Air condition RENAULT SCENIC 2012 J95 / 3.G Engine And Peripherals EDC16CP33 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2012, Model line: SCENIC, Model: RENAULT SCENIC 2012 J95 / 3.GPages: 510, PDF Size: 2.98 MB

Page 197 of 510

13B-197

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$073.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

diff.*: Differential

temp.*: Temperature

DF311

PRESENT

OR

STOREDFAILED REGENERATIONS LIMIT EXCEEDED

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present after the engine is started or following a road test.

Special notes:

If the fault is present:

–the level 1 warning light is lit,

– particle filter regenerations when driving are inhibited.

Priorities when dealing with a number of faults:

Deal with the following faults first:

– DF308 Particle filter clogged if it is present or stored.

– DF315 Particle filter diff.* pressure sensor if it is present or stored.

– DF717 Particle filter upstream pressure if it is present or stored.

– DF569 Turbocharging circuit if it is present or stored.

– DF309 Particle filter downstream temperature sensor if it is present or stored.

– DF899 Regeneration temperature threshold exceeded if it is present or stored.

– DF310 Particle filter upstream temperature sensor if it is present or stored.

– DF652 Turbine upstream temperature sensor circuit if it is present or stored.

– DF272 EGR valve control circuit if it is present or stored.

– DF647 EGR valve position regulation if it is present or stored.

EDC16CP33_V18_DF311 / EDC16CP33_V1C_DF311 / EDC16CP33_V54_DF311 / EDC16CP33_V20_DF311 / EDC16CP33_V58_DF311 /

EDC16CP33_V5C_DF311 / EDC16CP33_V24_DF311 / EDC16CP33_V26_DF311 / EDC16CP33_V60_DF311

EDC16CP33

Program No.: C4

Vdiag No.: 18, 1C, 20, 24,

26, 54, 58, 5C, 60

Page 199 of 510

13B-199

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$073.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

diff.*: Differential

DF312

PRESENT

OR

STOREDSPEED REQUEST

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present after the engine is started or following a road test.

Special notes:

If the fault is present:

– the special Regenerate particle filter warning light is lit or a warning message is

displayed on the instrument panel,

– A specific kind of driving is required to bring about regeneration of the particle filter

when driving.

Priorities when dealing with a number of faults:

Firstly, deal with the following faults:

–DF308 Particle filter clogged if it is present or stored.

–DF311 Failed regenerations limit exceeded if it is present.

–DF315 Particle filter diff* pressure sensor if it is present or stored.

–DF717 Particle filter upstream pressure if it is present or stored.

EDC16CP33_V18_DF312 / EDC16CP33_V1C_DF312 / EDC16CP33_V54_DF312 / EDC16CP33_V20_DF312 / EDC16CP33_V58_DF312 /

EDC16CP33_V5C_DF312 / EDC16CP33_V24_DF312 / EDC16CP33_V26_DF312 / EDC16CP33_V60_DF312

EDC16CP33

Program No.: C4

Vdiag No.: 18, 1C, 20, 24,

26, 54, 58, 5C, 60

Page 204 of 510

13B-204

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$074.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF312

CONTINUED 5

PART D

Procedure to switch off the Particle filter message or warning light on the instrument panel

Certain types of driving can trigger illumination of the particle filter warning light or message, and activate fault

DF312. The customer must carry out a specific driving operation (cf. vehicle user manual) that consists of:

1. When the engine is warm, drive at a speed greater than 48 mph (80 km/h) for 2 minutes to trigger the

regeneration procedure.

2.Keep driving at an average speed of 48 mph (80 km/h), until the "particle filter" warning light or message on

the instrument panel goes out. In order for the procedure to succeed, it is necessary to drive without stopping

the engine or leaving the engine running at idle speed for an extended period of time. The regeneration time

depends on the vehicle and driving conditions but should last for 20 minutes maximum.

If regeneration fails when driving (the warning light does not go out or the service warning light comes on), check

the exhaust pipe for leaks or blockage. Repair if necessary. Proceed with an After Sales regeneration. Run

command SC017 (see Interpretation of commands).

If the fault is still present, contact the Techline.

