relay RENAULT SCENIC 2014 J95 / 3.G Petrol Injection - Sagem3000 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2014, Model line: SCENIC, Model: RENAULT SCENIC 2014 J95 / 3.GPages: 181

Page 19 of 181

PETROL INJECTION

Fault finding – Fault summary table17B

17B - 19V12 MR-372-J84-17B000$270.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

*AT: Automatic Transmission

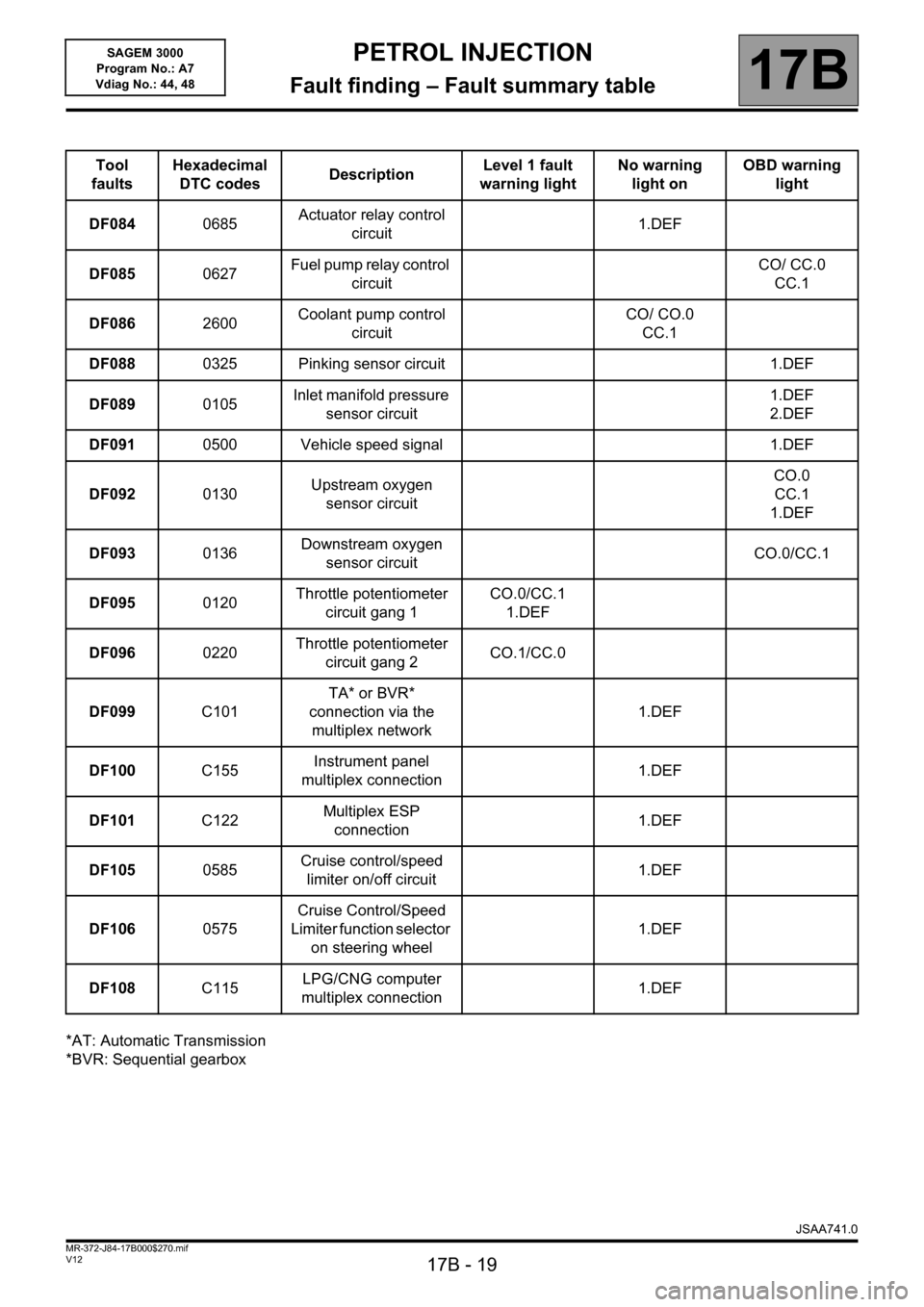

*BVR: Sequential gearboxTool

faultsHexadecimal

DTC codesDescriptionLevel 1 fault

warning lightNo warning

light onOBD warning

light

DF0840685Actuator relay control

circuit1.DEF

DF0850627Fuel pump relay control

circuitCO/ CC.0

CC.1

DF0862600Coolant pump control

circuitCO/ CO.0

CC.1

DF0880325 Pinking sensor circuit 1.DEF

DF0890105Inlet manifold pressure

sensor circuit1.DEF

2.DEF

DF0910500 Vehicle speed signal 1.DEF

DF0920130Upstream oxygen

sensor circuitCO.0

CC.1

1.DEF

DF0930136Downstream oxygen

sensor circuitCO.0/CC.1

DF0950120Throttle potentiometer

circuit gang 1CO.0/CC.1

1.DEF

DF0960220Throttle potentiometer

