engine RENAULT SCENIC 2012 J95 / 3.G Engine And Peripherals EDC16CP33 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2012, Model line: SCENIC, Model: RENAULT SCENIC 2012 J95 / 3.GPages: 510, PDF Size: 2.98 MB

Page 479 of 510

13B-479

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V12 MR-372-J84-13B300$170.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

ALP4

CONTINUED 3

Check:

– That the diesel filter is not clogged.

– That there are no leaks on the high and low pressure diesel circuits: run Test 3 Low pressure circuit check.

–Test the high pressure fuel circuit:

Run scenario SC035 High pressure fuel circuit fault finding (see Interpretation of commands).

Continue by checking the following:

– The connection of the oil vapour rebreathing circuit.

– The pump pressure regulator (MPROP), (jamming - sticking); apply the interpretation of command AC226 Pump

pressure regulator.

– The rail pressure regulator (DRV), (jamming - sticking); apply the interpretation of command AC225 Rail

pressure regulator.

– Check the engine timing (and the position of the high pressure pump sprocket).

– Check the engine compressions: use a compression gauge, M9R hose end piece, part no. Mot. 1772 and apply

command VP036 Fuel supply inhibition (see Interpretation of commands).

If the fault is still present, contact the techline.

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 480 of 510

13B-480

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V12 MR-372-J84-13B300$170.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

ALP5 Irregular engine operation

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic tool.

If the customer complaint is not eliminated, perform the following checks.

Use the Wiring Diagram Technical Note, Laguna II ph2, Vel Satis ph2, Espace IV

ph2, Mégane II ph2, Scénic II ph2.

If the engine races during gear changes, if there is a floor mat, check that this is not blocking the accelerator pedal,

the brake pedal and the clutch pedal, then check the conformity of the clutch switch and the conformity of the

accelerator pedal sensor when the pedal is released (see PR086 Pedal potentiometer voltage gang 1 and

PR088 Pedal potentiometer voltage gang 2, Sensor supply).

Measure the resistance between connections 3BG and 3BL of component 149.

If the sensor resistance is not between:

741 Ω < X < 905 Ω at +20°C, replace the sensor.

Check the continuity and absence of interference resistance on the following connections:

•3BG between the components 120 and 149,

•3BL between components 120 and 149.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the conformity of the engine earths (oxidation, tightness, etc.).

Check the mounting and condition (overheating) of the sensor.

Check the low pressure circuit: run Test 3 Low pressure circuit check.

Apply the air flow checking procedure, (see conformity in the interpretation of statuses and parameters).

Check the turbocharger: apply Test 7 Variable geometry turbocharger control.

If the fault is still present, test the high pressure fuel circuit:

Run scenario SC035 High pressure fuel circuit fault finding.

To interpret the result, apply the interpretation of command SC035 (see Interpretation of commands).

EDC16CP33_V18_ALP05 / EDC16CP33_V1C_ALP05 / EDC16CP33_V54_ALP05 / EDC16CP33_V20_ALP05 / EDC16CP33_V58_ALP05 /

EDC16CP33_V5C_ALP05 / EDC16CP33_V24_ALP05 / EDC16CP33_V04_ALP05 / EDC16CP33_V08_ALP05 / EDC16CP33_V44_ALP05 /

EDC16CP33_V4C_ALP05 / EDC16CP33_V34_ALP05 / EDC16CP33_V38_ALP05 / EDC16CP33_V74_ALP05 / EDC16CP33_V28_ALP05 /

EDC16CP33_V62_ALP05 / EDC16CP33_V26_ALP05 / EDC16CP33_V60_ALP05

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 481 of 510

13B-481

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V12 MR-372-J84-13B300$170.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

