Temperature RENAULT SCENIC 2012 J95 / 3.G Engine And Peripherals EDC16CP33 User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2012, Model line: SCENIC, Model: RENAULT SCENIC 2012 J95 / 3.GPages: 510, PDF Size: 2.98 MB

Page 29 of 510

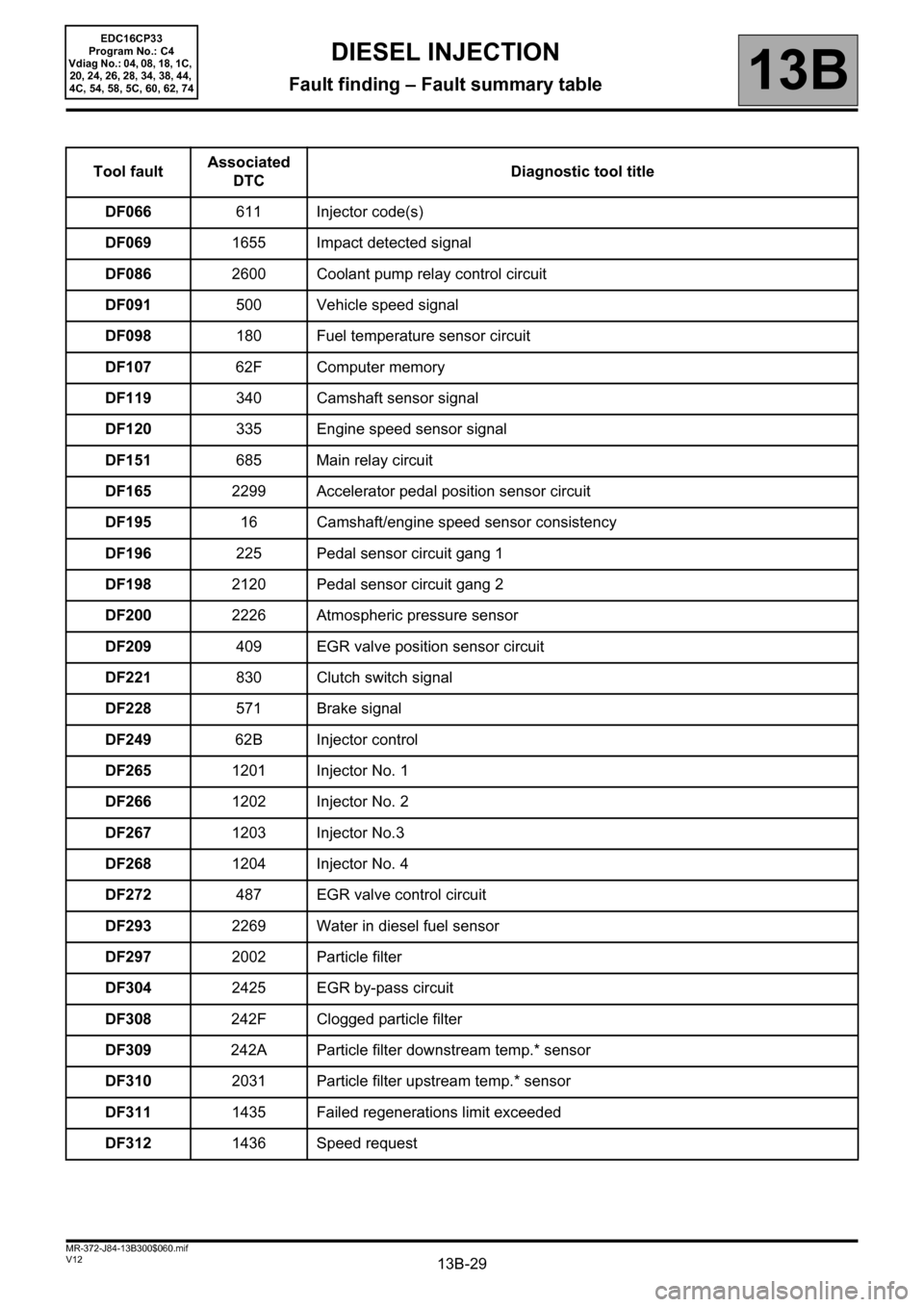

13B-29V12 MR-372-J84-13B300$060.mif

DIESEL INJECTION

Fault finding – Fault summary table13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Tool faultAssociated

