fuel filter RENAULT SCENIC 2012 J95 / 3.G Engine And Peripherals EDC16CP33 User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2012, Model line: SCENIC, Model: RENAULT SCENIC 2012 J95 / 3.GPages: 510, PDF Size: 2.98 MB

Page 325 of 510

13B-325V12 MR-372-J84-13B300$110.mif

13B

EDC16CP33

Program No.: C4

VDiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

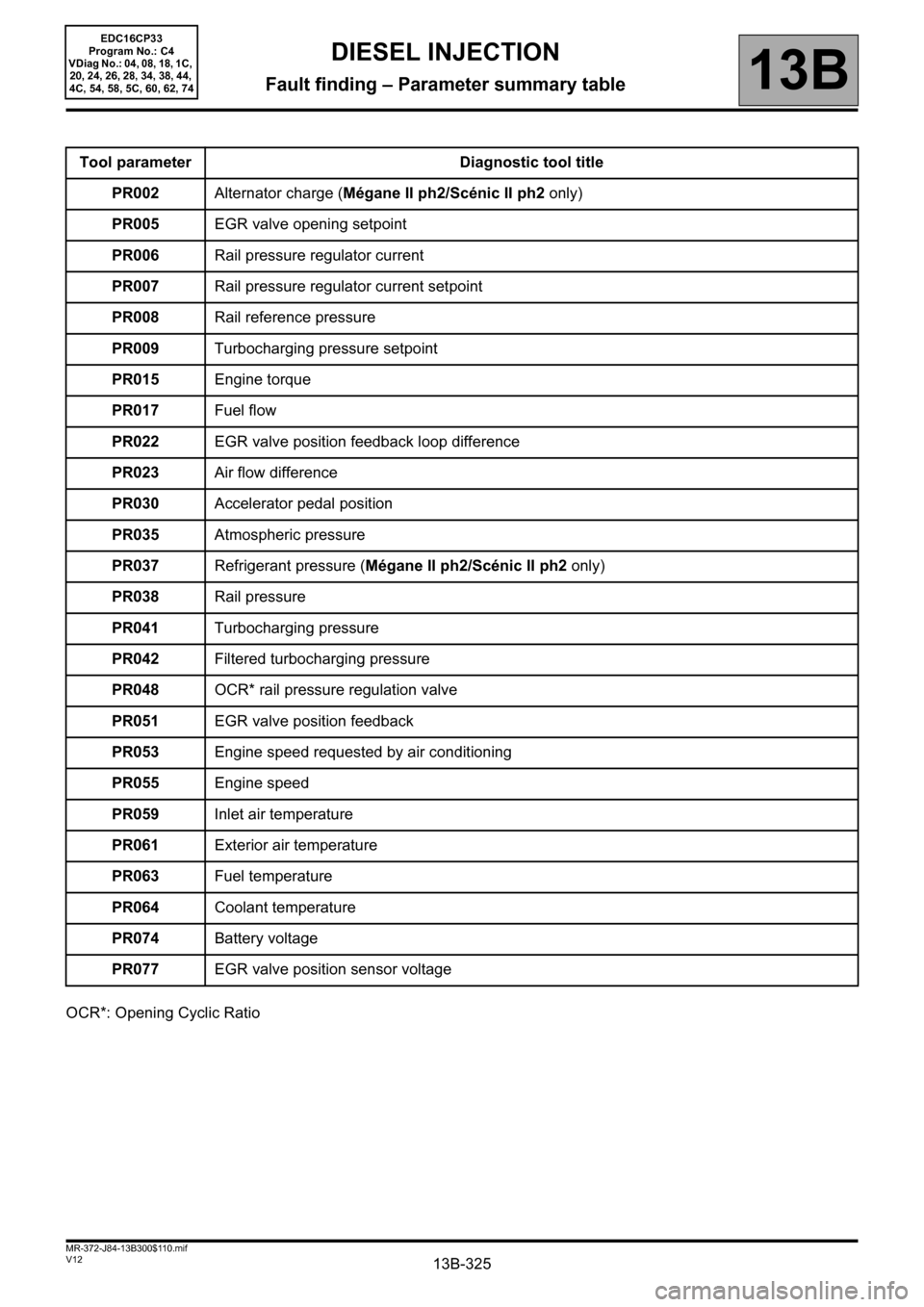

OCR*: Opening Cyclic RatioTool parameter Diagnostic tool title

PR002Alternator charge (Mégane II ph2/Scénic II ph2 only)

PR005EGR valve opening setpoint

PR006Rail pressure regulator current

PR007Rail pressure regulator current setpoint

PR008Rail reference pressure

PR009Turbocharging pressure setpoint

PR015Engine torque

PR017Fuel flow

PR022EGR valve position feedback loop difference

PR023Air flow difference

PR030Accelerator pedal position

PR035Atmospheric pressure

PR037Refrigerant pressure (Mégane II ph2/Scénic II ph2 only)

