stop start RENAULT SCENIC 2014 J95 / 3.G Petrol Injection - Sagem3000 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2014, Model line: SCENIC, Model: RENAULT SCENIC 2014 J95 / 3.GPages: 181

Page 9 of 181

PETROL INJECTION

Fault finding – System operation17B

17B - 9V12 MR-372-J84-17B000$090.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

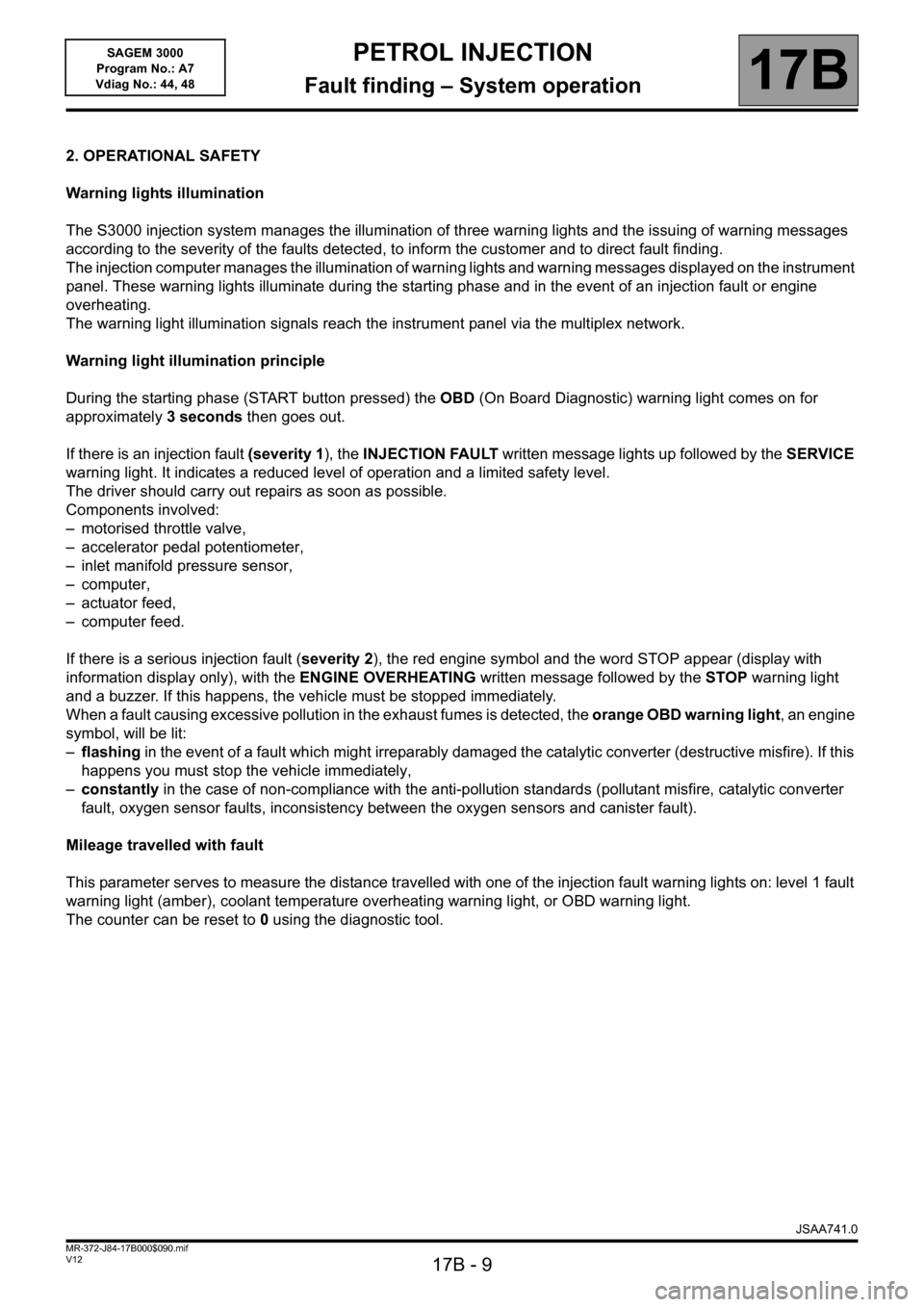

2. OPERATIONAL SAFETY

Warning lights illumination

The S3000 injection system manages the illumination of three warning lights and the issuing of warning messages

according to the severity of the faults detected, to inform the customer and to direct fault finding.

The injection computer manages the illumination of warning lights and warning messages displayed on the instrument

panel. These warning lights illuminate during the starting phase and in the event of an injection fault or engine

overheating.

The warning light illumination signals reach the instrument panel via the multiplex network.

Warning light illumination principle

During the starting phase (START button pressed) the OBD (On Board Diagnostic) warning light comes on for

approximately 3 seconds then goes out.

If there is an injection fault (severity 1), the INJECTION FAULT written message lights up followed by the SERVICE

warning light. It indicates a reduced level of operation and a limited safety level.

The driver should carry out repairs as soon as possible.

Components involved:

– motorised throttle valve,

– accelerator pedal potentiometer,

– inlet manifold pressure sensor,

–computer,

– actuator feed,

– computer feed.

If there is a serious injection fault (severity 2), the red engine symbol and the word STOP appear (display with

information display only), with the ENGINE OVERHEATING written message followed by the STOP warning light

and a buzzer. If this happens, the vehicle must be stopped immediately.

When a fault causing excessive pollution in the exhaust fumes is detected, the orange OBD warning light, an engine

symbol, will be lit:

–flashing in the event of a fault which might irreparably damaged the catalytic converter (destructive misfire). If this

happens you must stop the vehicle immediately,

–constantly in the case of non-compliance with the anti-pollution standards (pollutant misfire, catalytic converter

fault, oxygen sensor faults, inconsistency between the oxygen sensors and canister fault).