DTCDiagnostic tool title

DF066611 Injector code(s)

DF0691655 Impact detected signal

DF0862600 Coolant pump relay control circuit

DF091500 Vehicle speed signal

DF098180 Fuel temperature sensor circuit

DF10762F Computer memory

DF119340 Camshaft sensor signal

DF120335 Engine speed sensor signal

DF151685 Main relay circuit

DF1652299 Accelerator pedal position sensor circuit

DF19516 Camshaft/engine speed sensor consistency

DF196225 Pedal sensor circuit gang 1

DF1982120 Pedal sensor circuit gang 2

DF2002226 Atmospheric pressure sensor

DF209409 EGR valve position sensor circuit

DF221830 Clutch switch signal

DF228571 Brake signal

DF24962B Injector control

DF2651201 Injector No. 1

DF2661202 Injector No. 2

DF2671203 Injector No.3

DF2681204 Injector No. 4

DF272487 EGR valve control circuit

DF2932269 Water in diesel fuel sensor

DF2972002 Particle filter

DF3042425 EGR by-pass circuit

DF308242F Clogged particle filter

DF309242A Particle filter downstream temp.* sensor

DF3102031 Particle filter upstream temp.* sensor

DF3111435 Failed regenerations limit exceeded

DF3121436 Speed request

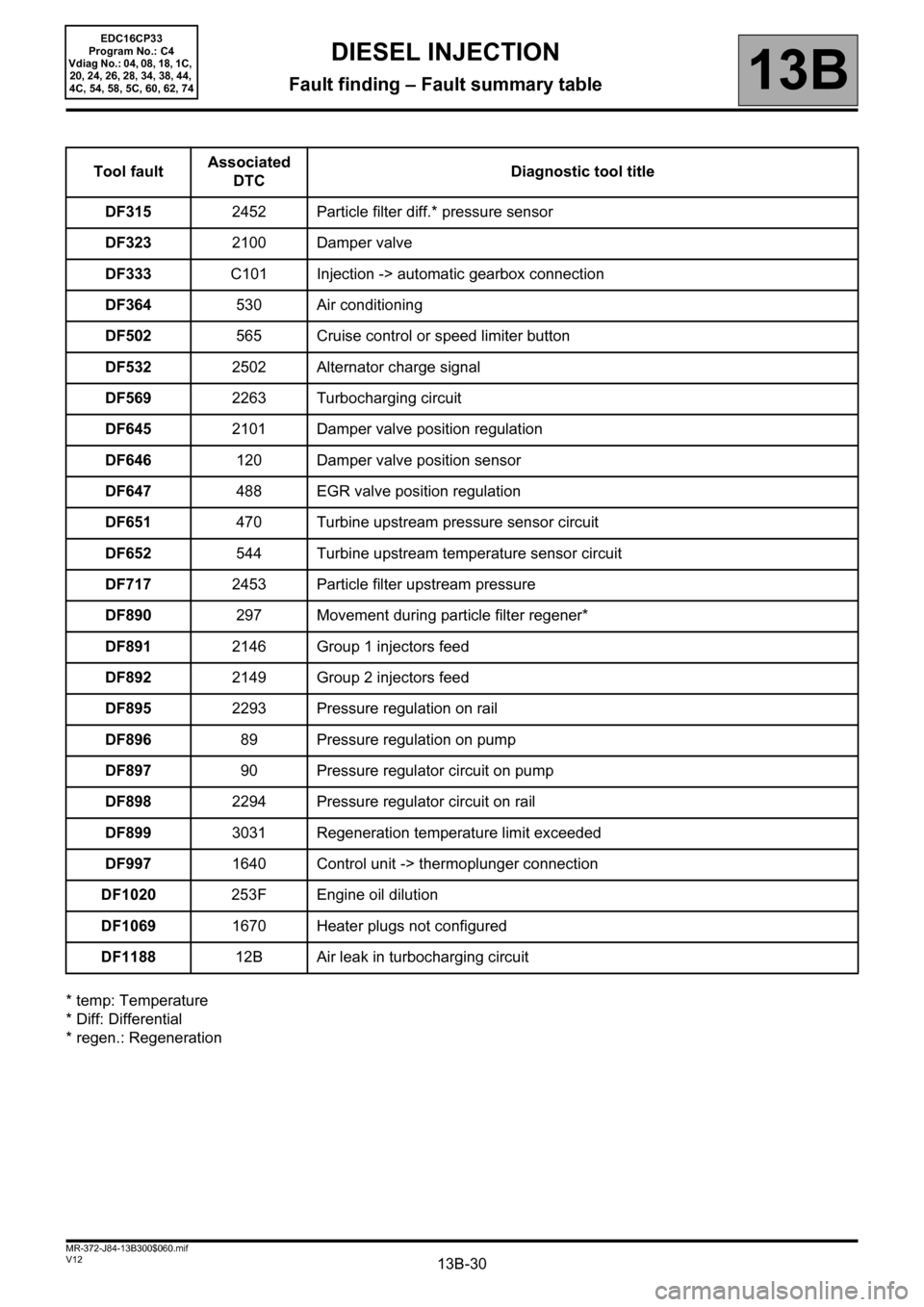

Page 30 of 510

13B-30V12 MR-372-J84-13B300$060.mif

DIESEL INJECTION

Fault finding – Fault summary table13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