circuit gang 2CO.1/CC.0

DF099C101TA* or BVR*

connection via the

multiplex network1.DEF

DF100C155Instrument panel

multiplex connection1.DEF

DF101C122Multiplex ESP

connection1.DEF

DF1050585Cruise control/speed

limiter on/off circuit1.DEF

DF1060575Cruise Control/Speed

Limiter function selector

on steering wheel1.DEF

DF108C115LPG/CNG computer

multiplex connection1.DEF

JSAA741.0

Page 28 of 181

PETROL INJECTION

Fault finding – Interpretation of faults17B

17B-28V12 MR-372-J84-17B000$315.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

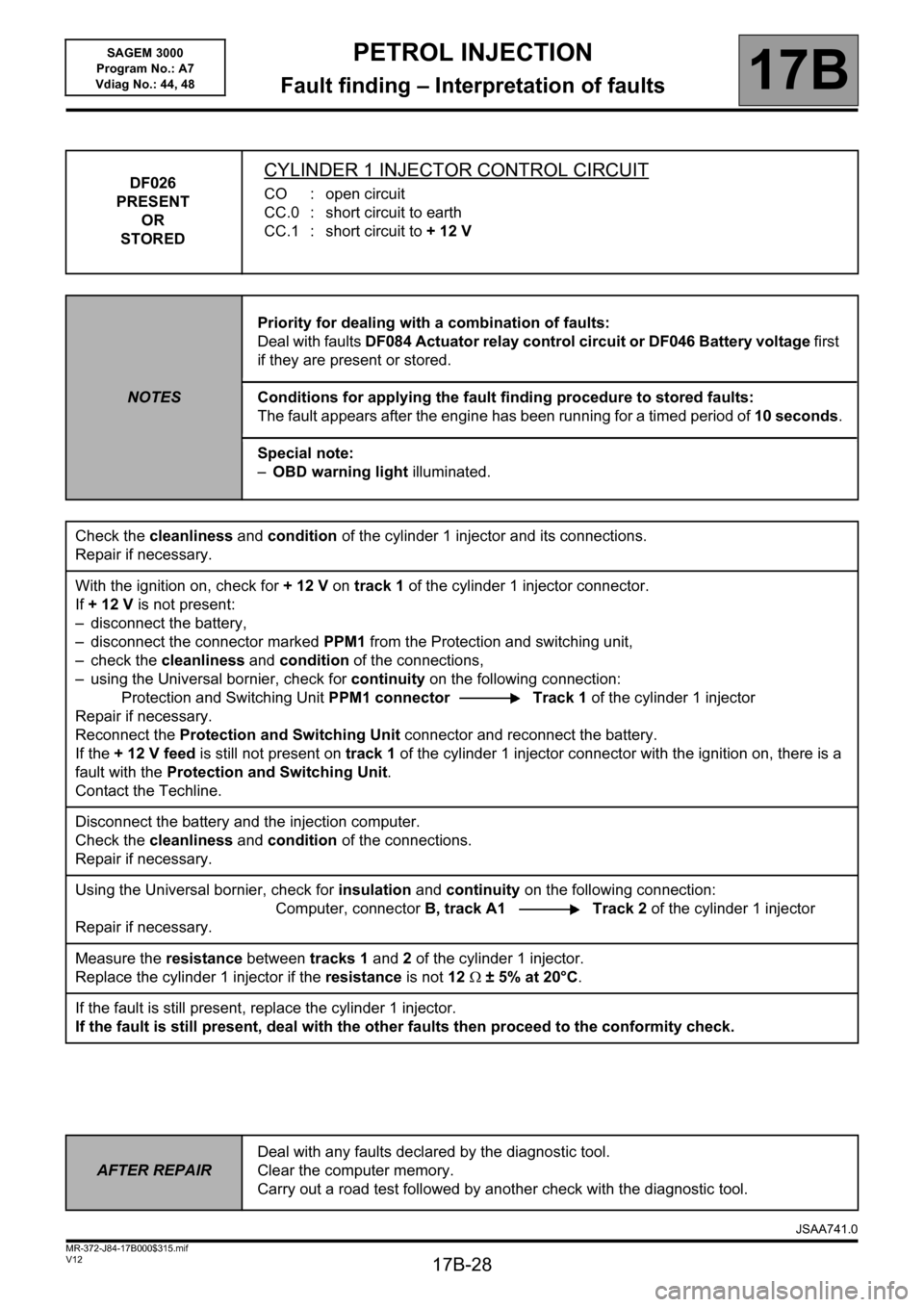

DF026

PRESENT

OR

STOREDCYLINDER 1 INJECTOR CONTROL CIRCUIT

CO : open circuit

CC.0 : short circuit to earth

CC.1 : short circuit to + 12 V

NOTESPriority for dealing with a combination of faults:

Deal with faults DF084 Actuator relay control circuit or DF046 Battery voltage first

if they are present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault appears after the engine has been running for a timed period of 10 seconds.

