engine RENAULT SCENIC 2012 J95 / 3.G Engine And Peripherals EDC16CP33 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2012, Model line: SCENIC, Model: RENAULT SCENIC 2012 J95 / 3.GPages: 510, PDF Size: 2.98 MB

Page 506 of 510

13B-506V12 MR-372-J84-13B300$180.mif

DIESEL INJECTION

Fault finding – Test13B

TEST10

CONTINUED 3

Part C:

Confirmation of flow correction fault finding for each injector (individual correction):

Clear the faults and run a test with the engine at idle speed and the fuel temperature > 50°C, check that no faults

appear on the diagnostic tool and that the correction values do not reach X = ± 5 mg/stroke to confirm the repair.

– If one or more cylinders have flow correction values for an injector which exceed X = ± 5 mg/stroke, follow the

fault finding procedure described in Part A: Fuel regulation balance check for each injector (individual) of

Test 10.

– Otherwise, follow the fault finding procedure described in Part D of Test 10.

Part D:

Injector nozzle sealing check:

Check the level and condition of the engine oil:

– If there is contamination from the diesel fuel, the leaking injector nozzle will be "greasy".

– Disconnect the preheating relay.

– Ensure that this is not caused by rising engine oil by checking the engine compression values.

– Check the condition of the heater plug: this must not be wet. If it is, change the defective injector.

– If the engine compression values are correct: locate the faulty injector by looking at the condition of the cylinders

and the pistons through the heater plug wells (greasy cylinder, overheating, signs of damage, etc.).

– If the cylinder - piston examination is not conclusive, remove the injectors and change the one with the greasy

nozzle.

– If the fault finding checks do not enable the engine to be repaired, contact the Techline.

After replacing the injector, follow the injector code programming procedure (see Replacement of components),

run SC036 Reinitialise programming, and select the number of the injector replaced.

Note:

Before replacing an injector, check for the sealing washer and its conformity (see Fault finding chart ALP4 Poor

performance).

IMPORTANT:

When removing / refitting injectors, follow the cleanliness and safety instructions (see MR 395 (Laguna II ph2),

402 (Vel Satis), 405 (Espace IV Ph2), 364 (Megane II ph2), 370 (Scenic II ph2) Mechanical, 13B, Diesel

injection, Diesel injectors: Removal - Refitting).