* temp: Temperature

* Diff: Differential

* regen.: RegenerationTool faultAssociated

DTCDiagnostic tool title

DF3152452 Particle filter diff.* pressure sensor

DF3232100 Damper valve

DF333C101 Injection -> automatic gearbox connection

DF364530 Air conditioning

DF502565 Cruise control or speed limiter button

DF5322502 Alternator charge signal

DF5692263 Turbocharging circuit

DF6452101 Damper valve position regulation

DF646120 Damper valve position sensor

DF647488 EGR valve position regulation

DF651470 Turbine upstream pressure sensor circuit

DF652544 Turbine upstream temperature sensor circuit

DF7172453 Particle filter upstream pressure

DF890297 Movement during particle filter regener*

DF8912146 Group 1 injectors feed

DF8922149 Group 2 injectors feed

DF8952293 Pressure regulation on rail

DF89689 Pressure regulation on pump

DF89790 Pressure regulator circuit on pump

DF8982294 Pressure regulator circuit on rail

DF8993031 Regeneration temperature limit exceeded

DF9971640 Control unit -> thermoplunger connection

DF1020253F Engine oil dilution

DF10691670 Heater plugs not configured

DF118812B Air leak in turbocharging circuit

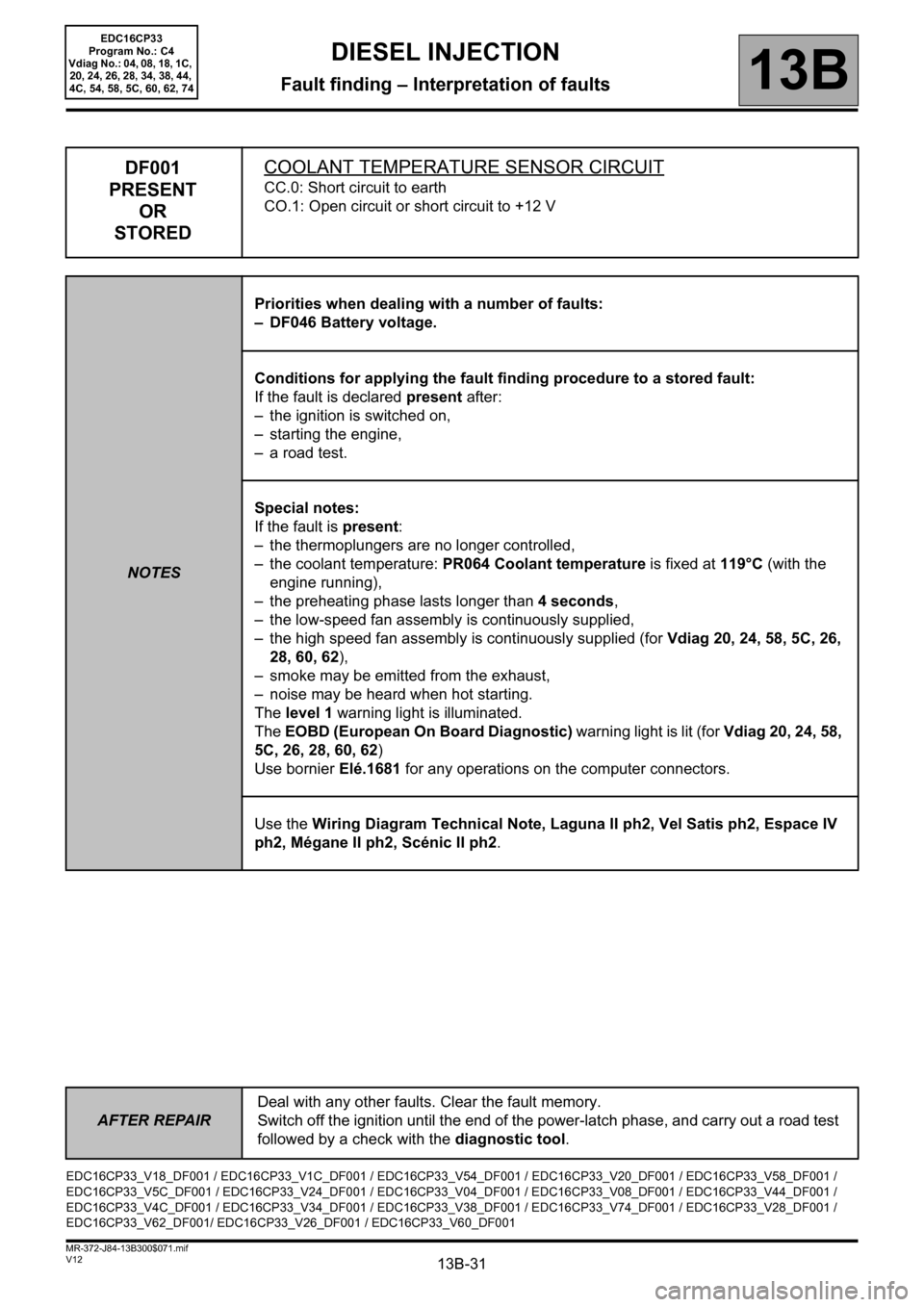

Page 31 of 510

13B-31

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$071.mif

13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

DF001

PRESENT

OR

STOREDCOOLANT TEMPERATURE SENSOR CIRCUIT

CC.0: Short circuit to earth

CO.1: Open circuit or short circuit to +12 V

NOTESPriorities when dealing with a number of faults:

– DF046 Battery voltage.

Conditions for applying the fault finding procedure to a stored fault:

If the fault is declared present after:

– the ignition is switched on,

– starting the engine,

– a road test.

Special notes:

If the fault is present:

– the thermoplungers are no longer controlled,

– the coolant temperature: PR064 Coolant temperature is fixed at 119°C (with the

engine running),

– the preheating phase lasts longer than 4 seconds,

– the low-speed fan assembly is continuously supplied,

– the high speed fan assembly is continuously supplied (for Vdiag 20, 24, 58, 5C, 26,

28, 60, 62),

– smoke may be emitted from the exhaust,

– noise may be heard when hot starting.

The level 1 warning light is illuminated.

