Wheel RENAULT TALISMAN 2016 1.G Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2016, Model line: TALISMAN, Model: RENAULT TALISMAN 2016 1.GPages: 328, PDF Size: 3.39 MB

Page 262 of 328

5.2

PUNCTURE, EMERGENCY SPARE WHEEL

If the vehicle is parked on

the hard shoulder, you must

warn other road users of

your vehicle’s presence

with a warning triangle or with other

devices as per the legislation apply-

ing to the country you are in.

Special note

The Tyre Pressure Monitor function

does not check the emergency spare

wheel (the wheel replaced by the emer-

gency spare wheel disappears from the

instrument panel display).

Refer to the information on the “Tyre

pressure monitoring system” in

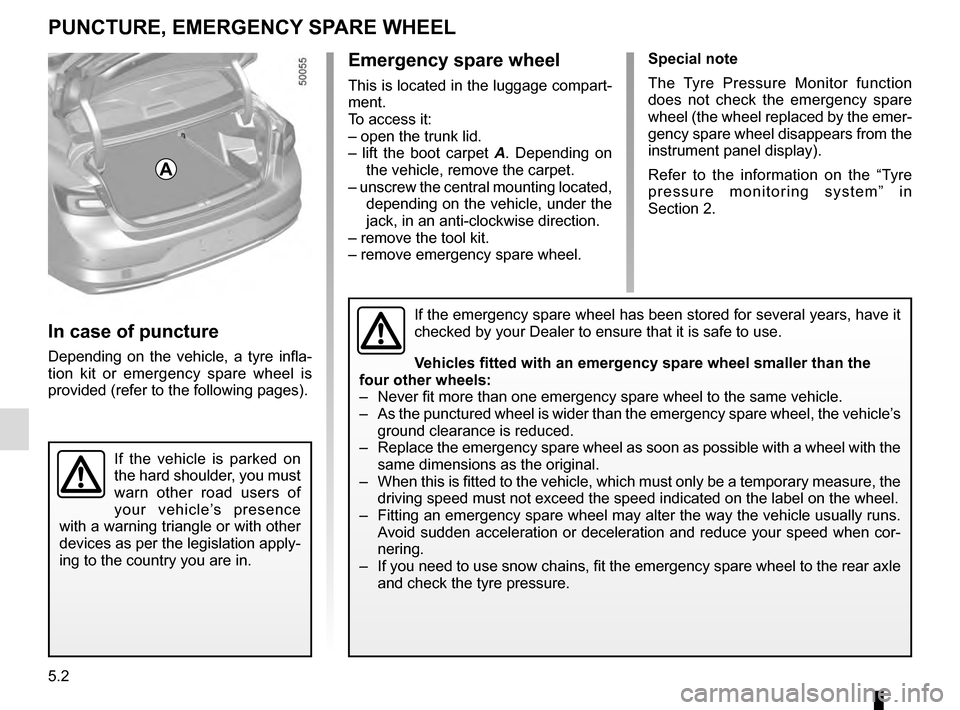

Section 2.Emergency spare wheel

This is located in the luggage compart-

ment.

To access it:

– open the trunk lid.

– lift the boot carpet A . Depending on

the vehicle, remove the carpet.

– unscrew the central mounting located, depending on the vehicle, under the

jack, in an anti-clockwise direction.

– remove the tool kit.

– remove emergency spare wheel.

If the emergency spare wheel has been stored for several years, have it \

checked by your Dealer to ensure that it is safe to use.

Vehicles fitted with an emergency spare wheel smaller than the

four other wheels:

– Never fit more than one emergency spare wheel to the same vehicle.

– As the punctured wheel is wider than the emergency spare wheel, the vehi\

cle’s ground clearance is reduced.

– Replace the emergency spare wheel as soon as possible with a wheel with \

the same dimensions as the original.

– When this is fitted to the vehicle, which must only be a temporary measu\

re, the driving speed must not exceed the speed indicated on the label on the wh\

eel.

