Df056 RENAULT SCENIC 2012 J95 / 3.G Engine And Peripherals EDC16CP33 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2012, Model line: SCENIC, Model: RENAULT SCENIC 2012 J95 / 3.GPages: 510, PDF Size: 2.98 MB

Page 20 of 510

13B-20V12 MR-372-J84-13B300$030.mif

DIESEL INJECTION

Fault finding – System operation13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

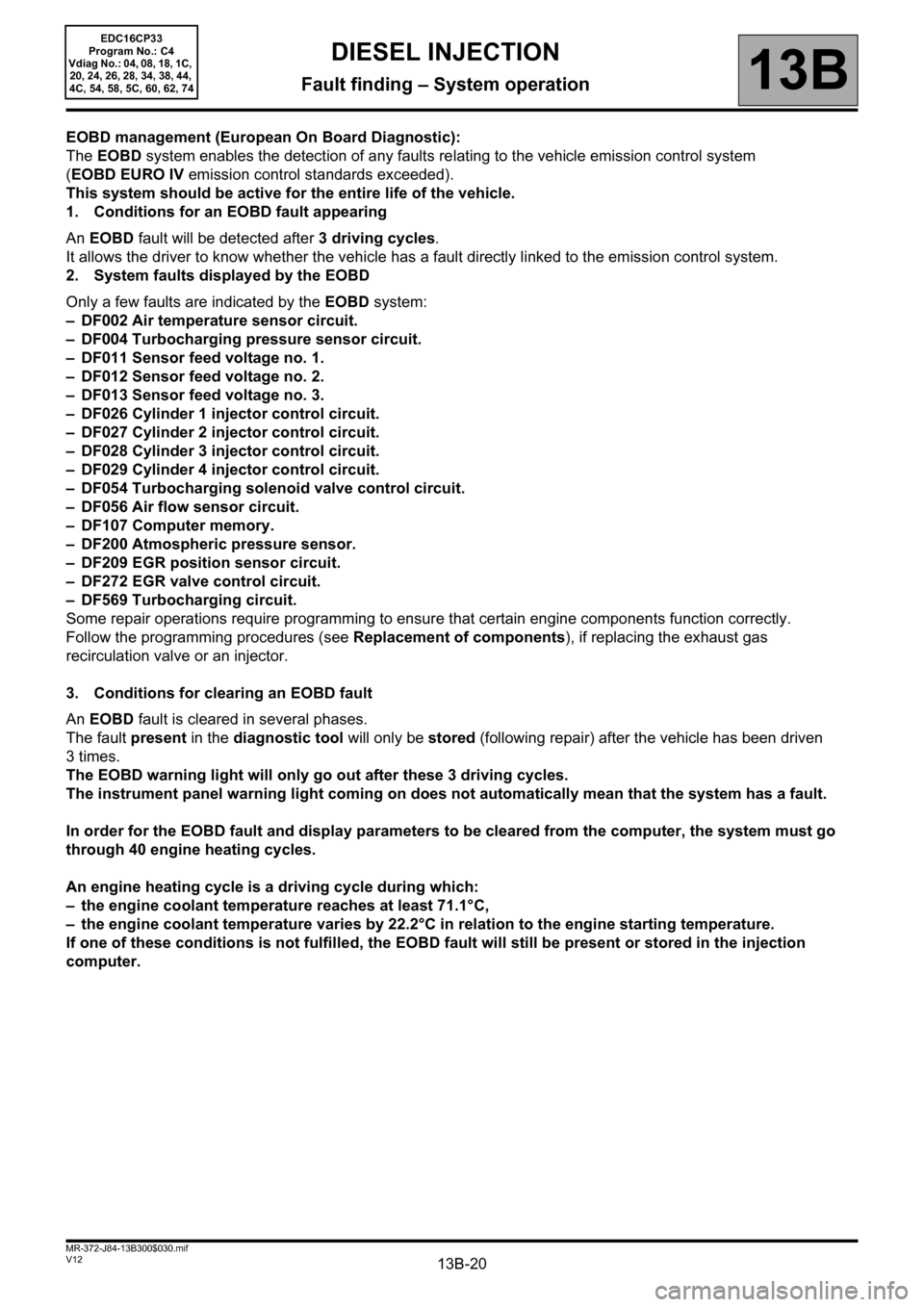

EOBD management (European On Board Diagnostic):

The EOBD system enables the detection of any faults relating to the vehicle emission control system

(EOBD EURO IV emission control standards exceeded).