The EOBD (European On Board Diagnostic) warning light is lit (for Vdiag 20, 24, 58,

5C, 26, 28, 60, 62)

Use bornier Elé.1681 for any operations on the computer connectors.

Use the Wiring Diagram Technical Note, Laguna II ph2, Vel Satis ph2, Espace IV

ph2, Mégane II ph2, Scénic II ph2.

EDC16CP33_V18_DF001 / EDC16CP33_V1C_DF001 / EDC16CP33_V54_DF001 / EDC16CP33_V20_DF001 / EDC16CP33_V58_DF001 /

EDC16CP33_V5C_DF001 / EDC16CP33_V24_DF001 / EDC16CP33_V04_DF001 / EDC16CP33_V08_DF001 / EDC16CP33_V44_DF001 /

EDC16CP33_V4C_DF001 / EDC16CP33_V34_DF001 / EDC16CP33_V38_DF001 / EDC16CP33_V74_DF001 / EDC16CP33_V28_DF001 /

EDC16CP33_V62_DF001/ EDC16CP33_V26_DF001 / EDC16CP33_V60_DF001

DIESEL INJECTION

Fault finding – Interpretation of faults

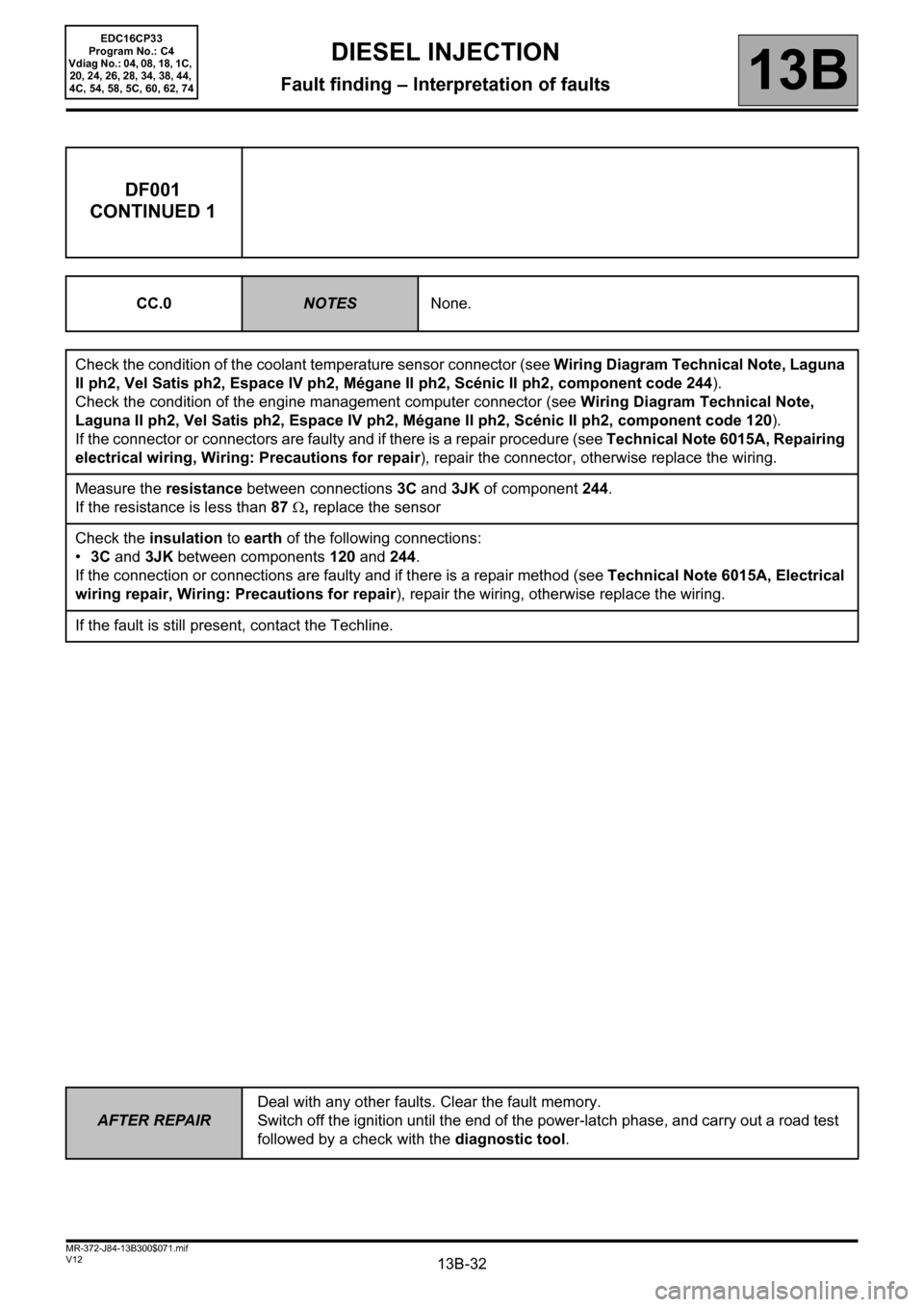

Page 32 of 510

13B-32

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$071.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

DF001

CONTINUED 1

CC.0NOTESNone.

Check the condition of the coolant temperature sensor connector (see Wiring Diagram Technical Note, Laguna

II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 244).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Measure the resistance between connections 3C and 3JK of component 244.

If the resistance is less than 87 Ω, replace the sensor

Check the insulation to earth of the following connections:

•3C and 3JK between components 120 and 244.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the fault is still present, contact the Techline.

Page 33 of 510

13B-33

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$071.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

DF001

CONTINUED 2

CO.1NOTESNone.

Check the condition of the coolant temperature sensor connector (see Wiring Diagram Technical Note, Laguna

II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 244).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Measure the resistance between connections 3C and 3JK of component 244.