Mileage travelled with fault

This parameter serves to measure the distance travelled with one of the injection fault warning lights on: level 1 fault

warning light (amber), coolant temperature overheating warning light, or OBD warning light.

The counter can be reset to 0 using the diagnostic tool.

JSAA741.0

Page 15 of 181

PETROL INJECTION

Fault finding – Replacement of components17B

17B - 15V12 MR-372-J84-17B000$180.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48PETROL INJECTION

Fault finding – Replacement of components

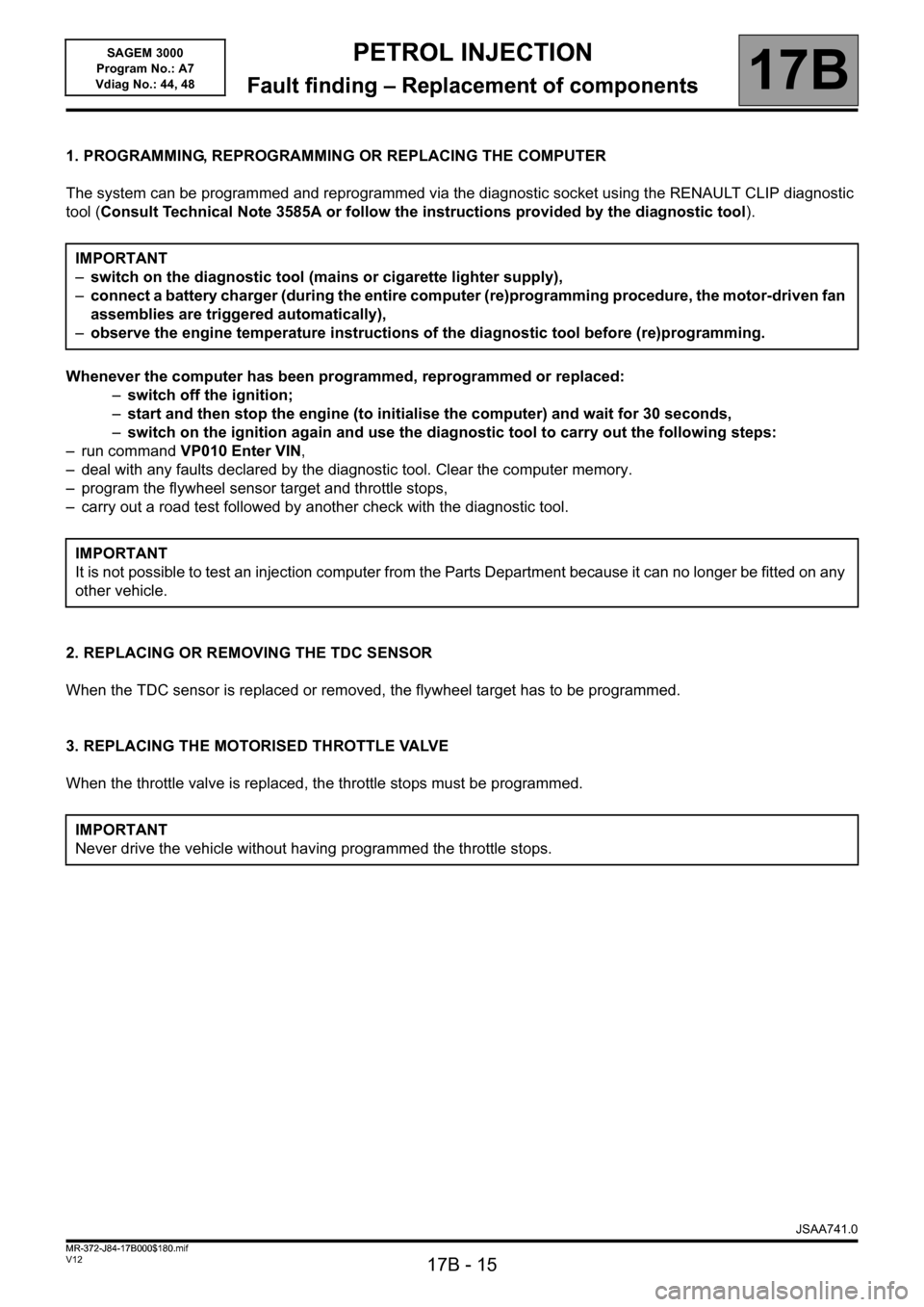

1. PROGRAMMING, REPROGRAMMING OR REPLACING THE COMPUTER

The system can be programmed and reprogrammed via the diagnostic socket using the RENAULT CLIP diagnostic

tool (Consult Technical Note 3585A or follow the instructions provided by the diagnostic tool).

Whenever the computer has been programmed, reprogrammed or replaced:

–switch off the ignition;

–start and then stop the engine (to initialise the computer) and wait for 30 seconds,

–switch on the ignition again and use the diagnostic tool to carry out the following steps:

– run command VP010 Enter VIN,

– deal with any faults declared by the diagnostic tool. Clear the computer memory.

– program the flywheel sensor target and throttle stops,

– carry out a road test followed by another check with the diagnostic tool.

2. REPLACING OR REMOVING THE TDC SENSOR

When the TDC sensor is replaced or removed, the flywheel target has to be programmed.

3. REPLACING THE MOTORISED THROTTLE VALVE

When the throttle valve is replaced, the throttle stops must be programmed.IMPORTANT

–switch on the diagnostic tool (mains or cigarette lighter supply),

–connect a battery charger (during the entire computer (re)programming procedure, the motor-driven fan

assemblies are triggered automatically),

–observe the engine temperature instructions of the diagnostic tool before (re)programming.