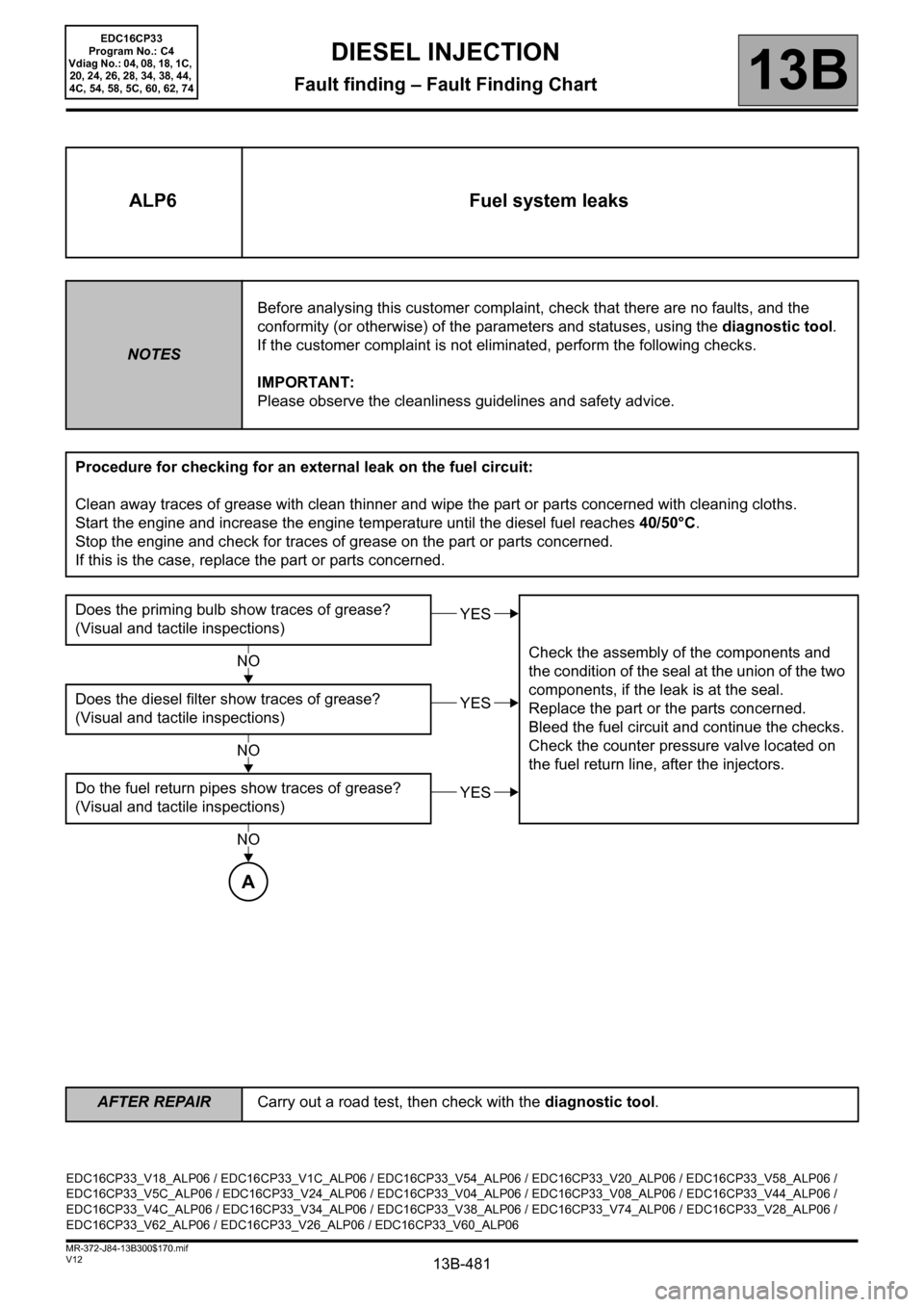

ALP6 Fuel system leaks

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic tool.

If the customer complaint is not eliminated, perform the following checks.

IMPORTANT:

Please observe the cleanliness guidelines and safety advice.

Procedure for checking for an external leak on the fuel circuit:

Clean away traces of grease with clean thinner and wipe the part or parts concerned with cleaning cloths.

Start the engine and increase the engine temperature until the diesel fuel reaches 40/50°C.

Stop the engine and check for traces of grease on the part or parts concerned.

If this is the case, replace the part or parts concerned.

Does the priming bulb show traces of grease?

(Visual and tactile inspections)

Check the assembly of the components and

the condition of the seal at the union of the two

components, if the leak is at the seal.

Replace the part or the parts concerned.

Bleed the fuel circuit and continue the checks.

Check the counter pressure valve located on

the fuel return line, after the injectors. Does the diesel filter show traces of grease?

(Visual and tactile inspections)

Do the fuel return pipes show traces of grease?

(Visual and tactile inspections)

YES

NO

YES

NO

YES

NO

A

EDC16CP33_V18_ALP06 / EDC16CP33_V1C_ALP06 / EDC16CP33_V54_ALP06 / EDC16CP33_V20_ALP06 / EDC16CP33_V58_ALP06 /

EDC16CP33_V5C_ALP06 / EDC16CP33_V24_ALP06 / EDC16CP33_V04_ALP06 / EDC16CP33_V08_ALP06 / EDC16CP33_V44_ALP06 /

EDC16CP33_V4C_ALP06 / EDC16CP33_V34_ALP06 / EDC16CP33_V38_ALP06 / EDC16CP33_V74_ALP06 / EDC16CP33_V28_ALP06 /

EDC16CP33_V62_ALP06 / EDC16CP33_V26_ALP06 / EDC16CP33_V60_ALP06

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 484 of 510

13B-484

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V12 MR-372-J84-13B300$170.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

