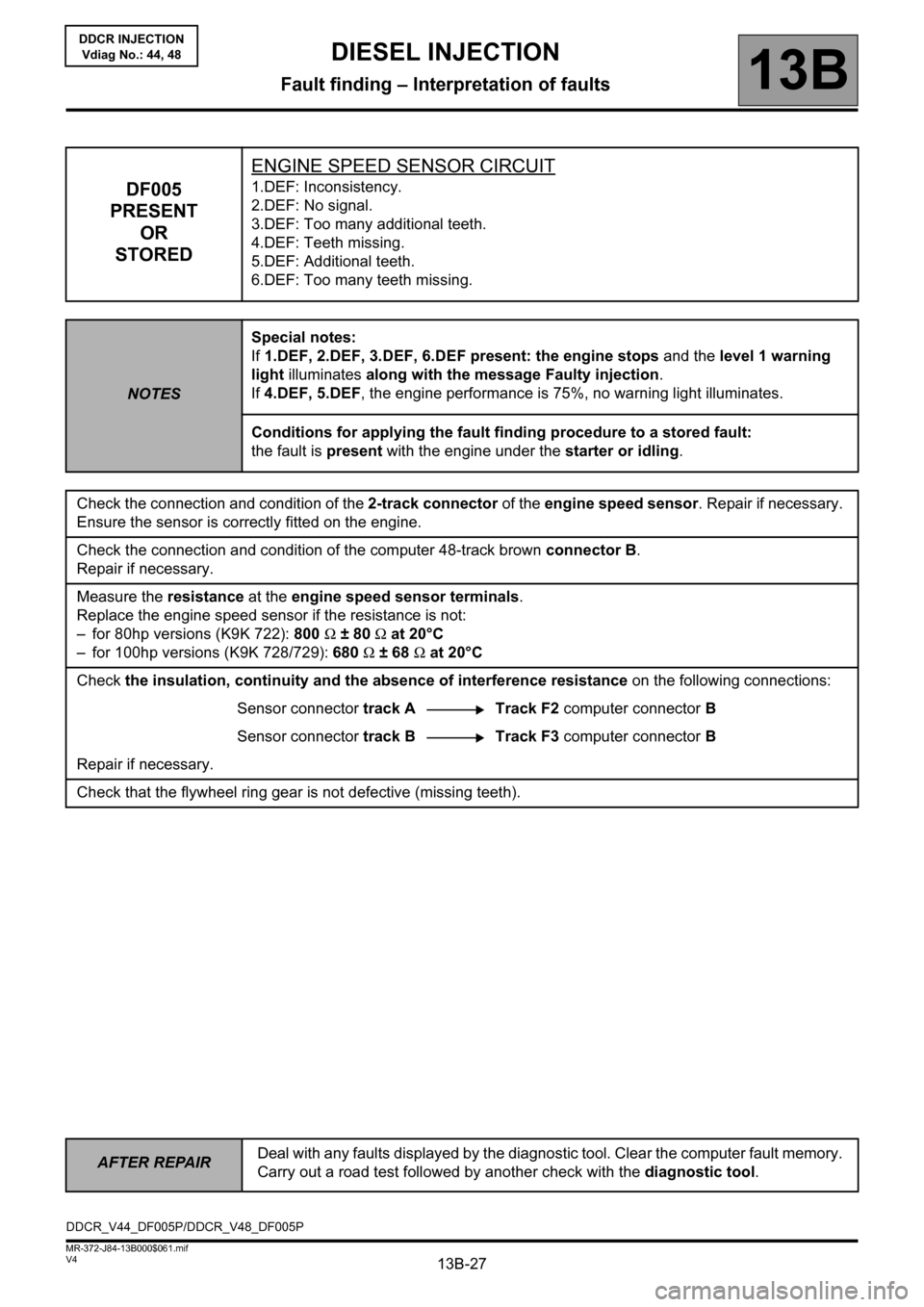

AFTER REPAIRDeal with any faults displayed by the diagnostic tool. Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V4 MR-372-J84-13B000$061.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DDCR INJECTION

Vdiag No.: 44, 48

DF005

PRESENT

OR

STOREDENGINE SPEED SENSOR CIRCUIT1.DEF: Inconsistency.

2.DEF: No signal.

3.DEF: Too many additional teeth.

4.DEF: Teeth missing.

5.DEF: Additional teeth.

6.DEF: Too many teeth missing.

NOTESSpecial notes:

If 1.DEF, 2.DEF, 3.DEF, 6.DEF present: the engine stops and the level 1 warning

light illuminates along with the message Faulty injection.

If 4.DEF, 5.DEF, the engine performance is 75%, no warning light illuminates.

Conditions for applying the fault finding procedure to a stored fault:

the fault is present with the engine under the starter or idling.

Check the connection and condition of the 2-track connector of the engine speed sensor. Repair if necessary.