IMPORTANT

It is not possible to test an injection computer from the Parts Department because it can no longer be fitted on any

other vehicle.

IMPORTANT

Never drive the vehicle without having programmed the throttle stops.

JSAA741.0

MR-372-J84-17B000$180.mif

Page 102 of 181

PETROL INJECTION

Fault finding – Conformity check17B

17B-102V12 MR-372-J84-17B000$450.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

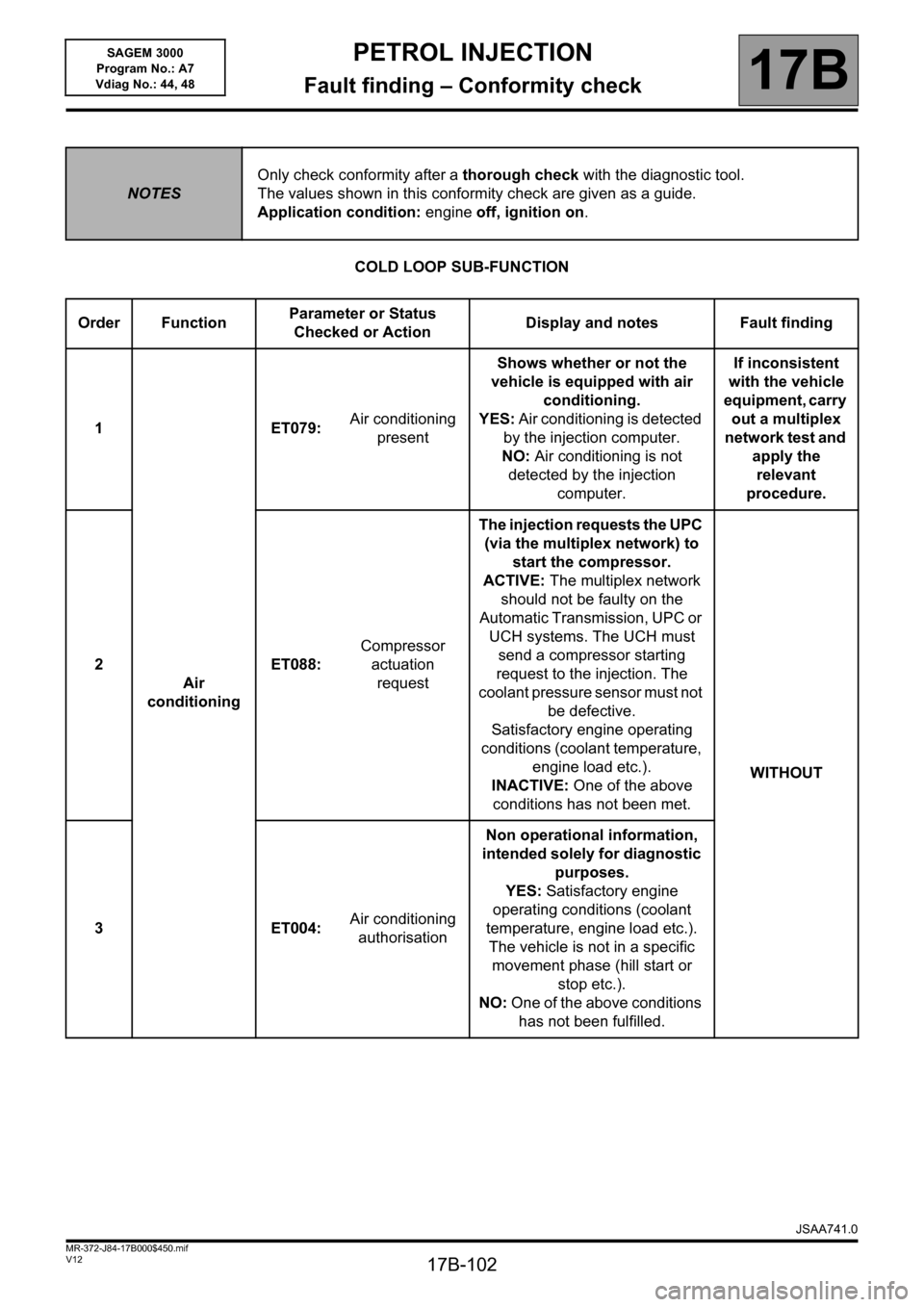

COLD LOOP SUB-FUNCTION

NOTESOnly check conformity after a thorough check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application condition: engine off, ignition on.

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

1

Air

conditioningET079: Air conditioning

presentShows whether or not the

vehicle is equipped with air

conditioning.

YES: Air conditioning is detected

by the injection computer.

NO: Air conditioning is not

detected by the injection

computer.If inconsistent

with the vehicle

equipment, carry

out a multiplex

network test and

apply the

relevant

procedure.

2ET088: Compressor

actuation

requestThe injection requests the UPC

(via the multiplex network) to

start the compressor.

ACTIVE: The multiplex network

should not be faulty on the

Automatic Transmission, UPC or

UCH systems. The UCH must

send a compressor starting

request to the injection. The

coolant pressure sensor must not

be defective.

Satisfactory engine operating

conditions (coolant temperature,

engine load etc.).

INACTIVE: One of the above

conditions has not been met.WITHOUT

3ET004: Air conditioning

authorisationNon operational information,

intended solely for diagnostic

purposes.

YES: Satisfactory engine

operating conditions (coolant

temperature, engine load etc.).

The vehicle is not in a specific

movement phase (hill start or

stop etc.).

NO: One of the above conditions

has not been fulfilled.