If the resistance is greater than 83 kΩ, replace the sensor

Check the insulation from + 12 V of the following connections:

•3C and 3JK between components 120 and 244.

Check the continuity of the following connections:

•3C between components 120 and 244,

•3JK between components 120 and 244.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the fault is still present, contact the Techline.

Page 34 of 510

13B-34

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$071.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

DF002

PRESENT

OR

STOREDAIR TEMPERATURE SENSOR CIRCUIT

CC.0: Short circuit to earth

CO.1: Open circuit or short circuit to +12 V

NOTESPriorities when dealing with a number of faults:

– DF046 Battery voltage.

Conditions for applying the fault finding procedure to a stored fault:

If the fault is declared present after:

– the ignition is switched on,

– starting the engine,

– a road test.

Special notes:

If the fault is present:

–The EOBD (European On Board Diagnostic) warning light is lit.

– the thermoplungers are inhibited,

– the inlet air temperature is in defect mode, PR059 Inlet air temperature = 20°C (with

the engine running).

The air temperature sensor is integrated into the air flowmeter.

Use bornier Elé. 1681 for all operations on the engine management computer

connectors.

Use the Wiring Diagram Technical Note, Laguna II ph2, Vel Satis ph2, Espace IV

ph2, Mégane II ph2, Scénic II ph2.

EDC16CP33_V18_DF002 / EDC16CP33_V1C_DF002 / EDC16CP33_V54_DF002 / EDC16CP33_V20_DF002 / EDC16CP33_V58_DF002 /

EDC16CP33_V5C_DF002 / EDC16CP33_V24_DF002 / EDC16CP33_V04_DF002 / EDC16CP33_V08_DF002 / EDC16CP33_V44_DF002 /

EDC16CP33_V4C_DF002 / EDC16CP33_V34_DF002 / EDC16CP33_V38_DF002 / EDC16CP33_V74_DF002 / EDC16CP33_V28_DF002 /

EDC16CP33_V62_DF002/ EDC16CP33_V26_DF002 / EDC16CP33_V60_DF002

Page 38 of 510

13B-38

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$071.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

DF004

CONTINUED 1

CC.0NOTESNone.