Ensure the sensor is correctly fitted on the engine.

Check the connection and condition of the computer 48-track brown connector B.

Repair if necessary.

Measure the resistance at the engine speed sensor terminals.

Replace the engine speed sensor if the resistance is not:

– for 80hp versions (K9K 722): 800 Ω ± 80 Ω at 20°C

– for 100hp versions (K9K 728/729): 680 Ω ± 68 Ω at 20°C

Check the insulation, continuity and the absence of interference resistance on the following connections:

Sensor connector track A Track F2 computer connector B

Sensor connector track BTrack F3 computer connector B

Repair if necessary.

Check that the flywheel ring gear is not defective (missing teeth).

DDCR_V44_DF005P/DDCR_V48_DF005P

Page 73 of 198

13B-73

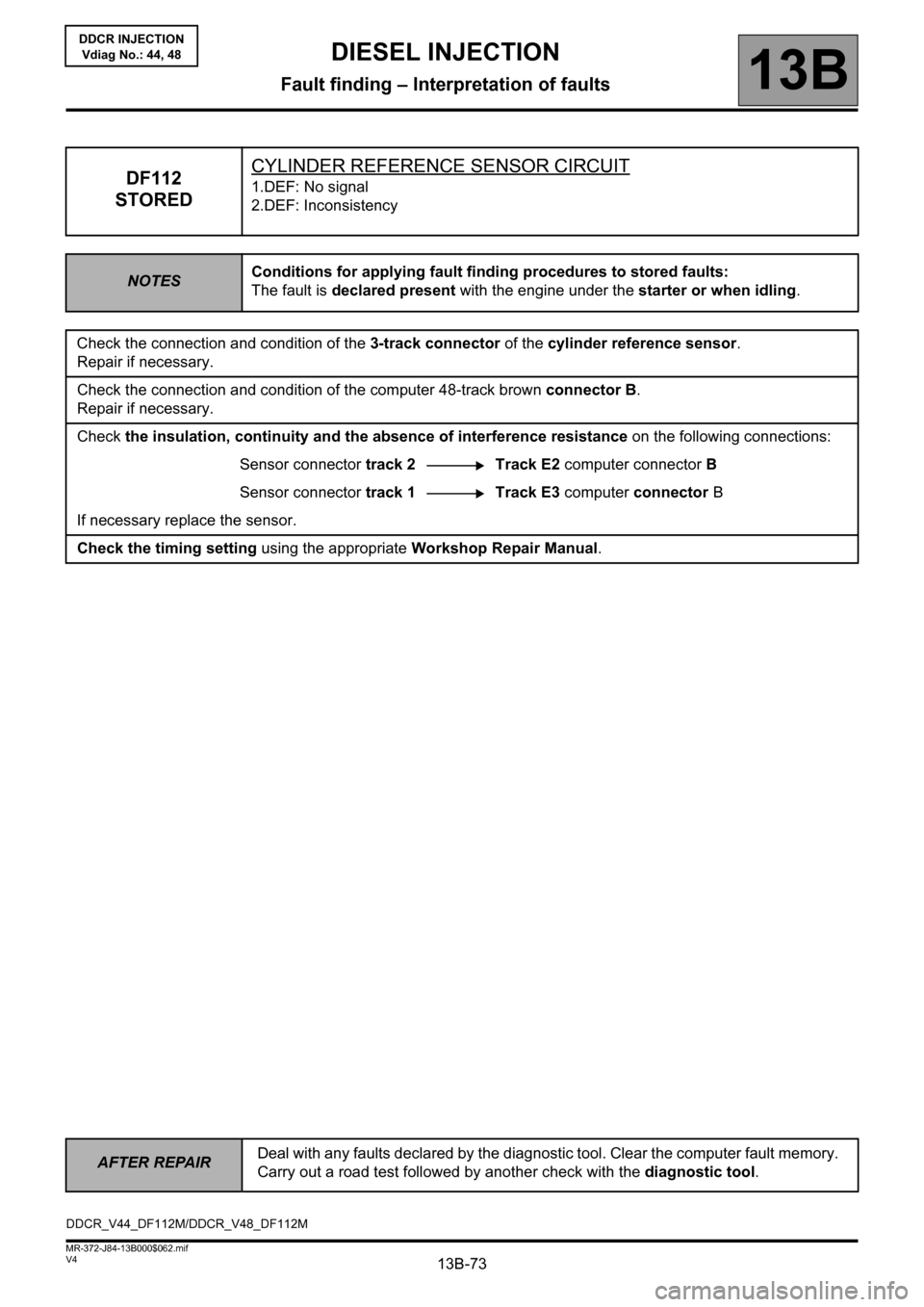

AFTER REPAIRDeal with any faults declared by the diagnostic tool. Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V4 MR-372-J84-13B000$062.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DDCR INJECTION

Vdiag No.: 44, 48

DF112

STOREDCYLINDER REFERENCE SENSOR CIRCUIT1.DEF: No signal

2.DEF: Inconsistency

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present with the engine under the starter or when idling.