JSAA741.0

Page 108 of 181

PETROL INJECTION

Fault finding – Conformity check17B

17B-108V12 MR-372-J84-17B000$450.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

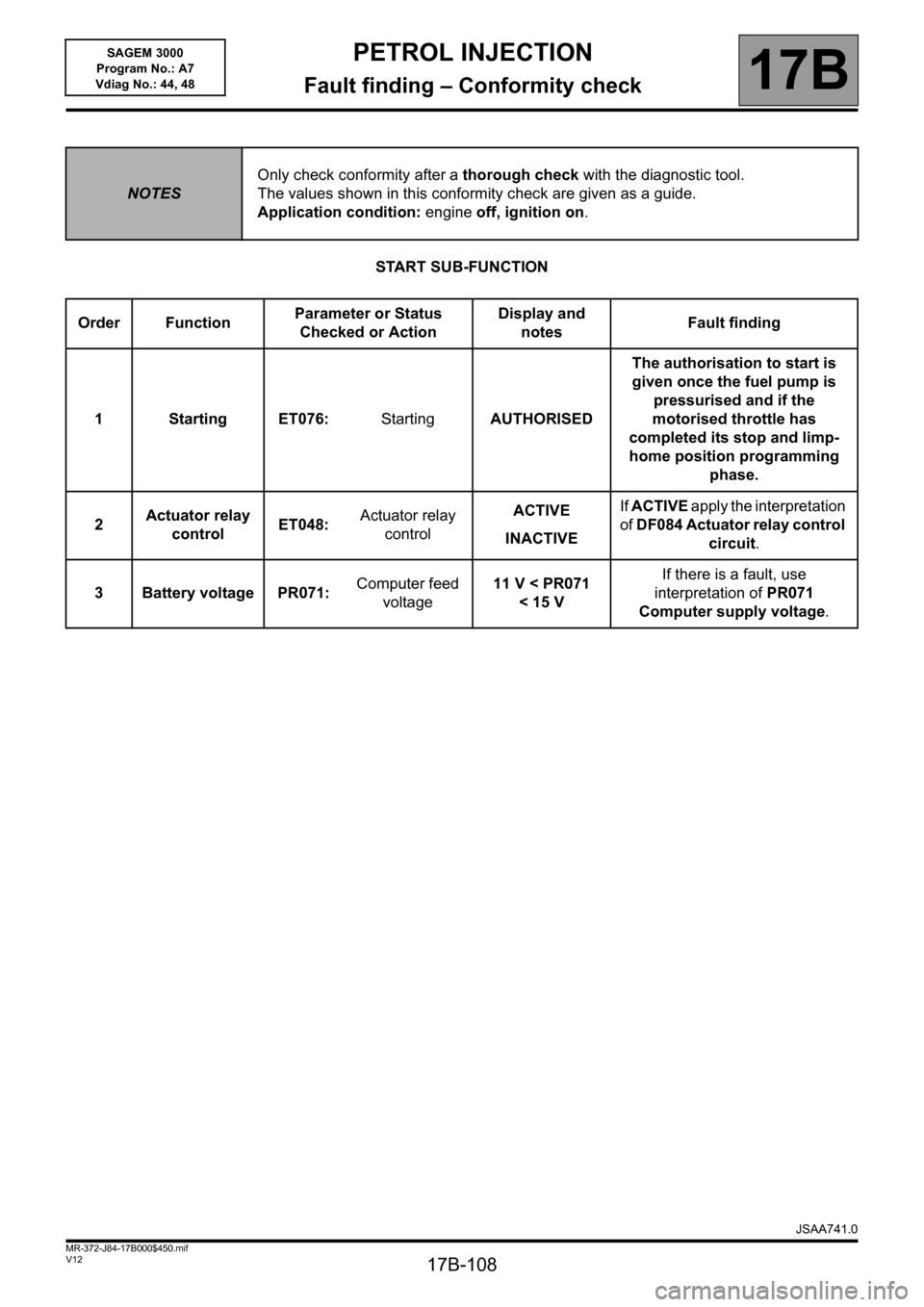

START SUB-FUNCTION

NOTESOnly check conformity after a thorough check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application condition: engine off, ignition on.

Order FunctionParameter or Status

Checked or ActionDisplay and

notes Fault finding

1 Starting ET076: StartingAUTHORISEDThe authorisation to start is

given once the fuel pump is

pressurised and if the

motorised throttle has

completed its stop and limp-

home position programming

phase.

2Actuator relay

controlET048: Actuator relay

controlACTIVE

INACTIVEIf ACTIVE apply the interpretation

of DF084 Actuator relay control

circuit.

3 Battery voltage PR071: Computer feed

voltage11 V < PR071

<15VIf there is a fault, use

interpretation of PR071

Computer supply voltage.

JSAA741.0

Page 109 of 181

PETROL INJECTION

Fault finding – Conformity check17B

17B-109V12 MR-372-J84-17B000$450.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