Special note:

–OBD warning light illuminated.

Check the cleanliness and condition of the cylinder 1 injector and its connections.

Repair if necessary.

With the ignition on, check for + 12 V on track 1 of the cylinder 1 injector connector.

If +12V is not present:

– disconnect the battery,

– disconnect the connector marked PPM1 from the Protection and switching unit,

– check the cleanliness and condition of the connections,

– using the Universal bornier, check for continuity on the following connection:

Protection and Switching Unit PPM1 connector Track 1 of the cylinder 1 injector

Repair if necessary.

Reconnect the Protection and Switching Unit connector and reconnect the battery.

If the + 12 V feed is still not present on track 1 of the cylinder 1 injector connector with the ignition on, there is a

fault with the Protection and Switching Unit.

Contact the Techline.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Repair if necessary.

Using the Universal bornier, check for insulation and continuity on the following connection:

Computer, connector B, track A1 Track 2 of the cylinder 1 injector

Repair if necessary.

Measure the resistance between tracks 1 and 2 of the cylinder 1 injector.

Replace the cylinder 1 injector if the resistance is not 12 ± 5% at 20°C.

If the fault is still present, replace the cylinder 1 injector.

If the fault is still present, deal with the other faults then proceed to the conformity check.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

JSAA741.0

Page 29 of 181

PETROL INJECTION

Fault finding – Interpretation of faults17B

17B-29V12 MR-372-J84-17B000$315.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

DF027

PRESENT

OR

STOREDCYLINDER 2 INJECTOR CONTROL CIRCUIT

CO : open circuit

CC.0 : short circuit to earth

CC.1 : short circuit to + 12 V

NOTESPriority for dealing with a combination of faults:

Deal with faults DF084 Actuator relay control circuit or DF046 Battery voltage first

if they are present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the engine has been running for a timed period of

10 seconds.

Special note:

–OBD warning light illuminated.

Check the cleanliness and condition of the cylinder 2 injector and its connections.

Repair if necessary.

With the ignition on, check for + 12 V on track 1 of the cylinder 2 injector connector.

If +12V is not present:

– disconnect the battery,

– disconnect the connector marked PPM1 from the Protection and switching unit,

– check the cleanliness and condition of the connections,

– using the Universal bornier, check for continuity on the following connection:

Protection and Switching Unit PPM1 connector Track 1 of the cylinder 2 injector

Repair if necessary.

Reconnect the Protection and Switching Unit connector and reconnect the battery.

If the + 12 V feed on track 1 is still not present on the cylinder 2 injector connector with the ignition on, there is a

fault with the Protection and Switching Unit.

Contact the Techline.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Repair if necessary.

Using the universal bornier, check for insulation and continuity on the following connection:

Computer, connector B, track A2 Track 2 of the cylinder 2 injector

Repair if necessary.

Measure the resistance of the cylinder 2 injector between tracks 1 and 2.

Replace the cylinder 2 injector if the resistance is not 12 ± 5% at 20°C.

If the fault is still present, replace the cylinder 2 injector.

If the fault is still present, deal with the other faults then proceed to the conformity check.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

JSAA741.0

Page 30 of 181

PETROL INJECTION

Fault finding – Interpretation of faults17B

17B-30V12 MR-372-J84-17B000$315.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