Check the connection and condition of the 3-track connector of the cylinder reference sensor.

Repair if necessary.

Check the connection and condition of the computer 48-track brown connector B.

Repair if necessary.

Check the insulation, continuity and the absence of interference resistance on the following connections:

Sensor connector track 2 Track E2 computer connector B

Sensor connector track 1Track E3 computer connector B

If necessary replace the sensor.

Check the timing setting using the appropriate Workshop Repair Manual.

DDCR_V44_DF112M/DDCR_V48_DF112M

Page 85 of 198

13B-85V4 MR-372-J84-13B000$070.mif

DIESEL INJECTION

Fault finding – Conformity check13B

DDCR INJECTION

Vdiag No.: 44, 48

MAIN COMPUTER STATUSES AND PARAMETERS: (continued 2)

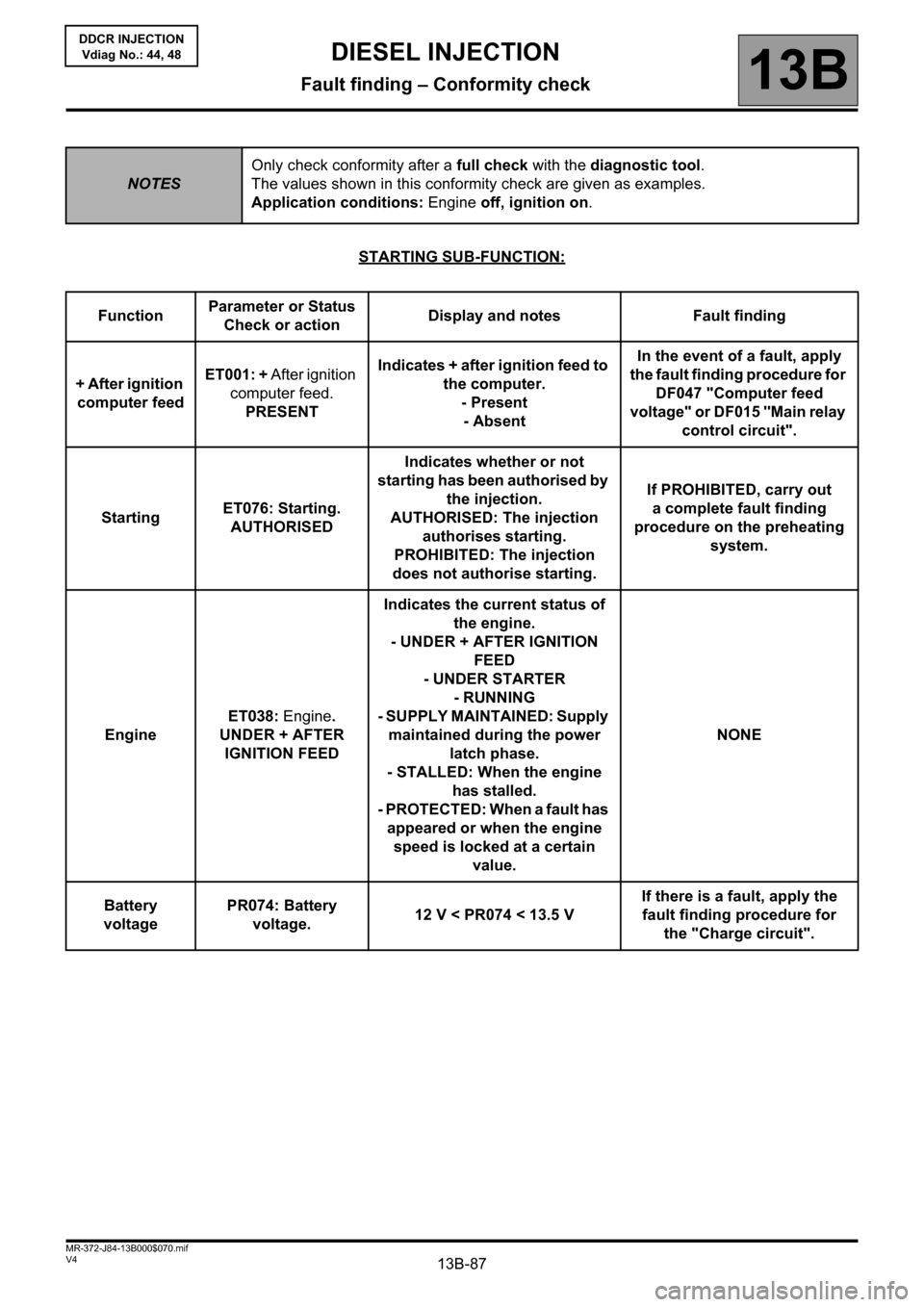

NOTESOnly check conformity after a full check with the diagnostic tool.