PR038Rail pressure

PR041Turbocharging pressure

PR042Filtered turbocharging pressure

PR048OCR* rail pressure regulation valve

PR051EGR valve position feedback

PR053Engine speed requested by air conditioning

PR055Engine speed

PR059Inlet air temperature

PR061Exterior air temperature

PR063Fuel temperature

PR064Coolant temperature

PR074Battery voltage

PR077EGR valve position sensor voltage

DIESEL INJECTION

Fault finding – Parameter summary table

Page 326 of 510

13B-326V12 MR-372-J84-13B300$110.mif

DIESEL INJECTION

Fault finding – Parameter summary table13B

EDC16CP33

Program No.: C4

VDiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

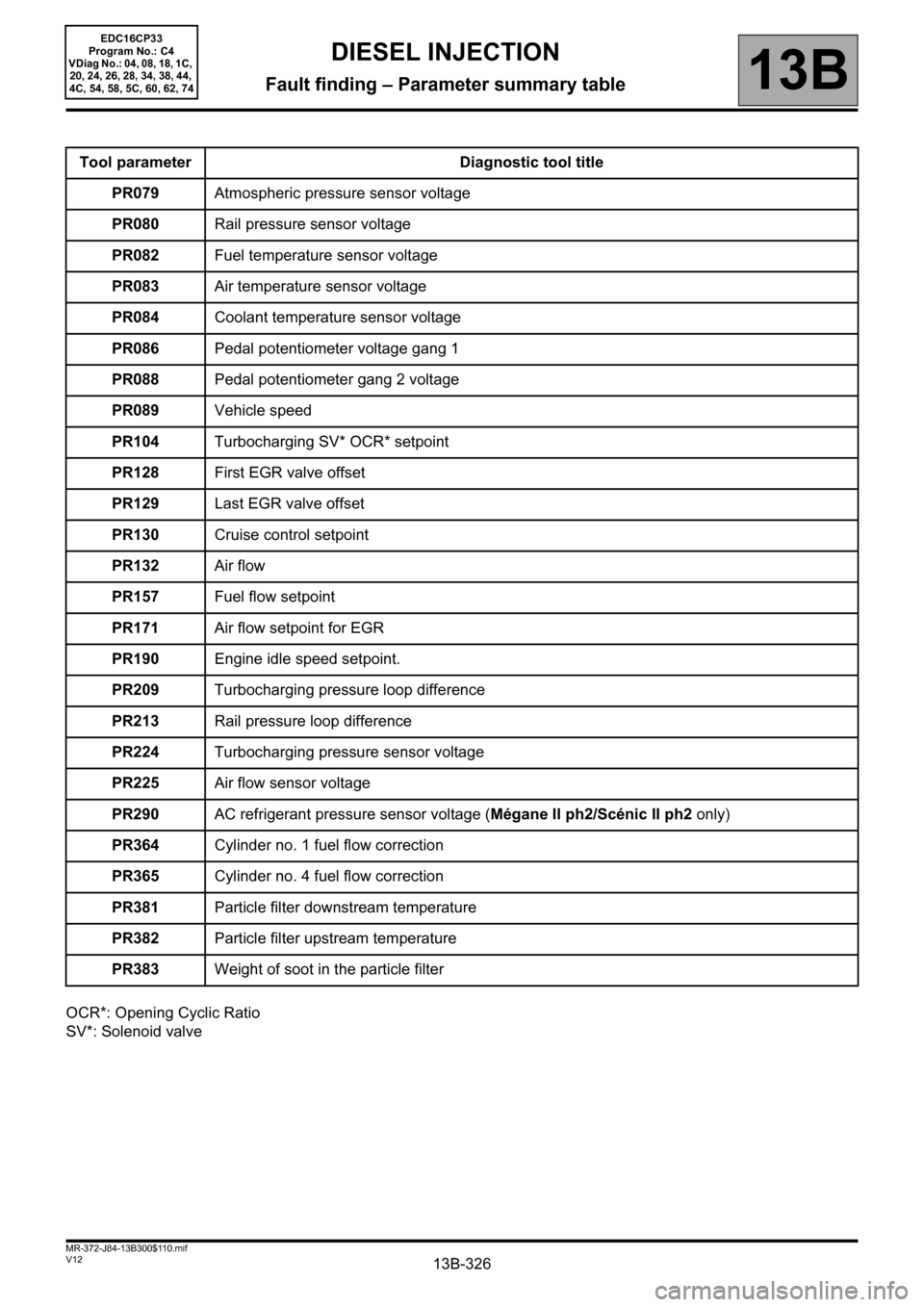

OCR*: Opening Cyclic Ratio

SV*: Solenoid valveTool parameter Diagnostic tool title

PR079Atmospheric pressure sensor voltage

PR080Rail pressure sensor voltage

PR082Fuel temperature sensor voltage

PR083Air temperature sensor voltage

PR084Coolant temperature sensor voltage

PR086Pedal potentiometer voltage gang 1

PR088Pedal potentiometer gang 2 voltage

PR089Vehicle speed

PR104Turbocharging SV* OCR* setpoint

PR128First EGR valve offset

PR129Last EGR valve offset

PR130Cruise control setpoint

PR132Air flow

PR157Fuel flow setpoint

PR171Air flow setpoint for EGR

PR190Engine idle speed setpoint.

