coolant RENAULT SCENIC 2014 J95 / 3.G Petrol Injection - Sagem3000 Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2014, Model line: SCENIC, Model: RENAULT SCENIC 2014 J95 / 3.GPages: 181

Page 125 of 181

PETROL INJECTION

Fault finding – Conformity check17B

17B - 125V12 MR-372-J84-17B000$495.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

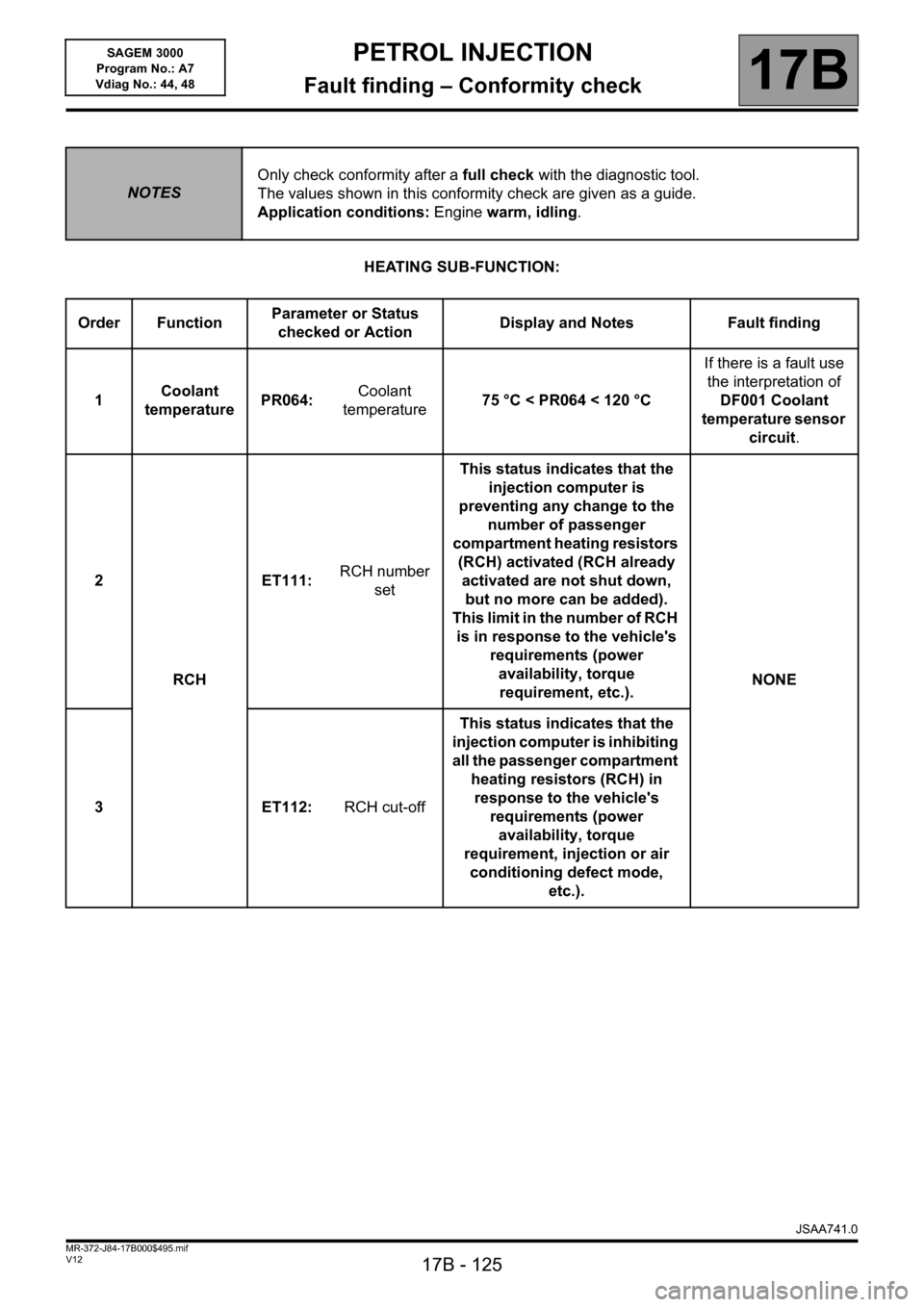

HEATING SUB-FUNCTION:

NOTESOnly check conformity after a full check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine warm, idling.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

1Coolant

temperaturePR064: Coolant

temperature75 °C < PR064 < 120 °CIf there is a fault use

the interpretation of

DF001 Coolant

temperature sensor

circuit.

2

RCHET111: RCH number

setThis status indicates that the

injection computer is

preventing any change to the

number of passenger

compartment heating resistors

(RCH) activated (RCH already

activated are not shut down,

but no more can be added).

This limit in the number of RCH

is in response to the vehicle's

requirements (power

availability, torque

requirement, etc.).NONE

3 ET112: RCH cut-offThis status indicates that the

injection computer is inhibiting

all the passenger compartment

heating resistors (RCH) in

response to the vehicle's

requirements (power

availability, torque

requirement, injection or air

conditioning defect mode,

etc.).

JSAA741.0

Page 133 of 181

PETROL INJECTION

Fault finding – Status summary table17B

17B - 133V12 MR-372-J84-17B000$540.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

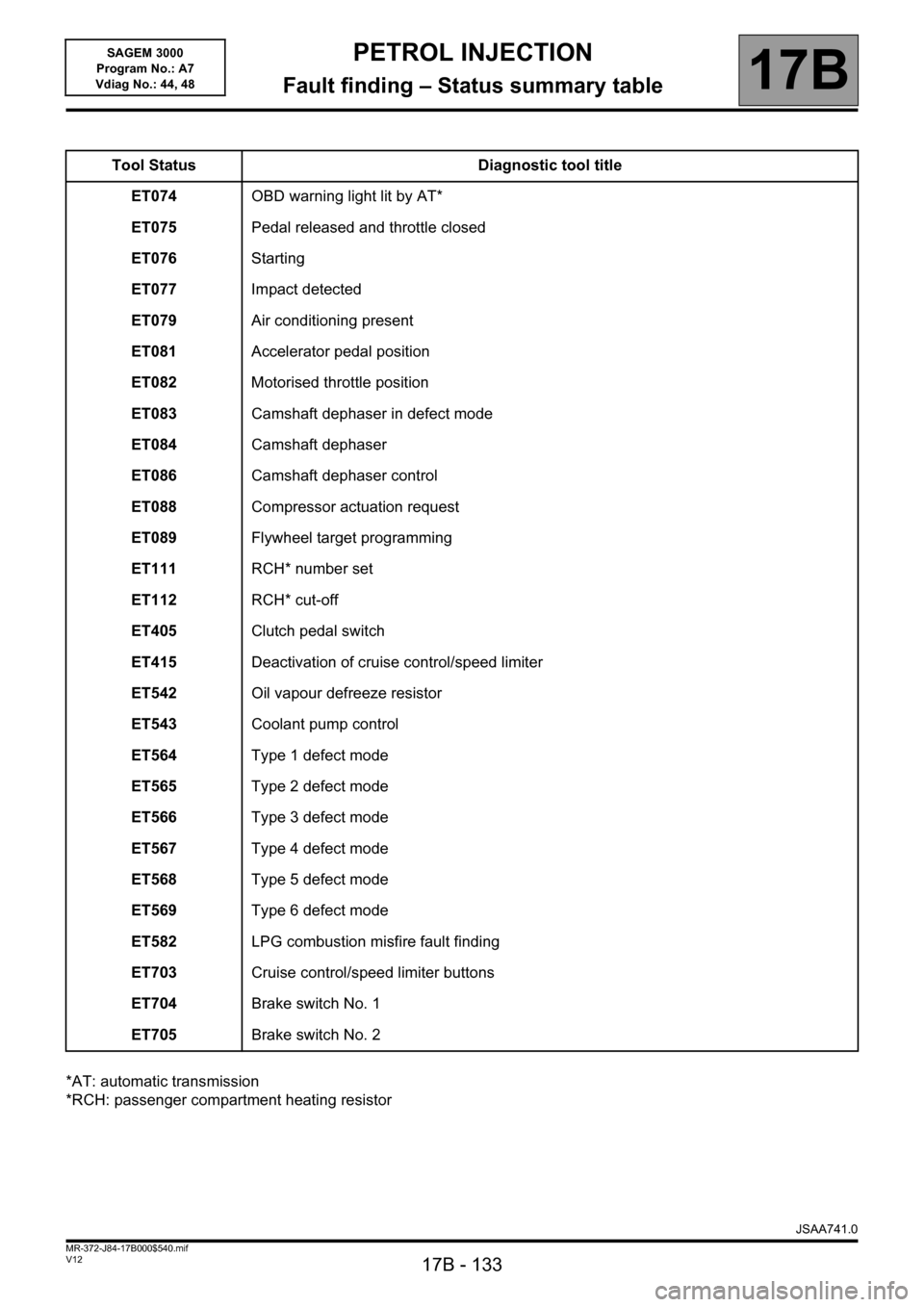

*AT: automatic transmission

*RCH: passenger compartment heating resistorTool Status Diagnostic tool title

ET074OBD warning light lit by AT*

ET075Pedal released and throttle closed

ET076Starting

ET077Impact detected

ET079Air conditioning present

ET081Accelerator pedal position

ET082Motorised throttle position

ET083Camshaft dephaser in defect mode

ET084Camshaft dephaser

ET086Camshaft dephaser control

ET088Compressor actuation request

ET089Flywheel target programming

ET111RCH* number set

ET112RCH* cut-off

ET405Clutch pedal switch

ET415Deactivation of cruise control/speed limiter

ET542Oil vapour defreeze resistor

ET543Coolant pump control

ET564Type 1 defect mode

ET565Type 2 defect mode

ET566Type 3 defect mode

ET567Type 4 defect mode

ET568Type 5 defect mode

ET569Type 6 defect mode

ET582LPG combustion misfire fault finding

ET703Cruise control/speed limiter buttons

ET704Brake switch No. 1

ET705Brake switch No. 2

JSAA741.0

Page 156 of 181

PETROL INJECTION

Fault finding – Parameter summary table17B

17B - 156V12 MR-372-J84-17B000$630.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48PETROL INJECTION

