heater RENAULT SCENIC 2012 J95 / 3.G Engine And Peripherals EDC16CP33 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2012, Model line: SCENIC, Model: RENAULT SCENIC 2012 J95 / 3.GPages: 510, PDF Size: 2.98 MB

Page 18 of 510

13B-18V12 MR-372-J84-13B300$030.mif

DIESEL INJECTION

Fault finding – System operation13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

VI - Pre-postheating actuation

Pre/postheating control involves actuating the heater plugs and the preheating indicator light on the instrument

panel (multiplex signal).

The heater plugs are actuated by a static relay.

After the ignition is switched on, a preheating delay is activated. The length of time that the warning light is lit

depends on the coolant temperature, air temperature, atmospheric pressure and battery voltage. When the coolant

temperature is below a certain threshold, a postheating function can be used to improve the combustion stability,

and consequently engine operation (reducing unburnt particles and pollutant emissions). Postheating can last up

to5 minutes.

IMPORTANT:

There are two types of heater plug: SLOW and FAST:

SLOW plugs are identified by a black ring.

FAST plugs are identified by a white ring.

The heater plugs fitted on the vehicle must be replaced with plugs of the same type; otherwise there is

a risk of the heater plugs deteriorating which could lead to engine destruction.

Only Vdiag 20, 24, 38 and 74:

when replacing heater plugs with plugs which differ from those currently fitted on the vehicle (replacement of

SLOW plugs with FAST plugs), the computer must be configured (see Replacement of components, Replacing

heater plugs) by running command SC036 Reinitialise programming and selecting Heater plugs if this choice

is available, then following the procedure.

Page 22 of 510

13B-22V12 MR-372-J84-13B300$050.mif

13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

COMPUTER REPLACEMENT OR REPROGRAMMING

Two operations must be performed when replacing or reprogramming the computer:

SC003 Save computer data and SC001 Enter saved data.

–Run SC003 before replacing or reprogramming the computer. This enables certain data to be saved in the

diagnostic tool so that the new computer* can be reconfigured like the old one. The saved data includes: injector

codes, EGR programming, specific data for particle filter operation and vehicle options.

–Run SC001 after replacing or reprogramming the computer. It enables you to rewrite the data (saved by

command SC003) to the new computer*.

Only Vdiag 20, 24, 38 and 74:

–Run SC036 Reinitialise programming and select Heater plugs (see Interpretation of commands); this will allow

you to configure the correct type of heater plugs fitted on the vehicle, if necessary.

If you cannot establish dialogue with the computer being replaced: you will not be able to save anything. After

replacing the computer:

– Write the IMA codes for each injector manually by reading the code on each injector; run command SC002 Enter

injector codes.

– Check the exhaust pipe for leaks or blockage. Repair if necessary.

– Perform an After-Sales regeneration, follow the procedure for command SC017 Particle filter regeneration (see

Interpretation of commands).

– It is essential to change the engine oil and oil filter.

– Enter the data specific to particle filter operation by running SC036 Reinitialise programming and selecting after

replacing injection computer with no save option.

– Enter the VIN into the computer, use command VP010 Enter VIN.

–Only for Vdiag 20, 24, 38 and 74: Configure the type of heater plugs fitted on the vehicle by running SC036

Reinitialise programming and selecting Heater plugs (see Interpretation of commands).

Exhaust gas recirculation valve data is programmed automatically the 1st time the new computer is turned on*.

* New computer or reprogrammed computer.

IMA*: Individual injector correctionOperations to be carried out before the injection computer is reprogrammed:

Before reprogramming the injection computer, move the main cruise control/speed limiter switch to the rest

position. The information about the cruise control or the speed limiter displayed on the instrument panel

disappears.

Otherwise, if the main switch remains in the cruise control or speed limiter position during and after reprogramming,

the cruise control/speed limiter function will not be operational.

The procedure for resetting the function is as follows:

Vehicle ignition on.

• Position the cruise control/speed limiter switch in the rest position (the computer detects the rest position at that

moment).

• Position the cruise control/speed limiter switch in the Cruise control position to activate the cruise control

function.