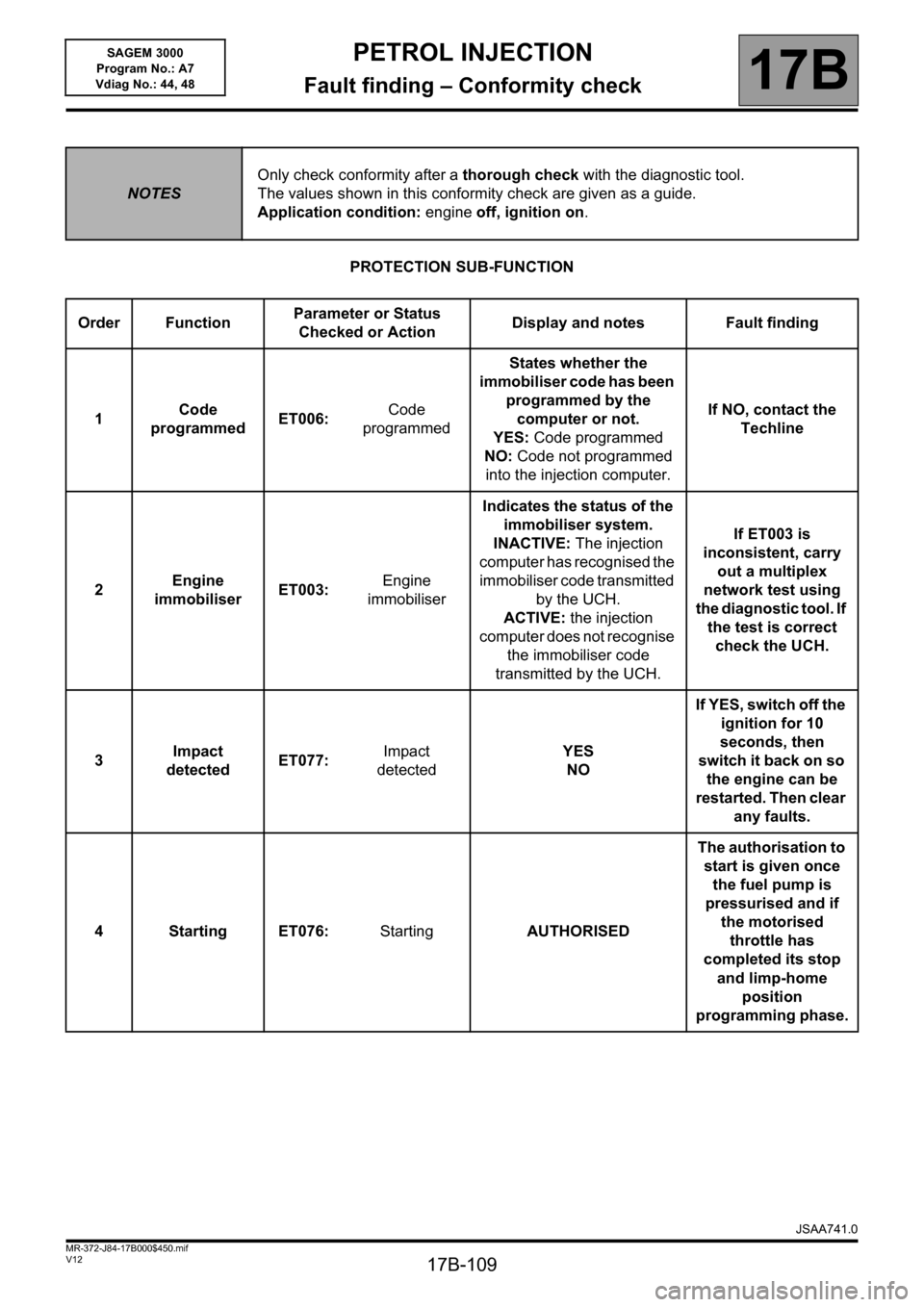

PROTECTION SUB-FUNCTION

NOTESOnly check conformity after a thorough check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application condition: engine off, ignition on.

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

1Code

programmedET006: Code

programmedStates whether the

immobiliser code has been

programmed by the

computer or not.

YES: Code programmed

NO: Code not programmed

into the injection computer.If NO, contact the

Techline

2Engine

immobiliserET003: Engine

immobiliserIndicates the status of the

immobiliser system.

INACTIVE: The injection

computer has recognised the

immobiliser code transmitted

by the UCH.

ACTIVE: the injection

computer does not recognise

the immobiliser code

transmitted by the UCH.If ET003 is

inconsistent, carry

out a multiplex

network test using

the diagnostic tool. If

the test is correct

check the UCH.

3Impact

detectedET077: Impact

detectedYES

NOIf YES, switch off the

ignition for 10

seconds, then

switch it back on so

the engine can be

restarted. Then clear

any faults.

4 Starting ET076: StartingAUTHORISEDThe authorisation to

start is given once

the fuel pump is

pressurised and if

the motorised

throttle has

completed its stop

and limp-home

position

programming phase.

JSAA741.0

Page 123 of 181

PETROL INJECTION

Fault finding – Conformity check17B

17B - 123V12 MR-372-J84-17B000$495.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