This system should be active for the entire life of the vehicle.

1. Conditions for an EOBD fault appearing

An EOBD fault will be detected after 3 driving cycles.

It allows the driver to know whether the vehicle has a fault directly linked to the emission control system.

2. System faults displayed by the EOBD

Only a few faults are indicated by the EOBD system:

– DF002 Air temperature sensor circuit.

– DF004 Turbocharging pressure sensor circuit.

– DF011 Sensor feed voltage no. 1.

– DF012 Sensor feed voltage no. 2.

– DF013 Sensor feed voltage no. 3.

– DF026 Cylinder 1 injector control circuit.

– DF027 Cylinder 2 injector control circuit.

– DF028 Cylinder 3 injector control circuit.

– DF029 Cylinder 4 injector control circuit.

– DF054 Turbocharging solenoid valve control circuit.

– DF056 Air flow sensor circuit.

– DF107 Computer memory.

– DF200 Atmospheric pressure sensor.

– DF209 EGR position sensor circuit.

– DF272 EGR valve control circuit.

– DF569 Turbocharging circuit.

Some repair operations require programming to ensure that certain engine components function correctly.

Follow the programming procedures (see Replacement of components), if replacing the exhaust gas

recirculation valve or an injector.

3. Conditions for clearing an EOBD fault

An EOBD fault is cleared in several phases.

The fault present in the diagnostic tool will only be stored (following repair) after the vehicle has been driven

3times.

The EOBD warning light will only go out after these 3 driving cycles.

The instrument panel warning light coming on does not automatically mean that the system has a fault.

In order for the EOBD fault and display parameters to be cleared from the computer, the system must go

through 40 engine heating cycles.

An engine heating cycle is a driving cycle during which:

– the engine coolant temperature reaches at least 71.1°C,

– the engine coolant temperature varies by 22.2°C in relation to the engine starting temperature.

If one of these conditions is not fulfilled, the EOBD fault will still be present or stored in the injection

computer.