PR209Turbocharging pressure loop difference

PR213Rail pressure loop difference

PR224Turbocharging pressure sensor voltage

PR225Air flow sensor voltage

PR290AC refrigerant pressure sensor voltage (Mégane II ph2/Scénic II ph2 only)

PR364Cylinder no. 1 fuel flow correction

PR365Cylinder no. 4 fuel flow correction

PR381Particle filter downstream temperature

PR382Particle filter upstream temperature

PR383Weight of soot in the particle filter

Page 327 of 510

13B-327V12 MR-372-J84-13B300$110.mif

DIESEL INJECTION

Fault finding – Parameter summary table13B

EDC16CP33

Program No.: C4

VDiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

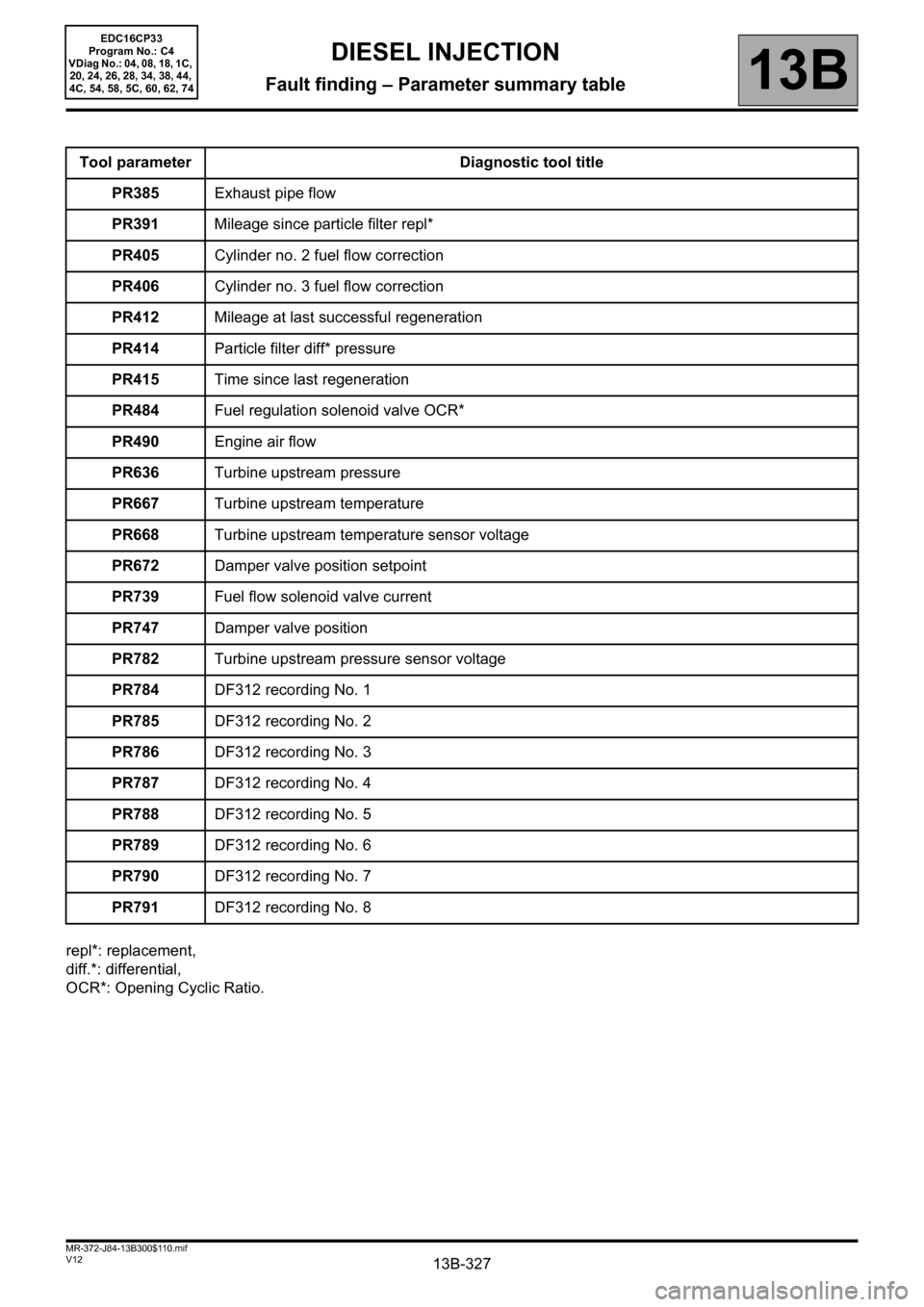

repl*: replacement,

diff.*: differential,

OCR*: Opening Cyclic Ratio.Tool parameter Diagnostic tool title

PR385Exhaust pipe flow

PR391Mileage since particle filter repl*

PR405Cylinder no. 2 fuel flow correction

PR406Cylinder no. 3 fuel flow correction

PR412Mileage at last successful regeneration

PR414Particle filter diff* pressure

PR415Time since last regeneration

PR484Fuel regulation solenoid valve OCR*

PR490Engine air flow

PR636Turbine upstream pressure

PR667Turbine upstream temperature

PR668Turbine upstream temperature sensor voltage

PR672Damper valve position setpoint