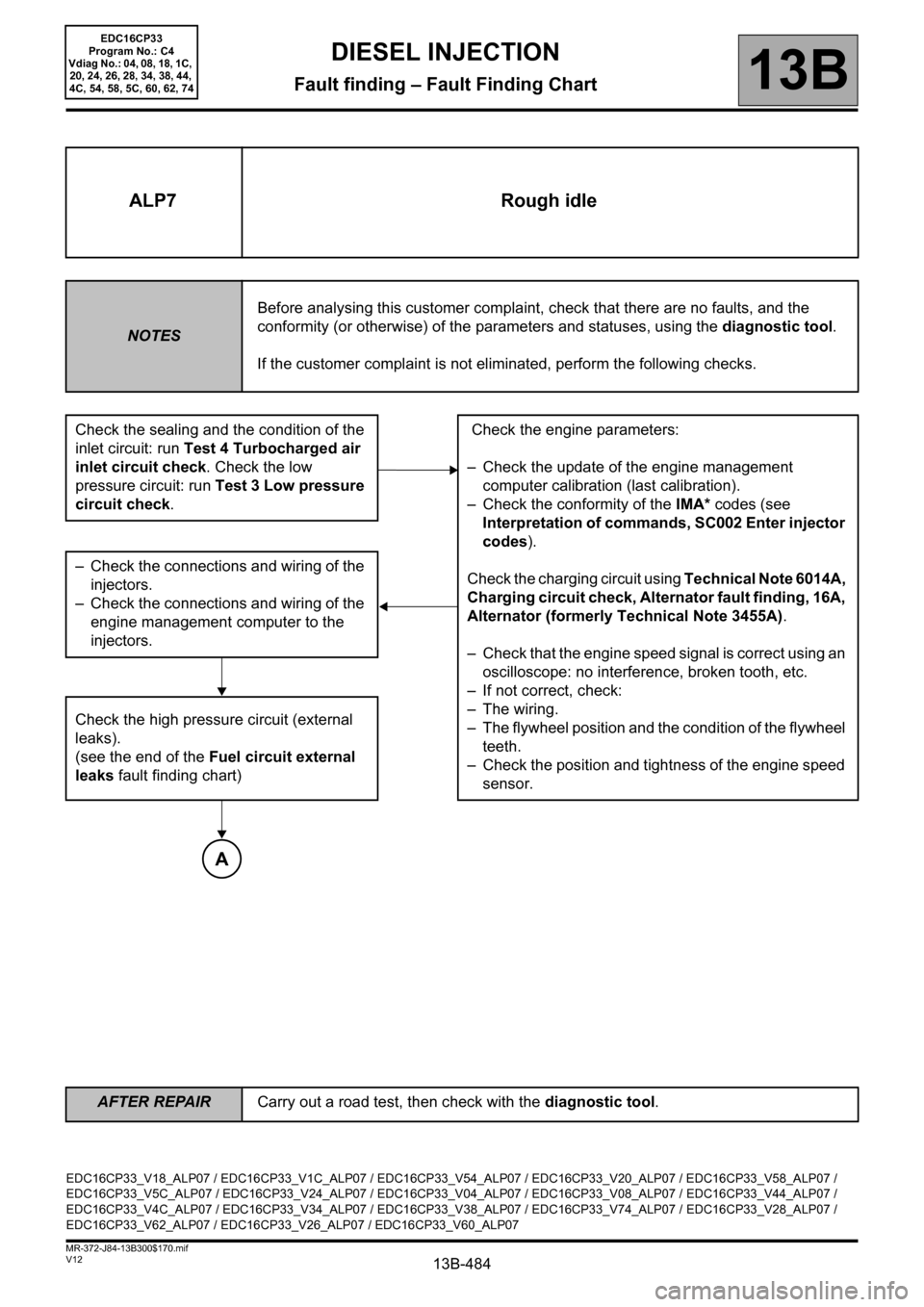

ALP7 Rough idle

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic tool.

If the customer complaint is not eliminated, perform the following checks.

Check the sealing and the condition of the

inlet circuit: run Test 4 Turbocharged air

inlet circuit check. Check the low

pressure circuit: run Test 3 Low pressure

circuit check. Check the engine parameters:

– Check the update of the engine management

computer calibration (last calibration).

– Check the conformity of the IMA* codes (see

Interpretation of commands, SC002 Enter injector

codes).

Check the charging circuit using Technical Note 6014A,

Charging circuit check, Alternator fault finding, 16A,

Alternator (formerly Technical Note 3455A).

– Check that the engine speed signal is correct using an

oscilloscope: no interference, broken tooth, etc.

– If not correct, check:

– The wiring.

– The flywheel position and the condition of the flywheel

teeth.

– Check the position and tightness of the engine speed

sensor. – Check the connections and wiring of the

injectors.

– Check the connections and wiring of the

engine management computer to the

injectors.

Check the high pressure circuit (external

leaks).

(see the end of the Fuel circuit external

leaks fault finding chart)

A

EDC16CP33_V18_ALP07 / EDC16CP33_V1C_ALP07 / EDC16CP33_V54_ALP07 / EDC16CP33_V20_ALP07 / EDC16CP33_V58_ALP07 /

EDC16CP33_V5C_ALP07 / EDC16CP33_V24_ALP07 / EDC16CP33_V04_ALP07 / EDC16CP33_V08_ALP07 / EDC16CP33_V44_ALP07 /

EDC16CP33_V4C_ALP07 / EDC16CP33_V34_ALP07 / EDC16CP33_V38_ALP07 / EDC16CP33_V74_ALP07 / EDC16CP33_V28_ALP07 /

EDC16CP33_V62_ALP07 / EDC16CP33_V26_ALP07 / EDC16CP33_V60_ALP07

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 485 of 510

13B-485

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V12 MR-372-J84-13B300$170.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