• Position the cruise control/speed limiter switch in the Speed limiter position to activate the speed limiter function.

DIESEL INJECTION

Fault finding – Replacement of components

Page 23 of 510

13B-23V12 MR-372-J84-13B300$050.mif

DIESEL INJECTION

Fault finding – Replacement of components13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

PROCEDURE

• Before replacing or reprogramming the computer:

–Select SC003 Save computer data,

– if the following message appears: there is a saved file; do you want to overwrite this data?: (this file

corresponds to the last save carried out on the tool)

–Select YES,

When the save has been performed, replace the computer or carry out the programming then proceed to the next

step.

• After replacing or reprogramming the computer:

Select SC001 Write saved data.

Follow the instructions,

– When the command is finished, switch off the ignition, wait for the message to appear on the diagnostic tool

(maximum time 8 minutes): Loss of dialogue with the computer: EDC16 CP33, check the connection of the

tool and the computer supply.

– Switch on the ignition again and use command VP010 Enter VIN if the VIN has been cleared.

–Only Vdiag 20, 24, 38 and 74: Establish communication and run SC036 Reinitialise programming and select

Heater plugs (see Interpretation of commands), this will allow you to configure the correct type of heater plugs

fitted on the vehicle, if necessary.

– For all Vdiags, clear the fault memory.

– End of procedure.

Page 27 of 510

13B-27V12 MR-372-J84-13B300$050.mif

DIESEL INJECTION

Fault finding – Replacement of components13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

REPLACING THE DAMPER VALVE

After replacing the damper valve, run command SC036 Reinitialise programming and select damper valve.

When the command is complete, switch off the ignition and exit fault finding mode.

Wait for the diagnostic tool message (maximum wait 8 minutes): Loss of dialogue with the computer: EDC16

CP33, check the tool connection and the computer supply before switching the ignition back on.

REPLACING THE PARTICLE FILTER (Vdiag: 18, 1C, 54, 20, 58, 5C, 24, 26, 28, 60 and 62 only)

After replacing the particle filter, reconfigure the computer.

The system must be configured via the diagnostic socket using the RENAULT CLIP tool.

Carry out the following steps:

– switch on the ignition,

– run command SC036,

–select After particle filter replacement as the operation type and follow the instructions,

–switch off the ignition and wait for the diagnostic tool message (maximum wait 8 minutes): Loss of dialogue

with the computer: EDC16 CP33, check the tool connection and the computer supply voltage,

– then switch on the ignition again,

–clear the faults from the computer memory (this operation must be carried out within 3 minutes of the ignition

being switched on)

Carry out a road test followed by a complete check with the diagnostic tool.

REPLACING THE HEATER PLUGS (Vdiag 20, 24, 38 and 74 only)

SLOW plugs are identified by a black ring.

FAST plugs are identified by a white ring.

After replacing the heater plugs with plugs of a different type, reconfigure the type of plugs fitted on the vehicle.

Carry out the following steps:

– switch on the ignition,

– run command SC036 Reinitialise programming,

–select Heater plugs as the operation type and follow the instructions,

–switch off the ignition and wait for the diagnostic tool message (maximum wait 8 minutes): Loss of dialogue

with the computer: EDC16 CP33, check the tool connection and the computer supply voltage,

– then switch on the ignition again,

– clear the faults from the computer memory.

Carry out a road test followed by a complete check with the diagnostic tool. Note:

When reinitialisation is complete, the Emission control / EOBD (European On Board Diagnostic) sub-function

displays:

PR858

≠ 0%, PR859 ≠ 0%, PR860 ≠ 0% and PR861 ≠ 0%.