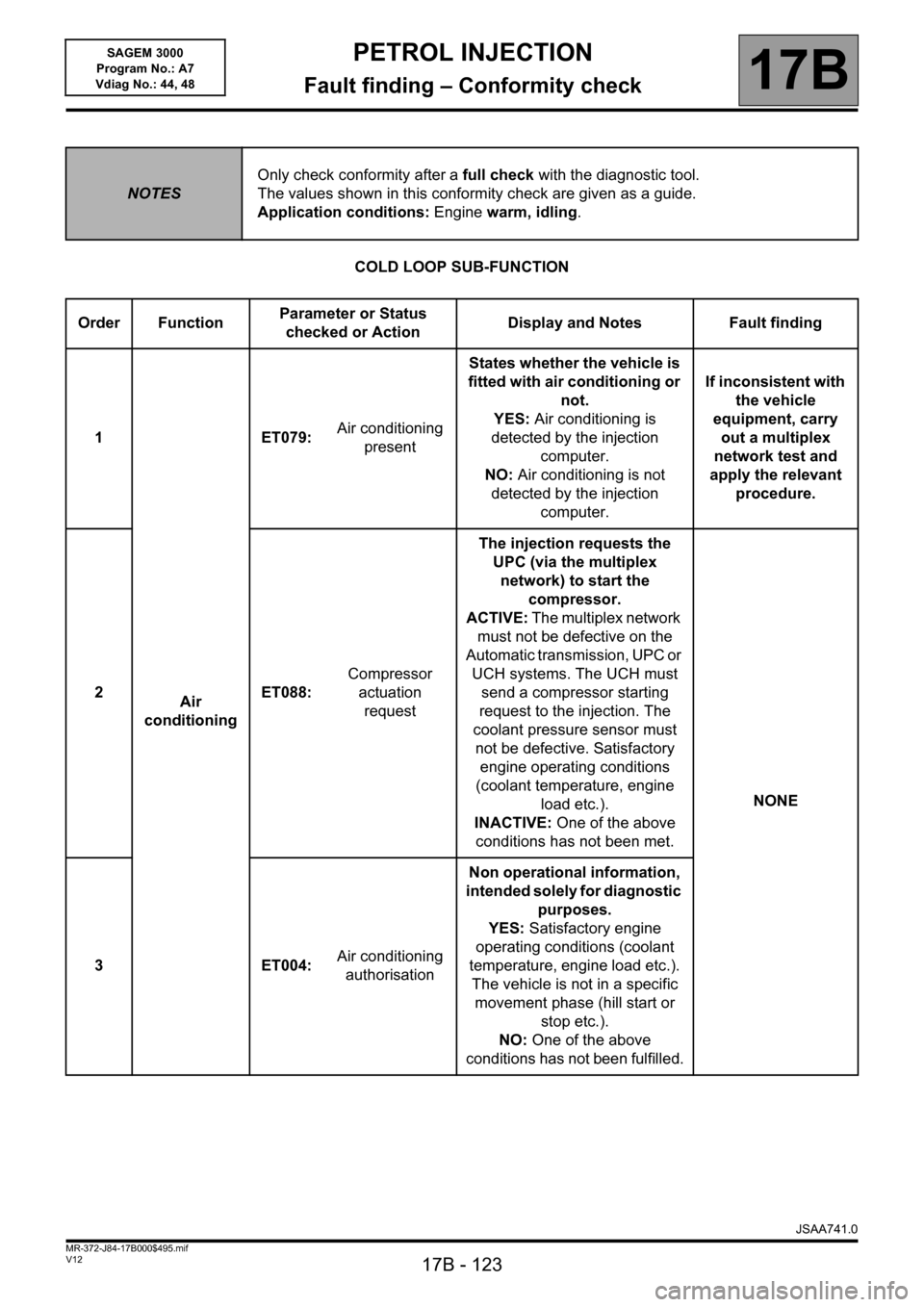

COLD LOOP SUB-FUNCTION

NOTESOnly check conformity after a full check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine warm, idling.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

1

Air

conditioningET079: Air conditioning

presentStates whether the vehicle is

fitted with air conditioning or

not.

YES: Air conditioning is

detected by the injection

computer.

NO: Air conditioning is not

detected by the injection

computer.If inconsistent with

the vehicle

equipment, carry

out a multiplex

network test and

apply the relevant

procedure.

2ET088: Compressor

actuation

requestThe injection requests the

UPC (via the multiplex

network) to start the

compressor.

ACTIVE: The multiplex network

must not be defective on the

Automatic transmission, UPC or

UCH systems. The UCH must

send a compressor starting

request to the injection. The

coolant pressure sensor must

not be defective. Satisfactory

engine operating conditions

(coolant temperature, engine

load etc.).

INACTIVE: One of the above

conditions has not been met.NONE

3ET004: Air conditioning

authorisationNon operational information,

intended solely for diagnostic

purposes.

YES: Satisfactory engine

operating conditions (coolant

temperature, engine load etc.).

The vehicle is not in a specific

movement phase (hill start or

stop etc.).

NO: One of the above

conditions has not been fulfilled.

JSAA741.0

Page 129 of 181

PETROL INJECTION

Fault finding – Conformity check17B

17B - 129V12 MR-372-J84-17B000$495.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