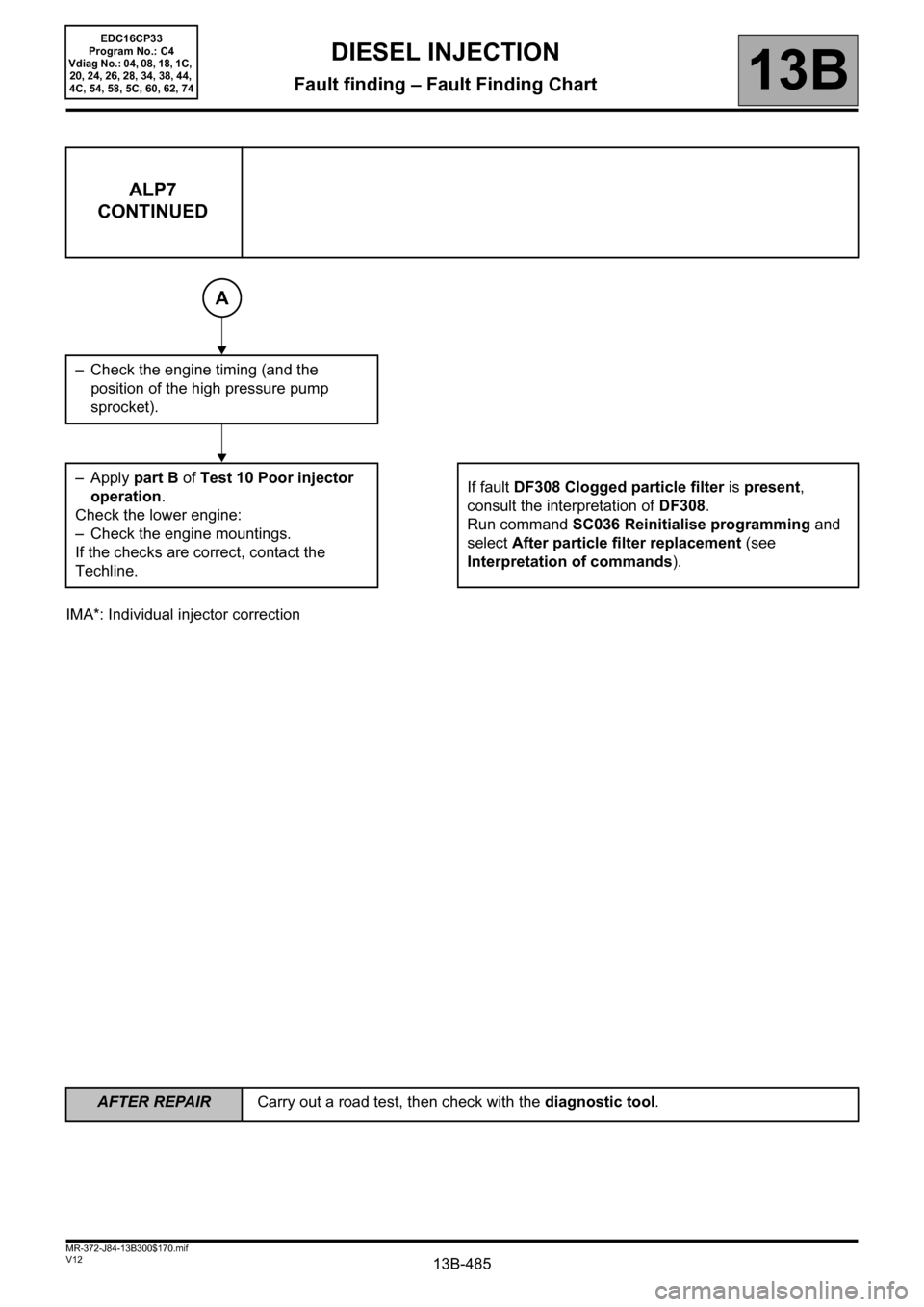

IMA*: Individual injector correction

ALP7

CONTINUED

– Check the engine timing (and the

position of the high pressure pump

sprocket).

–Apply part B of Test 10 Poor injector

operation.

Check the lower engine:

– Check the engine mountings.

If the checks are correct, contact the

Techline.If fault DF308 Clogged particle filter is present,

consult the interpretation of DF308.

Run command SC036 Reinitialise programming and

select After particle filter replacement (see

Interpretation of commands).

A

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 486 of 510

13B-486

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V12 MR-372-J84-13B300$170.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

ALP8 Engine stalling

NOTESBefore analysing this customer complaint, check that there are no faults, and the

conformity (or otherwise) of the parameters and statuses, using the diagnostic tool.

If the customer complaint is not eliminated, perform the following checks.

Apply the interpretation of fault DF569 Turbocharging circuit to deal with ALP8.

EDC16CP33_V18_ALP08 / EDC16CP33_V1C_ALP08 / EDC16CP33_V54_ALP08 / EDC16CP33_V20_ALP08 / EDC16CP33_V58_ALP08 /

EDC16CP33_V5C_ALP08 / EDC16CP33_V24_ALP08 / EDC16CP33_V04_ALP08 / EDC16CP33_V08_ALP08 / EDC16CP33_V44_ALP08 /

EDC16CP33_V4C_ALP08 / EDC16CP33_V34_ALP08 / EDC16CP33_V38_ALP08 / EDC16CP33_V74_ALP08 / EDC16CP33_V28_ALP08 /

EDC16CP33_V62_ALP08 / EDC16CP33_V26_ALP08 / EDC16CP33_V60_ALP08

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 487 of 510

13B-487

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V12 MR-372-J84-13B300$170.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