– Fitting an emergency spare wheel may alter the way the vehicle usually r\

uns. Avoid sudden acceleration or deceleration and reduce your speed when cor-\

nering.

– If you need to use snow chains, fit the emergency spare wheel to the rea\

r axle and check the tyre pressure.

A

In case of puncture

Depending on the vehicle, a tyre infla-

tion kit or emergency spare wheel is

provided (refer to the following pages).

Page 263 of 328

5.3

TYRE INFLATION KIT (1/4)

The kit is only approved for

inflating the tyres of the ve-

hicle originally equipped

with the kit.

It must never be used to inflate

the tyres of another vehicle, or any

other inflatable object (rubber ring,

rubber boat, etc.).

Avoid spillage on skin when hand-

ling the repair liquid bottle. If drop-

lets do leak out, rinse them off with

plenty of water.

Keep the repair kit away from chil-

dren.

Do not dispose of the empty bottle

in the countryside. Return it to your

approved dealer or to a recycling or-

ganisation.

The bottle has a limited service

life which is indicated on its label.

Check the expiry date.

Contact an approved dealer to re-

place the inflation tube and repair

product bottle.

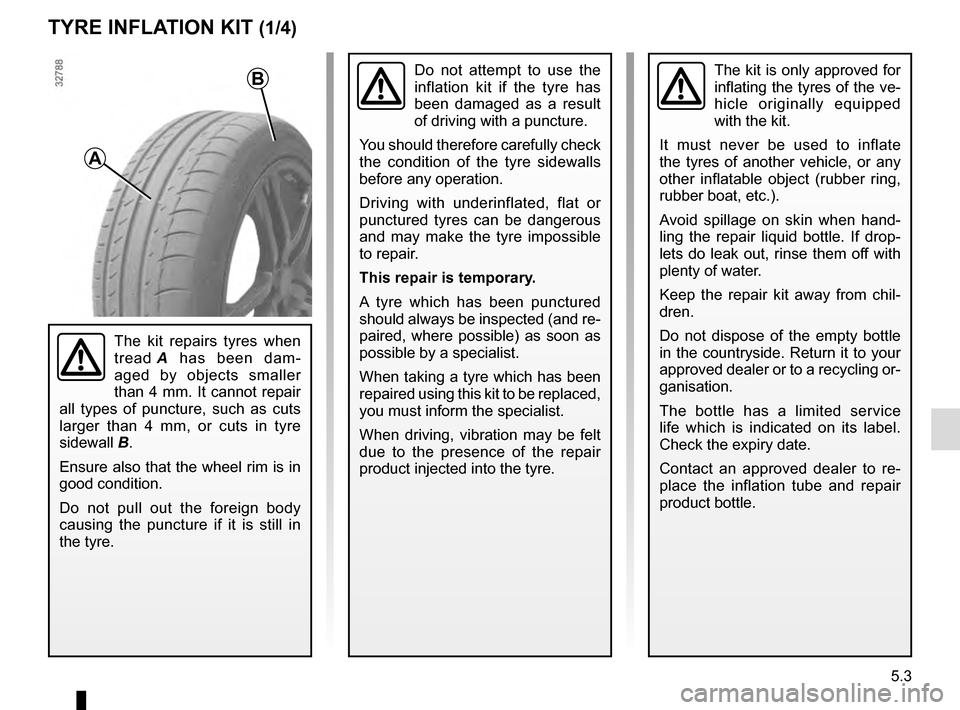

A

B

The kit repairs tyres when

tread A has been dam-

aged by objects smaller

than 4 mm. It cannot repair

all types of puncture, such as cuts

larger than 4 mm, or cuts in tyre

sidewall B.

Ensure also that the wheel rim is in

good condition.

Do not pull out the foreign body

causing the puncture if it is still in

the tyre.

Do not attempt to use the

inflation kit if the tyre has

been damaged as a result

of driving with a puncture.