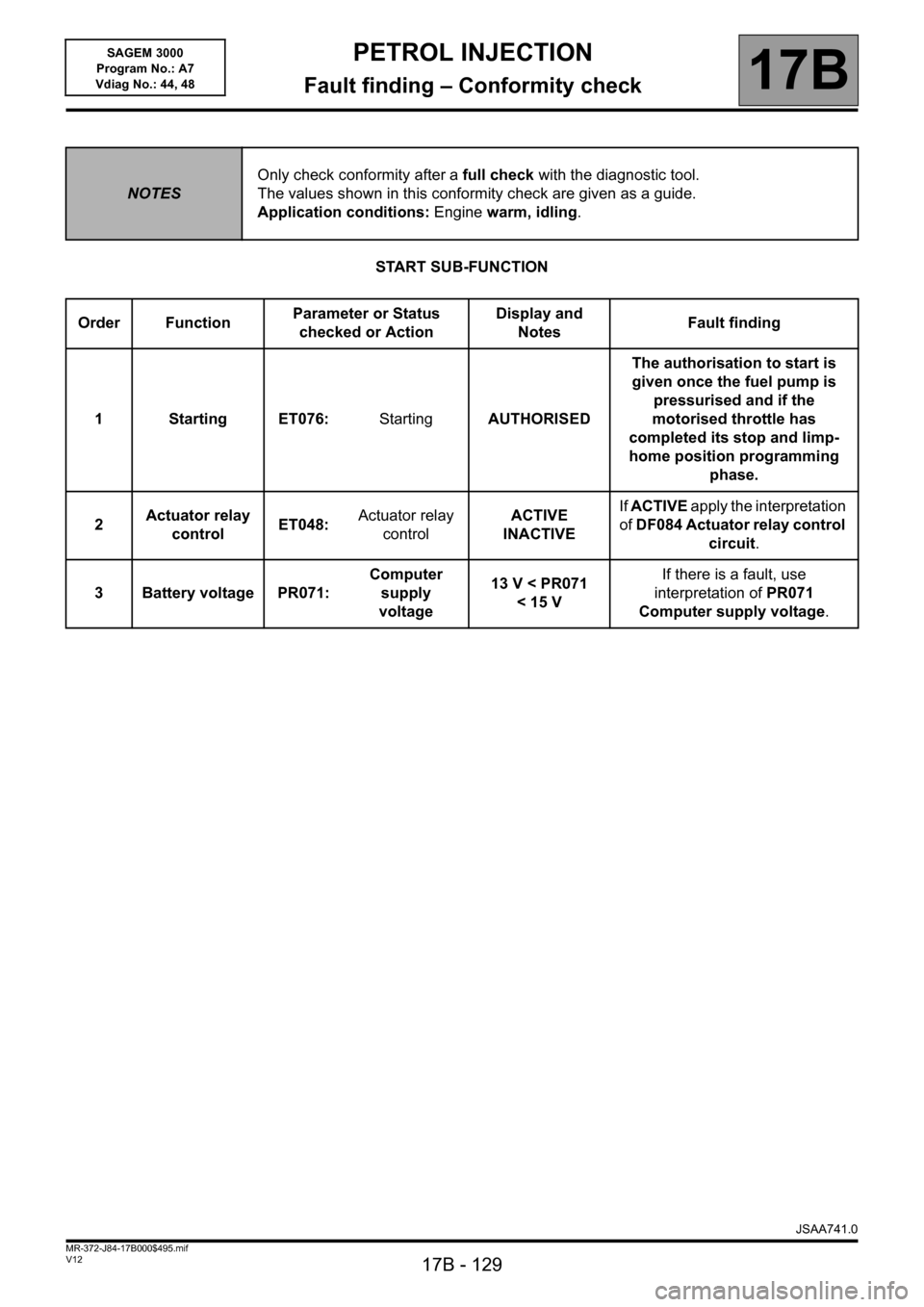

START SUB-FUNCTION

NOTESOnly check conformity after a full check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine warm, idling.

Order FunctionParameter or Status

checked or ActionDisplay and

Notes Fault finding

1 Starting ET076: StartingAUTHORISEDThe authorisation to start is

given once the fuel pump is

pressurised and if the

motorised throttle has

completed its stop and limp-

home position programming

phase.

2Actuator relay

controlET048: Actuator relay

controlACTIVE

INACTIVEIf ACTIVE apply the interpretation

of DF084 Actuator relay control

circuit.

3 Battery voltage PR071: Computer

supply

voltage13 V < PR071

<15VIf there is a fault, use

interpretation of PR071

Computer supply voltage.

JSAA741.0

Page 130 of 181

PETROL INJECTION

Fault finding – Conformity check17B

17B - 130V12 MR-372-J84-17B000$495.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