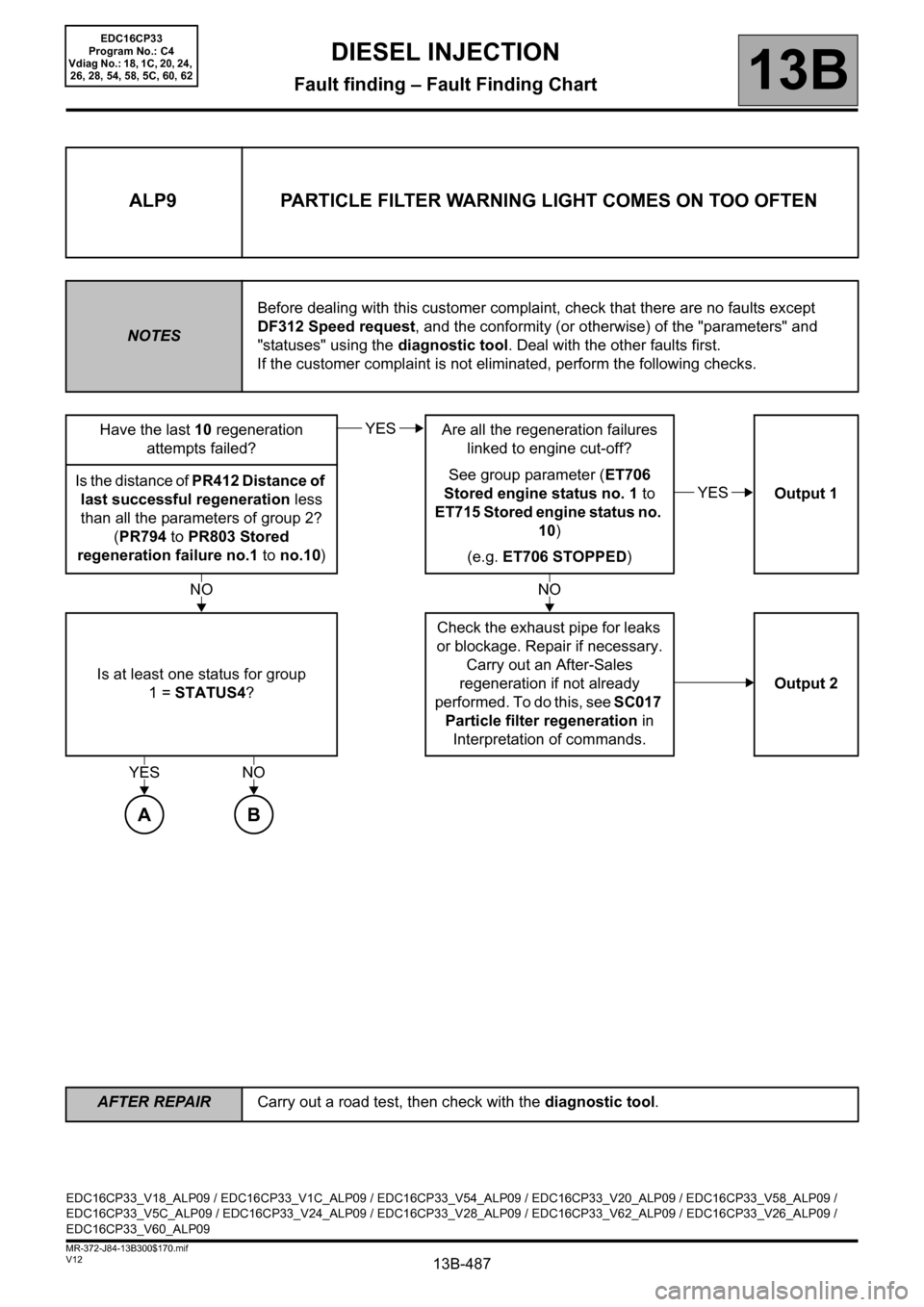

ALP9 PARTICLE FILTER WARNING LIGHT COMES ON TOO OFTEN

NOTESBefore dealing with this customer complaint, check that there are no faults except

DF312 Speed request, and the conformity (or otherwise) of the "parameters" and

"statuses" using the diagnostic tool. Deal with the other faults first.

If the customer complaint is not eliminated, perform the following checks.

Have the last 10 regeneration

attempts failed?Are all the regeneration failures

linked to engine cut-off?

See group parameter (ET706

Stored engine status no. 1 to

ET715 Stored engine status no.

10)

(e.g. ET706 STOPPED)Output 1 Is the distance of PR412 Distance of

last successful regeneration less

than all the parameters of group 2?

(PR794 to PR803 Stored

regeneration failure no.1 to no.10)

Is at least one status for group

1 = STATUS4?Check the exhaust pipe for leaks

or blockage. Repair if necessary.

