fuel filter RENAULT SCENIC 2012 J95 / 3.G Engine And Peripherals EDC16CP33 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2012, Model line: SCENIC, Model: RENAULT SCENIC 2012 J95 / 3.GPages: 510, PDF Size: 2.98 MB

Page 11 of 510

13B-11V12 MR-372-J84-13B300$030.mif

13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

System outline

The high pressure injection system is designed to deliver a precise quantity of diesel fuel to the engine at a set

moment.

It is fitted with a BOSCH computer, type EDC16CP33.

The system comprises:

– a priming bulb,

– a diesel filter,

– a high pressure pump,

– a fuel pressure regulator (or actuator) on the high pressure pump (MPROP),

– a fuel pressure regulator (or actuator) mounted on the injector rail (DRV),

– an injector rail,

– a fuel pressure sensor,

– four piezoelectric injectors,

– a diesel temperature sensor,

– a coolant temperature sensor,

– an upstream air temperature sensor,

– a cylinder reference sensor,

– an engine speed sensor,

– a turbocharger pressure sensor,

– an exhaust gas recirculation valve,

– a recycled gas cooling solenoid valve,

– an accelerator pedal potentiometer,

– an atmospheric pressure sensor integrated into the injection computer,

– a flow sensor,

– a turbocharging limiter solenoid valve,

– a damper valve,

– a particle filter,

– a turbo upstream temperature sensor,

– a turbo upstream pressure sensor,

– a particle filter differential pressure sensor,

– a particle filter upstream temperature sensor,

– a particle filter downstream temperature sensor,

– an electric coolant pump (turbocharger),

– four thermoplungers.

The common rail direct high pressure injection system works sequentially (based on the petrol engine

multipoint injection).

This system uses piezoelectric injectors which enable a more precise injection since opening and closing times

are shorter compared to conventional solenoid injectors.

This injection system reduces operating noise, reduces the volume of pollutant gases and particles and produces

high engine torque at low engine speeds thanks to a pre-injection procedure.

The high pressure pump generates the high pressure and transmits it to the injector rail. The actuator located on

the pump controls the quantity of diesel supplied, according to the demand determined by the computer.

The rail supplies each injector through a steel pipe. The actuator located on the injector rail controls the pressure

of diesel fuel in the rail according to the demand determined by the computer.

DIESEL INJECTION

Fault finding – System operation

Page 12 of 510

13B-12V12 MR-372-J84-13B300$030.mif

DIESEL INJECTION

Fault finding – System operation13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

a. The computer:

Determines the injection pressure value necessary for the correct operation of the engine; the pressure can reach

1600 bar in the rail and it must be constantly regulated.

Checks that the pressure value is correct by analysing the value transmitted by the pressure sensor located on

the rail.

Determines the injection duration required to deliver the right quantity of diesel fuel and the moment when injection

should start. Controls each injector electrically and individually after determining these two values.

The quantity of fuel injected is determined by:

– Engine speed (Crankshaft + Cam for synchronisation).

– Accelerator pedal.

– Turbocharging pressure.

– Coolant temperature,

– Inlet air temperature.

–Air flow

– Pressure in the rail.

– Vehicle speed.

The computer manages:

– idling regulation,

– exhaust gas flow reinjection to the inlet,

– fuel supply check (advance, flow and rail pressure),

– the fan assembly control,

– the air conditioning (cold loop function),

– cruise control/speed limiter function,

– pre-post heating control,

– indicator lights control via the multiplex network,

– the operation of the catalysed particle filter,

– turbocharging pressure.

The high pressure pump is supplied at low pressure by an integrated low pressure pump (transfer pump).

It supplies the rail, the pressure in which is regulated by:

–the pressure regulator on the rail (DRV) for starting phases, starting the engine when cold (increase in

temperature to heat the diesel circuit) and when throttling-off,

–the pressure regulator on the pump (MPROP) for all other phases (90% of cases).

As natural leaks in piezoelectric injectors are very low, opening the pressure regulator (DRV) is the only quick

method of dumping the rail pressure and it prevents overpressure when injection is restarted.

The pressure regulator on the pump (MPROP) enables the high pressure pump to supply just the exact quantity

of diesel fuel required to maintain the rail pressure. This component minimises the heat generated and improves

engine output.