EDC16CP33

Program No.: C4

Vdiag No.: 18, 1C, 20, 24,

26, 54, 58, 5C, 60

Page 205 of 510

13B-205

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$074.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF315

PRESENT

OR

STOREDPARTICLE FILTER DIFFERENTIAL PRESSURE SENSOR

CO: Open circuit

CO.0: Open circuit or short circuit to earth

CC.1: Short circuit to + 12 V

NOTESConditions for applying fault finding procedures to stored faults:

The fault is declared present after the engine is started or following a road test.

Special notes:

If the fault is present:

–the level 1 warning light is lit,

– the EOBD (European On Board Diagnostic) warning light will come on after three

consecutive driving cycles (starting + 5 seconds + switching off the ignition and

waiting for 1 minute),

– the particle filter fault finding procedure is inhibited,

– particle filter regeneration is inhibited.

Priorities when dealing with a number of faults:

–DF315 if it is present.

–DF308 Particle filter clogged if DF315 is stored and DF308 is present.

–DF011 Sensor supply voltage no. 1 if it is present or stored.

CC.1

NOTESNone.

Check the condition of the differential pressure sensor connector (see Wiring Diagram Technical Note, Laguna

II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 1290).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

EDC16CP33_V18_DF315 / EDC16CP33_V1C_DF315 / EDC16CP33_V54_DF315 / EDC16CP33_V20_DF315 / EDC16CP33_V58_DF315 /

EDC16CP33_V5C_DF315 / EDC16CP33_V24_DF315 / EDC16CP33_V28_DF315 / EDC16CP33_V62_DF315 / EDC16CP33_V26_DF315 /

EDC16CP33_V60_DF315

EDC16CP33

Program No.: C4

Vdiag No.: 18, 1C, 20, 24,

26, 28, 54, 58, 5C, 60, 62

Page 206 of 510

13B-206

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$074.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF315

CONTINUED

Check the continuity and insulation from + 12 V of the following connections:

•3TL between components 120 and 1290,

•3TM between components 120 and 1290.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the fault is still present, replace the differential pressure sensor.

CO.0

CO

NOTESNone.

Check the condition of the differential pressure sensor connector (see Wiring Diagram Technical Note, Laguna

II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 1290).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the continuity and insulation to earth of the following connections:

•3TL between components 120 and 1290,

•3TM between components 120 and 1290.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the wiring of the particle filter downstream temperature sensor, component code 1288, is present (with or without

the sensor being present), check the electrical insulation in relation to + 12 V between the following connections:

–3XU between components 120 and 1288,

–3TG between components 120 and 1288.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the differential pressure sensor.

EDC16CP33

Program No.: C4

Vdiag No.: 18, 1C, 20, 24,

26, 28, 54, 58, 5C, 60, 62

Page 207 of 510

13B-207

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$074.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF323

PRESENT

OR

STOREDDAMPER VALVECC.0: Short circuit to earth

CC.1: Short circuit to + 12 V

CC: Short circuit

C0: Open circuit

1.DEF: Internal electronic fault

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after the ignition has been switched on.

Special notes:

If the fault is present:

–the level 1 warning light is lit (for Vdiag 20, 58, 24, 5C, 26, 28, 60 and 62),

– particle filter regeneration is inhibited.

Use bornier Elé. 1681 for all operations on the engine management computer

connector.

Use the Wiring Diagram Technical Note, Laguna II ph2, Vel Satis ph2, Espace IV

ph2, Mégane II ph2, Scénic II ph2.

CC.0

CC.1

NOTESNone.

Check the condition of the damper valve connector (see Wiring Diagram Technical Note, Laguna II ph2, Vel

Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 1461).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Measure the resistance between connections 3AAX and 3AAY of component 1461.

If the resistance of the damper valve is less than 0.5 Ω or greater than 400 Ω, replace the damper valve.

Then run command SC036: Reinitialise programming and select Damper valve to reinitialise the valve's

opening and closing stops.