The values shown in this conformity check are given as examples.

Application conditions: Engine off, ignition on.

FunctionParameter or Status

Check or actionDisplay and notes Fault finding

EngineET038: Engine.

UNDER + AFTER

IGNITION FEEDIndicates the current status of

the engine.

- UNDER + AFTER IGNITION

FEED

- UNDER STARTER

- RUNNING

- SUPPLY MAINTAINED: Supply

maintained during the power

latch phase.

- STALLED: When the engine

has stalled.

- PROTECTED: When a level 2

fault has appeared or when

the engine speed is locked at

a certain value.NONE

Engine

immobiliserET003: Engine

immobiliser.

INACTIVEIndicates the status of the

immobiliser system.

- INACTIVE: The injection

computer has recognised the

immobiliser code transmitted

by the UCH.

- ACTIVE: The injection

computer does not recognise

the immobiliser code

transmitted by the UCH.If ACTIVE, apply the

associated Help given in

the tool.

Code

programmedET006: Code

programmed

YESIndicates whether the

immobiliser code has been

programmed into the computer.

- YES: Code is programmed.

- NO: Code was not

programmed into the injection

computer.If NO, contact the Techline.

Page 87 of 198

13B-87V4 MR-372-J84-13B000$070.mif

DIESEL INJECTION

Fault finding – Conformity check13B

DDCR INJECTION

Vdiag No.: 44, 48

STARTING SUB-FUNCTION:

NOTESOnly check conformity after a full check with the diagnostic tool.

The values shown in this conformity check are given as examples.

Application conditions: Engine off, ignition on.

FunctionParameter or Status

Check or actionDisplay and notes Fault finding

+ After ignition

computer feedET001: + After ignition

computer feed.

PRESENTIndicates + after ignition feed to

the computer.

- Present

- AbsentIn the event of a fault, apply

the fault finding procedure for

DF047 "Computer feed

voltage" or DF015 "Main relay

control circuit".

StartingET076: Starting.

AUTHORISEDIndicates whether or not

starting has been authorised by

the injection.

AUTHORISED: The injection

authorises starting.

PROHIBITED: The injection

does not authorise starting.If PROHIBITED, carry out

a complete fault finding

procedure on the preheating

system.

EngineET038: Engine.

UNDER + AFTER

IGNITION FEEDIndicates the current status of

the engine.

- UNDER + AFTER IGNITION

FEED

- UNDER STARTER

- RUNNING

- SUPPLY MAINTAINED: Supply

maintained during the power

latch phase.

- STALLED: When the engine

has stalled.

- PROTECTED: When a fault has

appeared or when the engine

speed is locked at a certain

value.NONE

Battery

voltagePR074: Battery

voltage.12 V < PR074 < 13.5 VIf there is a fault, apply the

fault finding procedure for

the "Charge circuit".