Fault finding – Parameter summary table

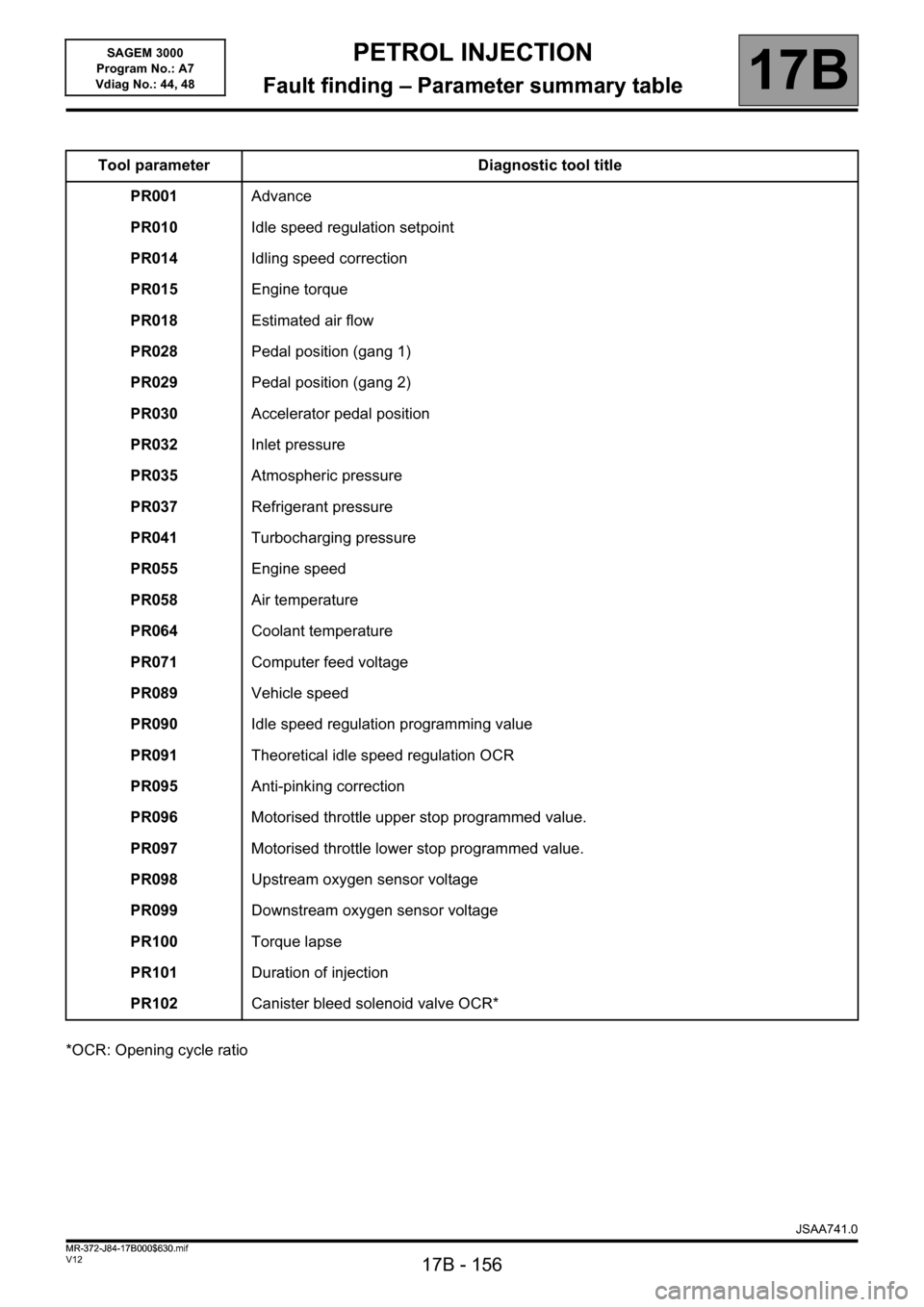

*OCR: Opening cycle ratioTool parameter Diagnostic tool title

PR001Advance

PR010Idle speed regulation setpoint

PR014Idling speed correction

PR015Engine torque

PR018Estimated air flow

PR028Pedal position (gang 1)

PR029Pedal position (gang 2)

PR030Accelerator pedal position

PR032Inlet pressure

PR035Atmospheric pressure

PR037Refrigerant pressure

PR041Turbocharging pressure

PR055Engine speed

PR058Air temperature

PR064Coolant temperature

PR071Computer feed voltage

PR089Vehicle speed

PR090Idle speed regulation programming value

PR091Theoretical idle speed regulation OCR

PR095Anti-pinking correction

PR096Motorised throttle upper stop programmed value.

PR097Motorised throttle lower stop programmed value.