PR739Fuel flow solenoid valve current

PR747Damper valve position

PR782Turbine upstream pressure sensor voltage

PR784DF312 recording No. 1

PR785DF312 recording No. 2

PR786DF312 recording No. 3

PR787DF312 recording No. 4

PR788DF312 recording No. 5

PR789DF312 recording No. 6

PR790DF312 recording No. 7

PR791DF312 recording No. 8

Page 422 of 510

13B-422V12 MR-372-J84-13B300$140.mif

13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

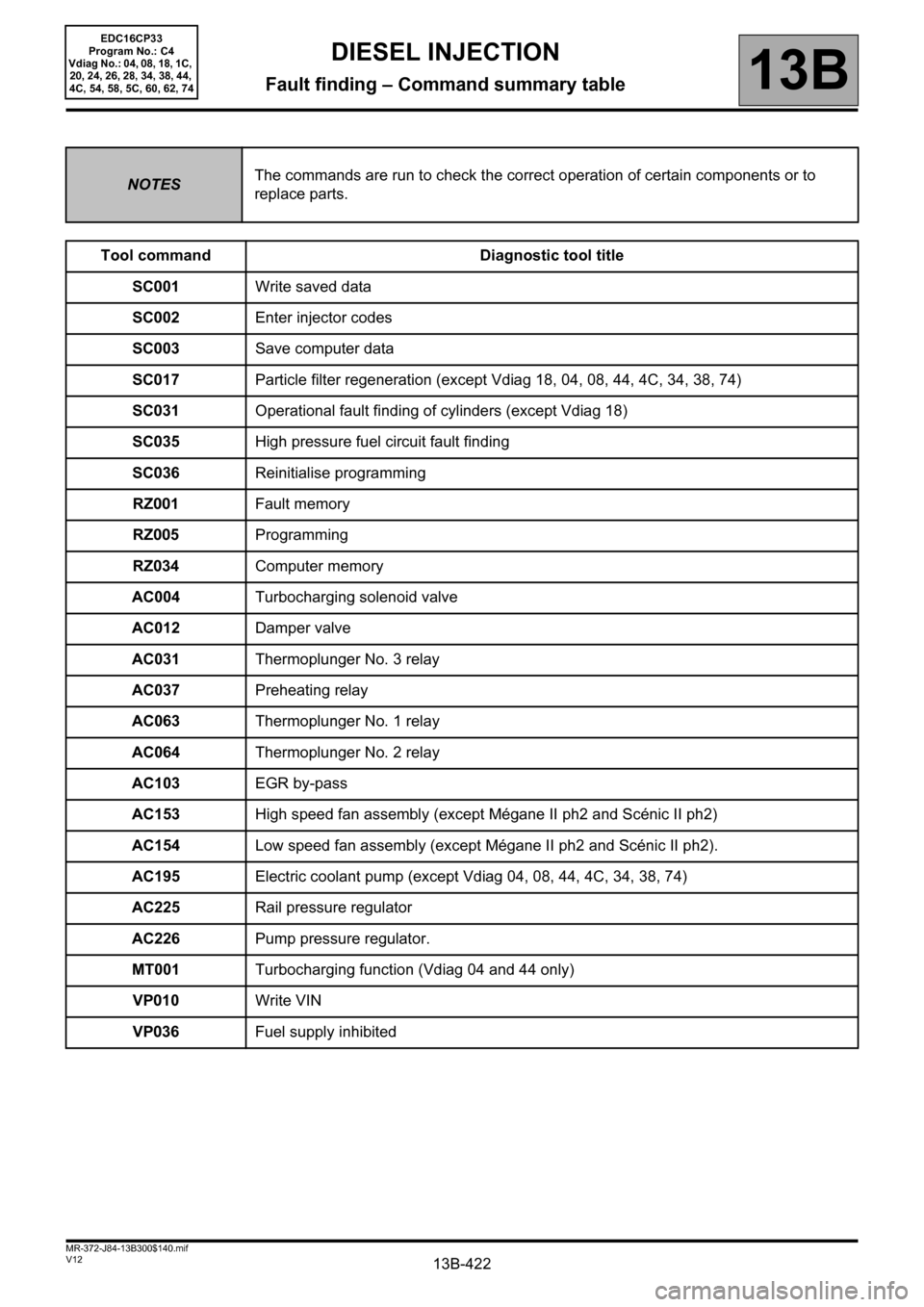

NOTESThe commands are run to check the correct operation of certain components or to

replace parts.

Tool command Diagnostic tool title

SC001Write saved data

SC002Enter injector codes

SC003Save computer data

SC017Particle filter regeneration (except Vdiag 18, 04, 08, 44, 4C, 34, 38, 74)

SC031Operational fault finding of cylinders (except Vdiag 18)

SC035High pressure fuel circuit fault finding

SC036Reinitialise programming

RZ001Fault memory

RZ005Programming

RZ034Computer memory

AC004Turbocharging solenoid valve

AC012Damper valve

AC031Thermoplunger No. 3 relay

AC037Preheating relay

AC063Thermoplunger No. 1 relay

AC064Thermoplunger No. 2 relay

AC103EGR by-pass

AC153High speed fan assembly (except Mégane II ph2 and Scénic II ph2)

AC154Low speed fan assembly (except Mégane II ph2 and Scénic II ph2).