Page 28 of 510

13B-28V12 MR-372-J84-13B300$060.mif

13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

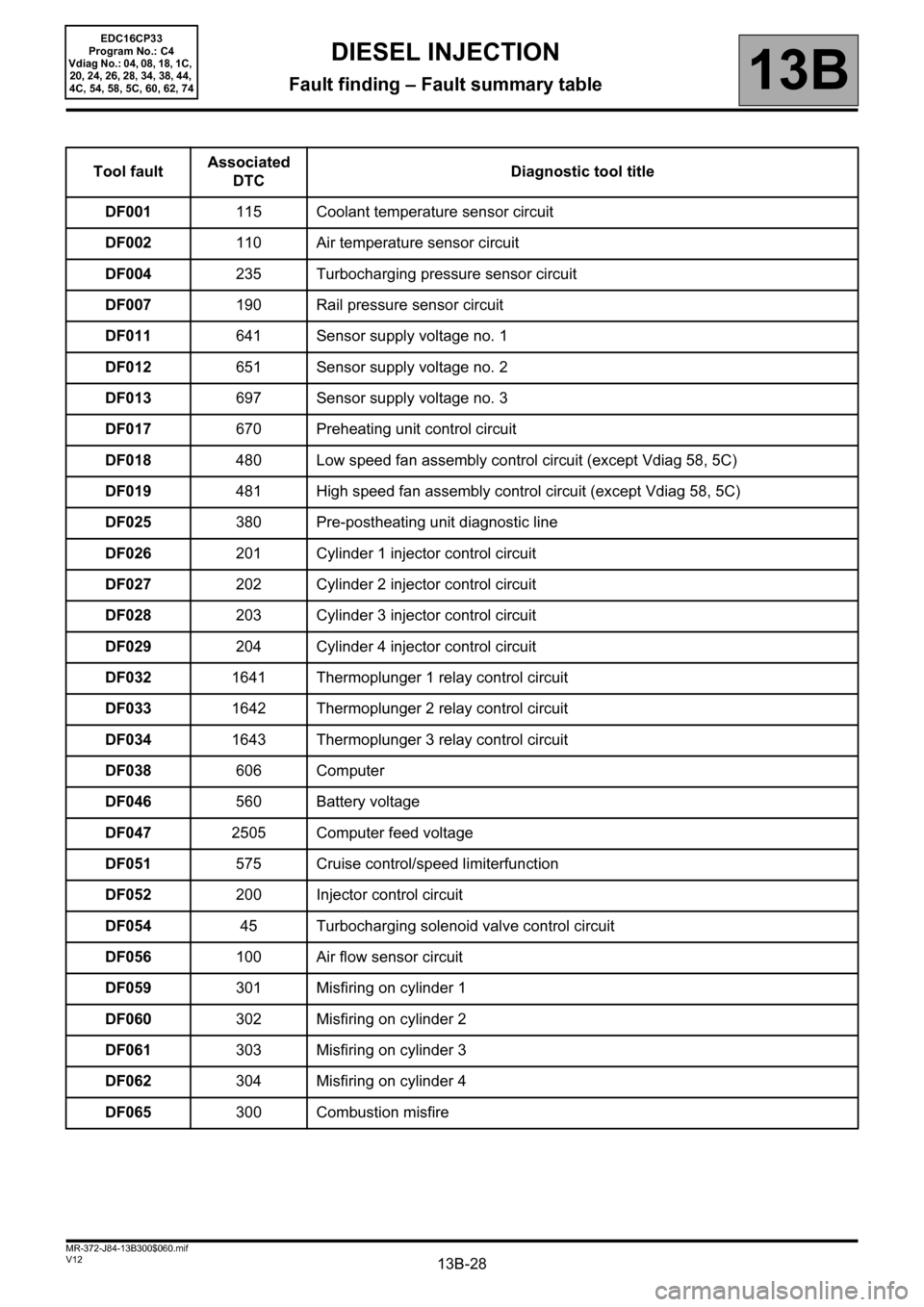

Tool faultAssociated

DTCDiagnostic tool title

DF001115 Coolant temperature sensor circuit

DF002110 Air temperature sensor circuit

DF004235 Turbocharging pressure sensor circuit

DF007190 Rail pressure sensor circuit

DF011641 Sensor supply voltage no. 1

DF012651 Sensor supply voltage no. 2

DF013697 Sensor supply voltage no. 3

DF017670 Preheating unit control circuit

DF018480 Low speed fan assembly control circuit (except Vdiag 58, 5C)

DF019481 High speed fan assembly control circuit (except Vdiag 58, 5C)

DF025380 Pre-postheating unit diagnostic line

DF026201 Cylinder 1 injector control circuit

DF027202 Cylinder 2 injector control circuit

DF028203 Cylinder 3 injector control circuit

DF029204 Cylinder 4 injector control circuit

DF0321641 Thermoplunger 1 relay control circuit

DF0331642 Thermoplunger 2 relay control circuit

DF0341643 Thermoplunger 3 relay control circuit

DF038606 Computer

DF046560 Battery voltage

DF0472505 Computer feed voltage

DF051575 Cruise control/speed limiterfunction

DF052200 Injector control circuit

DF05445 Turbocharging solenoid valve control circuit

DF056100 Air flow sensor circuit

DF059301 Misfiring on cylinder 1

DF060302 Misfiring on cylinder 2

DF061303 Misfiring on cylinder 3

DF062304 Misfiring on cylinder 4

DF065300 Combustion misfire

DIESEL INJECTION

Fault finding – Fault summary table

Page 115 of 510

13B-115

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$072.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