PR098Upstream oxygen sensor voltage

PR099Downstream oxygen sensor voltage

PR100Torque lapse

PR101Duration of injection

PR102Canister bleed solenoid valve OCR*

JSAA741.0

MR-372-J84-17B000$630.mif

Page 165 of 181

PETROL INJECTION

Fault finding – Interpretation of parameters17B

17B - 165V12 MR-372-J84-17B000$675.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

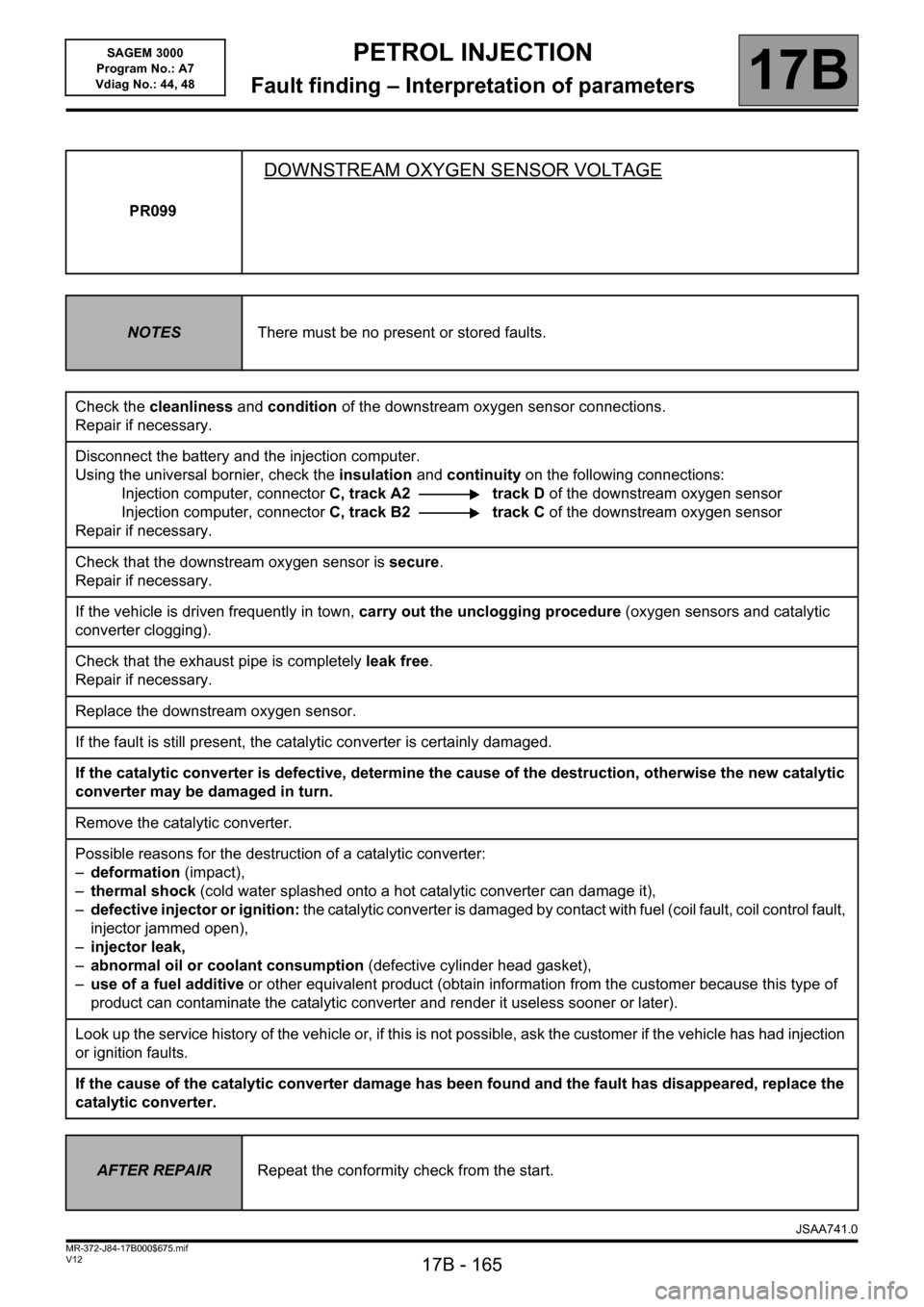

PR099

DOWNSTREAM OXYGEN SENSOR VOLTAGE

NOTESThere must be no present or stored faults.

Check the cleanliness and condition of the downstream oxygen sensor connections.

Repair if necessary.