Note:

Each piezoelectric injector is connected to the return rail. The injector return rail is kept pressurised by a

mechanical valve at the end of the return rail with a 10 bar calibration (by comparison, solenoid injectors used to

return directly into the common fuel return circuit). This feature is linked to the operation of piezoelectric injectors.

Page 13 of 510

13B-13V12 MR-372-J84-13B300$030.mif

DIESEL INJECTION

Fault finding – System operation13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Fuel surplus from the pump, injector return rail or rail is collected in a low pressure "octopus manifold" and is then

sent to the fuel filter, providing that the fuel is cold (recirculation), and then to the tank.

The system can inject diesel fuel into the engine at a pressure of up to 1600 bar. Before each operation, check that

the injector rail is depressurised and that the fuel temperature is not too high.

You must respect the cleanliness guidelines and safety advice specified in this document for any work on the high

pressure injection system.

Removal of the internal parts of the pump and injectors is prohibited. Only the fuel pressure regulator (or actuator)

on the high pressure pump (MPROP), the fuel pressure regulator (or actuator) on the injector rail (DRV) or the diesel

temperature sensor can be replaced.

For safety reasons, it is strictly prohibited to undo a high pressure pipe union when the engine is running.

It is not possible to remove the pressure sensor from the fuel rail because this may cause circuit contamination

faults. If the pressure sensor fails, replace the pressure sensor, the rail and the high pressure pipes.

Some vehicles have a presence sensor mounted in the filter for detecting water in the diesel. If there is water in

the diesel fuel, the orange "Injection and pre-post heating" warning light will come on.

Supplying + 12 V directly to any component in the system is prohibited.

Ultrasonic decoking and cleaning are prohibited.

Never start the engine unless the battery is connected correctly.

Disconnect the injection computer when carrying out any welding work on the vehicle.

b. The connections between the vehicle's various computers are multiplexed.

The electronic system fitted in this vehicle is multiplexed.

This enables dialogue between the various vehicle computers. As a result:

– the fault warning lights on the instrument panel are lit by the multiplex network,

– vehicle faults are displayed by the multiplex network,

– the vehicle speed sensor on the gearbox is not needed.

The vehicle speed signal on the instrument panel is sent by the ABS computer via the multiplex network. The vehicle

speed signal is mainly used by the injection computer, the airbag computer and the automatic transmission

computer (if the vehicle is fitted with this).WARNING:

The engine must not operate with:

– Diesel fuel containing more than 10% diester,

– petrol, even in tiny quantities.

Note:

For the M9R 724 (Vdiag 5C and 58):

The engine is limited to 3000 rpm if the vehicle is stationary or if the vehicle speed is less than 4 mph (7 km/h)

and if the engine is warm.

Page 29 of 510

13B-29V12 MR-372-J84-13B300$060.mif

DIESEL INJECTION

Fault finding – Fault summary table13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