You should therefore carefully check

the condition of the tyre sidewalls

before any operation.

Driving with underinflated, flat or

punctured tyres can be dangerous

and may make the tyre impossible

to repair.

This repair is temporary.

A tyre which has been punctured

should always be inspected (and re-

paired, where possible) as soon as

possible by a specialist.

When taking a tyre which has been

repaired using this kit to be replaced,

you must inform the specialist.

When driving, vibration may be felt

due to the presence of the repair

product injected into the tyre.

Page 264 of 328

5.4

TYRE INFLATION KIT (2/4)

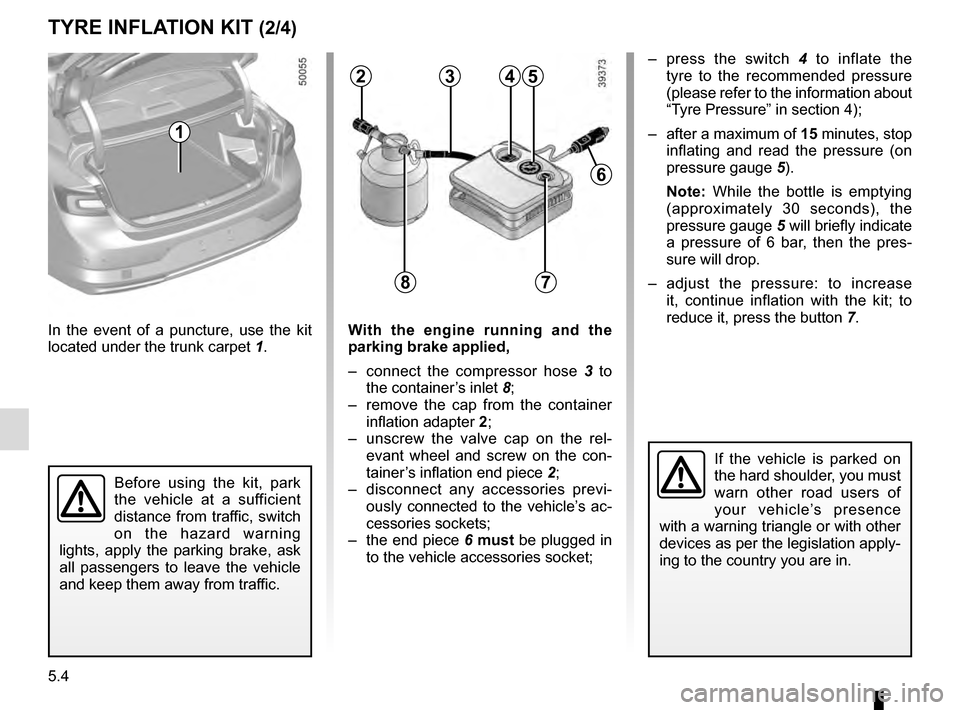

In the event of a puncture, use the kit

located under the trunk carpet 1.With the engine running and the

parking brake applied,

– connect the compressor hose 3 to

the container’s inlet 8;

– remove the cap from the container inflation adapter 2;

– unscrew the valve cap on the rel- evant wheel and screw on the con-

tainer’s inflation end piece 2;

– disconnect any accessories previ- ously connected to the vehicle’s ac-

cessories sockets;

– the end piece 6 must be plugged in

to the vehicle accessories socket;

452

Before using the kit, park

the vehicle at a sufficient

distance from traffic, switch

on the hazard warning

lights, apply the parking brake, ask

all passengers to leave the vehicle

and keep them away from traffic.

8

If the vehicle is parked on

the hard shoulder, you must

warn other road users of

your vehicle’s presence

with a warning triangle or with other

devices as per the legislation apply-

ing to the country you are in.

– press the switch 4 to inflate the

tyre to the recommended pressure

(please refer to the information about

“Tyre Pressure” in section 4);

– after a maximum of 15 minutes, stop inflating and read the pressure (on

pressure gauge 5).