Disconnect the battery and the injection computer.

Using the universal bornier, check the insulation and continuity on the following connections:

Injection computer, connectorC, track A2 track D of the downstream oxygen sensor

Injection computer, connectorC, track B2 track C of the downstream oxygen sensor

Repair if necessary.

Check that the downstream oxygen sensor is secure.

Repair if necessary.

If the vehicle is driven frequently in town, carry out the unclogging procedure (oxygen sensors and catalytic

converter clogging).

Check that the exhaust pipe is completely leak free.

Repair if necessary.

Replace the downstream oxygen sensor.

If the fault is still present, the catalytic converter is certainly damaged.

If the catalytic converter is defective, determine the cause of the destruction, otherwise the new catalytic

converter may be damaged in turn.

Remove the catalytic converter.

Possible reasons for the destruction of a catalytic converter:

–deformation (impact),

–thermal shock (cold water splashed onto a hot catalytic converter can damage it),

–defective injector or ignition: the catalytic converter is damaged by contact with fuel (coil fault, coil control fault,

injector jammed open),

–injector leak,

–abnormal oil or coolant consumption (defective cylinder head gasket),

–use of a fuel additive or other equivalent product (obtain information from the customer because this type of

product can contaminate the catalytic converter and render it useless sooner or later).

Look up the service history of the vehicle or, if this is not possible, ask the customer if the vehicle has had injection

or ignition faults.

If the cause of the catalytic converter damage has been found and the fault has disappeared, replace the

catalytic converter.

AFTER REPAIRRepeat the conformity check from the start.

