charging RENAULT TWINGO 2009 2.G Air Conditioning User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 122

Page 108 of 122

62A-27

AIR CONDITIONING

Expansion valve - intermediate pipe connecting pipe at the expansion valve outlet: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

REMOVAL

I - PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aDrain the coolant circuit using a refrigerant charg-

ing station (see 62A, Air conditioning, Refriger-

ant circuit: Draining - Filling, page 62A-8) .

aDisconnect the battery (see ) (MR 411, 80A, Bat-

tery).

aRemove:

-the wiper arms (see Windscreen wiper arm: Re-

moval - Refitting) (MR 411, 85A, Wipers - Wash-

ers),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (MR 412, 56A, Exterior

equipment),-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (MR 412, 56A, Exterior equipment).

II - REMOVAL OPERATION FOR PART

CONCERNED

aRemove the « dehydrator reservoir - expansion

valve » and « expansion valve intermediate pipe »

(see 62A, Air conditioning, Dehydrator reservoir

- expansion valve connecting pipe: Removal -

Refitting, page 62A-28) connecting pipe assembly.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit the « expansion valve - intermediate pipe » -

« expansion valve - dehydrator reservoir » (see

62A, Air conditioning, Dehydrator reservoir - ex-

pansion valve connecting pipe: Removal - Refit-

ting, page 62A-28) connecting pipe assembly.

II - FINAL OPERATION.

aRefit:

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (MR 412, 56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (MR 412, 56A, Exterior

equipment),

-the wiper arms (see Windscreen wiper arm: Re-

moval - Refitting) (MR 411, 85A, Washing - wip-

ing).

aConnect the battery (see ) (MR 411, 80A, Battery).

aConsult the refrigerant and oil quantity values before

filling the circuit (see 62A, Air conditioning, Air

conditioning: Parts and consumables for the re-

pair, page 62A-2) .

aFill the refrigerant circuit using a refrigerant charg-

ing station (see 62A, Air conditioning, Refriger-

ant circuit: Draining - Filling, page 62A-8) .

aCheck that the air conditioning system is operating

correctly (see 62A, Air conditioning, Air condi-

tioning: Check, page 62A-4) .

aCheck for leaks (see 62A, Air conditioning, Refrig-

erant circuit: Check, page 62A-7) . Equipment required

refrigerant charging station

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see 62A, Air conditioning, Air condition-

ing: Precautions for the repair, page 62A-1) .

Note:

Use blanking plugs for the fuel circuits with part

numbers 77 01 208 229 or 77 01 476 857 to plug

any openings exposed to the open air. They must

be clean. Do not use plugs which have already

been used to plug a fuel circuit.

Note:

The « expansion valve - intermediate pipe » and

« expansion valve - dehydrator reservoir » connect-

ing pipes cannot be separated.

WARNING

Consult the device's operating manual to avoid

incorrect use.

Page 109 of 122

62A-28

AIR CONDITIONING

Dehydrator reservoir - expansion valve connecting pipe: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDrain the refrigerant circuit using a refrigerant

charging station (see 62A, Air conditioning, Re-

frigerant circuit: Draining - Filling, page 62A-8) .

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the wiper arms (see Windscreen wiper arm: Re-

moval - Refitting) (85A, Wiping - Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment). Special tooling required

Mot. 1410Set of refrigerant pipe union

disconnection sockets.

(dimensions in inches): 5/16,

3/8, 1/2, 5/8, 3/4, 7/8.

Equipment required

refrigerant charging station

compressed air nozzle

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see 62A, Air conditioning, Air conditioning:

Precautions for the repair, page 62A-1) ,

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

WARNING

To prevent moisture from entering the system,

place plugs on the cold loop components which are

open to the air.

WARNING

In order to avoid any refrigerant leaks, do not dam-

age (deform, twist, etc.) the pipe.

Note:

Use blanking plugs for the fuel circuits with part

numbers 77 01 2008 229 or 77 01 476 857 to plug

any openings exposed to the open air. They must

be clean. Do not use any which have already been

used to plug a fuel circuit.

WARNING

To prevent the surrounding components from over-

heating, do not damage (tear, pierce, bend, etc.) a

heat shield.

Any damaged heat shields must be replaced.