Page 30 of 510

13B-30V12 MR-372-J84-13B300$060.mif

DIESEL INJECTION

Fault finding – Fault summary table13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

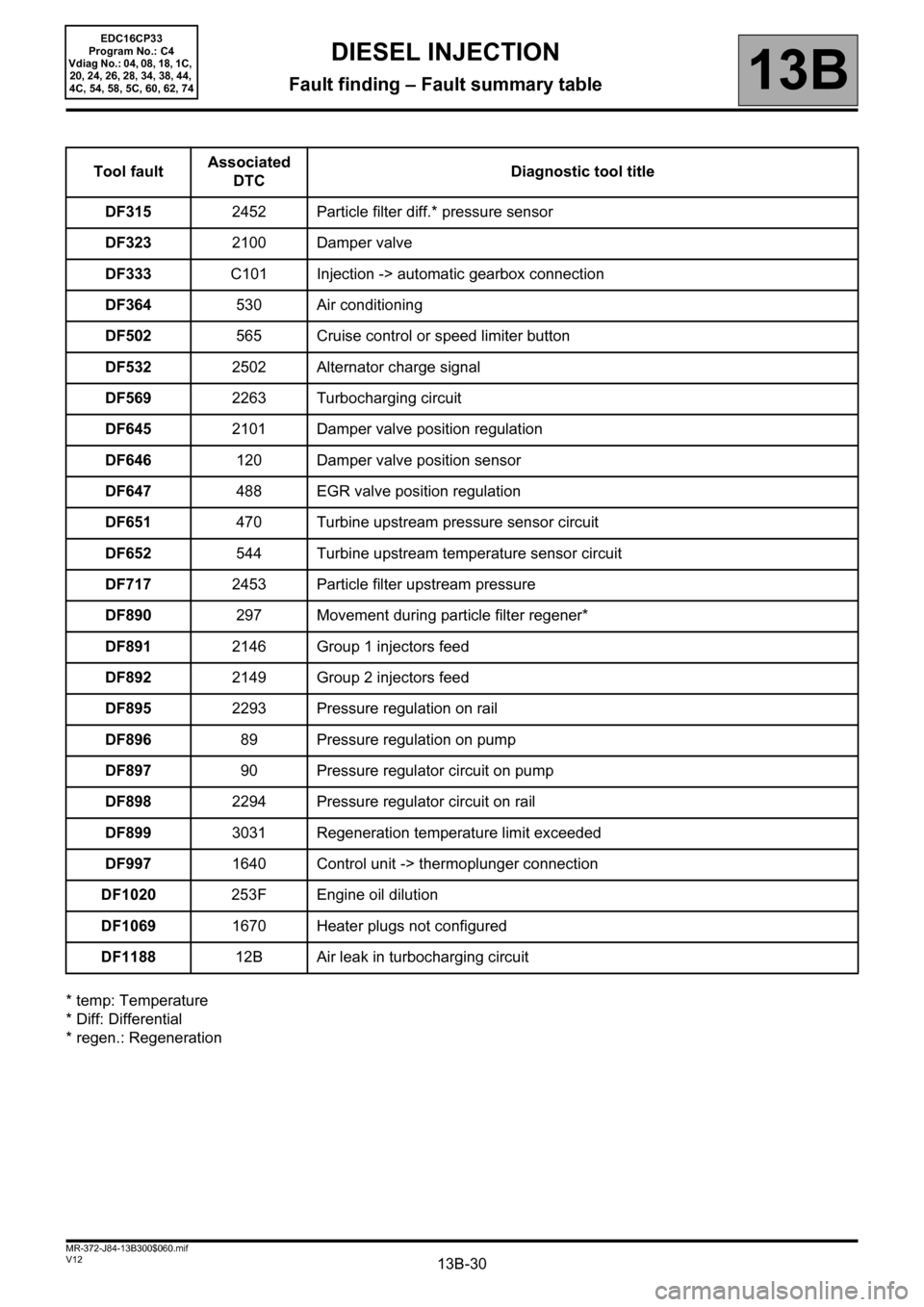

* temp: Temperature

* Diff: Differential

* regen.: RegenerationTool faultAssociated

DTCDiagnostic tool title

DF3152452 Particle filter diff.* pressure sensor

DF3232100 Damper valve

DF333C101 Injection -> automatic gearbox connection

DF364530 Air conditioning

DF502565 Cruise control or speed limiter button

DF5322502 Alternator charge signal

DF5692263 Turbocharging circuit

DF6452101 Damper valve position regulation

DF646120 Damper valve position sensor

DF647488 EGR valve position regulation

DF651470 Turbine upstream pressure sensor circuit

DF652544 Turbine upstream temperature sensor circuit

DF7172453 Particle filter upstream pressure

DF890297 Movement during particle filter regener*

DF8912146 Group 1 injectors feed

DF8922149 Group 2 injectors feed

DF8952293 Pressure regulation on rail

DF89689 Pressure regulation on pump

DF89790 Pressure regulator circuit on pump

DF8982294 Pressure regulator circuit on rail

DF8993031 Regeneration temperature limit exceeded

DF9971640 Control unit -> thermoplunger connection

DF1020253F Engine oil dilution

DF10691670 Heater plugs not configured

DF118812B Air leak in turbocharging circuit

Page 67 of 510

13B-67

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$071.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