Carry out an After-Sales

regeneration if not already

performed. To do this, see SC017

Particle filter regeneration in

Interpretation of commands.Output 2

YES

YES

NONO

YES

A

NO

B

EDC16CP33_V18_ALP09 / EDC16CP33_V1C_ALP09 / EDC16CP33_V54_ALP09 / EDC16CP33_V20_ALP09 / EDC16CP33_V58_ALP09 /

EDC16CP33_V5C_ALP09 / EDC16CP33_V24_ALP09 / EDC16CP33_V28_ALP09 / EDC16CP33_V62_ALP09 / EDC16CP33_V26_ALP09 /

EDC16CP33_V60_ALP09

EDC16CP33

Program No.: C4

Vdiag No.: 18, 1C, 20, 24,

26, 28, 54, 58, 5C, 60, 62

Page 491 of 510

13B-491

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V12 MR-372-J84-13B300$170.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

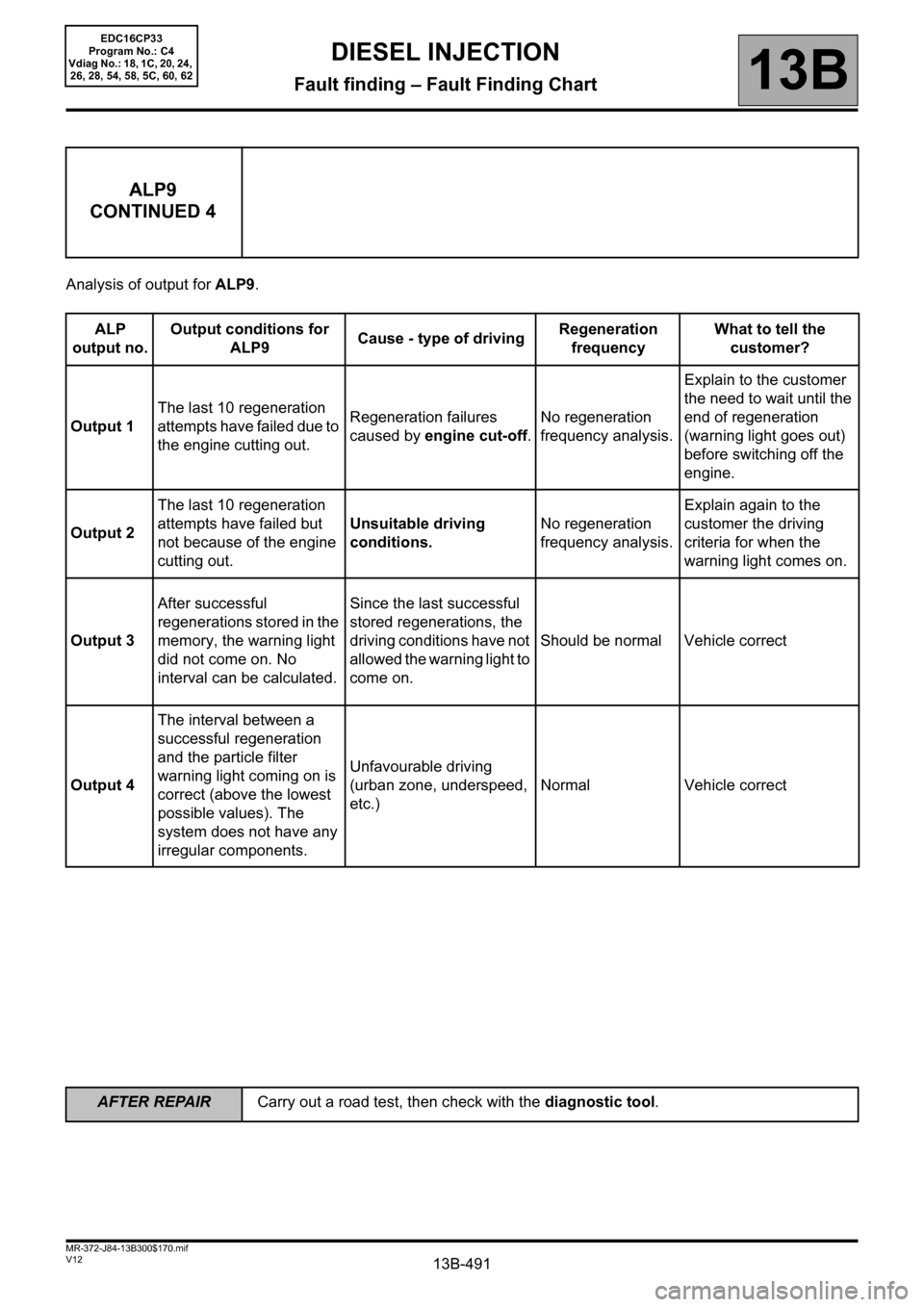

Analysis of output for ALP9.

ALP9

CONTINUED 4

ALP

output no.Output conditions for

ALP9Cause - type of drivingRegeneration

frequencyWhat to tell the

customer?

Output 1The last 10 regeneration

attempts have failed due to

the engine cutting out.Regeneration failures

caused by engine cut-off.No regeneration

frequency analysis.Explain to the customer

the need to wait until the

end of regeneration

(warning light goes out)

before switching off the

engine.

Output 2The last 10 regeneration

attempts have failed but

not because of the engine

cutting out.Unsuitable driving

conditions.No regeneration

frequency analysis.Explain again to the

customer the driving

criteria for when the

warning light comes on.