AC195Electric coolant pump (except Vdiag 04, 08, 44, 4C, 34, 38, 74)

AC225Rail pressure regulator

AC226Pump pressure regulator.

MT001Turbocharging function (Vdiag 04 and 44 only)

VP010Write VIN

VP036Fuel supply inhibited

DIESEL INJECTION

Fault finding – Command summary table

Page 434 of 510

13B-434V12 MR-372-J84-13B300$150.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

SC035

CONTINUED 1

Interpretation of incorrect results:

– Is one of the value definitions for the various displayed stages is “TOO SLOW” or “TOO FAST”, see the

following table:

STEP X

(X is the variable

from 1 to 4)Rail pressure Raise

timeRail pressure Dump

timeInterpretation of

results

STEP X TOO SLOW TOO SLOW Check 1

STEP X TOO SLOW TOO FAST Check 2

STEP X TOO SLOW OK Check 3

STEP X OK TOO SLOW Check 4

STEP X OK TOO FAST Check 5

STEP 5 TOO FAST Check 5

Explanation of results interpretation:

Check 1:

–Apply Test 10 Poor injector operation.

–Apply ALP6 Fuel circuit leaks.

–Apply Test 3 Low pressure circuit check.

– Replace the high pressure pump.

Check 2:

–Apply Test 10.

–Apply ALP6.

– Apply the part of Test 3 concerning the fuel filter.

– Replace the high pressure pump.

– Check the injector return flow and the injectors.

– Check the rail pressure regulator by running command AC225 Rail pressure regulator.

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 456 of 510

13B-456V12 MR-372-J84-13B300$150.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

AC225

CONTINUED

STEP 2

In the event of rail overpressure:

Check that there are no air bubbles in the diesel fuel low pressure circuit.

Check that the rail pressure sensor is working, and then interpret parameter PR038 Rail pressure.

If these checks do not reveal any faults, replace the rail regulator.

in the event of rail underpressure:

Check the correct operation of the rail pressure sensor, as well as the interpretation of parameter PR038.

Check the low pressure diesel circuit priming.

Check the conformity of the diesel filter connections.

Check the condition of the filter (clogging and water saturation).

Check that there are no air bubbles between the filter and the high pressure pump.

Check the sealing of the low and high pressure diesel fuel systems: use ALP6 Fuel circuit leaks (visual

inspections, touch tests, odours, etc.) on:

pump body, pressure release valve, pipes, rail and injectors unions, injector wells, etc.

Check the conformity of the seal fitting on the pressure regulator.

Check the operation of the injectors: run Test 10 Incorrect injector operation.

Carry out the necessary repairs.

If the engine starts:

Clear any faults.

Check the rail pressure regulator using ALP7 Rough idling.

With the engine warm, leave it to idle for a few minutes (3 to 5 minutes):

– If it stalls and the fault reappears, replace the rail pressure regulator.

– If it does not stall, stabilise the engine speed at 2000 rpm (1 minute) then depress the accelerator fully until the

maximum engine speed imposed by the computer is obtained (~5500 rpm). The maximum rotation speed of the

engine must be stabilised in the time taken to fully depress and then fully release the pedal. This test is carried

out with no load (engine in neutral).

– If the engine stalls, contact the Techline

If the engine does not start or there is no timing, first replace the rail pressure regulator.

If the fault is still present, contact the Techline

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 458 of 510

13B-458V12 MR-372-J84-13B300$150.mif

DIESEL INJECTION

Fault finding – Interpretation of commands13B

AC226

CONTINUED

STEP 2

In the event of rail overpressure:

Check that there are no air bubbles in the diesel fuel low pressure circuit.

Check that the rail pressure sensor is working, and then interpret parameter PR038 Rail pressure.

If these checks do not reveal any faults, replace the pump regulator.

in the event of rail underpressure:

Check the correct operation of the rail pressure sensor, as well as the interpretation of parameter PR038.

Check the low pressure diesel circuit priming.

Check the conformity of the diesel filter connections.

Check the condition of the filter (clogging and water saturation).

Check that there are no air bubbles between the filter and the high pressure pump.

Check the sealing of the low and high pressure diesel fuel systems: use ALP6 Fuel circuit leaks (visual

inspections, touch tests, odours, etc.) on:

pump body, pressure release valve, pipes, rail and injectors unions, injector wells, etc.

Check the conformity of the seal fitting on the pressure regulator.

Check the operation of the injectors: run Test 10 Poor injector operation in this document.

Carry out the necessary repairs.

If the engine starts:

Clear any faults.

Check the pump pressure regulator by applying (see ALP 7 Rough idle).

With the engine warm, leave it to idle for a few minutes (3 to 5 minutes):

– If it stalls and the fault reappears, replace the pump regulator.