Check the condition of the turbocharging pressure sensor connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 1071).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation to earth of the following connections:

•3LP and 3LN between components 120 and 1071.

Check the continuity of the following connections:

•3LQ between components 120 and 1071,

•3LP and 3LN between components 120 and 1071.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the wiring of the particle filter downstream temperature sensor, component code 1288, is present (with or without

the sensor being present), check the electrical insulation in relation to + 12 V between the following connections:

–3XU between components 120 and 1288,

–3TG between components 120 and 1288.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the turbocharging pressure sensor.

Page 41 of 510

13B-41

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$071.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

DF007

CONTINUED 1

CC.0NOTESNone.

Check the condition of the rail pressure sensor connector (see Wiring Diagram Technical Note, Laguna II ph2,

Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 1032).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the continuity of the following connection:

•3LX between components 120 and 1032.

Check the insulation to earth of the following connection:

•3LY between components 120 and 1032.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the wiring of the particle filter downstream temperature sensor, component code 1288, is present (with or without

the sensor being present), check the electrical insulation in relation to + 12 V between the following connections:

–3XU between components 120 and 1288,

–3TG between components 120 and 1288.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact the Techline.

Page 43 of 510

13B-43

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$071.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

DF007

CONTINUED 3

1.DEF

2.DEFNOTESSpecial notes:

The fault is declared present or stored after an attempt to

start or after starting, with the engine cold, several hours after

the last trip (the difference in the coolant temperature from the

last engine stop and the present attempt to start must be at

least 60°C).

Check the condition of the rail pressure sensor connector (see Wiring Diagram Technical Note, Laguna II ph2,

Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 1032).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check that there are no external diesel leaks from the high pressure fuel circuit.

Check the continuity and absence of interference resistance of the following connections:

•3LX between components 120 and 1032,

•3LY between components 120 and 1032,

•3LZ between components 120 and 1032.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

With the ignition on and the engine stopped for over 1 minute:

View parameter PR038 Rail pressure.

– If the pressure is below 90 bar, the sensor is in order.

– If the pressure is above 90 bar, contact the Techline.

If the fault is still present, contact the Techline.