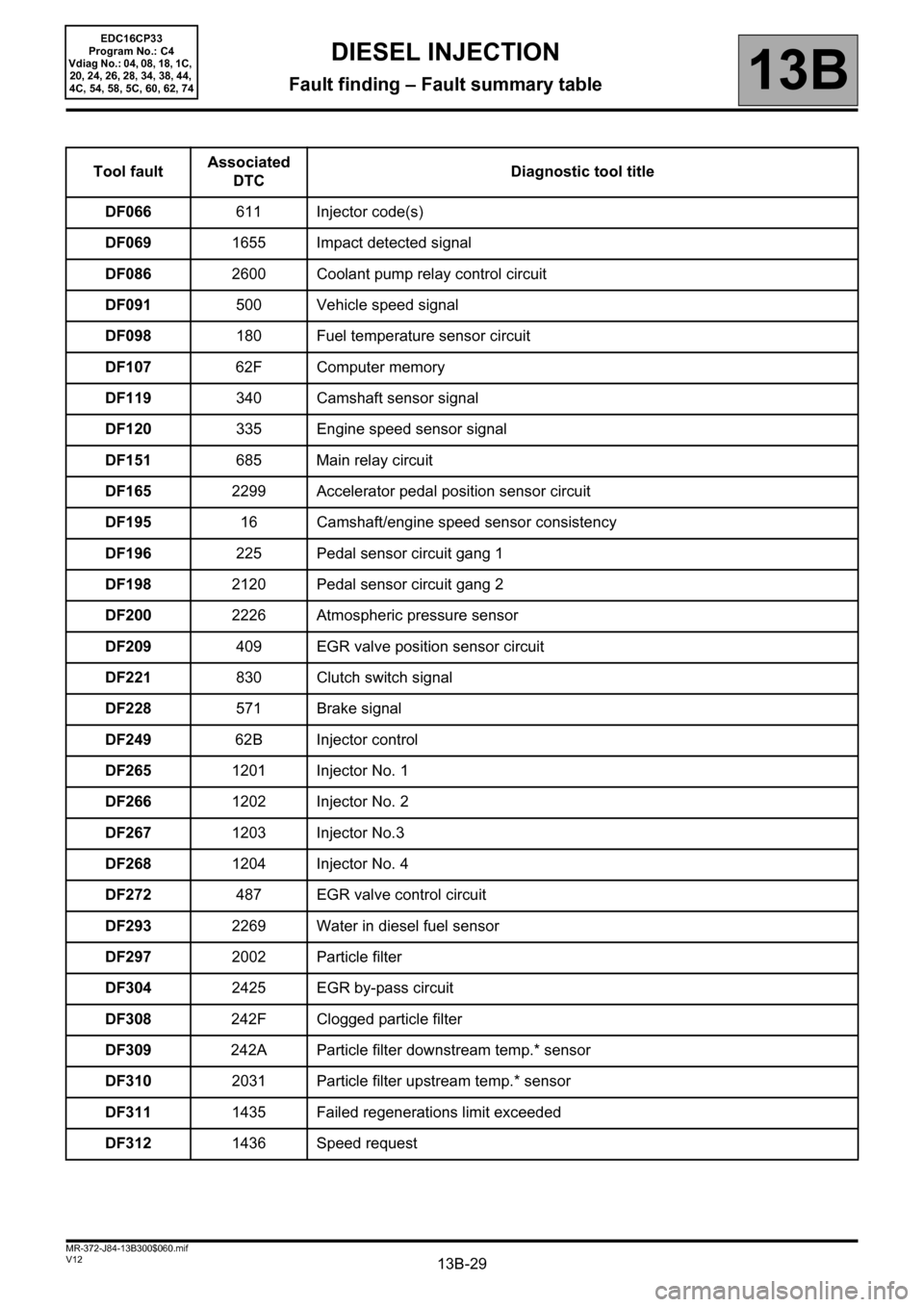

Tool faultAssociated

DTCDiagnostic tool title

DF066611 Injector code(s)

DF0691655 Impact detected signal

DF0862600 Coolant pump relay control circuit

DF091500 Vehicle speed signal

DF098180 Fuel temperature sensor circuit

DF10762F Computer memory

DF119340 Camshaft sensor signal

DF120335 Engine speed sensor signal

DF151685 Main relay circuit

DF1652299 Accelerator pedal position sensor circuit

DF19516 Camshaft/engine speed sensor consistency

DF196225 Pedal sensor circuit gang 1

DF1982120 Pedal sensor circuit gang 2

DF2002226 Atmospheric pressure sensor

DF209409 EGR valve position sensor circuit

DF221830 Clutch switch signal

DF228571 Brake signal

DF24962B Injector control

DF2651201 Injector No. 1

DF2661202 Injector No. 2

DF2671203 Injector No.3

DF2681204 Injector No. 4

DF272487 EGR valve control circuit

DF2932269 Water in diesel fuel sensor

DF2972002 Particle filter

DF3042425 EGR by-pass circuit

DF308242F Clogged particle filter

DF309242A Particle filter downstream temp.* sensor

DF3102031 Particle filter upstream temp.* sensor

DF3111435 Failed regenerations limit exceeded

DF3121436 Speed request

Page 138 of 510

13B-138

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$072.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

DF098

CONTINUED

CO.1NOTESNone.

If the wiring of the particle filter downstream temperature sensor, component code 1288, is present (with or without

the sensor being present), check the electrical insulation in relation to + 12 V between the following connections:

–3XU between components 120 and 1288,

–3TG between components 120 and 1288.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the condition of the fuel temperature sensor connector (see Wiring Diagram Technical Note, Laguna II

ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 1066).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Measure the resistance between connections 3FAB and 3LD of component 1066.

Replace the fuel temperature sensor if its resistance is less than 85 Ω or greater than 50 kΩ.

Check the continuity of the following connections:

•3FAB between components 120 and 1066,

•3LD between components 120 and 1066.