Note: While the bottle is emptying

(approximately 30 seconds), the

pressure gauge 5 will briefly indicate

a pressure of 6 bar, then the pres-

sure will drop.

– adjust the pressure: to increase it, continue inflation with the kit; to

reduce it, press the button 7.

6

3

7

1

Page 267 of 328

5.7

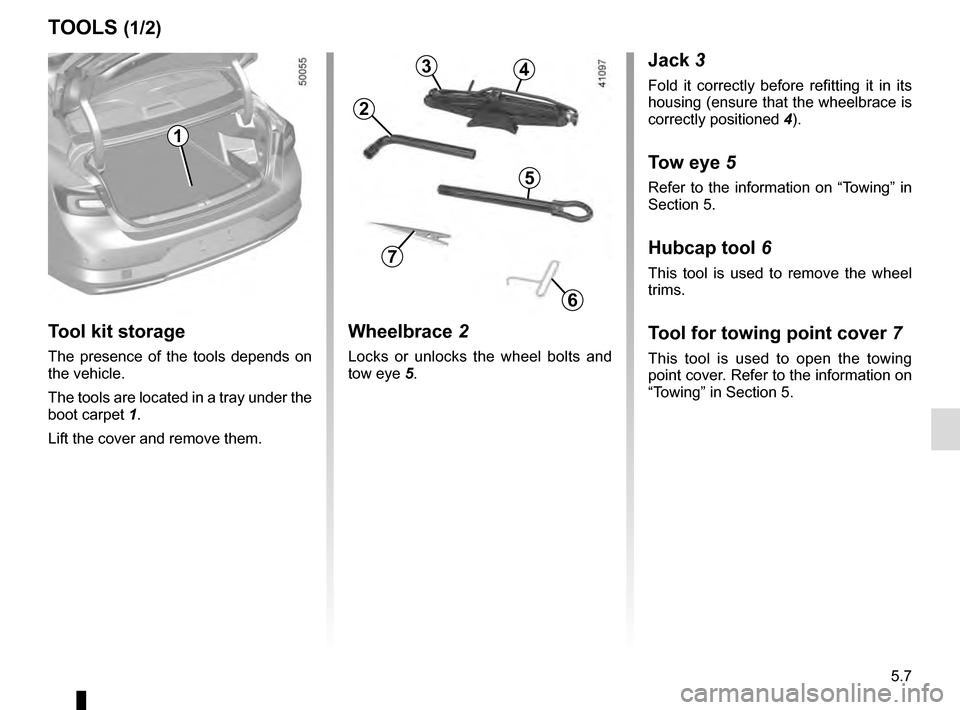

Jack 3

Fold it correctly before refitting it in its

housing (ensure that the wheelbrace is

correctly positioned 4).

Tow eye 5

Refer to the information on “Towing” in

Section 5.

Hubcap tool 6

This tool is used to remove the wheel

trims.

Tool for towing point cover 7

This tool is used to open the towing

point cover. Refer to the information on

“Towing” in Section 5.

Wheelbrace 2

Locks or unlocks the wheel bolts and

tow eye 5.

TOOLS (1/2)

3

2

5

64

B

Tool kit storage

The presence of the tools depends on

the vehicle.

The tools are located in a tray under the

boot carpet 1.

Lift the cover and remove them.

1

6

7

Page 268 of 328

5.8

TOOLS (2/2)/WHEEL TRIM

A

BC

D

Wheel trim

Remove using the hubcap tool 6 by

connecting the hook in the recess pro-

vided next to the valve 8 (to secure the

metal clip).

To refit the wheel trim, align it with

valve 8. Push the retaining hooks in

fully, starting with side A near the valve,

followed by B and C, finishing at D op-

posite the valve.

Note: if you are using anti-theft bolts,

refer to the information on “Changing a

wheel”.