Page 107 of 510

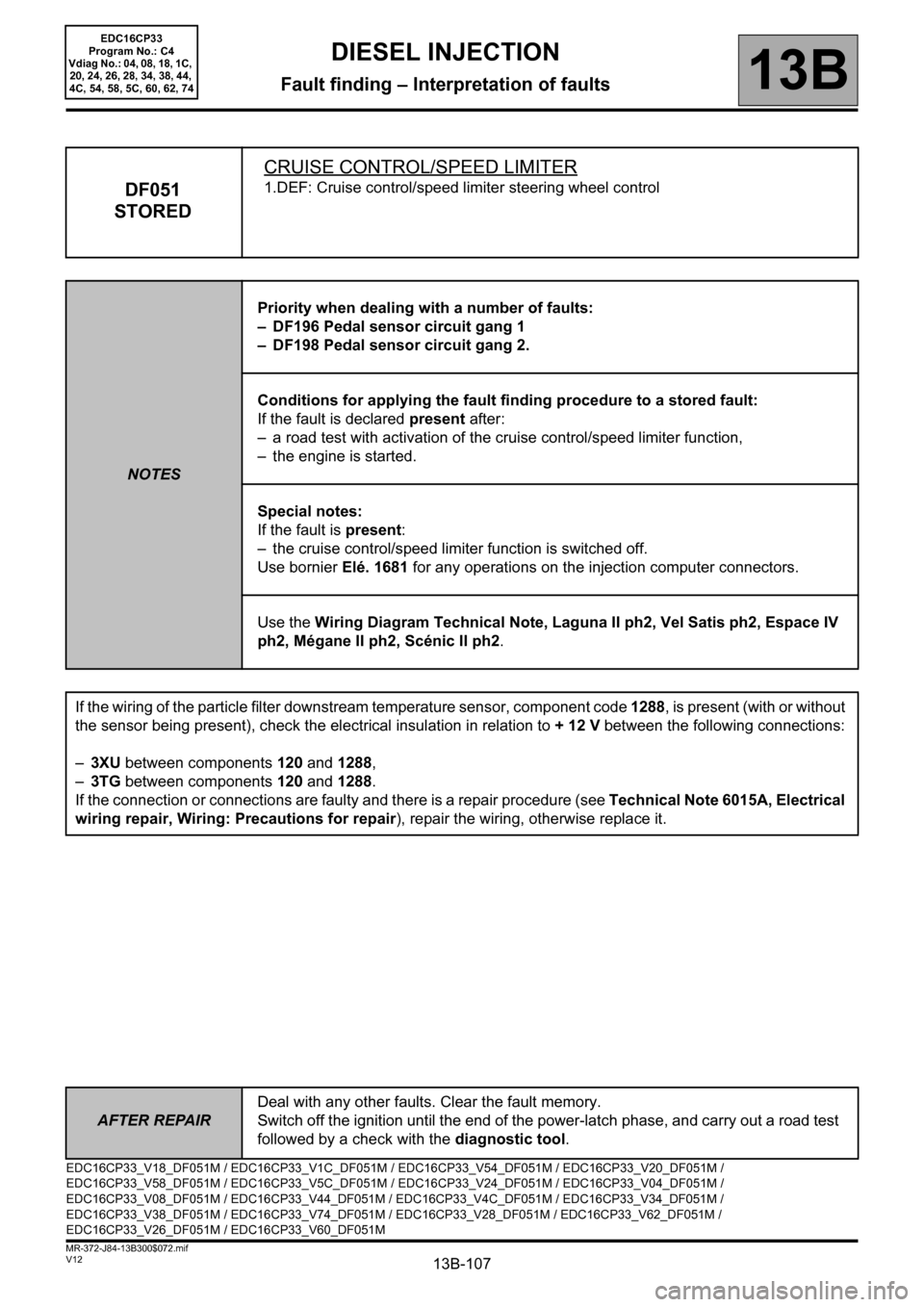

13B-107

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$072.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

DF051

STOREDCRUISE CONTROL/SPEED LIMITER1.DEF: Cruise control/speed limiter steering wheel control

NOTESPriority when dealing with a number of faults:

– DF196 Pedal sensor circuit gang 1

– DF198 Pedal sensor circuit gang 2.

Conditions for applying the fault finding procedure to a stored fault:

If the fault is declared present after:

– a road test with activation of the cruise control/speed limiter function,

– the engine is started.

Special notes:

If the fault is present:

– the cruise control/speed limiter function is switched off.

Use bornier Elé. 1681 for any operations on the injection computer connectors.

Use the Wiring Diagram Technical Note, Laguna II ph2, Vel Satis ph2, Espace IV

ph2, Mégane II ph2, Scénic II ph2.

If the wiring of the particle filter downstream temperature sensor, component code 1288, is present (with or without

the sensor being present), check the electrical insulation in relation to + 12 V between the following connections:

–3XU between components 120 and 1288,

–3TG between components 120 and 1288.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

EDC16CP33_V18_DF051M / EDC16CP33_V1C_DF051M / EDC16CP33_V54_DF051M / EDC16CP33_V20_DF051M /

EDC16CP33_V58_DF051M / EDC16CP33_V5C_DF051M / EDC16CP33_V24_DF051M / EDC16CP33_V04_DF051M /

EDC16CP33_V08_DF051M / EDC16CP33_V44_DF051M / EDC16CP33_V4C_DF051M / EDC16CP33_V34_DF051M /

EDC16CP33_V38_DF051M / EDC16CP33_V74_DF051M / EDC16CP33_V28_DF051M / EDC16CP33_V62_DF051M /

EDC16CP33_V26_DF051M / EDC16CP33_V60_DF051M