– If the engine does not stall, stabilise the engine speed at 2000 rpm (1 minute) then depress the accelerator

pedal fully until the maximum engine speed imposed by the computer is obtained (~5500 rpm). The maximum

rotation speed of the engine must be stabilised in the time taken to fully depress and then fully release the pedal.

This test is carried out with no load (engine in neutral).

– If the engine stalls, contact the Techline

If the engine does not start or does not stall, first replace the pump regulator.

If the fault is still present, contact the techline.

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 469 of 510

13B-469

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$160.mif

13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

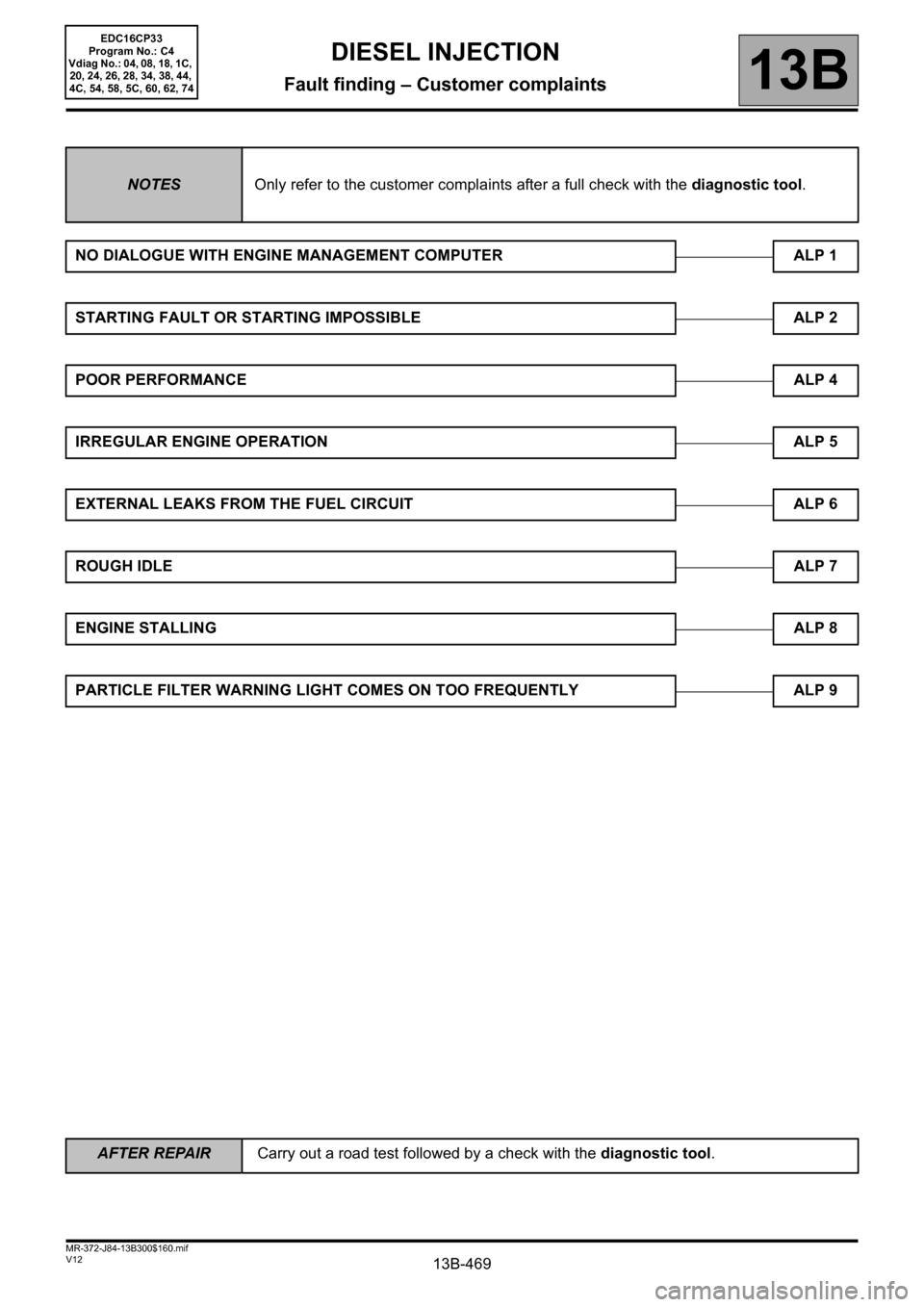

NOTESOnly refer to the customer complaints after a full check with the diagnostic tool.