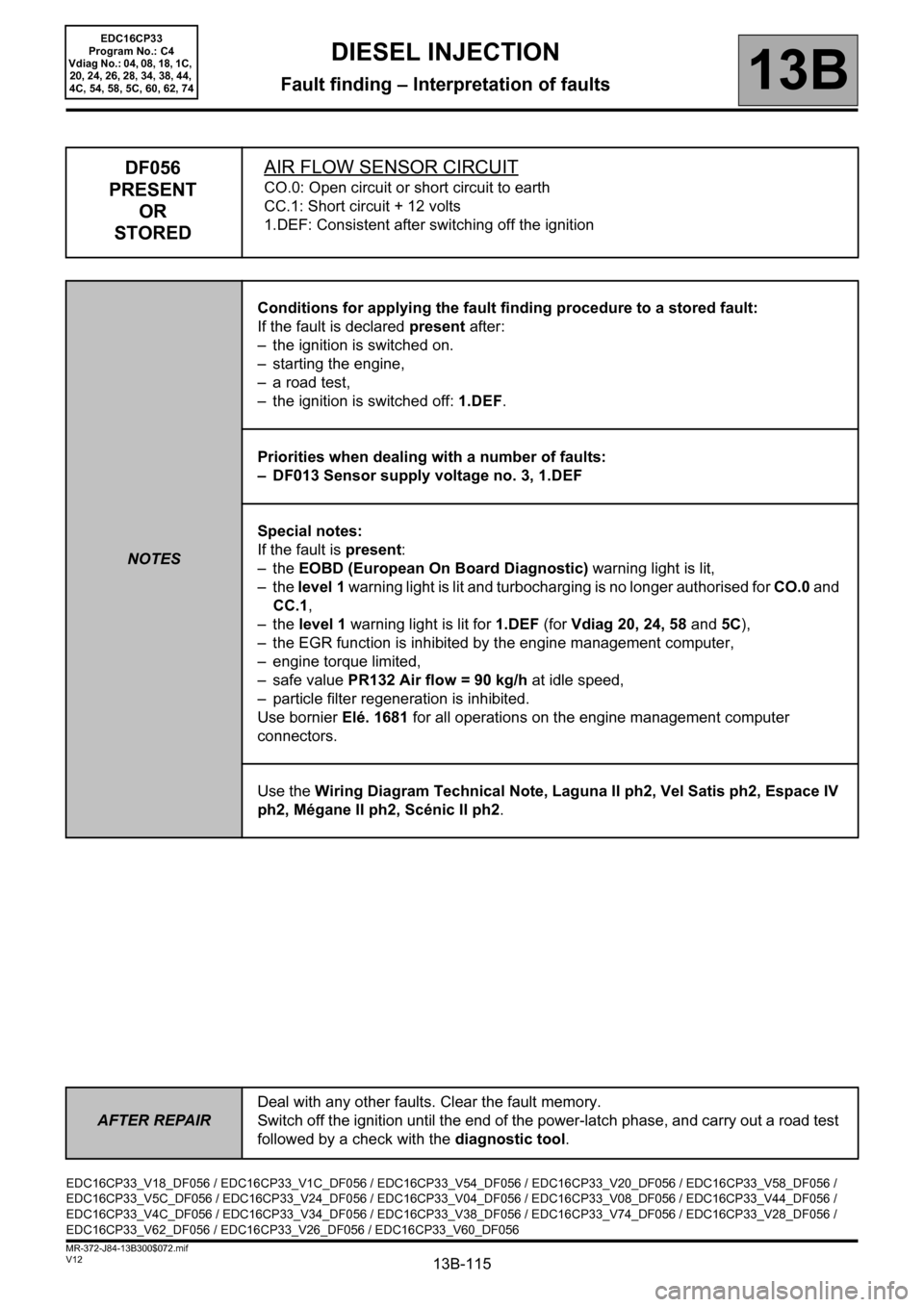

DF056

PRESENT

OR

STOREDAIR FLOW SENSOR CIRCUIT

CO.0: Open circuit or short circuit to earth

CC.1: Short circuit + 12 volts

1.DEF: Consistent after switching off the ignition

NOTESConditions for applying the fault finding procedure to a stored fault:

If the fault is declared present after:

– the ignition is switched on.

– starting the engine,

– a road test,

– the ignition is switched off: 1.DEF.

Priorities when dealing with a number of faults:

– DF013 Sensor supply voltage no. 3, 1.DEF

Special notes:

If the fault is present:

–the EOBD (European On Board Diagnostic) warning light is lit,

–the level 1 warning light is lit and turbocharging is no longer authorised for CO.0 and

CC.1,

–the level 1 warning light is lit for 1.DEF (for Vdiag 20, 24, 58 and 5C),

– the EGR function is inhibited by the engine management computer,

– engine torque limited,

– safe value PR132 Air flow = 90 kg/h at idle speed,

– particle filter regeneration is inhibited.

Use bornier Elé. 1681 for all operations on the engine management computer

connectors.

Use the Wiring Diagram Technical Note, Laguna II ph2, Vel Satis ph2, Espace IV

ph2, Mégane II ph2, Scénic II ph2.