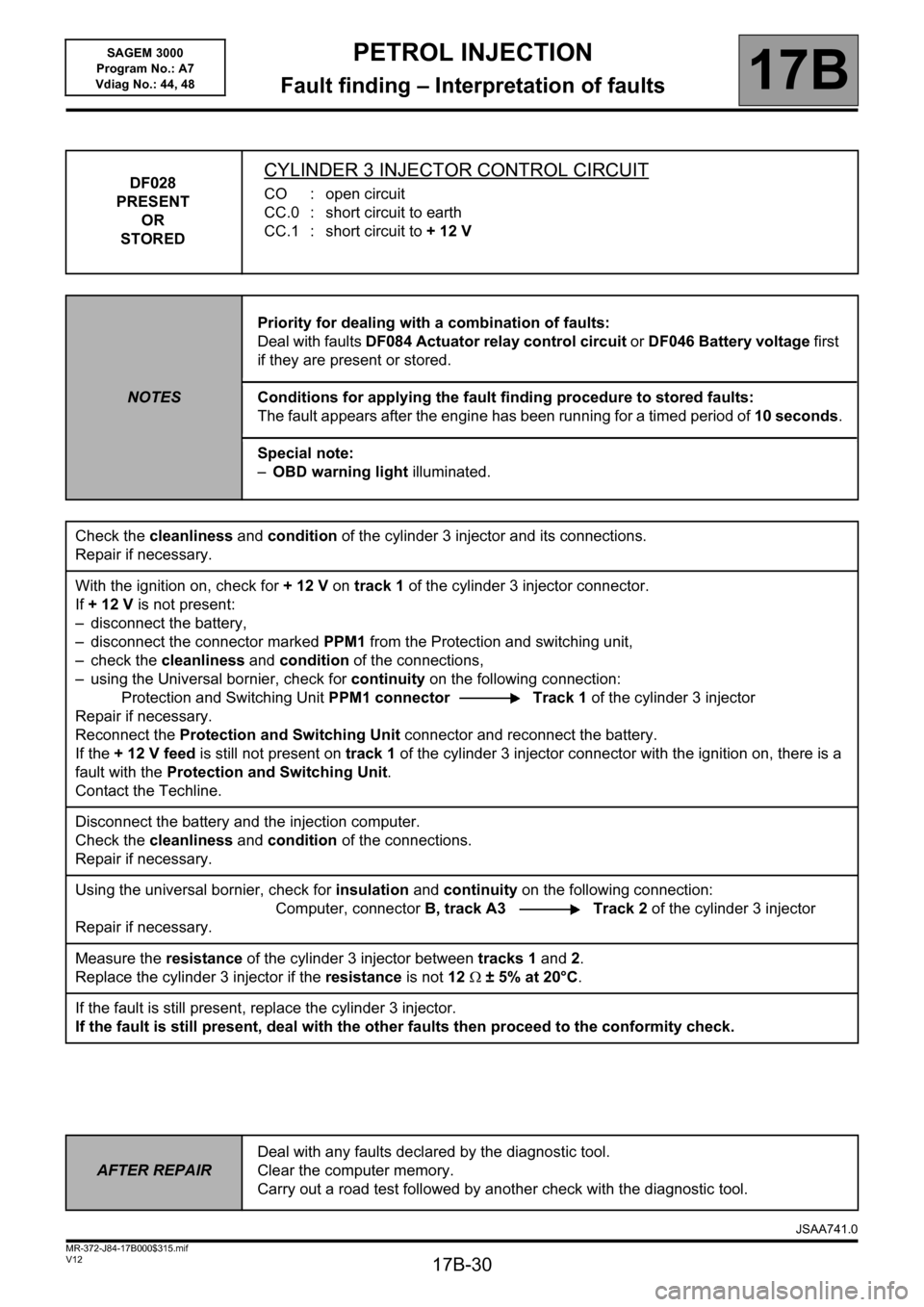

DF028

PRESENT

OR

STOREDCYLINDER 3 INJECTOR CONTROL CIRCUIT

CO : open circuit

CC.0 : short circuit to earth

CC.1 : short circuit to + 12 V

NOTESPriority for dealing with a combination of faults:

Deal with faults DF084 Actuator relay control circuit or DF046 Battery voltage first

if they are present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault appears after the engine has been running for a timed period of 10 seconds.

Special note:

–OBD warning light illuminated.

Check the cleanliness and condition of the cylinder 3 injector and its connections.

Repair if necessary.

With the ignition on, check for + 12 V on track 1 of the cylinder 3 injector connector.

If +12V is not present:

– disconnect the battery,

– disconnect the connector marked PPM1 from the Protection and switching unit,

– check the cleanliness and condition of the connections,

– using the Universal bornier, check for continuity on the following connection:

Protection and Switching Unit PPM1 connector Track 1 of the cylinder 3 injector

Repair if necessary.

Reconnect the Protection and Switching Unit connector and reconnect the battery.

If the + 12 V feed is still not present on track 1 of the cylinder 3 injector connector with the ignition on, there is a

fault with the Protection and Switching Unit.

Contact the Techline.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Repair if necessary.

Using the universal bornier, check for insulation and continuity on the following connection:

Computer, connector B, track A3 Track 2 of the cylinder 3 injector

Repair if necessary.

Measure the resistance of the cylinder 3 injector between tracks 1 and 2.

Replace the cylinder 3 injector if the resistance is not 12 ± 5% at 20°C.

If the fault is still present, replace the cylinder 3 injector.