NO DIALOGUE WITH ENGINE MANAGEMENT COMPUTER ALP 1

STARTING FAULT OR STARTING IMPOSSIBLE ALP 2

POOR PERFORMANCEALP 4

IRREGULAR ENGINE OPERATION ALP 5

EXTERNAL LEAKS FROM THE FUEL CIRCUIT ALP 6

ROUGH IDLEALP 7

ENGINE STALLINGALP 8

PARTICLE FILTER WARNING LIGHT COMES ON TOO FREQUENTLY ALP 9

DIESEL INJECTION

Fault finding – Customer complaints

Page 475 of 510

13B-475

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V12 MR-372-J84-13B300$170.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

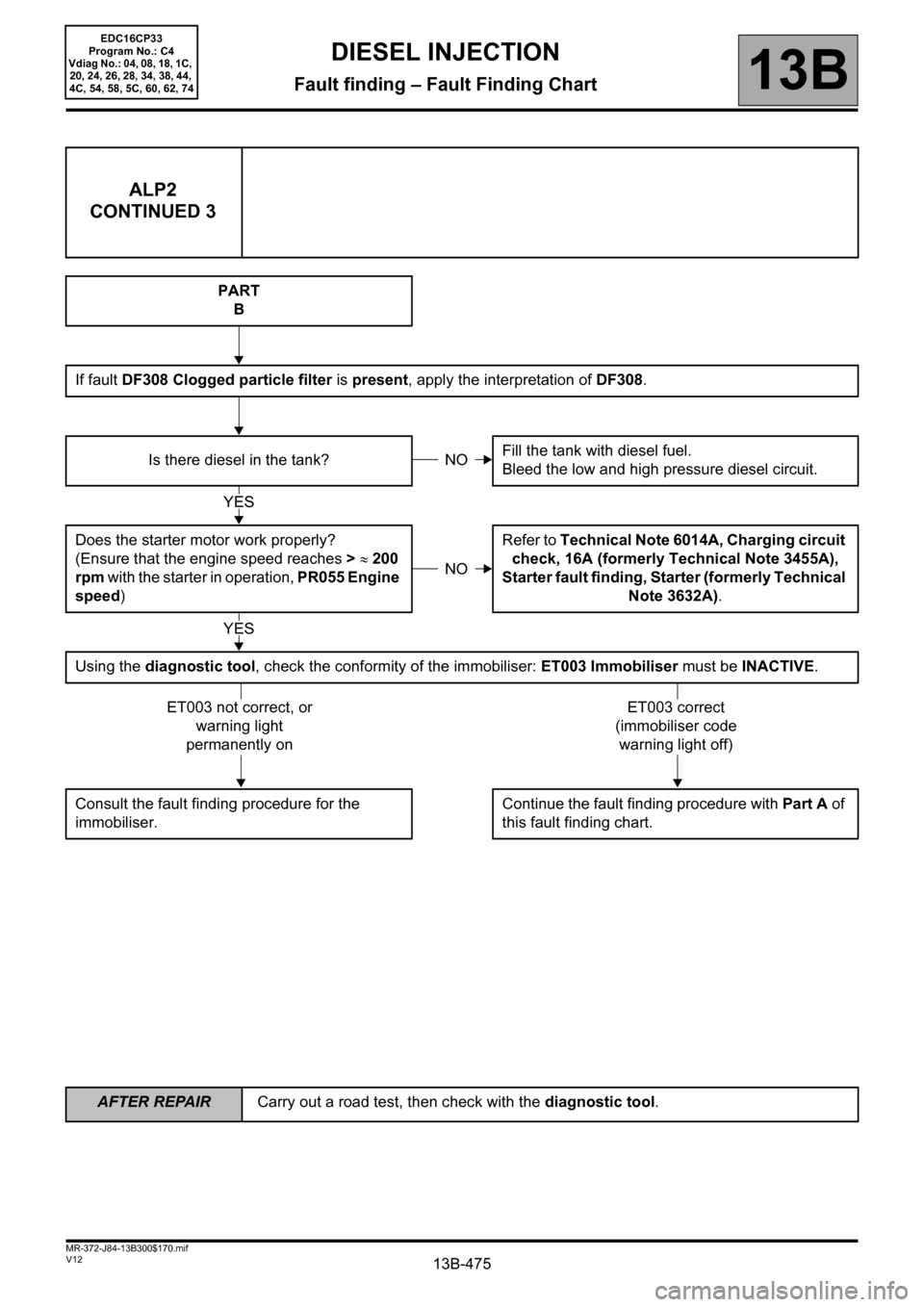

ALP2

CONTINUED 3

PART

B

If fault DF308 Clogged particle filter is present, apply the interpretation of DF308.

Is there diesel in the tank?Fill the tank with diesel fuel.

Bleed the low and high pressure diesel circuit.

Does the starter motor work properly?

(Ensure that the engine speed reaches > ≈ 200

rpm with the starter in operation, PR055 Engine

speed)Refer to Technical Note 6014A, Charging circuit

check, 16A (formerly Technical Note 3455A),

Starter fault finding, Starter (formerly Technical

Note 3632A).

Using the diagnostic tool, check the conformity of the immobiliser: ET003 Immobiliser must be INACTIVE.

Consult the fault finding procedure for the

immobiliser.Continue the fault finding procedure with Part A of

this fault finding chart.