JSAA741.0

Page 167 of 181

17B-167

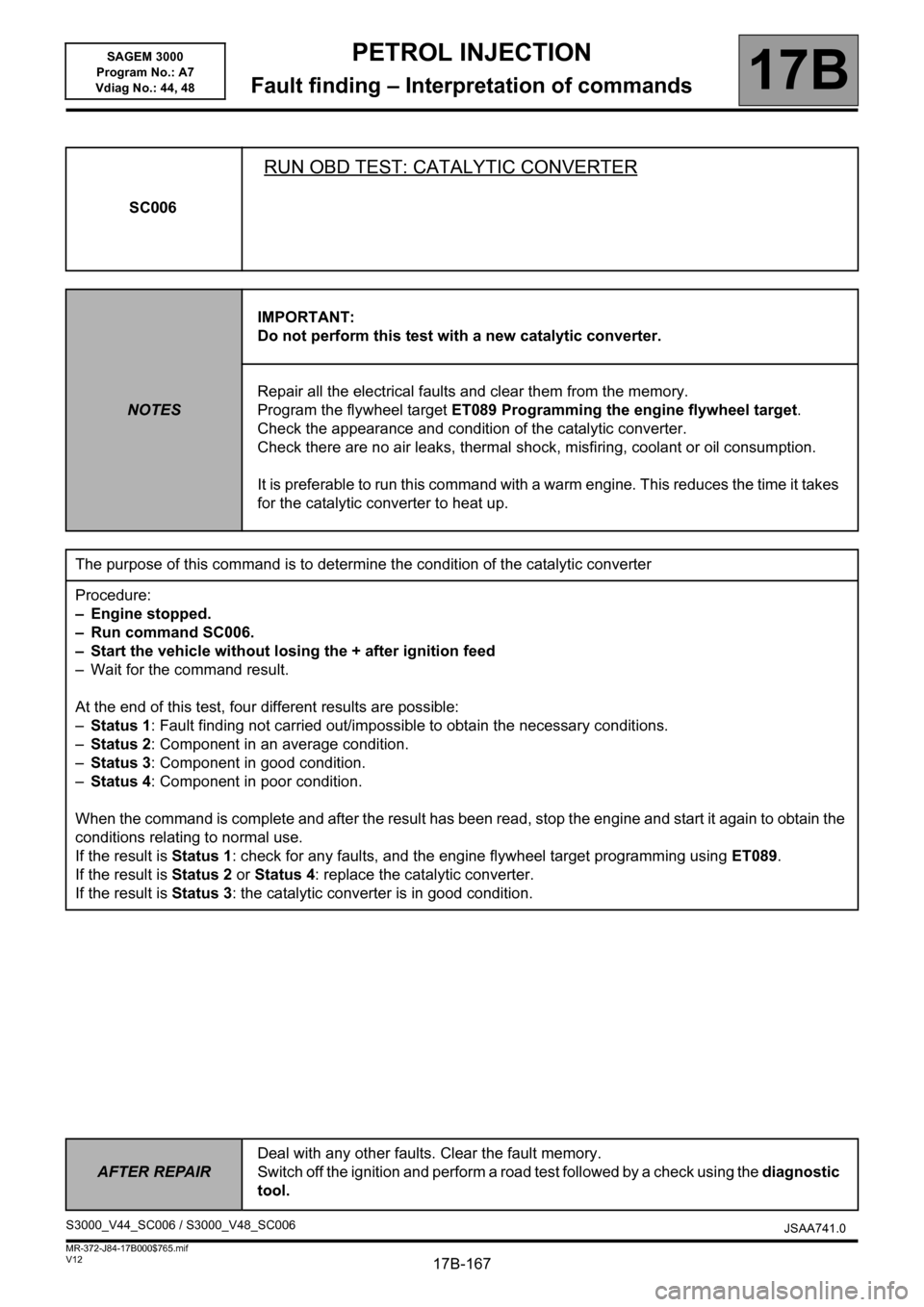

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and perform a road test followed by a check using the diagnostic

tool.

V12 MR-372-J84-17B000$765.mif

17B

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

SC006

RUN OBD TEST: CATALYTIC CONVERTER

NOTESIMPORTANT:

Do not perform this test with a new catalytic converter.

Repair all the electrical faults and clear them from the memory.

Program the flywheel target ET089 Programming the engine flywheel target.

Check the appearance and condition of the catalytic converter.

Check there are no air leaks, thermal shock, misfiring, coolant or oil consumption.

It is preferable to run this command with a warm engine. This reduces the time it takes

for the catalytic converter to heat up.

The purpose of this command is to determine the condition of the catalytic converter

Procedure:

– Engine stopped.

– Run command SC006.

– Start the vehicle without losing the + after ignition feed

– Wait for the command result.

At the end of this test, four different results are possible:

–Status 1: Fault finding not carried out/impossible to obtain the necessary conditions.

–Status 2: Component in an average condition.

–Status 3: Component in good condition.

–Status 4: Component in poor condition.

When the command is complete and after the result has been read, stop the engine and start it again to obtain the

conditions relating to normal use.

If the result is Status 1: check for any faults, and the engine flywheel target programming using ET089.

If the result is Status 2 or Status 4: replace the catalytic converter.

If the result is Status 3: the catalytic converter is in good condition.

S3000_V44_SC006 / S3000_V48_SC006

JSAA741.0

PETROL INJECTION

Fault finding – Interpretation of commands

Page 174 of 181

PETROL INJECTION

Fault finding – Help17B

17B - 174V12 MR-372-J84-17B000$810.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