Do not leave the tools un-

secured inside the vehicle

as they may come loose

under braking. After use,

check that all the tools are correctly

clipped into the tool kit, then posi-

tion it correctly in its housing: risk of

injury.

If wheel bolts are supplied in the

tool kit, only use these bolts for the

emergency spare wheel: refer to the

label affixed to the emergency spare

wheel.

The jack is designed for wheel

changing purposes only. Under no

circumstances should it be used for

carrying out repairs underneath the

vehicle or to gain access to the un-

derside of the vehicle.

6

8

Page 269 of 328

5.9

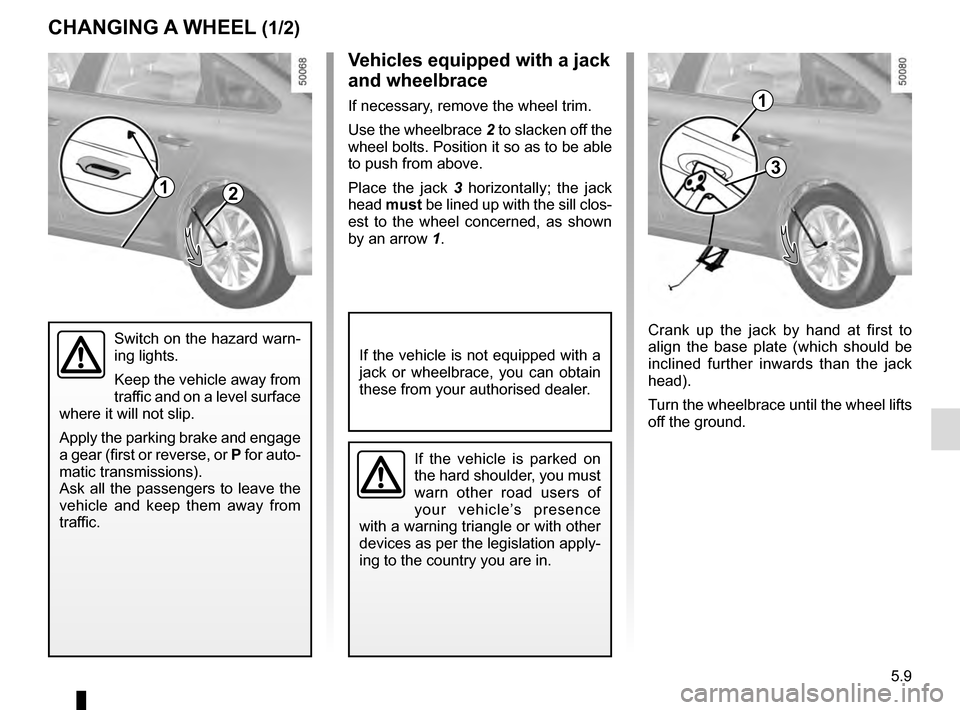

CHANGING A WHEEL (1/2)

2

Crank up the jack by hand at first to

align the base plate (which should be

inclined further inwards than the jack

head).

Turn the wheelbrace until the wheel lifts

off the ground.

Vehicles equipped with a jack

and wheelbrace

If necessary, remove the wheel trim.

Use the wheelbrace 2 to slacken off the

wheel bolts. Position it so as to be able

to push from above.

Place the jack 3 horizontally; the jack

head must be lined up with the sill clos-

est to the wheel concerned, as shown

by an arrow 1.

Switch on the hazard warn-

ing lights.

Keep the vehicle away from

traffic and on a level surface

where it will not slip.

Apply the parking brake and engage

a gear (first or reverse, or P for auto-

matic transmissions).

Ask all the passengers to leave the

vehicle and keep them away from

traffic.

If the vehicle is parked on

the hard shoulder, you must

warn other road users of

your vehicle’s presence

with a warning triangle or with other

devices as per the legislation apply-

ing to the country you are in.

If the vehicle is not equipped with a

jack or wheelbrace, you can obtain

these from your authorised dealer.