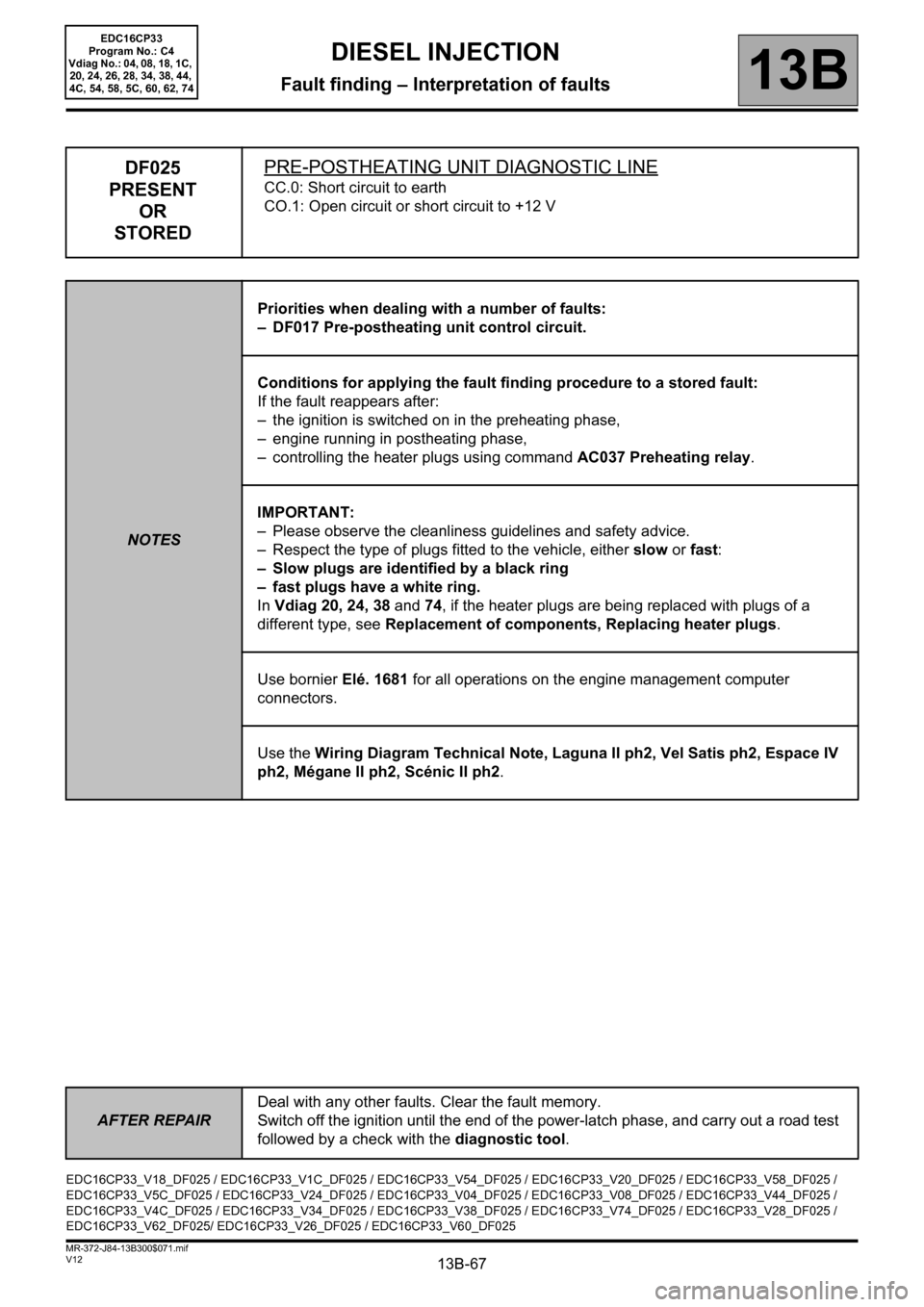

DF025

PRESENT

OR

STOREDPRE-POSTHEATING UNIT DIAGNOSTIC LINE

CC.0: Short circuit to earth

CO.1: Open circuit or short circuit to +12 V

NOTESPriorities when dealing with a number of faults:

– DF017 Pre-postheating unit control circuit.

Conditions for applying the fault finding procedure to a stored fault:

If the fault reappears after:

– the ignition is switched on in the preheating phase,

– engine running in postheating phase,

– controlling the heater plugs using command AC037 Preheating relay.

IMPORTANT:

– Please observe the cleanliness guidelines and safety advice.

– Respect the type of plugs fitted to the vehicle, either slow or fast:

– Slow plugs are identified by a black ring

– fast plugs have a white ring.

In Vdiag 20, 24, 38 and 74, if the heater plugs are being replaced with plugs of a

different type, see Replacement of components, Replacing heater plugs.

Use bornier Elé. 1681 for all operations on the engine management computer

connectors.

Use the Wiring Diagram Technical Note, Laguna II ph2, Vel Satis ph2, Espace IV

ph2, Mégane II ph2, Scénic II ph2.

EDC16CP33_V18_DF025 / EDC16CP33_V1C_DF025 / EDC16CP33_V54_DF025 / EDC16CP33_V20_DF025 / EDC16CP33_V58_DF025 /

EDC16CP33_V5C_DF025 / EDC16CP33_V24_DF025 / EDC16CP33_V04_DF025 / EDC16CP33_V08_DF025 / EDC16CP33_V44_DF025 /

EDC16CP33_V4C_DF025 / EDC16CP33_V34_DF025 / EDC16CP33_V38_DF025 / EDC16CP33_V74_DF025 / EDC16CP33_V28_DF025 /

EDC16CP33_V62_DF025/ EDC16CP33_V26_DF025 / EDC16CP33_V60_DF025

Page 68 of 510

13B-68

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$071.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