If the fault is still present, deal with the other faults then proceed to the conformity check.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

JSAA741.0

Page 31 of 181

PETROL INJECTION

Fault finding – Interpretation of faults17B

17B-31V12 MR-372-J84-17B000$315.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

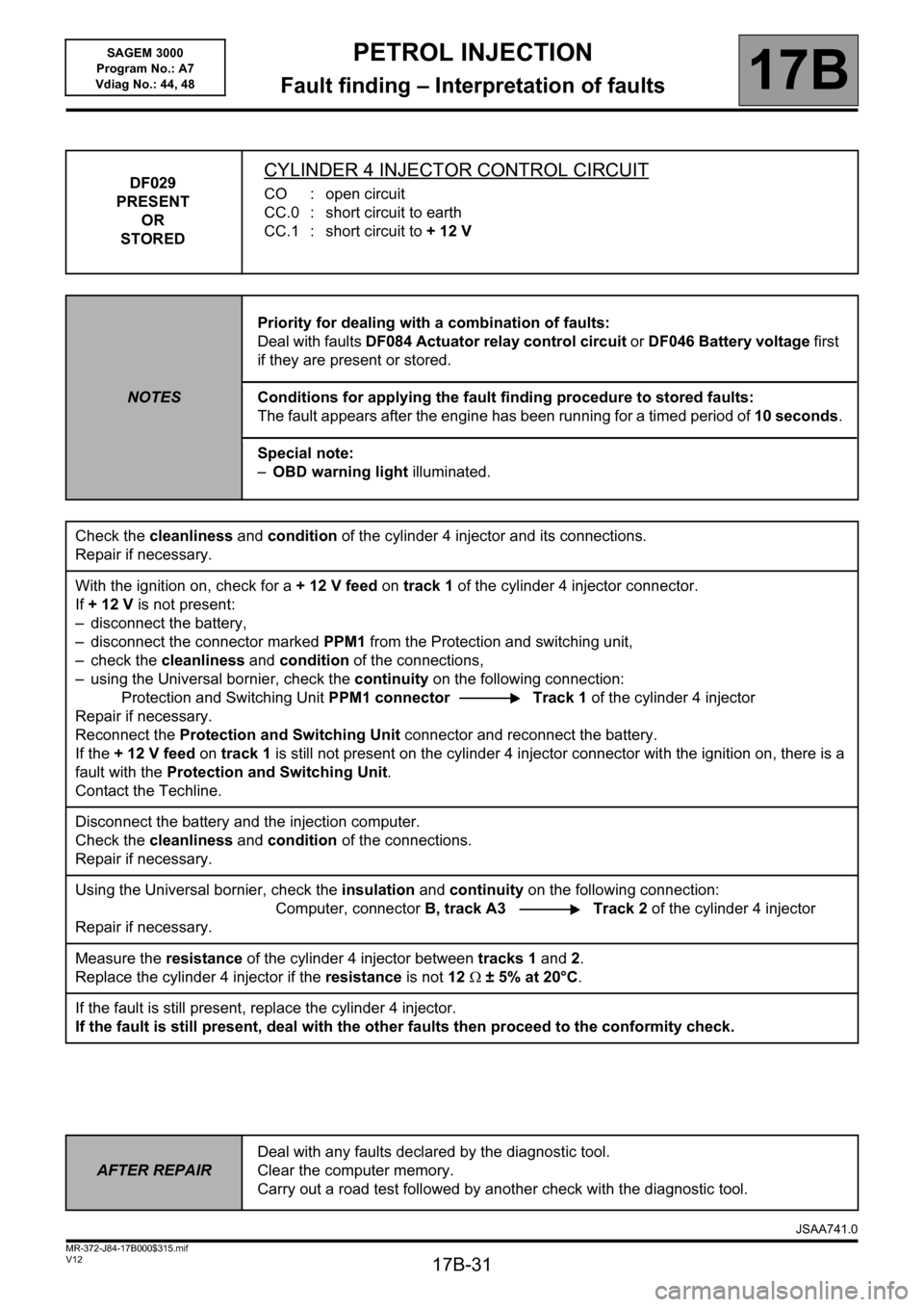

DF029

PRESENT

OR

STOREDCYLINDER 4 INJECTOR CONTROL CIRCUIT

CO : open circuit

CC.0 : short circuit to earth

CC.1 : short circuit to + 12 V

NOTESPriority for dealing with a combination of faults:

Deal with faults DF084 Actuator relay control circuit or DF046 Battery voltage first

if they are present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault appears after the engine has been running for a timed period of 10 seconds.

Special note:

–OBD warning light illuminated.

Check the cleanliness and condition of the cylinder 4 injector and its connections.

Repair if necessary.

With the ignition on, check for a + 12 V feed on track 1 of the cylinder 4 injector connector.