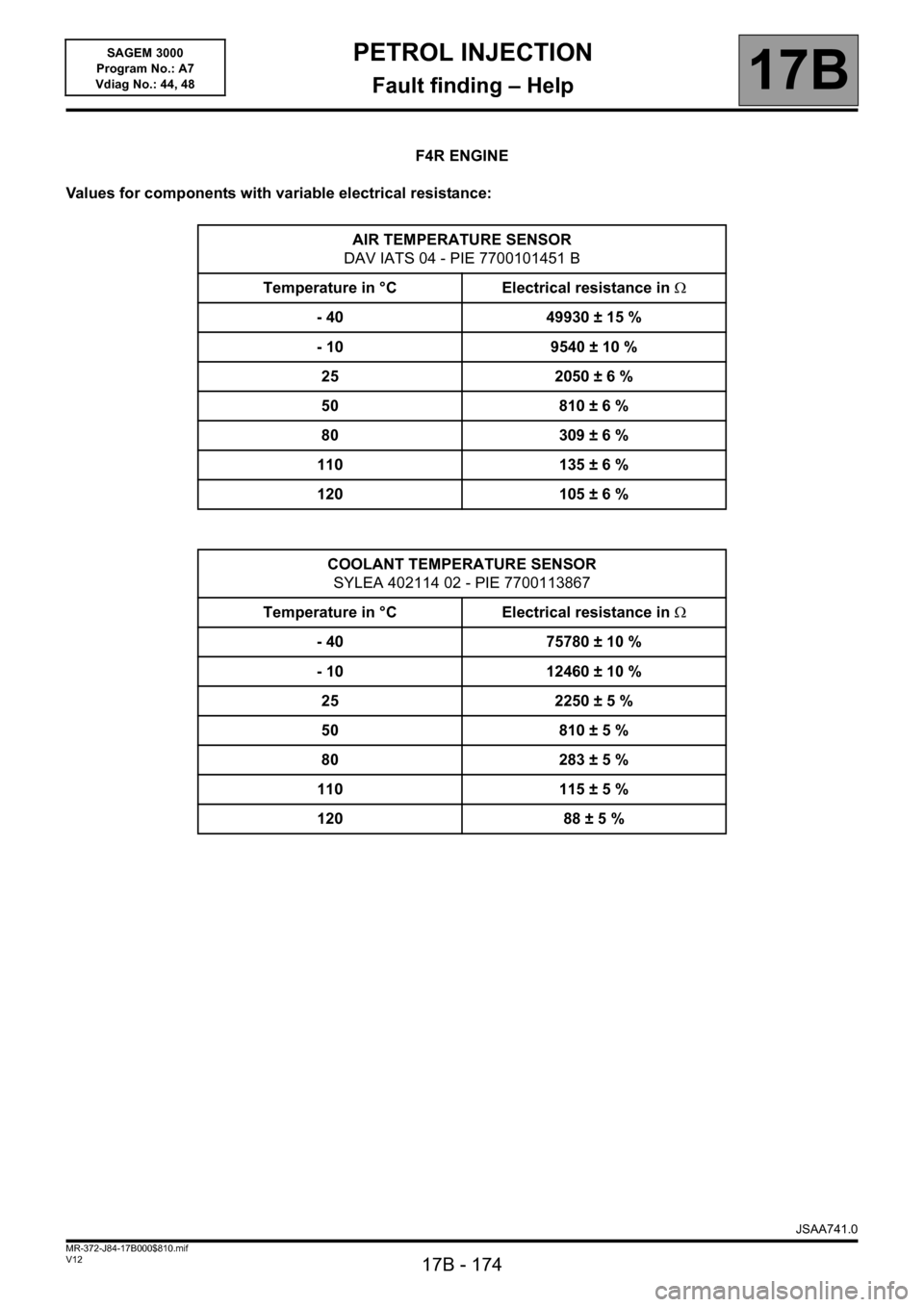

F4R ENGINE

Values for components with variable electrical resistance:

AIR TEMPERATURE SENSOR

DAV IATS 04 - PIE 7700101451 B

Temperature in °C Electrical resistance in

- 40 49930 ± 15 %

- 10 9540 ± 10 %

25 2050 ± 6 %

50 810 ± 6 %

80 309 ± 6 %

110 135 ± 6 %

120 105 ± 6 %

COOLANT TEMPERATURE SENSOR

SYLEA 402114 02 - PIE 7700113867

Temperature in °C Electrical resistance in

- 40 75780 ± 10 %

- 10 12460 ± 10 %

25 2250 ± 5 %

50 810 ± 5 %

80 283 ± 5 %

110 115 ± 5 %

120 88 ± 5 %

JSAA741.0