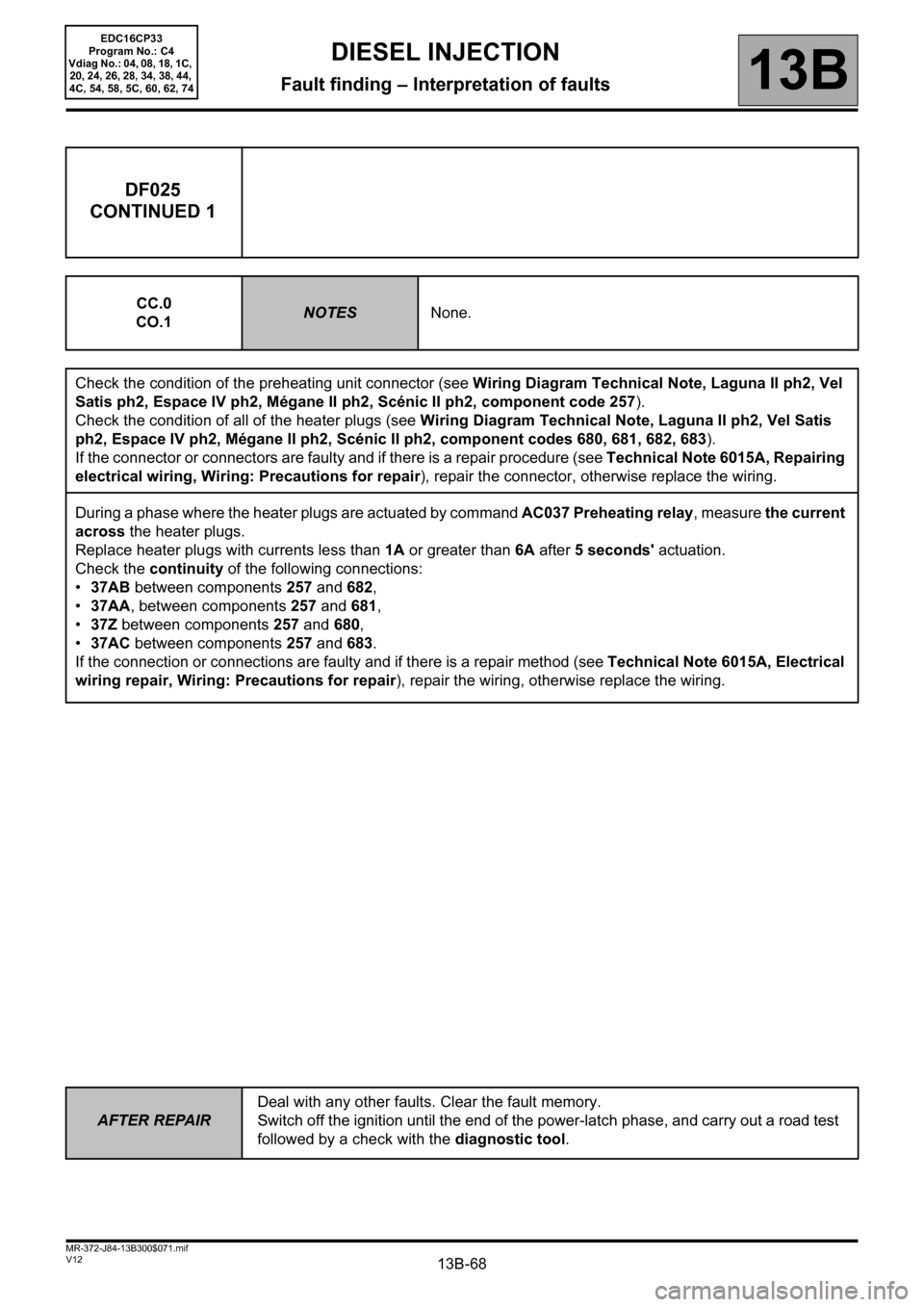

DF025

CONTINUED 1

CC.0

CO.1NOTESNone.

Check the condition of the preheating unit connector (see Wiring Diagram Technical Note, Laguna II ph2, Vel

Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 257).

Check the condition of all of the heater plugs (see Wiring Diagram Technical Note, Laguna II ph2, Vel Satis

ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component codes 680, 681, 682, 683).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

During a phase where the heater plugs are actuated by command AC037 Preheating relay, measure the current

across the heater plugs.

Replace heater plugs with currents less than 1A or greater than 6A after 5 seconds' actuation.

Check the continuity of the following connections:

•37AB between components 257 and 682,

•37AA, between components 257 and 681,

•37Z between components 257 and 680,

•37AC between components 257 and 683.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Page 90 of 510

13B-90

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$071.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