If +12V is not present:

– disconnect the battery,

– disconnect the connector marked PPM1 from the Protection and switching unit,

– check the cleanliness and condition of the connections,

– using the Universal bornier, check the continuity on the following connection:

Protection and Switching Unit PPM1 connector Track 1 of the cylinder 4 injector

Repair if necessary.

Reconnect the Protection and Switching Unit connector and reconnect the battery.

If the + 12 V feed on track 1 is still not present on the cylinder 4 injector connector with the ignition on, there is a

fault with the Protection and Switching Unit.

Contact the Techline.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Repair if necessary.

Using the Universal bornier, check the insulation and continuity on the following connection:

Computer, connector B, track A3 Track 2 of the cylinder 4 injector

Repair if necessary.

Measure the resistance of the cylinder 4 injector between tracks 1 and 2.

Replace the cylinder 4 injector if the resistance is not 12 ± 5% at 20°C.

If the fault is still present, replace the cylinder 4 injector.

If the fault is still present, deal with the other faults then proceed to the conformity check.

AFTER REPAIRDeal with any faults declared by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

JSAA741.0

Page 34 of 181

PETROL INJECTION

Fault finding – Interpretation of faults17B

17B-34V12 MR-372-J84-17B000$315.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

DF046

PRESENT

OR

STOREDBATTERY VOLTAGE

1.DEF : open circuit or short circuit

NOTESPriority for dealing with a combination of faults:

Apply the procedure for dealing with fault DF084 Actuators relay control circuit first

if it is present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared as present at an engine speed above 2000 rpm.

Special note:

– Throttle valve defect mode types 1, 2 and 6.

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the computer connections.

Repair if necessary.

Disconnect the connector marked PPM1 from the Protection and Switching Unit.

Check the cleanliness and condition of the connections.

Repair if necessary.

Using the Universal bornier, check for continuity on the following connection:

Computer, connectorB, track M2Protection and Switching Unit PPM1 connector track 1

Repair if necessary.

Carry out fault finding on the Protection and Switching Unit (the Protection and Switching Unit powers the

injection system).

– clean the battery terminals and all connections to the + and the Earth.

– check the battery voltage.

– check the charging circuit (see MR 364 Mechanical, 16A, Starting - Charging).

Repair or replace the faulty components, if necessary.

AFTER REPAIRDeal with any faults detected by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

JSAA741.0

Page 46 of 181

PETROL INJECTION

Fault finding – Interpretation of faults17B

17B-46V12 MR-372-J84-17B000$315.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

DF072

PRESENT

OR

STOREDIGNITION COIL CIRCUIT, CYLINDER 1

CO.0 : open circuit or short circuit to earth

CC.1 : short circuit to + 12 V

NOTESPriority for dealing with a combination of faults:

Deal with faults DF046 Battery voltage, DF084 Actuator relay control circuit or

DF085 Fuel pump relay control circuit first if they are present or stored.

If the DF075 Cylinder 4 ignition coil circuit fault is also present or stored, deal with

it first.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the starter has been in operation for 10 seconds or

after the engine has been running for 10 seconds.

Special note:

–OBD warning light illuminated.

Disconnect the cylinder 1 pencil coil connector.

Check the cleanliness and condition of the pencil coil and its connections.

Check that the correct fuel is being used.

Measure the primary and secondary resistance of the cylinder 1 pencil coil.

Replace the cylinder 1 pencil coil if the resistances are not:

– for K4 engines:

primary resistance: 540 m ± 27 m

secondary resistance: 10.7 k ± 1.6 k

– for F4 engines:

primary resistance: 520 m ± 50 m

secondary resistance: 6.7 k ± 0.7 k

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the universal bornier, check for insulation and continuity on the following connections:

Computer, connector C, track M4 Track 2 of coil 1

Coil 4 track 2 Track 1 of coil 1

Repair if necessary.

If the fault is still present, replace the defective pencil coil.

If the fault is still present, deal with the other faults then proceed to the conformity check.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the fault memory.

JSAA741.0

Page 47 of 181

PETROL INJECTION

Fault finding – Interpretation of faults17B

17B-47V12 MR-372-J84-17B000$315.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

DF073

PRESENT

OR

STOREDIGNITION COIL CIRCUIT, CYLINDER 2

CO.0 : open circuit or short circuit to earth

CC.1 : short circuit to + 12 V

NOTESPriority for dealing with a combination of faults:

Deal with faults DF046 Battery voltage, DF084 Actuator relay control circuit or

DF085 Fuel pump relay control circuit first if they are present or stored.

If the fault DF074 Cylinder ignition coil circuit 3 is also present or stored, deal with

it first.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the starter has been in operation for 10 seconds or

after the engine has been running for 10 seconds.