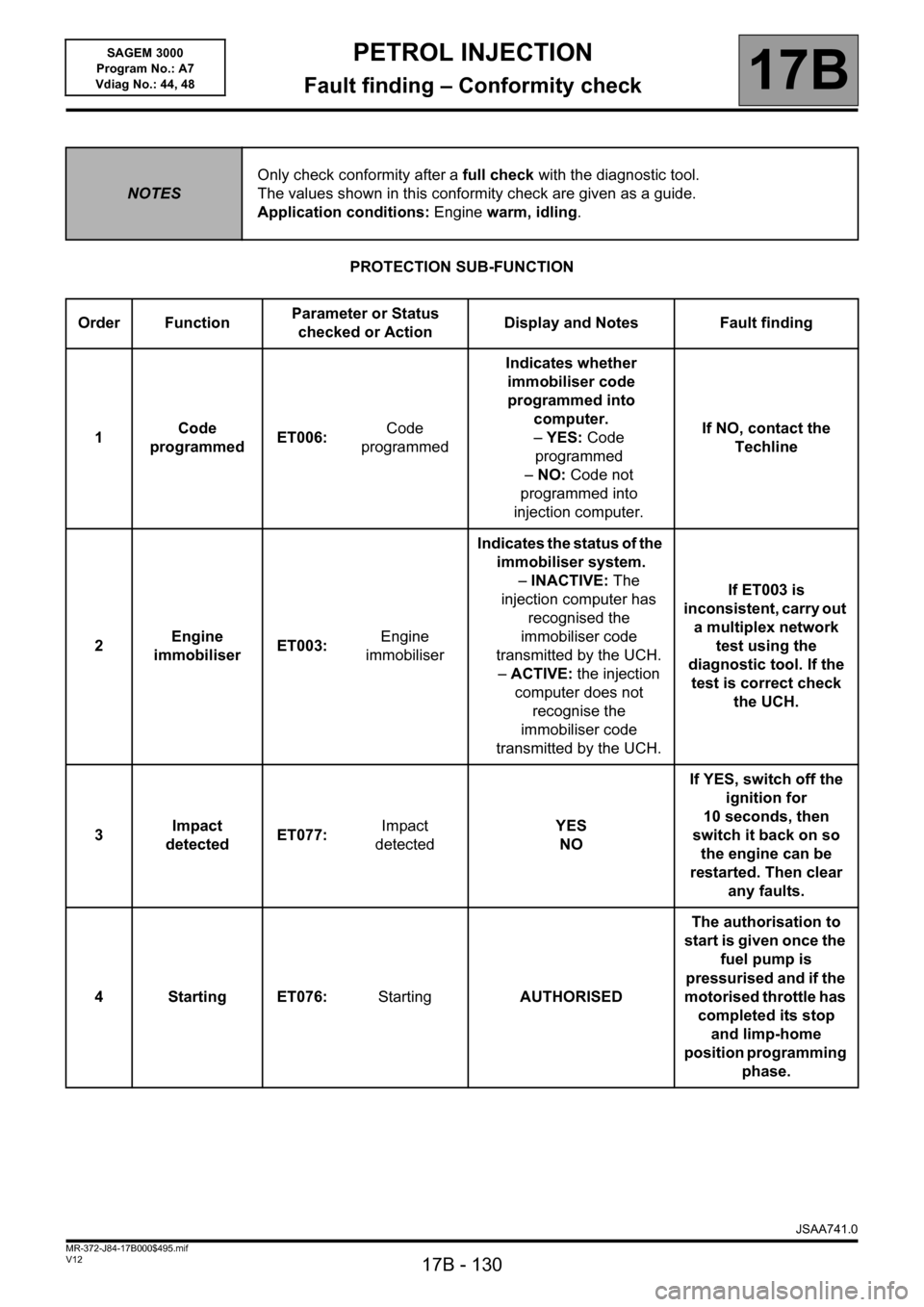

PROTECTION SUB-FUNCTION

NOTESOnly check conformity after a full check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application conditions: Engine warm, idling.

Order FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

1Code

programmedET006: Code

programmedIndicates whether

immobiliser code

programmed into

computer.

–YES: Code

programmed

–NO: Code not

programmed into

injection computer.If NO, contact the

Techline

2Engine

immobiliserET003: Engine

immobiliserIndicates the status of the

immobiliser system.

–INACTIVE: The

injection computer has

recognised the

immobiliser code

transmitted by the UCH.

–ACTIVE: the injection

computer does not

recognise the

immobiliser code

transmitted by the UCH.If ET003 is

inconsistent, carry out

a multiplex network

test using the

diagnostic tool. If the

test is correct check

the UCH.

3Impact

detectedET077: Impact

detectedYES

NOIf YES, switch off the

ignition for

10 seconds, then

switch it back on so

the engine can be

restarted. Then clear

any faults.

4 Starting ET076: StartingAUTHORISEDThe authorisation to

start is given once the

fuel pump is

pressurised and if the

motorised throttle has

completed its stop

and limp-home

position programming

phase.

JSAA741.0

Page 167 of 181

17B-167

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and perform a road test followed by a check using the diagnostic

tool.

V12 MR-372-J84-17B000$765.mif

17B

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

SC006

RUN OBD TEST: CATALYTIC CONVERTER

NOTESIMPORTANT:

Do not perform this test with a new catalytic converter.

Repair all the electrical faults and clear them from the memory.

Program the flywheel target ET089 Programming the engine flywheel target.

Check the appearance and condition of the catalytic converter.

Check there are no air leaks, thermal shock, misfiring, coolant or oil consumption.

It is preferable to run this command with a warm engine. This reduces the time it takes

for the catalytic converter to heat up.

The purpose of this command is to determine the condition of the catalytic converter

Procedure:

– Engine stopped.

– Run command SC006.

– Start the vehicle without losing the + after ignition feed

– Wait for the command result.

At the end of this test, four different results are possible:

–Status 1: Fault finding not carried out/impossible to obtain the necessary conditions.

–Status 2: Component in an average condition.

–Status 3: Component in good condition.

–Status 4: Component in poor condition.

When the command is complete and after the result has been read, stop the engine and start it again to obtain the

conditions relating to normal use.

If the result is Status 1: check for any faults, and the engine flywheel target programming using ET089.

If the result is Status 2 or Status 4: replace the catalytic converter.

If the result is Status 3: the catalytic converter is in good condition.

S3000_V44_SC006 / S3000_V48_SC006

JSAA741.0

PETROL INJECTION

Fault finding – Interpretation of commands

Page 168 of 181

17B-168

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition and perform a road test followed by a check using the diagnostic

tool.

V12 MR-372-J84-17B000$765.mif

PETROL INJECTION

Fault finding – Interpretation of commands17B

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

*EOBD: European On Board DiagnosticsSC007

RUN OBD TEST: O2 SENSOR

NOTESRepair all the electrical faults and clear them from the memory.

Program the flywheel target ET089 Programming the engine flywheel target.

It is preferable to run this command with a warm engine. This reduces the time it takes

for the catalytic converter to heat up.

The aim of this command is to detect a fault causing the EOBD* threshold for pollutant emissions to be exceeded.

There are two kinds of oxygen sensor damage:

– mechanical damage to the component (breakage, cut in wire) which leads to an electrical fault,

– chemical or thermal damage to the component leading to a slower response time of the sensor and to the

increase in the average reaction time.

Procedure:

– Engine stopped.

– Run command SC007.

– Start the vehicle without losing the + after ignition feed

– Wait for the command result.

Fault finding is entirely autonomous. When completed, the throttle control ceases and the engine returns to idling

speed regulation operation.

At the end of this test, four different results are possible:

–Status 1: Fault finding not carried out/impossible to obtain the necessary conditions.

–Status 2: Component in an average condition.

–Status 3: Component in good condition.

–Status 4: Component in poor condition.

When the command is complete and after the result has been read, stop the engine and start it again to obtain the

conditions relating to normal use.

If the result is Status 1: check for any faults, and the engine flywheel target programming using ET089.

If the result is Status 2 or Status 4: replace the sensor.

If the result is Status 3: the sensor is in good condition.

S3000_V44_SC007 / S3000_V48_SC007

JSAA741.0