Page 105 of 198

13B-105V4 MR-372-J84-13B000$070.mif

DIESEL INJECTION

Fault finding – Conformity check13B

DDCR INJECTION

Vdiag No.: 44, 48

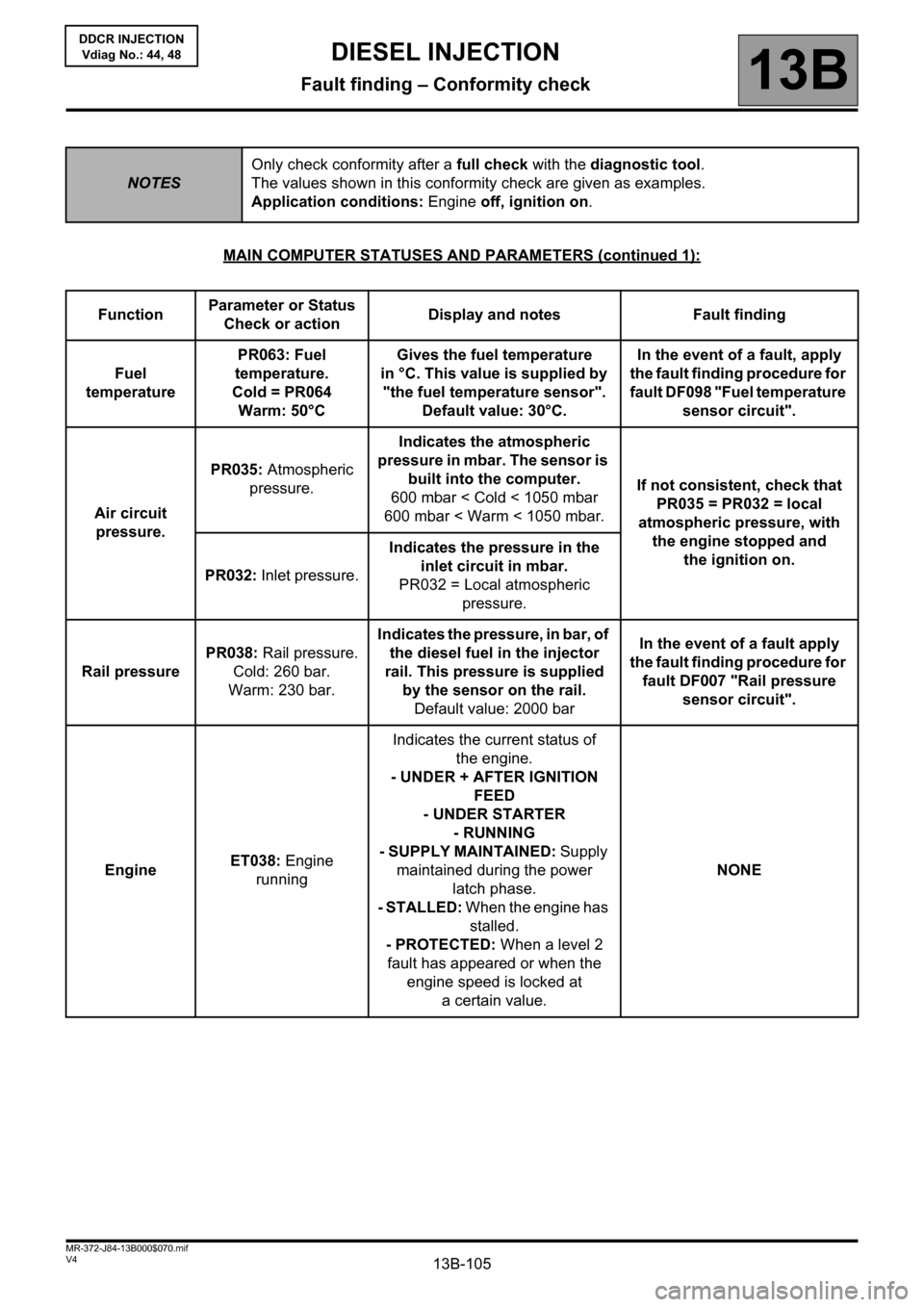

MAIN COMPUTER STATUSES AND PARAMETERS (continued 1):

NOTESOnly check conformity after a full check with the diagnostic tool.

The values shown in this conformity check are given as examples.

Application conditions: Engine off, ignition on.

FunctionParameter or Status

Check or actionDisplay and notes Fault finding

Fuel

temperaturePR063: Fuel

temperature.

Cold = PR064

Warm: 50°CGives the fuel temperature

in °C. This value is supplied by

"the fuel temperature sensor".

Default value: 30°C.In the event of a fault, apply

the fault finding procedure for

fault DF098 "Fuel temperature

sensor circuit".

Air circuit

pressure.PR035: Atmospheric

pressure.Indicates the atmospheric

pressure in mbar. The sensor is

built into the computer.

600 mbar < Cold < 1050 mbar

600 mbar < Warm < 1050 mbar.If not consistent, check that

PR035 = PR032 = local

atmospheric pressure, with

the engine stopped and

the ignition on.

PR032: Inlet pressure.Indicates the pressure in the

inlet circuit in mbar.

PR032 = Local atmospheric

pressure.

Rail pressurePR038: Rail pressure.

Cold: 260 bar.

Warm: 230 bar.Indicates the pressure, in bar, of

the diesel fuel in the injector

rail. This pressure is supplied

by the sensor on the rail.

Default value: 2000 barIn the event of a fault apply

the fault finding procedure for

fault DF007 "Rail pressure

sensor circuit".

EngineET038: Engine

runningIndicates the current status of

the engine.

- UNDER + AFTER IGNITION

FEED

- UNDER STARTER

- RUNNING

- SUPPLY MAINTAINED: Supply

maintained during the power

latch phase.

- STALLED: When the engine has

stalled.