EDC16CP33_V18_DF323 / EDC16CP33_V1C_DF323 / EDC16CP33_V54_DF323 / EDC16CP33_V20_DF323 / EDC16CP33_V58_DF323 /

EDC16CP33_V5C_DF323 / EDC16CP33_V24_DF323 / EDC16CP33_V04_DF323 / EDC16CP33_V08_DF323 / EDC16CP33_V44_DF323 /

EDC16CP33_V4C_DF323 / EDC16CP33_V34_DF323 / EDC16CP33_V38_DF323 / EDC16CP33_V74_DF323 / EDC16CP33_V28_DF323 /

EDC16CP33_V62_DF323 / EDC16CP33_V26_DF323 / EDC16CP33_V60_DF323

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 208 of 510

13B-208

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$074.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF323

CONTINUED 1

Check the insulation to earth of the following connections:

•3AAX between components 120 and 1461,

•3AAY between the components 120 and 1461.

Check the insulation from + 12 V of the following connections:

•3AAX between components 120 and 1461,

•3AAY between the components 120 and 1461.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the fault is still present, contact the Techline.

CC

NOTESNone.

Check the condition of the damper valve connector (see Wiring Diagram Technical Note, Laguna II ph2, Vel

Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 1461).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Measure the resistance between connections 3AAX and 3AAY of component 1461.

If the resistance of the damper valve is less than 0.5 Ω or greater than 400 Ω, replace the damper valve.

Then run command SC036 Reinitialise programming and select Damper valve to reinitialise the valve's opening

and closing stops.

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 209 of 510

13B-209

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$074.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF323

CONTINUED 2

Check the insulation between the following connections:

•3AAX between components 120 and 1461,

•3AAY between the components 120 and 1461.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the fault is still present, contact the Techline.

CO

NOTESNone.

Check the condition of the damper valve connector (see Wiring Diagram Technical Note, Laguna II ph2, Vel

Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 1461).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Measure the resistance between connections 3AAX and 3AAY of component 1461.

If the resistance of the damper valve is less than 0.5 Ω or greater than 400 Ω, replace the damper valve.

Then run command SC036: Reinitialise programming and select Damper valve to reinitialise the valve's

opening and closing stops.

Check the continuity of the following connections:

•3AAX between components 120 and 1461,

•3AAY between the components 120 and 1461.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the fault is still present, contact the Techline.

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 210 of 510

13B-210

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$074.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