Output 3After successful

regenerations stored in the

memory, the warning light

did not come on. No

interval can be calculated.Since the last successful

stored regenerations, the

driving conditions have not

allowed the warning light to

come on.Should be normal Vehicle correct

Output 4The interval between a

successful regeneration

and the particle filter

warning light coming on is

correct (above the lowest

possible values). The

system does not have any

irregular components.Unfavourable driving

(urban zone, underspeed,

etc.)Normal Vehicle correct

EDC16CP33

Program No.: C4

Vdiag No.: 18, 1C, 20, 24,

26, 28, 54, 58, 5C, 60, 62

Page 492 of 510

13B-492V12 MR-372-J84-13B300$180.mif

13B

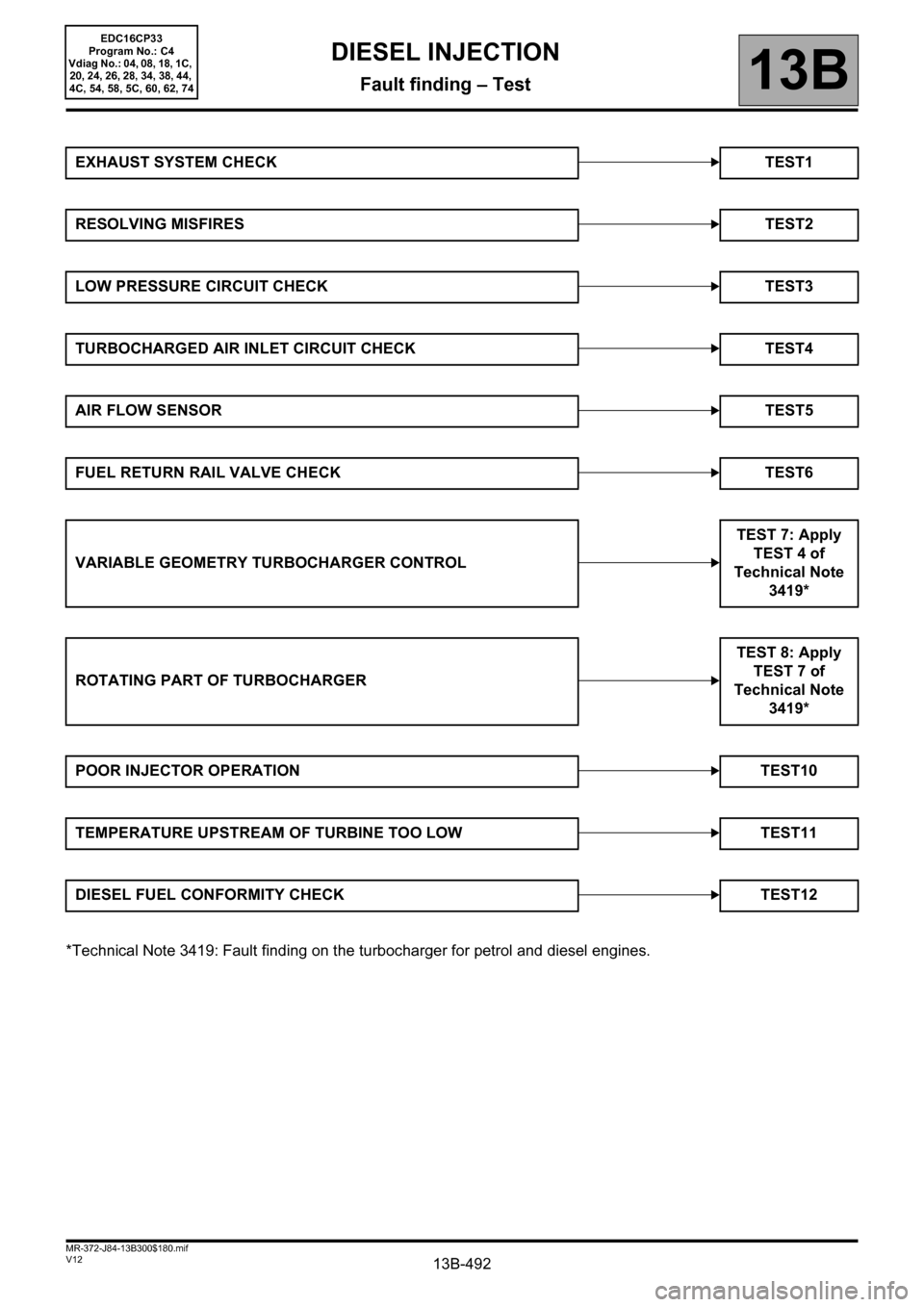

*Technical Note 3419: Fault finding on the turbocharger for petrol and diesel engines. EXHAUST SYSTEM CHECK TEST1