- PROTECTED: When a level 2

fault has appeared or when the

engine speed is locked at

a certain value.NONE

Page 107 of 198

13B-107V4 MR-372-J84-13B000$070.mif

DIESEL INJECTION

Fault finding – Conformity check13B

DDCR INJECTION

Vdiag No.: 44, 48

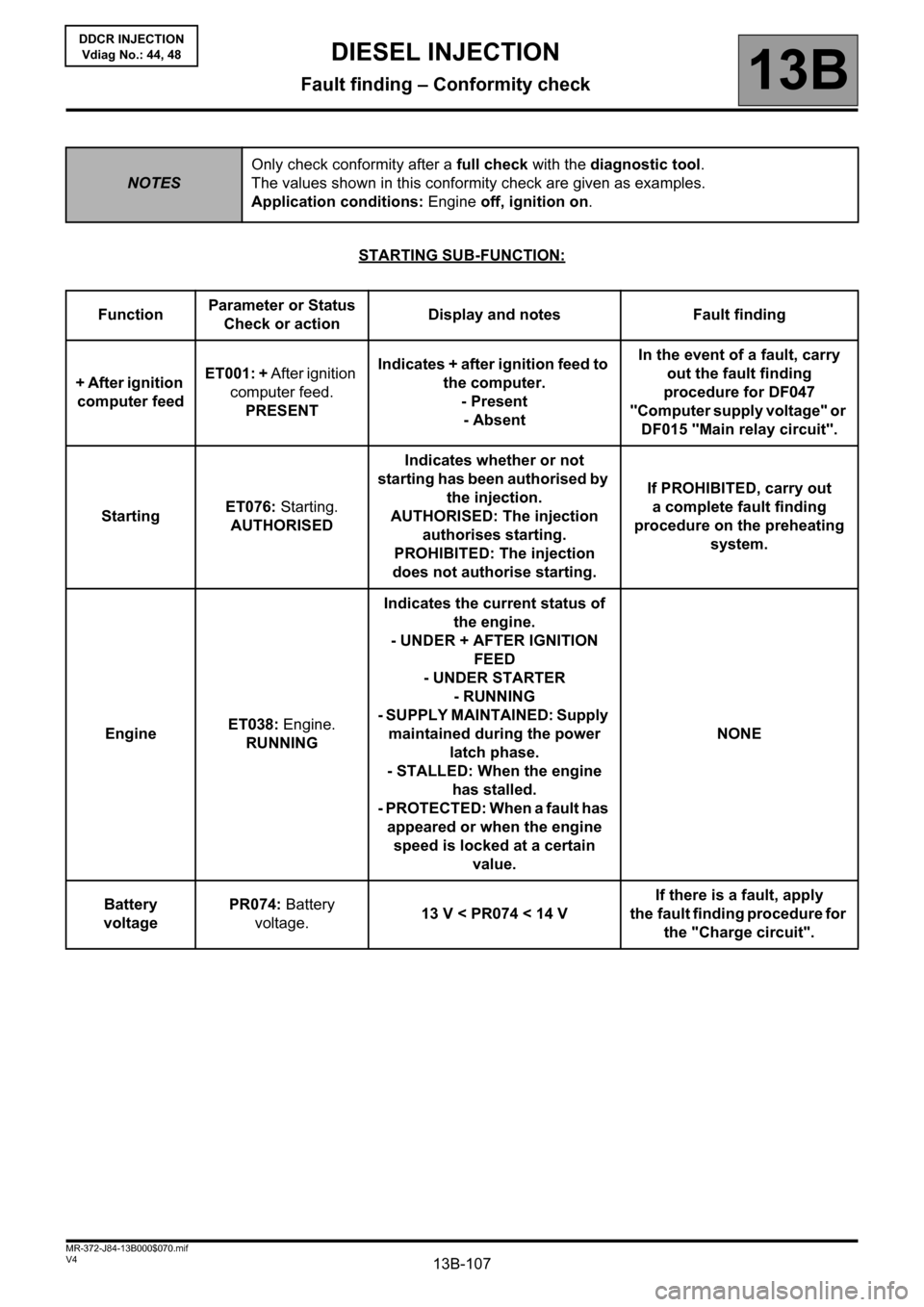

STARTING SUB-FUNCTION:

NOTESOnly check conformity after a full check with the diagnostic tool.

The values shown in this conformity check are given as examples.

Application conditions: Engine off, ignition on.

FunctionParameter or Status

Check or actionDisplay and notes Fault finding

+ After ignition

computer feedET001: + After ignition

computer feed.

PRESENTIndicates + after ignition feed to

the computer.

- Present

- AbsentIn the event of a fault, carry

out the fault finding

procedure for DF047

"Computer supply voltage" or

DF015 "Main relay circuit".

StartingET076: Starting.

AUTHORISEDIndicates whether or not

starting has been authorised by

the injection.

AUTHORISED: The injection

authorises starting.

PROHIBITED: The injection

does not authorise starting.If PROHIBITED, carry out

a complete fault finding

procedure on the preheating

system.

EngineET038: Engine.

RUNNINGIndicates the current status of

the engine.

- UNDER + AFTER IGNITION

FEED

- UNDER STARTER

- RUNNING

- SUPPLY MAINTAINED: Supply

maintained during the power

latch phase.

- STALLED: When the engine

has stalled.

- PROTECTED: When a fault has

appeared or when the engine

speed is locked at a certain

value.NONE

Battery

voltagePR074: Battery

voltage.13 V < PR074 < 14 VIf there is a fault, apply

the fault finding procedure for

the "Charge circuit".