1

3

1

Page 270 of 328

5.10

Undo the bolts and take off the wheel.

Fit the emergency spare wheel onto

the hub and rotate it until the mounting

holes in the wheel coincide with those

of the hub.

If bolts are supplied with the emergency

spare wheel, only use these bolts for

the emergency spare wheel. Tighten

the bolts, checking that the wheel is

correctly positioned on its hub and un-

screw the jack.

With the wheel on the ground, tighten

the bolts fully and have the tightness of

the bolts checked and the emergency

spare wheel pressure checked as soon

as possible.

Anti-theft bolt

If you use anti-theft bolts, fit these

nearest the valve (wheel embel-

lisher may not be able to fit).

If you have a puncture, re-

place the wheel as soon as

possible.

A tyre which has been punc-

tured should always be inspected

(and repaired, where possible) by a

specialist.

CHANGING A WHEEL (2/2)

Page 271 of 328

5.11

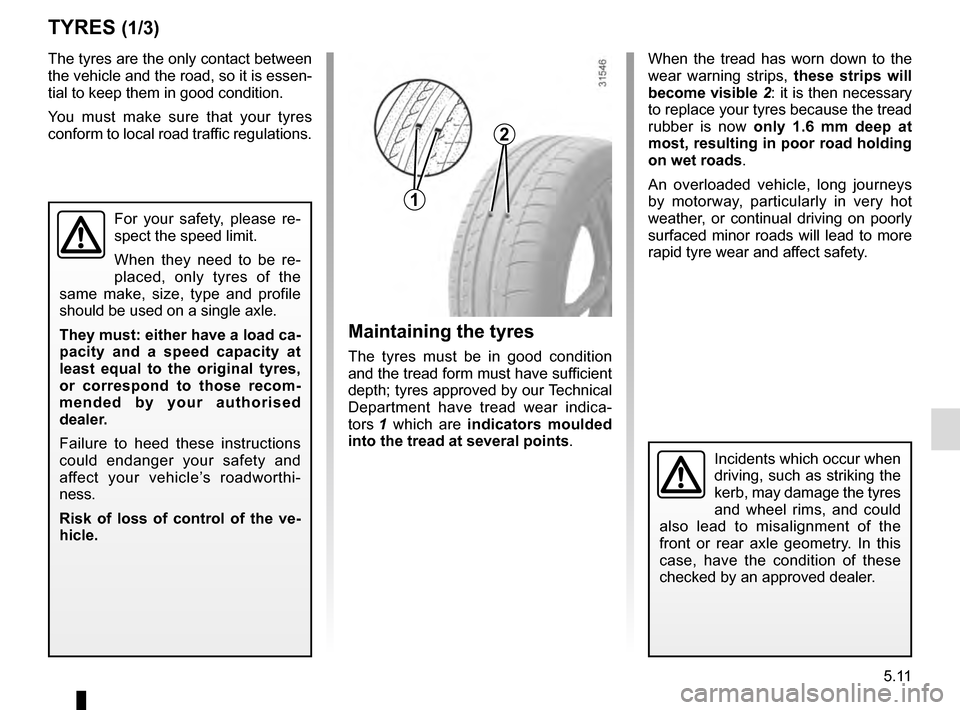

TYRES (1/3)

Maintaining the tyres

The tyres must be in good condition

and the tread form must have sufficient

depth; tyres approved by our Technical

Department have tread wear indica-

tors 1 which are indicators moulded

into the tread at several points .

The tyres are the only contact between

the vehicle and the road, so it is essen-

tial to keep them in good condition.

You must make sure that your tyres

conform to local road traffic regulations.

When the tread has worn down to the

wear warning strips,

these strips will

become visible 2: it is then necessary

to replace your tyres because the tread

rubber is now only 1.6 mm deep at

most, resulting in poor road holding

on wet roads.