RESOLVING MISFIRESTEST2

LOW PRESSURE CIRCUIT CHECK TEST3

TURBOCHARGED AIR INLET CIRCUIT CHECK TEST4

AIR FLOW SENSORTEST5

FUEL RETURN RAIL VALVE CHECK TEST6

VARIABLE GEOMETRY TURBOCHARGER CONTROLTEST 7: Apply

TEST 4 of

Technical Note

3419*

ROTATING PART OF TURBOCHARGERTEST 8: Apply

TEST 7 of

Technical Note

3419*

POOR INJECTOR OPERATION TEST10

TEMPERATURE UPSTREAM OF TURBINE TOO LOW TEST11

DIESEL FUEL CONFORMITY CHECK TEST12

DIESEL INJECTION

Fault finding – Test

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 493 of 510

13B-493V12 MR-372-J84-13B300$180.mif

DIESEL INJECTION

Fault finding – Test13B

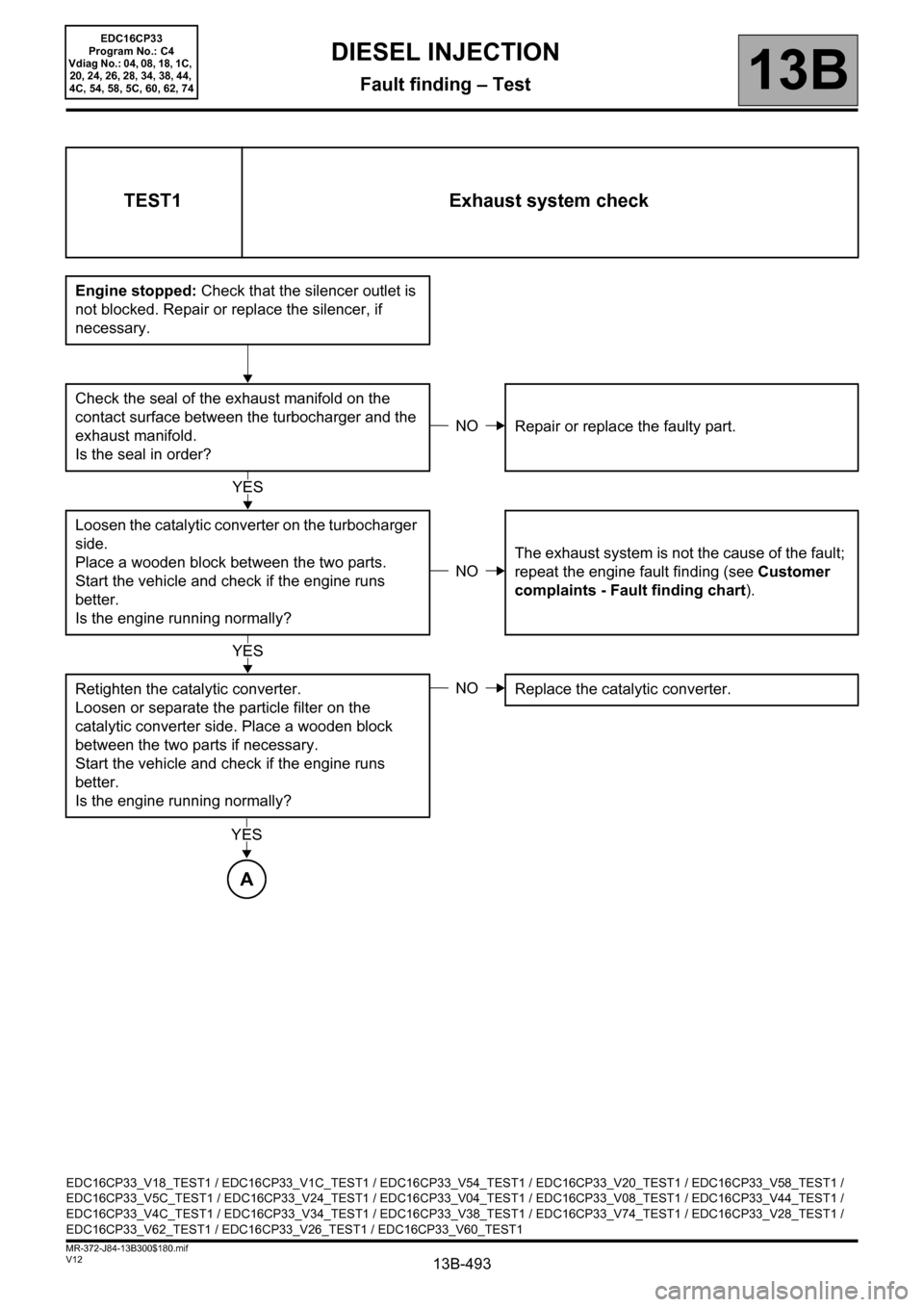

TEST1 Exhaust system check

Engine stopped: Check that the silencer outlet is

not blocked. Repair or replace the silencer, if

necessary.

Check the seal of the exhaust manifold on the

contact surface between the turbocharger and the

exhaust manifold.

Is the seal in order?Repair or replace the faulty part.

Loosen the catalytic converter on the turbocharger

side.

Place a wooden block between the two parts.

Start the vehicle and check if the engine runs

better.

Is the engine running normally?The exhaust system is not the cause of the fault;

repeat the engine fault finding (see Customer

complaints - Fault finding chart).

Retighten the catalytic converter.

Loosen or separate the particle filter on the

catalytic converter side. Place a wooden block

between the two parts if necessary.

Start the vehicle and check if the engine runs

better.

Is the engine running normally?Replace the catalytic converter.

NO

YES

NO

YES

NO

YES

A

EDC16CP33_V18_TEST1 / EDC16CP33_V1C_TEST1 / EDC16CP33_V54_TEST1 / EDC16CP33_V20_TEST1 / EDC16CP33_V58_TEST1 /

EDC16CP33_V5C_TEST1 / EDC16CP33_V24_TEST1 / EDC16CP33_V04_TEST1 / EDC16CP33_V08_TEST1 / EDC16CP33_V44_TEST1 /

EDC16CP33_V4C_TEST1 / EDC16CP33_V34_TEST1 / EDC16CP33_V38_TEST1 / EDC16CP33_V74_TEST1 / EDC16CP33_V28_TEST1 /

EDC16CP33_V62_TEST1 / EDC16CP33_V26_TEST1 / EDC16CP33_V60_TEST1

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74