Check the insulation in relation to +12 V of the following connection:

•3FAB between components 120 and 1066.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Page 183 of 510

13B-183

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$073.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF293

PRESENT

OR

STOREDWATER IN DIESEL FUEL SENSOR

1.DEF: Open circuit on the line or water present in the diesel fuel

NOTESIMPORTANT:

Please observe the cleanliness guidelines and safety advice.

Use the Wiring Diagram Technical Note, Laguna II ph2, Vel Satis ph2, Espace IV

ph2, Mégane II ph2, Scénic II ph2.

Check that there is no water in the fuel filter.

Bleed the fuel filter and the low pressure diesel circuit if necessary.

Start the engine and wait at least 1 minute to confirm the repair.

If the fault was stored but not present, carry out a road test (see Note).

If the fault is still present:

Check the continuity and absence of interference resistance on the following connection:

•3WT between the components 120 and 414.

Check the + 12 V after relay supply to the water detection sensor on the following connection:

•3FB of component 414.

Check that the earth is in order on connection NT or M of component 414.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Start the engine and wait at least 1 minute to confirm the repair.

If the fault is still present, check the conformity of the fuel used:

– Check that the fuel tank has been filled correctly.

–Run Test 12 Fuel conformity check.

– If the diesel fuel is not correct:

– Replace the diesel fuel.

– Change the diesel filter.

– Bleed the low pressure diesel circuit.

EDC16CP33_V18_DF293 / EDC16CP33_V1C_DF293 / EDC16CP33_V54_DF293 / EDC16CP33_V20_DF293 / EDC16CP33_V58_DF293 /

EDC16CP33_V5C_DF293 / EDC16CP33_V24_DF293 / EDC16CP33_V04_DF293 / EDC16CP33_V08_DF293 / EDC16CP33_V44_DF293 /

EDC16CP33_V4C_DF293 / EDC16CP33_V34_DF293 / EDC16CP33_V38_DF293 / EDC16CP33_V74_DF293 / EDC16CP33_V28_DF293 /

EDC16CP33_V62_DF293 / EDC16CP33_V26_DF293 / EDC16CP33_V60_DF293

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 184 of 510

13B-184

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$073.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF293

CONTINUED

If none of these checks reveal any faults:

– Replace the water detection sensor.

– Clear the fault.

Start the engine and wait at least 1 minute to confirm the repair.

Note:

When the water level in the fuel filter unit is below the sensor's electrodes, some driving conditions (cornering,

gradients) may result in water being detected (in fact, the sensor's off-centre position in the fuel filter unit, combined

with the driving conditions, causes water to be detected).

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 240 of 510

13B-240

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$074.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF895

PRESENT

OR

STOREDPRESSURE REGULATION ON RAIL1.DEF: Below minimum threshold

2.DEF: Above maximum threshold

3.DEF: Negative loop deviation

4.DEF: Positive loop deviation

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

– the ignition is switched on,

– with the engine running,

– road test.

Priorities when dealing with a number of faults:

– DF898 Pressure regulator circuit on rail,

– DF897 Pressure regulator circuit on pump,

– DF896 Pressure regulation on pump.

Special notes:

DF895 depends on the pressure regulator built into the rail (DRV).

DF896 Pressure regulation on pump depends on the pressure regulator integrated

in the pump (MPROP).

The fuel pressure regulator built into the rail (DRV) and the fuel pressure regulator built

into the pump (MPROP) are never actuated at the same time.

If the fault is present:

– particle filter regeneration is inhibited,

– the engine stops and the level 2 warning light comes on: 1.DEF, 4.DEF,

–the level 1 warning light comes on: 2.DEF, 3.DEF, 4.DEF,

– engine torque limited 2.DEF, 3.DEF, 4.DEF,

– the rail pressure is regulated by a regulator built into the pump (MPROP): 2.DEF,

3.DEF, 4.DEF.

Use bornier Elé.1681 for all operations on the engine management computer.

Use the Wiring Diagram Technical Note, Laguna II ph2, Vel Satis ph2, Espace IV

ph2, Mégane II ph2, Scénic II ph2.