An overloaded vehicle, long journeys

by motorway, particularly in very hot

weather, or continual driving on poorly

surfaced minor roads will lead to more

rapid tyre wear and affect safety.

Incidents which occur when

driving, such as striking the

kerb, may damage the tyres

and wheel rims, and could

also lead to misalignment of the

front or rear axle geometry. In this

case, have the condition of these

checked by an approved dealer.

2

1

For your safety, please re-

spect the speed limit.

When they need to be re-

placed, only tyres of the

same make, size, type and profile

should be used on a single axle.

They must: either have a load ca-

pacity and a speed capacity at

least equal to the original tyres,

or correspond to those recom-

mended by your authorised

dealer.

Failure to heed these instructions

could endanger your safety and

affect your vehicle’s roadworthi-

ness.

Risk of loss of control of the ve-

hicle.

Page 272 of 328

5.12

TYRES (2/3)

Tyre pressures

Adhere to the tyre pressures (including

the emergency spare wheel). The tyre

pressures should be checked at least

once a month and additionally before

any long journey (refer to the label af-

fixed to the edge of the driver’s door).The pressures should be checked cold:

ignore higher pressures which may be

reached in hot weather or following a

high speed journey.

If the tyre pressures cannot be checked

when the tyres are

cold, increase the

pressures from 0.2 to 0.3 bar (or 3 PSI).

Never deflate a hot tyre.

Special note

Depending on the vehicle, there may

be an adapter which needs to be posi-

tioned on the valve before air is added. Vehicle fitted with a tyre pressure

monitoring system

In cases of under-inflation (puncture,

low pressure, etc.), warning light

lights up on the instrument panel.

Please refer to the information on the

«Tyre pressure monitoring system» in

Section 2.

Emergency spare wheel

Refer to the information on “Puncture”

and “Changing a wheel” in Section 5.

Incorrect tyre pressures

lead to abnormal tyre wear

and unusually hot running.

These are factors which

may seriously affect safety and lead

to:

– poor road holding,

– risk of bursting or tread separa- tion.

The pressure depends on the load

and the speed of use. Adjust the

pressure according to the condi-

tions of use (refer to the label affixed

to the edge of the driver’s door).

Please be aware that a

poorly tightened or missing

valve cap can make the

tyres less airtight and lead

to pressure loss.

Always use valve caps identical to

those fitted originally and tighten

them fully.

Page 273 of 328

5.13

TYRES (3/3)

For safety reasons, this

operation must be carried

out by a specialist.

Fitting different tyres may

change your vehicle as follows:

– it may mean that your vehicle no longer conforms to current regu-

lations;

– it may change the way it handles when cornering;

– it may cause the steering to be heavy;

– It may affect the use of snow chains.

Use in winter

Chains

For safety reasons, fitting snow

chains to the rear axle is strictly for-

bidden.

Chains cannot be fitted to tyres which

are larger than those originally fitted to

the vehicle.

Snow or Winter tyres

We would recommend that these be

fitted to all four wheels to ensure that

your vehicle retains maximum adhe-

sion.

Warning : These tyres sometimes have

a specific direction of rotation and a

maximum speed index which may be

lower than the maximum speed of your

vehicle.

Snow chains may only be

fitted to tyres of the same

size as those originally

fitted to your vehicle.

In all cases, we would recommend

that you contact an authorised

dealer who will be able to advise you

on the choice of equipment which is

most suitable for your vehicle.

Changing a wheel

As the tyre pressure moni-

tor may take several min-

utes to correctly determine

the positions of the wheels and the

pressure values after driving, check

the tyre pressures following any op-

eration.

Studded tyres

This type of equipment may only be

used for a limited period and as laid

down by local legislation. It is neces-

sary to observe the speed specified by

current legislation.

These tyres must, at a minimum, be

fitted to the two front wheels.

18” wheels and larger

cannot be fitted with

chains.

If you wish to use special

equipment, consult an approved

dealer.

Fitting new tyres