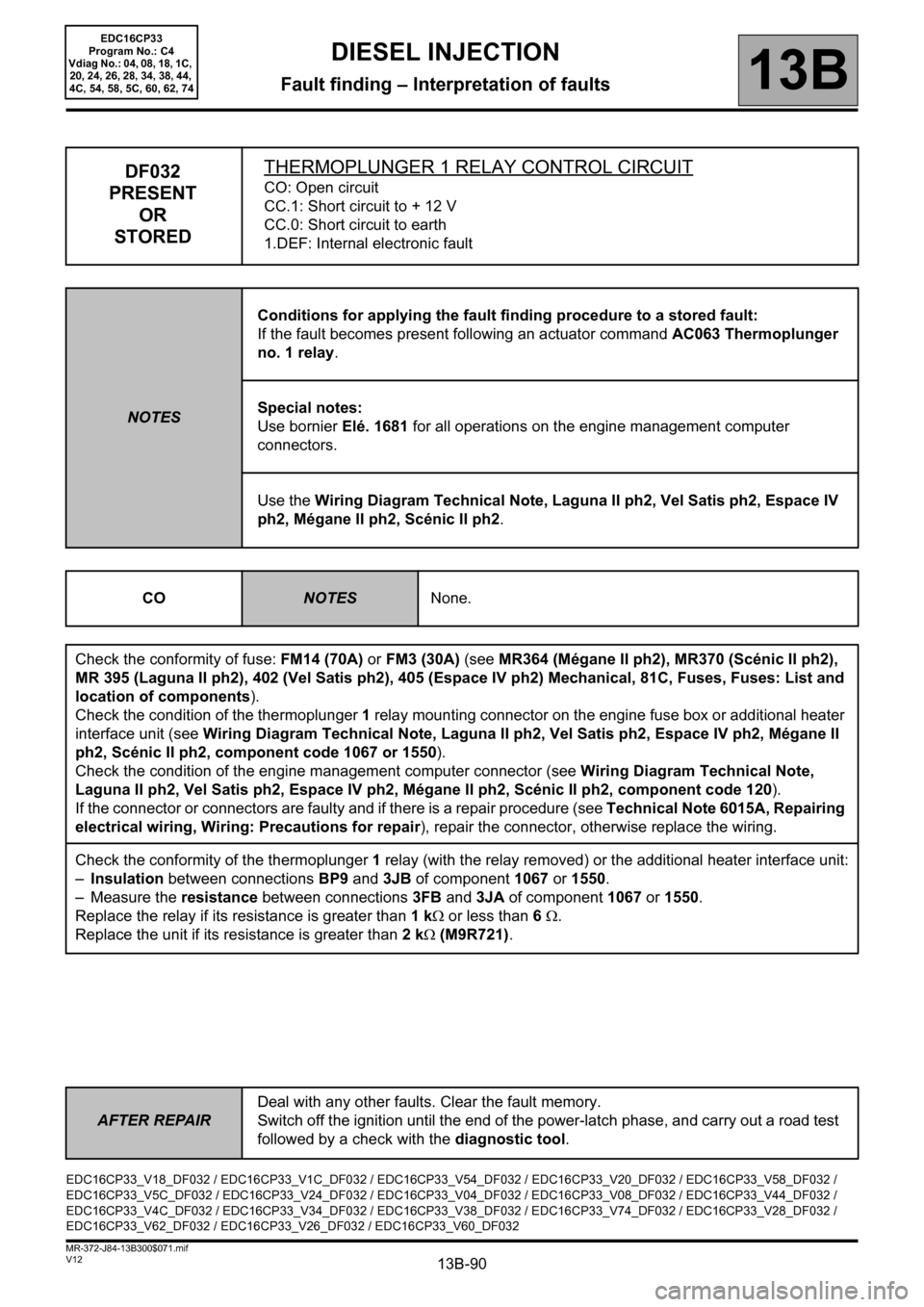

DF032

PRESENT

OR

STOREDTHERMOPLUNGER 1 RELAY CONTROL CIRCUITCO: Open circuit

CC.1: Short circuit to + 12 V

CC.0: Short circuit to earth

1.DEF: Internal electronic fault

NOTESConditions for applying the fault finding procedure to a stored fault:

If the fault becomes present following an actuator command AC063 Thermoplunger

no. 1 relay.

Special notes:

Use bornier Elé. 1681 for all operations on the engine management computer

connectors.

Use the Wiring Diagram Technical Note, Laguna II ph2, Vel Satis ph2, Espace IV

ph2, Mégane II ph2, Scénic II ph2.

CO

NOTESNone.

Check the conformity of fuse: FM14 (70A) or FM3 (30A) (see MR364 (Mégane II ph2), MR370 (Scénic II ph2),

MR 395 (Laguna II ph2), 402 (Vel Satis ph2), 405 (Espace IV ph2) Mechanical, 81C, Fuses, Fuses: List and

location of components).

Check the condition of the thermoplunger 1 relay mounting connector on the engine fuse box or additional heater

interface unit (see Wiring Diagram Technical Note, Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II

ph2, Scénic II ph2, component code 1067 or 1550).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the conformity of the thermoplunger 1 relay (with the relay removed) or the additional heater interface unit:

–Insulation between connections BP9 and 3JB of component 1067 or 1550.

– Measure the resistance between connections3FB and 3JA of component1067 or 1550.