EDC16CP33_V18_DF056 / EDC16CP33_V1C_DF056 / EDC16CP33_V54_DF056 / EDC16CP33_V20_DF056 / EDC16CP33_V58_DF056 /

EDC16CP33_V5C_DF056 / EDC16CP33_V24_DF056 / EDC16CP33_V04_DF056 / EDC16CP33_V08_DF056 / EDC16CP33_V44_DF056 /

EDC16CP33_V4C_DF056 / EDC16CP33_V34_DF056 / EDC16CP33_V38_DF056 / EDC16CP33_V74_DF056 / EDC16CP33_V28_DF056 /

EDC16CP33_V62_DF056 / EDC16CP33_V26_DF056 / EDC16CP33_V60_DF056

Page 116 of 510

13B-116

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$072.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

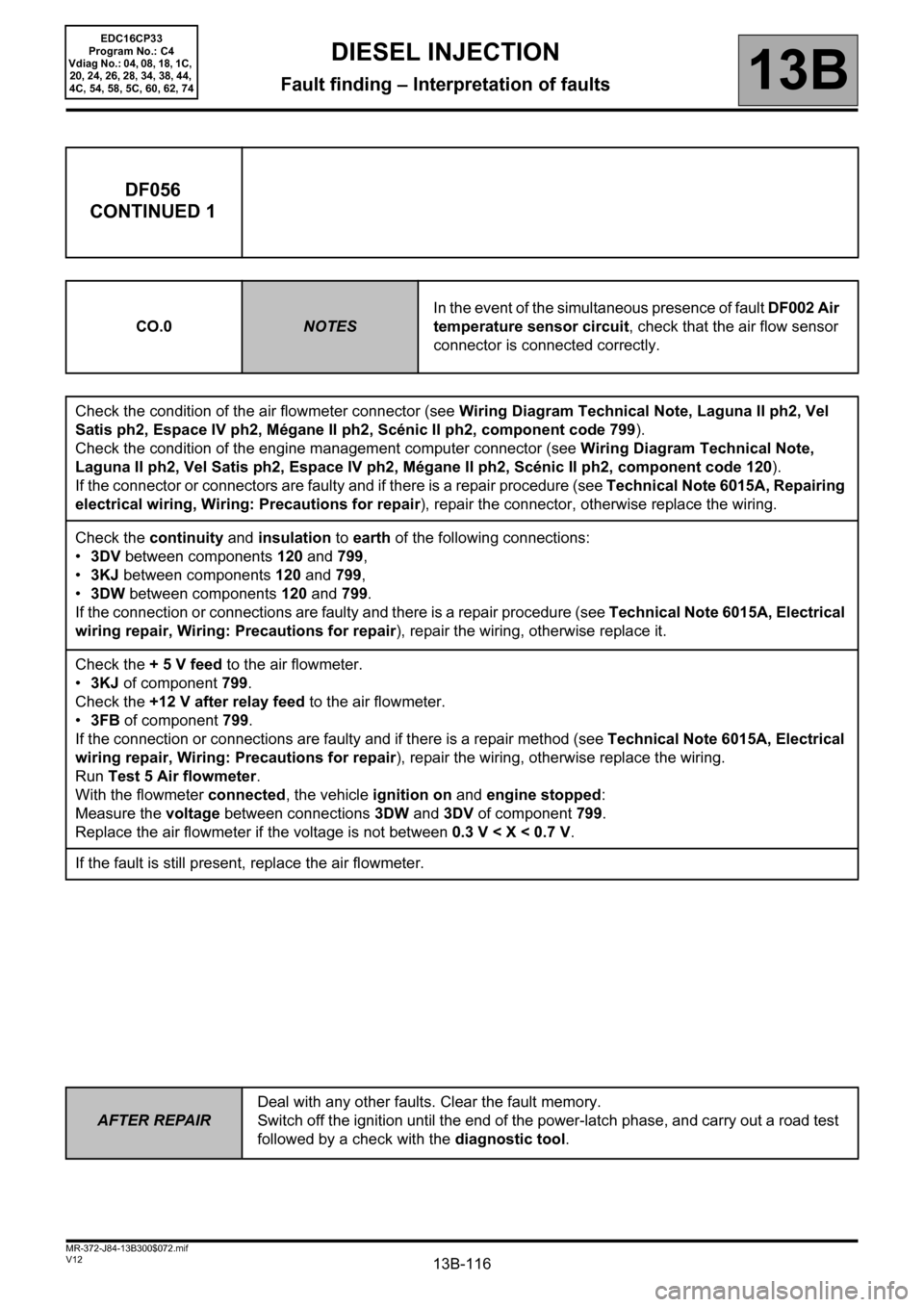

DF056

CONTINUED 1

CO.0NOTESIn the event of the simultaneous presence of fault DF002 Air

temperature sensor circuit, check that the air flow sensor

connector is connected correctly.