NO

YES

NO

YES

ET003 not correct, or

warning light

permanently onET003 correct

(immobiliser code

warning light off)

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

Page 477 of 510

13B-477

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

V12 MR-372-J84-13B300$170.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

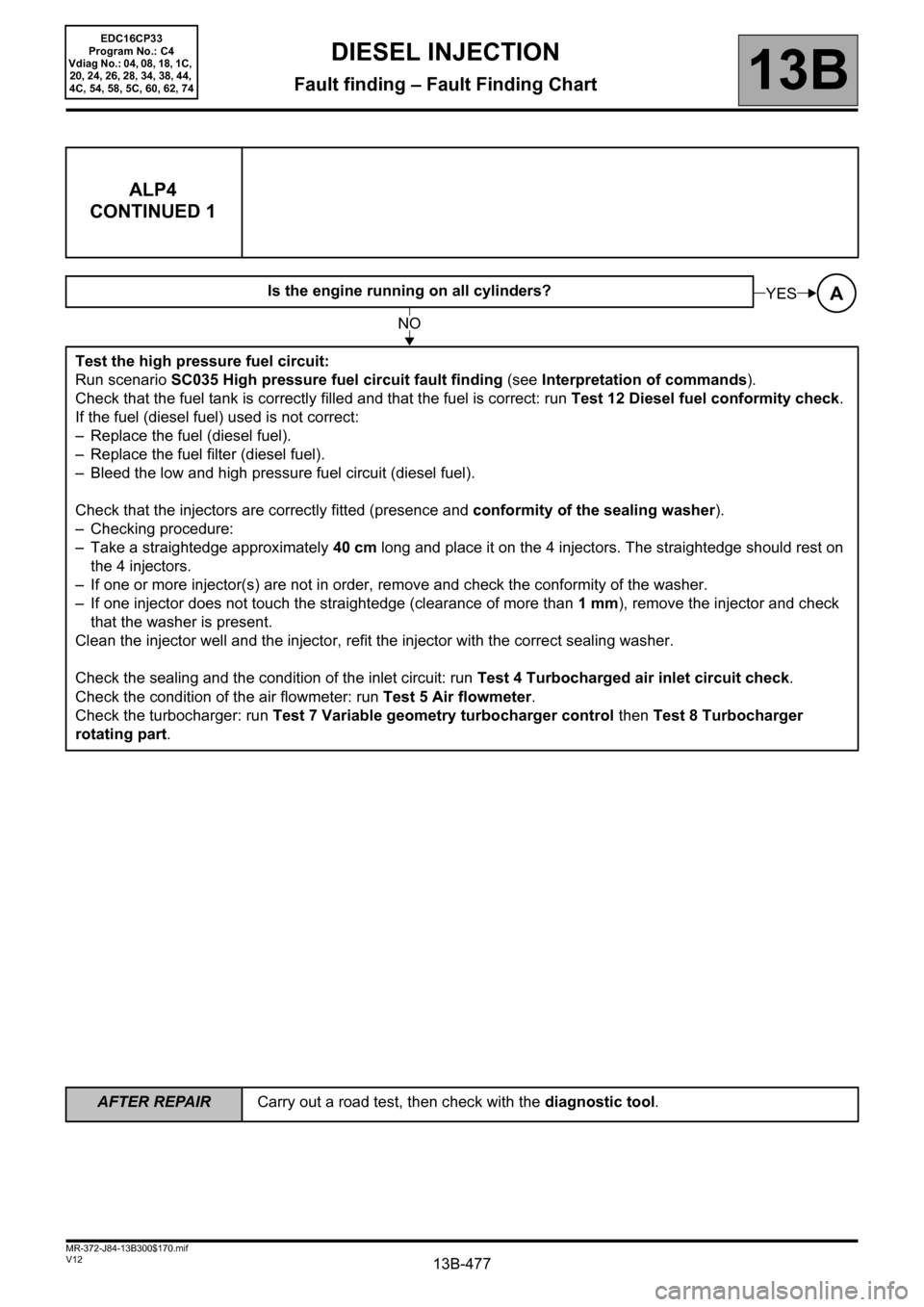

ALP4

CONTINUED 1

Is the engine running on all cylinders?

Test the high pressure fuel circuit:

Run scenario SC035 High pressure fuel circuit fault finding (see Interpretation of commands).

Check that the fuel tank is correctly filled and that the fuel is correct: run Test 12 Diesel fuel conformity check.

If the fuel (diesel fuel) used is not correct:

– Replace the fuel (diesel fuel).

– Replace the fuel filter (diesel fuel).

– Bleed the low and high pressure fuel circuit (diesel fuel).

Check that the injectors are correctly fitted (presence and conformity of the sealing washer).

– Checking procedure:

– Take a straightedge approximately 40 cm long and place it on the 4 injectors. The straightedge should rest on

the 4 injectors.

– If one or more injector(s) are not in order, remove and check the conformity of the washer.

– If one injector does not touch the straightedge (clearance of more than 1mm), remove the injector and check

that the washer is present.

Clean the injector well and the injector, refit the injector with the correct sealing washer.

Check the sealing and the condition of the inlet circuit: run Test 4 Turbocharged air inlet circuit check.

Check the condition of the air flowmeter: run Test 5 Air flowmeter.

Check the turbocharger: run Test 7 Variable geometry turbocharger control then Test 8 Turbocharger

rotating part.AYES

NO

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74