Special note:

–OBD warning light illuminated.

Disconnect the cylinder 2 pencil coil connector.

Check the cleanliness and condition of the pencil coil and its connections. Check that the correct fuel is being

used.

Measure the primary and secondary resistance of the cylinder 2 pencil coil.

Replace the cylinder 2 pencil coil if the resistances are not:

– for K4 engines:

primary resistance: 540 m ± 27 m

secondary resistance: 10.7 k ± 1.6 k

– for F4 engines:

primary resistance: 520 m ± 50 m

secondary resistance: 6.7 k ± 0.7 k

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the universal bornier, check for insulation and continuity on the following connections:

Computer, connector C, track M3 Track 2 of coil 2

Coil 3 track 2 Track 1 of coil 2

Repair if necessary.

If the fault is still present, replace the defective pencil coil.

If the fault is still present, deal with the other faults then proceed to the conformity check.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the fault memory.

JSAA741.0

Page 48 of 181

PETROL INJECTION

Fault finding – Interpretation of faults17B

17B-48V12 MR-372-J84-17B000$315.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

DF074

PRESENT

OR

STOREDIGNITION COIL CIRCUIT, CYLINDER 3

CO.0 : open circuit or short circuit to earth

CC.1 : short circuit to + 12 V

NOTESPriority for dealing with a combination of faults:

Deal with faults DF046 Battery voltage, DF084 Actuator relay control circuit or

DF085 Fuel pump relay control circuit first if they are present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the starter has been in operation for 10 seconds or

after the engine has been running for 10 seconds.

Special note:

–OBD warning light illuminated.

Disconnect the connector from the cylinder 3 pencil coil.

Check the cleanliness and condition of the pencil coil and its connections. Check that the correct fuel is being

used.

Measure the primary and secondary resistance of the cylinder 3 pencil coil.

Replace the cylinder 3 pencil coil if the resistances are not:

– for K4 engines:

primary resistance: 540 m ± 27 m

secondary resistance: 10.7 k ± 1.6 k

– for F4 engines:

primary resistance: 520 m ± 50 m

secondary resistance: 6.7 k ± 0.7 k

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the universal bornier, check for insulation and continuity on the following connections:

Computer, connector C, track M3 Track 2 of coil 2

Coil 3 track 2 Track 1 of coil 2

Repair if necessary.

Check for the + 12 V feed on track 1 of the cylinder 3 pencil coil connector with the ignition on.

If +12V is not present:

– disconnect the battery,

– disconnect the connector marked PPM2 in the Protection and Switching Unit,

–check the cleanliness and condition of the connections,

– using the Universal bornier, check for continuity on the following connection:

Protection and Switching Unit connector PPM1 track 8 track 1 of the cylinder 3 pencil coil

Repair if necessary.

Reconnect the Protection and Switching Unit connector and reconnect the battery.

If the + 12 V feed on track 1 is still not present on the cylinder 3 coil connector with the ignition on, there is a fault

with the Protection and Switching Unit. Contact the Techline.

If the fault is still present, replace the defective pencil coil.

If the fault is still present, deal with the other faults then proceed to the conformity check.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the fault memory.

JSAA741.0

Page 49 of 181

PETROL INJECTION

Fault finding – Interpretation of faults17B

17B-49V12 MR-372-J84-17B000$315.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