Check the condition of the air flowmeter connector (see Wiring Diagram Technical Note, Laguna II ph2, Vel

Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 799).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the continuity and insulation to earth of the following connections:

•3DV between components 120 and 799,

•3KJ between components 120 and 799,

•3DW between components120 and 799.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the + 5 V feed to the air flowmeter.

•3KJ of component 799.

Check the +12 V after relay feed to the air flowmeter.

•3FB of component 799.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Run Test 5 Air flowmeter.

With the flowmeter connected, the vehicle ignition on and engine stopped:

Measure the voltage between connections 3DW and 3DV

of component 799.

Replace the air flowmeter if the voltage is not between 0.3 V < X < 0.7 V.

If the fault is still present, replace the air flowmeter.

Page 117 of 510

13B-117

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$072.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

DF056

CONTINUED 2

CC.1NOTESNone.

Check the condition of the air flowmeter connector (see Wiring Diagram Technical Note, Laguna II ph2, Vel

Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 799).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation in relation to + 12 V of the following connections:

•3DV between components 120 and 799,

•3KJ between components 120 and 799,

•3DW between components 120 and 799.

Check the + 5 V supply of the air flowmeter on the following connection:

•3KJ of component 799.

Check the + 12 V after relay supply of the air flowmeter on the following connection:

•3FB of component 799.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

With the flowmeter connected, the vehicle ignition on and engine stopped:

Measure the voltage between connections 3DW and 3DV of component 799.

Replace the air flowmeter if the voltage is not between 0.3 V < X < 0.7 V.

If the fault is still present, replace the air flowmeter.

Page 118 of 510

13B-118

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$072.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

DF056

CONTINUED 3

1.DEFNOTESNone.

Check the condition of the air flowmeter connector (see Wiring Diagram Technical Note, Laguna II ph2, Vel

Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 799).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check for continuity and absence of interference resistance of the following connections:

•3DV between components 120 and 799,

•3KJ between components 120 and 799,

•3DW between components 120 and 799.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Check the condition of the flowmeter: no visible damage to the sensing element of the flowmeter.

Use the Monitool application: MT001 Turbocharging function to check the entire air line (for Vdiag 04 and 44).

If the fault is still present, replace the air flowmeter.

Page 339 of 510

13B-339

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V12 MR-372-J84-13B300$121.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

PR023DIFFERENCE IN AIR FLOW

PARAMETER

DEFINITIONThis parameter indicates the difference between the inlet air flow and the air entering

the engine in mg/st.

NOTESNone.

Conformity check: Engine stopped and ignition on, or engine running, and engine coolant

temperature > 80°C

In the event of a fault, consult the interpretation of fault DF056 Air flow sensor circuit.

EDC16CP33_V04_PR023 / EDC16CP33_V08_PR023 / EDC16CP33_V44_PR023 / EDC16CP33_V4C_PR023 / EDC16CP33_V34_PR023 /

EDC16CP33_V38_PR023 / EDC16CP33_V74_PR023 / EDC16CP33_V26_PR023 / EDC16CP33_V28_PR023 / EDC16CP33_V60_PR023 /

EDC16CP33_V62_PR023

EDC16CP33

Program No.: C4

VDiag No.: 04, 08, 26, 28,

34, 38, 44, 4C, 60, 62, 74

Page 382 of 510

13B-382V12 MR-372-J84-13B300$122.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

PR225AIR FLOW SENSOR VOLTAGE

PARAMETER

DEFINITIONThis parameter indicates the air flow sensor voltage in volts.

NOTESSpecial notes:

Only perform these tests if the parameters do not correspond with the system

operation programming.

There must be no faults present.

Perform this fault finding procedure:

– after finding an inconsistency in the parameter,

– or after a customer complaint (lack of power, smoke etc.).

Conformity check: Engine stopped and ignition on, or engine running, and engine coolant

temperature > 80°C

The air flow sensor voltage value must be between:

0 V < PR225 < 5 V.

In the event of a fault, consult the interpretation of parameter DF056 Air flow sensor circuit.