Page 157 of 198

13B-157V4 MR-372-J84-13B000$120.mif

DIESEL INJECTION

Fault finding – Tests13B

DDCR INJECTION

Vdiag No.: 44, 48

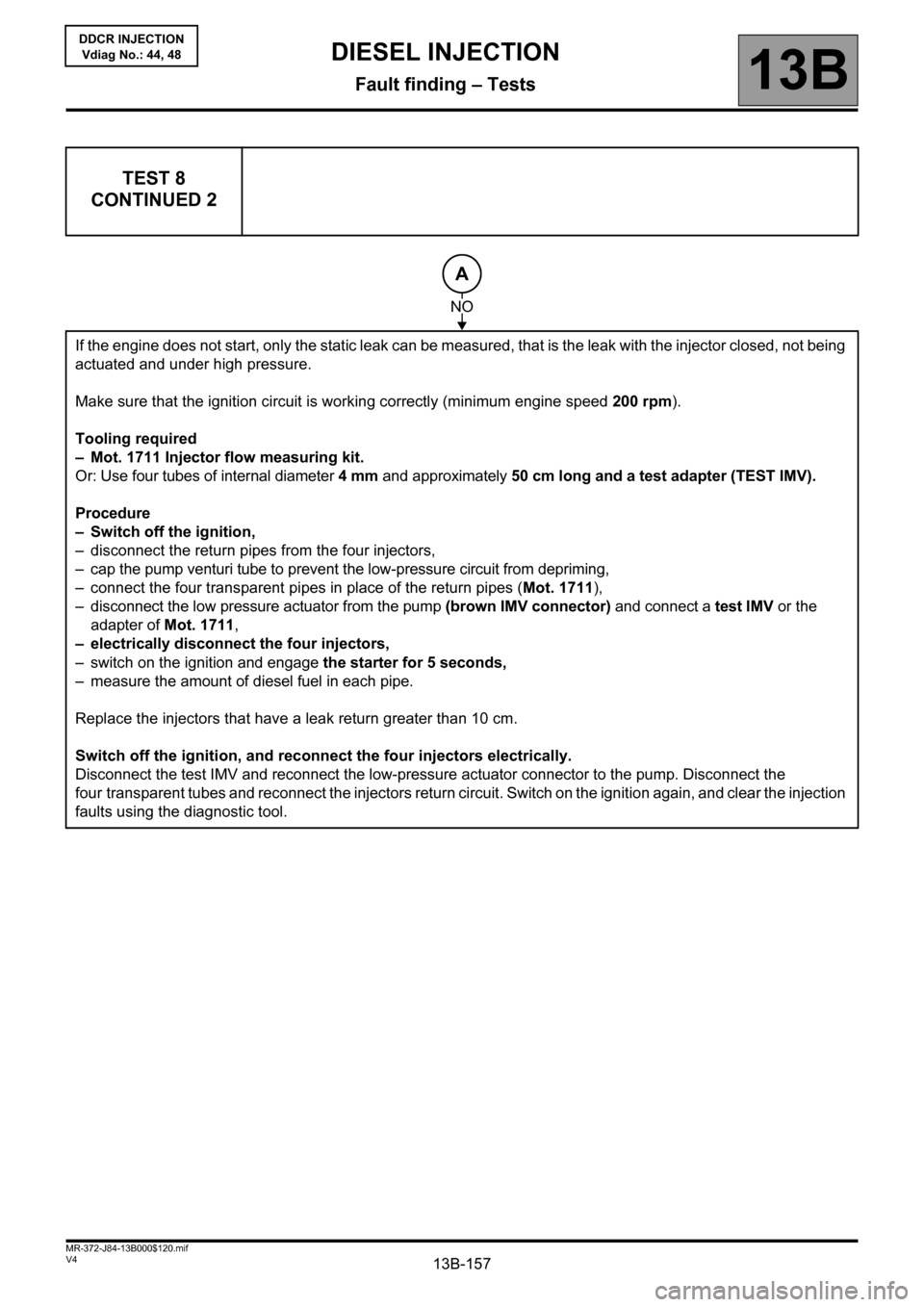

TEST 8

CONTINUED 2

If the engine does not start, only the static leak can be measured, that is the leak with the injector closed, not being

actuated and under high pressure.

Make sure that the ignition circuit is working correctly (minimum engine speed 200 rpm).

Tooling required

– Mot. 1711 Injector flow measuring kit.

Or: Use four tubes of internal diameter 4 mm and approximately 50 cm long and a test adapter (TEST IMV).

Procedure

– Switch off the ignition,

– disconnect the return pipes from the four injectors,

– cap the pump venturi tube to prevent the low-pressure circuit from depriming,

– connect the four transparent pipes in place of the return pipes (Mot. 1711),

– disconnect the low pressure actuator from the pump (brown IMV connector) and connect a test IMV or the

adapter of Mot. 1711,

– electrically disconnect the four injectors,

– switch on the ignition and engage the starter for 5 seconds,

– measure the amount of diesel fuel in each pipe.

Replace the injectors that have a leak return greater than 10 cm.

Switch off the ignition, and reconnect the four injectors electrically.