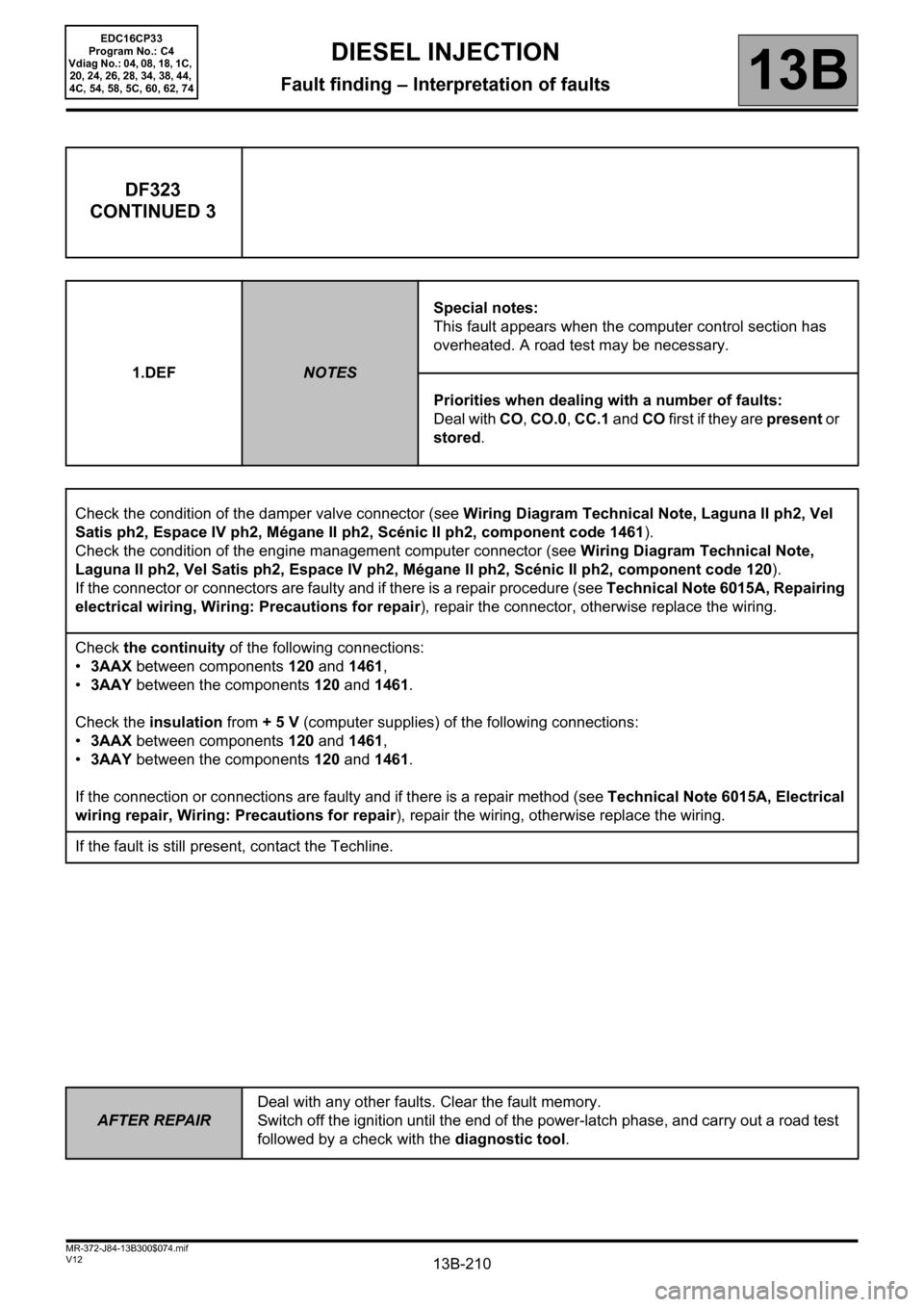

DF323

CONTINUED 3

1.DEFNOTESSpecial notes:

This fault appears when the computer control section has

overheated. A road test may be necessary.

Priorities when dealing with a number of faults:

Deal with CO, CO.0, CC.1 and CO first if they are present or

stored.

Check the condition of the damper valve connector (see Wiring Diagram Technical Note, Laguna II ph2, Vel

Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 1461).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the continuity of the following connections:

•3AAX between components 120 and 1461,

•3AAY between the components 120 and 1461.

Check the insulation from + 5 V (computer supplies) of the following connections:

•3AAX between components 120 and 1461,

•3AAY between the components 120 and 1461.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the fault is still present, contact the Techline.

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 211 of 510

13B-211

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$074.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF333

PRESENT

OR

STOREDINJECTION -> AUTOMATIC TRANSMISSION CONNECTION

1.DEF: Multiplex network

NOTESSpecial notes:

– Use bornier Elé. 1681 for all operations on the engine management computer

connectors.

–Do not clear the fault before reading the contexts of the fault.

(see Wiring diagram Technical Note for Mégane II ph2, Scénic II ph2,

Espace IV ph2)

Conditions for applying the fault finding procedure to a stored fault:

– The fault is declared present if the EOBD (European On Board Diagnostic)

warning light is lit.

Check the multiplex network.

Check the condition of the automatic transmission computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, Espace IV ph2, component code 119).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Mégane II ph2, Scénic II ph2, Espace IV ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation to earth, the continuity and absence of interference resistance on the following

connections:

•3MT between components 119 and 120,

•3MS between components 119 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, check that the automatic transmission computer is recognised by the CLIP diagnostic

tool.

If dialogue is not established (see MR 366, 372, 407, 23A, Automatic transmission).

EDC16CP33_V18_DF333 / EDC16CP33_V1C_DF333 / EDC16CP33_V54_DF333 / EDC16CP33_V20_DF333 / EDC16CP33_V58_DF333 /

EDC16CP33_V5C_DF333 / EDC16CP33_V24_DF333 / EDC16CP33_V28_DF333 / EDC16CP33_V62_DF333 / EDC16CP33_V26_DF333 /

EDC16CP33_V60_DF333

EDC16CP33

Program No.: C4

Vdiag No.: 18, 1C, 20, 24,

26, 28, 54, 58, 5C, 60, 62