EDC16CP33_V18_PR225 / EDC16CP33_V1C_PR225 / EDC16CP33_V54_PR225 / EDC16CP33_V20_PR225 / EDC16CP33_V58_PR225 /

EDC16CP33_V5C_PR225 / EDC16CP33_V24_PR225 / EDC16CP33_V04_PR225 / EDC16CP33_V08_PR225 / EDC16CP33_V44_PR225 /

EDC16CP33_V4C_PR225 / EDC16CP33_V34_PR225 / EDC16CP33_V38_PR225 / EDC16CP33_V74_PR225 / EDC16CP33_V28_PR225 /

EDC16CP33_V62_PR225 / EDC16CP33_V26_PR225 / EDC16CP33_V60_PR225

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 478 of 510

13B-478

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V12 MR-372-J84-13B300$170.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

ALP4

CONTINUED 2

Perform the following road test (looking for a loss of power when accelerating under full load):

– in the highest gear ratio, accelerate fully,

– lift your foot off the accelerator pedal completely for at least 2 seconds,

– accelerate fully again,

– release the accelerator pedal completely,

– accelerate slightly.

If the loss of power was not noted during slight acceleration and if there was a loss of engine power during each

acceleration at full load, replace the diesel fuel injector return rail and its overpressure valve (see MR364

(Mégane II ph2), MR370 (Scénic II ph2), MR 395 (Laguna II ph2), 402 (Vel Satis ph2), 405 (Espace IV ph2)

Mechanical, 13B, Diesel injection, Diesel injector fuel return rail: Removal - Refitting).

Check the connection and positioning of the differential pressure sensor (see MR 395 (Laguna II ph2), 402 (Vel

Satis Ph2), 405 (Espace IV ph2), 364 (Mégane II ph2), 370 (Scénic II ph2) Mechanical, 19B, Exhaust, Particle

filter pressure sensor: Removal - Refitting).

Check the conformity of the accelerator pedal position sensor, the brake pedal sensor, the atmospheric pressure

sensor, the exhaust gas recirculation valve, and the damper valve (see Interpretation of statuses and

parameters).

Check the consistency of the signal from the air flowmeter, the engine coolant temperature sensor, the fuel

temperature sensor and the engine speed sensor.

Check the connections, the continuity and the absence of interference resistance of the following components:

– the air flowmeter (apply DF056 Air flow sensor circuit)

– the engine coolant temperature sensor (apply DF001 Coolant temperature sensor circuit)

– the fuel temperature sensor (apply DF098 Fuel temperature sensor circuit)

– the engine speed sensor (apply DF195 Engine speed/camshaft sensor consistency).

A

YES

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 501 of 510

13B-501V12 MR-372-J84-13B300$180.mif

DIESEL INJECTION

Fault finding – Test13B

OCR*: Opening Cyclic Ratio

TEST5 Air flowmeter

Damage to electrical components

Visual inspection: remove the flow sensor - the components should not be broken.

Replace the air flowmeter if necessary.

Oxidation of the electrical components

Visual inspection: remove the air flowmeter, there should not be any greenish deposits on the electrical

components.

Replace the air flowmeter if necessary.

Clogging of the air flowmeter

Test:

– Check the values for conformity:

– During the first 5 seconds after starting,

–PR064 Coolant temperature: 80°C.

–PR055: Engine speed: idling.

–PR059: Air temperature between 30 and 70°C.

–PR146 Inlet air flow: between 20 and 28 kg/h.

–PR220 EGR valve OCR*: between 22 and 30%.

–PR132 Air flow: between 20 and 28 kg/h.

–PR051 EGR valve position feedback: between 22 and 30%.

–PR023 Air flow difference between - 50 and + 50 mg/stroke.

– Apply the procedure for DF056 Air flow sensor circuit for the checks on the air flowmeter.

Replace the air flowmeter if necessary.

END OF TEST.

EDC16CP33_V18_TEST5 / EDC16CP33_V1C_TEST5 / EDC16CP33_V54_TEST5 / EDC16CP33_V20_TEST5 / EDC16CP33_V58_TEST5 /

EDC16CP33_V5C_TEST5 / EDC16CP33_V24_TEST5 / EDC16CP33_V04_TEST5 / EDC16CP33_V08_TEST5 / EDC16CP33_V44_TEST5 /

EDC16CP33_V4C_TEST5 / EDC16CP33_V34_TEST5 / EDC16CP33_V38_TEST5 / EDC16CP33_V74_TEST5 / EDC16CP33_V28_TEST5 /

EDC16CP33_V62_TEST5 / EDC16CP33_V26_TEST5 / EDC16CP33_V60_TEST5

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74