Disconnect the test IMV and reconnect the low-pressure actuator connector to the pump. Disconnect the

four transparent tubes and reconnect the injectors return circuit. Switch on the ignition again, and clear the injection

faults using the diagnostic tool.

A

NO

Page 168 of 198

13B-168

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V4 MR-372-J84-13B000$140.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

InjectionDDCR

Vdiag No.: 44, 48

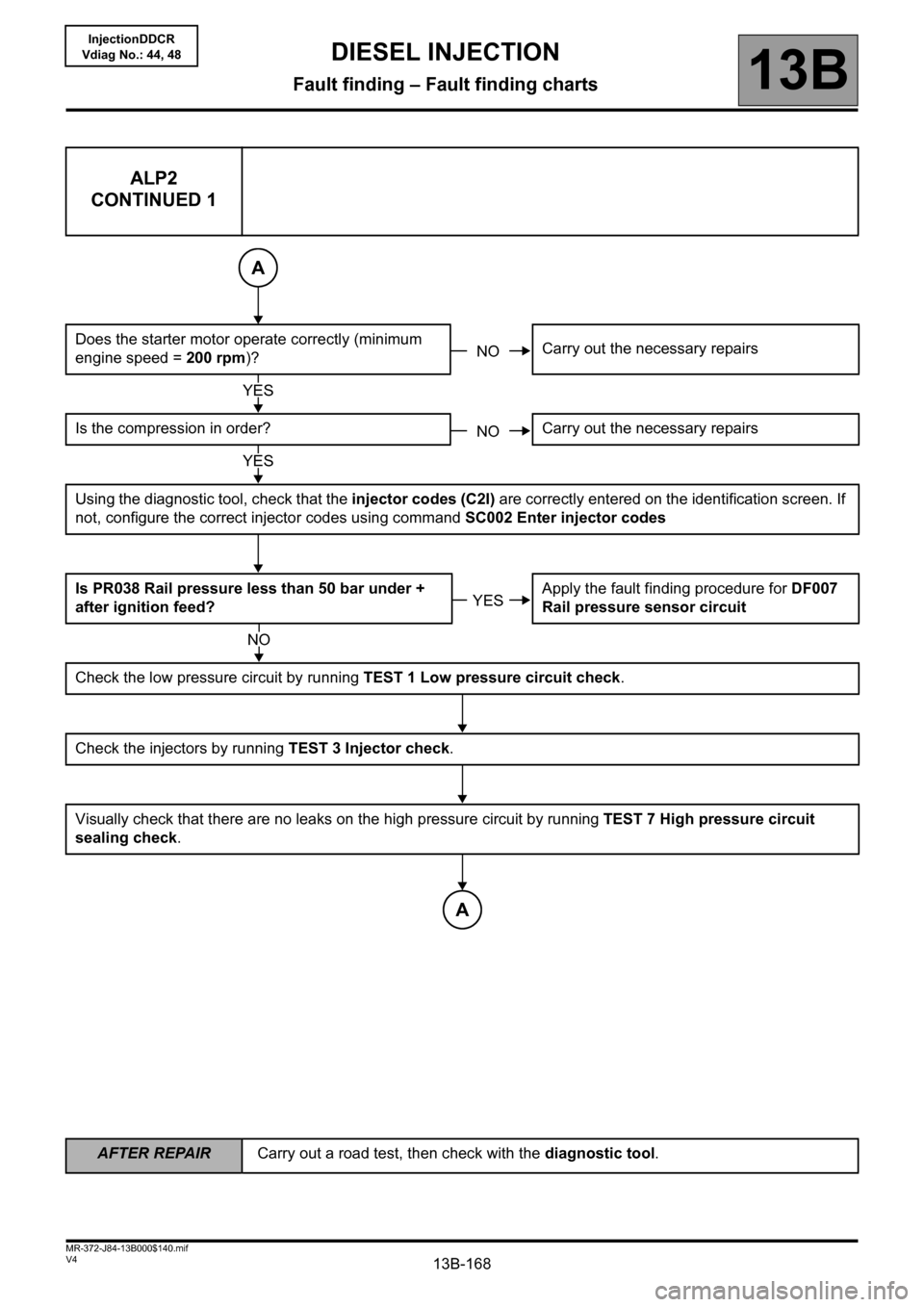

ALP2

CONTINUED 1

Does the starter motor operate correctly (minimum

engine speed = 200 rpm)?Carry out the necessary repairs

Is the compression in order? Carry out the necessary repairs

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes

Is PR038 Rail pressure less than 50 bar under +

after ignition feed?Apply the fault finding procedure for DF007

Rail pressure sensor circuit

Check the low pressure circuit by running TEST 1 Low pressure circuit check.

Check the injectors by running TEST 3 Injector check.

Visually check that there are no leaks on the high pressure circuit by running TEST 7 High pressure circuit

sealing check.

A

NO

YES

NO

YES

YES

NO

A