EDC16CP33_V18_DF895 / EDC16CP33_V1C_DF895 / EDC16CP33_V54_DF895 / EDC16CP33_V20_DF895 / EDC16CP33_V58_DF895 /

EDC16CP33_V5C_DF895 / EDC16CP33_V24_DF895 / EDC16CP33_V04_DF895 / EDC16CP33_V08_DF895 / EDC16CP33_V44_DF895 /

EDC16CP33_V4C_DF895 / EDC16CP33_V34_DF895 / EDC16CP33_V38_DF895 / EDC16CP33_V74_DF895 / EDC16CP33_V28_DF895 /

EDC16CP33_V62_DF895 / EDC16CP33_V26_DF895 / EDC16CP33_V60_DF895

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 243 of 510

13B-243

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$074.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF896

PRESENT

OR

STOREDPRESSURE REGULATOR ON PUMP1.DEF: Below minimum threshold

2.DEF: Above maximum threshold

3.DEF: Negative loop deviation

4.DEF: Positive loop deviation

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is declared present after:

– the ignition is switched on.

– engine running.

Priorities when dealing with a number of faults:

– DF897 Pressure regulator circuit on pump

– DF898 Pressure regulator circuit on rail

Special notes:

If the fault is present:

– particle filter regeneration is inhibited,

– the engine stops and the level 2 warning light comes on: 1.DEF,

–the level 1 warning light comes on: 2.DEF, 3.DEF, 4.DEF,

– engine torque is limited: 2.DEF, 3.DEF, 4.DEF,

– the rail pressure is regulated by a regulator built into the rail (DRV): 2.DEF, 3.DEF,

4.DEF.

1.DEF

2.DEF

3.DEF

4.DEF

NOTESNone.

Check that there are no leaks on the high pressure diesel fuel circuit.

Repair if necessary.

Check the level of fuel in the tank.

Check the low pressure circuit using Test 3 Low pressure circuit test and check that there are no exterior air

leaks in the low pressure fuel circuit.

EDC16CP33_V18_DF896 / EDC16CP33_V1C_DF896 / EDC16CP33_V54_DF896 / EDC16CP33_V20_DF896 / EDC16CP33_V58_DF896 /

EDC16CP33_V5C_DF896 / EDC16CP33_V24_DF896 / EDC16CP33_V04_DF896 / EDC16CP33_V08_DF896 / EDC16CP33_V44_DF896 /

EDC16CP33_V4C_DF896 / EDC16CP33_V34_DF896 / EDC16CP33_V38_DF896 / EDC16CP33_V74_DF896 / EDC16CP33_V28_DF896 /

EDC16CP33_V62_DF896 / EDC16CP33_V26_DF896 / EDC16CP33_V60_DF896

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 245 of 510

13B-245

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$074.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DF897

PRESENT

OR

STOREDPUMP PRESSURE REGULATOR CIRCUITCO: Open circuit

CC.0: Short circuit to earth

CC.1: Short circuit to + 12 V

1.DEF: Internal electronic fault

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault reappears after:

– the ignition is switched on,

– the regulator is controlled using command AC226 Pump pressure regulator.

Special notes:

The fuel flow regulator is built into the high pressure pump.

If the fault is present:

– particle filter regeneration is inhibited,

– the quantity of fuel injected is limited and the engine speed is limited to 3000 rpm:

CO, CC.1, 1.DEF,

– regulation with open loop for fuel flow,

–the level 2 warning light comes on: CC.0: engine stop,

–the level 1 warning light comes on: CO, CC.1, 1.DEF,

– pressure is regulated by the pump pressure regulator (MPROP).

Use bornier Elé. 1681 for all operations on the engine management computer

connectors.

Use the Wiring Diagram Technical Note, Laguna II ph2, Vel Satis ph2, Espace IV

ph2, Mégane II ph2, Scénic II ph2.

CO

NOTESNone.

Check the condition of the pressure regulator connector on the pump (MPROP) (see Wiring Diagram Technical

Note, Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 1105).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

EDC16CP33_V18_DF897 / EDC16CP33_V1C_DF897 / EDC16CP33_V54_DF897 / EDC16CP33_V20_DF897 / EDC16CP33_V58_DF897 /

EDC16CP33_V5C_DF897 / EDC16CP33_V24_DF897 / EDC16CP33_V04_DF897 / EDC16CP33_V08_DF897 / EDC16CP33_V44_DF897 /

EDC16CP33_V4C_DF897 / EDC16CP33_V34_DF897 / EDC16CP33_V38_DF897 / EDC16CP33_V74_DF897 / EDC16CP33_V28_DF897 /

EDC16CP33_V62_DF897 / EDC16CP33_V26_DF897/ EDC16CP33_V60_DF897

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74