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 507 of 510

13B-507V12 MR-372-J84-13B300$180.mif

DIESEL INJECTION

Fault finding – Test13B

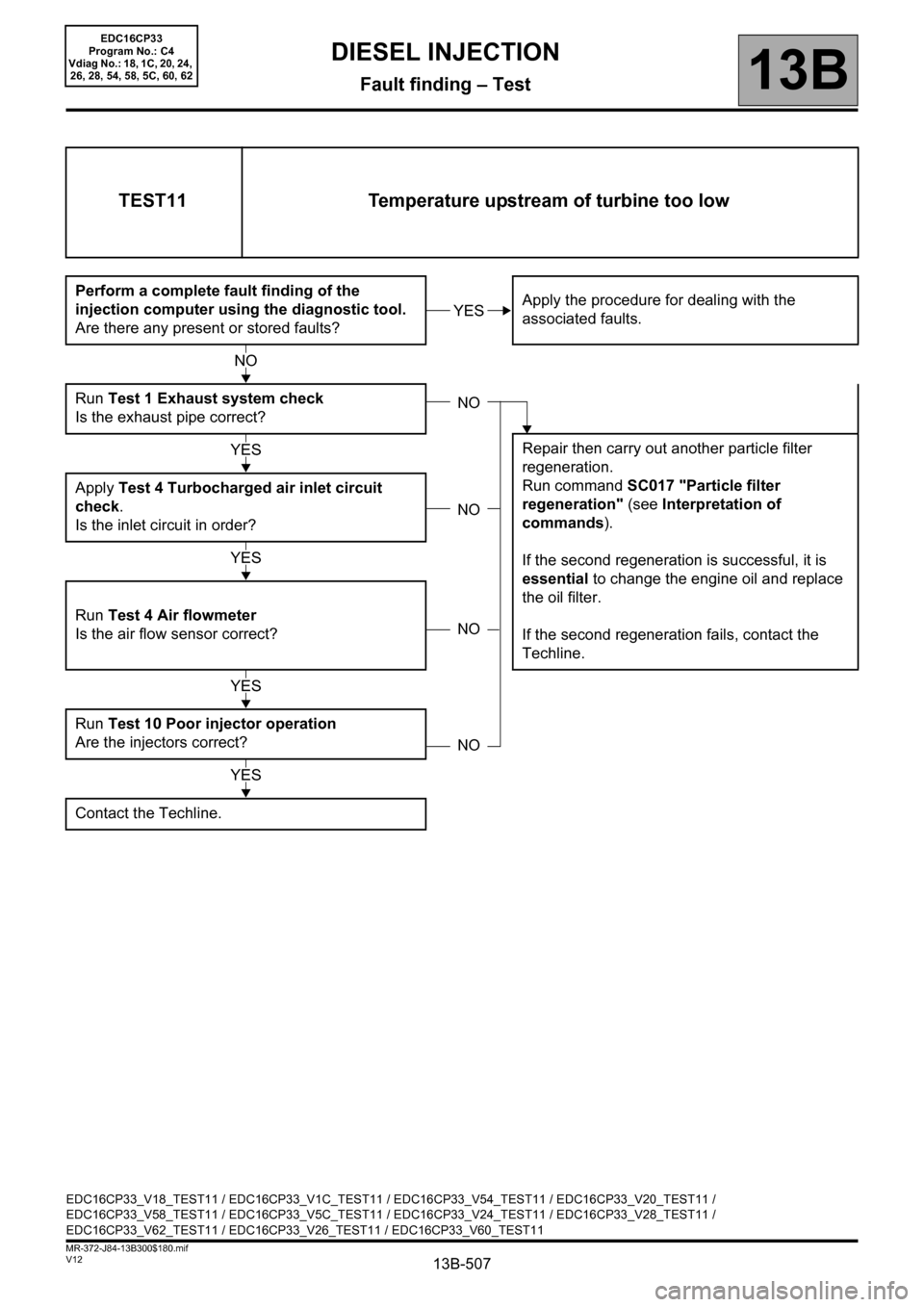

TEST11 Temperature upstream of turbine too low

Perform a complete fault finding of the

injection computer using the diagnostic tool.

Are there any present or stored faults?Apply the procedure for dealing with the

associated faults.

Run Test 1 Exhaust system check

Is the exhaust pipe correct?

Repair then carry out another particle filter

regeneration.

Run command SC017 "Particle filter

regeneration" (see Interpretation of

commands).

If the second regeneration is successful, it is

essential to change the engine oil and replace

the oil filter.

If the second regeneration fails, contact the

Techline. Apply Test 4 Turbocharged air inlet circuit

check.

Is the inlet circuit in order?

Run Test 4 Air flowmeter

Is the air flow sensor correct?

Run Test 10 Poor injector operation

Are the injectors correct?

Contact the Techline.

YES

NO

NO

NONO

NO

NO

YES

YES

YES

YES

EDC16CP33_V18_TEST11 / EDC16CP33_V1C_TEST11 / EDC16CP33_V54_TEST11 / EDC16CP33_V20_TEST11 /

EDC16CP33_V58_TEST11 / EDC16CP33_V5C_TEST11 / EDC16CP33_V24_TEST11 / EDC16CP33_V28_TEST11 /

EDC16CP33_V62_TEST11 / EDC16CP33_V26_TEST11 / EDC16CP33_V60_TEST11

EDC16CP33

Program No.: C4

Vdiag No.: 18, 1C, 20, 24,

26, 28, 54, 58, 5C, 60, 62