Replace the relay if its resistance is greater than 1 kΩ or less than 6 Ω.

Replace the unit if its resistance is greater than 2 kΩ (M9R721).

EDC16CP33_V18_DF032 / EDC16CP33_V1C_DF032 / EDC16CP33_V54_DF032 / EDC16CP33_V20_DF032 / EDC16CP33_V58_DF032 /

EDC16CP33_V5C_DF032 / EDC16CP33_V24_DF032 / EDC16CP33_V04_DF032 / EDC16CP33_V08_DF032 / EDC16CP33_V44_DF032 /

EDC16CP33_V4C_DF032 / EDC16CP33_V34_DF032 / EDC16CP33_V38_DF032 / EDC16CP33_V74_DF032 / EDC16CP33_V28_DF032 /

EDC16CP33_V62_DF032 / EDC16CP33_V26_DF032 / EDC16CP33_V60_DF032

Page 91 of 510

13B-91

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$071.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

DF032

CONTINUED 1

Check the continuity of the following connection:

•3JA between components 120 and 1067 or 1550.

Check the + 12 V after relay supply to the thermoplunger 1 relay mounting or the additional heater interface unit

on the following connection:

•3FB of component 1067 or 1550.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

CC.1

NOTESNone.

Check the conformity of fuse: FM14 (70A) or FM3 (30A) (see MR364 (Mégane II ph2), MR370 (Scénic II ph2),

MR 395 (Laguna II ph2), 402 (Vel Satis ph2), 405 (Espace IV ph2) Mechanical, 81C, Fuses, Fuses: List and

location of components).

Check the condition of the thermoplunger 1 relay mounting connector on the engine fuse box or additional heater

interface unit (see Wiring Diagram Technical Note, Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II

ph2, Scénic II ph2, component code 1067 or 1550).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the conformity of the thermoplunger 1 relay (with the relay removed) or the additional heater interface unit:

–Insulation between connections BP9 and 3JB of component 1067 or 1550.

– Measure the resistance between connections3FB and 3JA of component1067 or 1550.

Replace the relay if its resistance is greater than 1 kΩ or less than 6 Ω.

Replace the unit if its resistance is greater than 1 kΩ (M9R721).

Check the insulation in relation to +12 V of the following connection:

•3JA between components 120 and 1067 or 1550.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Page 92 of 510

13B-92

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition until the end of the power-latch phase, and carry out a road test

followed by a check with the diagnostic tool.

V12 MR-372-J84-13B300$071.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

EDC16CP33

Program No.: C4

Vdiag No.: 04, 08, 18, 1C,

20, 24, 26, 28, 34, 38, 44,

4C, 54, 58, 5C, 60, 62, 74

DF032

CONTINUED 2

CC.0NOTESNone.

Check the conformity of fuse: FM14 (70A) or FM3 (30A) (see MR364 (Mégane II ph2), MR370 (Scénic II ph2),

MR 395 (Laguna II ph2), 402 (Vel Satis ph2), 405 (Espace IV ph2) Mechanical, 81C, Fuses, Fuses: List and

location of components).

Check the condition of the thermoplunger 1 relay mounting connector on the engine fuse box or additional heater

interface unit (see Wiring Diagram Technical Note, Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II

ph2, Scénic II ph2, component code 1067 or 1550).

Check the condition of the engine management computer connector (see Wiring Diagram Technical Note,

Laguna II ph2, Vel Satis ph2, Espace IV ph2, Mégane II ph2, Scénic II ph2, component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the conformity of the thermoplunger 1 relay (with the relay removed) or the additional heater interface unit:

–Insulation between connections BP9 and 3JB of component 1067 or 1550.

– Measure the resistance between connections3FB and 3JA of component1067 or 1550.

Replace the relay if its resistance is greater than 1 kΩ or less than 6 Ω.

Replace the unit if its resistance is less than 450 Ω (M9R721).

Check the insulation to earth of the following connection:

•3JA between components 120 and 1067.

Check the + 12 V after relay supply to the thermoplunger 1 relay mounting on the following connection:

•3FB of component 1067.

If the connection or connections are faulty and if there is a repair method (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.