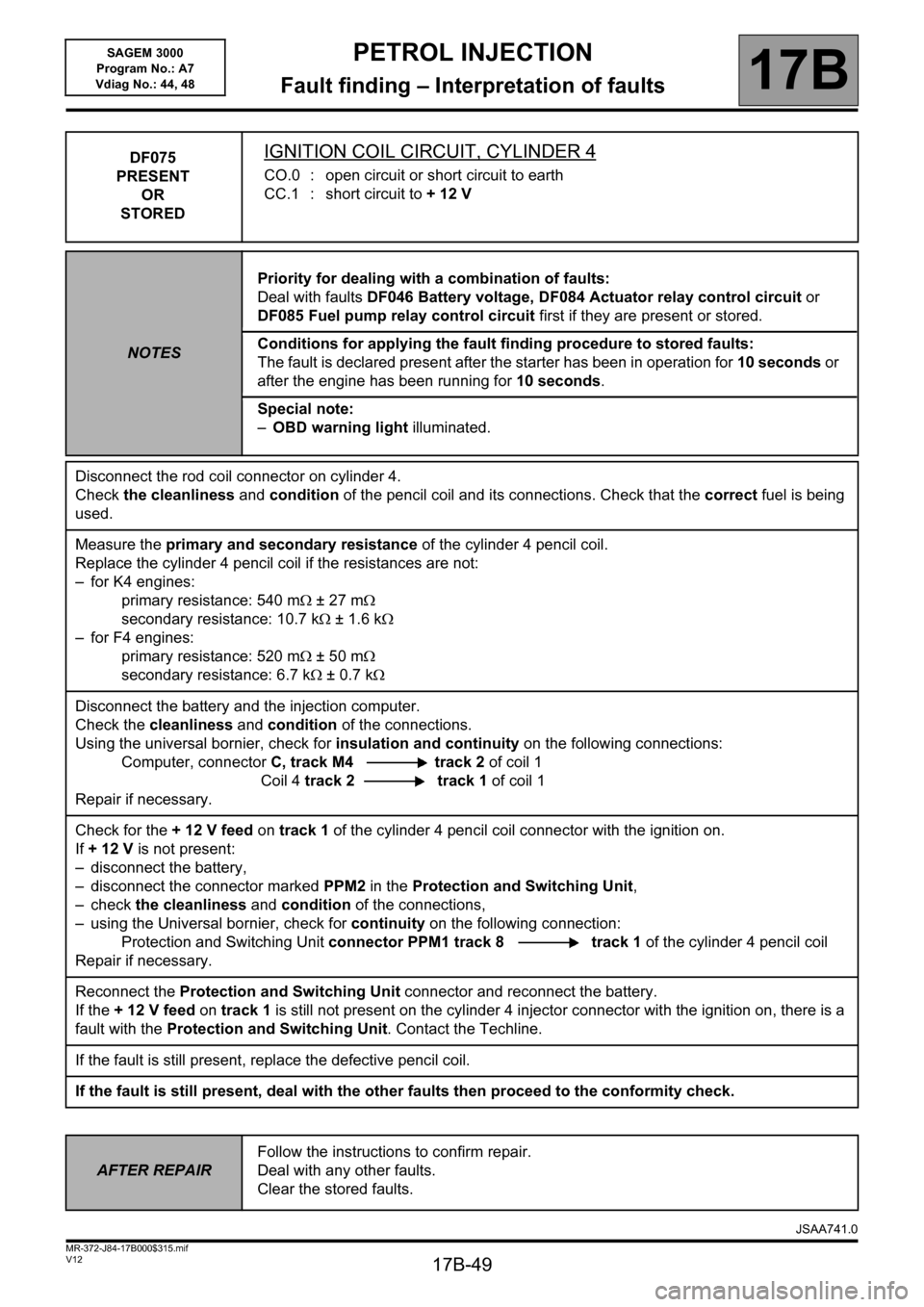

DF075

PRESENT

OR

STOREDIGNITION COIL CIRCUIT, CYLINDER 4

CO.0 : open circuit or short circuit to earth

CC.1 : short circuit to + 12 V

NOTESPriority for dealing with a combination of faults:

Deal with faults DF046 Battery voltage, DF084 Actuator relay control circuit or

DF085 Fuel pump relay control circuit first if they are present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the starter has been in operation for 10 seconds or

after the engine has been running for 10 seconds.

Special note:

–OBD warning light illuminated.

Disconnect the rod coil connector on cylinder 4.

Check the cleanliness and condition of the pencil coil and its connections. Check that the correct fuel is being

used.

Measure the primary and secondary resistance of the cylinder 4 pencil coil.

Replace the cylinder 4 pencil coil if the resistances are not:

– for K4 engines:

primary resistance: 540 m ± 27 m

secondary resistance: 10.7 k ± 1.6 k

– for F4 engines:

primary resistance: 520 m ± 50 m

secondary resistance: 6.7 k ± 0.7 k

Disconnect the battery and the injection computer.

Check the cleanliness and condition of the connections.

Using the universal bornier, check for insulation and continuity on the following connections:

Computer, connector C, track M4 track 2 of coil 1

Coil 4 track 2 track 1 of coil 1

Repair if necessary.

Check for the + 12 V feed on track 1 of the cylinder 4 pencil coil connector with the ignition on.

If +12V is not present:

– disconnect the battery,

– disconnect the connector marked PPM2 in the Protection and Switching Unit,

–check the cleanliness and condition of the connections,

– using the Universal bornier, check for continuity on the following connection:

Protection and Switching Unit connector PPM1 track 8 track 1 of the cylinder 4 pencil coil

Repair if necessary.

Reconnect the Protection and Switching Unit connector and reconnect the battery.

If the + 12 V feed on track 1 is still not present on the cylinder 4 injector connector with the ignition on, there is a

fault with the Protection and Switching Unit. Contact the Techline.

If the fault is still present, replace the defective pencil coil.

If the fault is still present, deal with the other faults then proceed to the conformity check.

AFTER REPAIRFollow the instructions to confirm repair.

Deal with any other faults.

Clear the stored faults.

JSAA741.0