Note:

The « expansion valve - intermediate pipe » and

« expansion valve - dehydrator reservoir » connect-

ing pipes cannot be separated.

WARNING

Consult the device's operating manual to avoid

incorrect use.

Page 114 of 122

62A-33

AIR CONDITIONING

Compressor - condenser connecting pipe: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDrain the refrigerant circuit using a refrigerant

charging station (see 62A, Air conditioning, Re-

frigerant circuit: Draining - Filling, page 62A-8) .

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

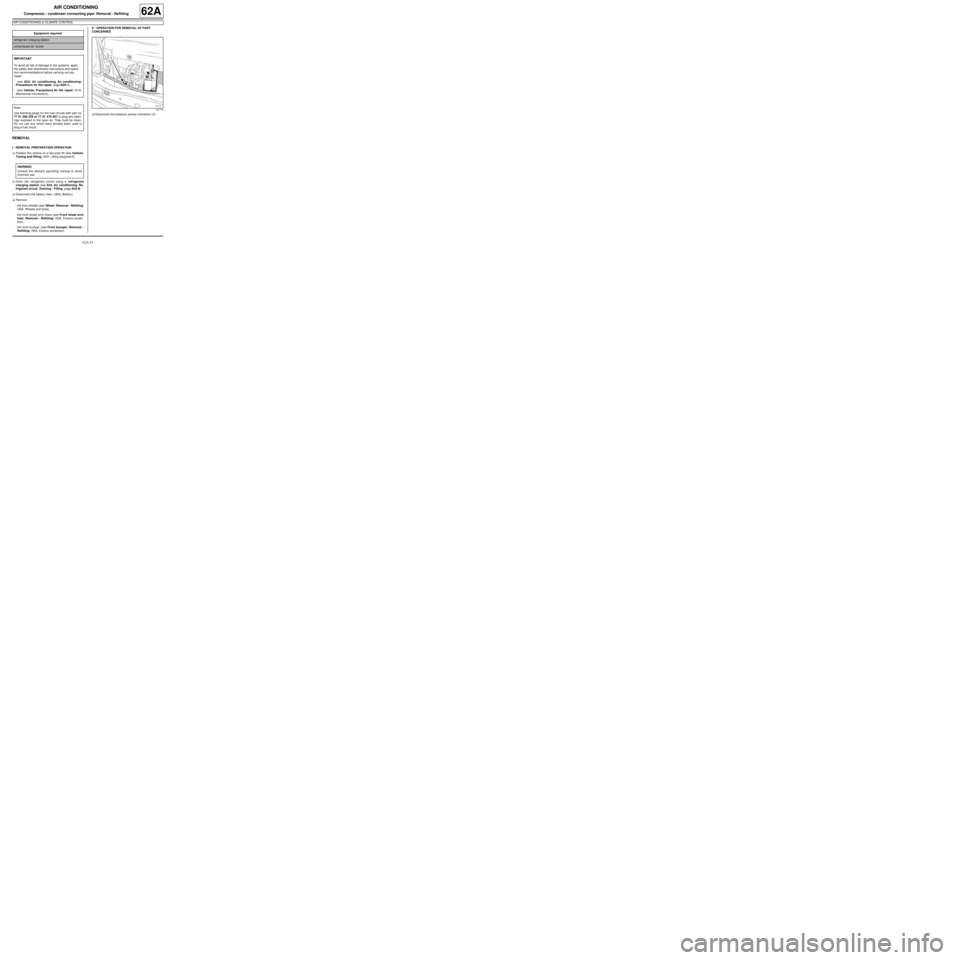

Refitting) (55A, Exterior protection).II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the pressure sensor connector (1) . Equipment required

refrigerant charging station

compressed air nozzle

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see 62A, Air conditioning, Air conditioning:

Precautions for the repair, page 62A-1) ,

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

Note:

Use blanking plugs for the fuel circuits with part no.

77 01 208 229 or 77 01 476 857 to plug any open-

ings exposed to the open air. They must be clean.

Do not use any which have already been used to

plug a fuel circuit.

WARNING

Consult the device's operating manual to avoid

incorrect use.

121174

Page 118 of 122

62A-37

AIR CONDITIONING

Compressor - intermediate pipe connecting pipe: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDrain the refrigerant circuit using a refrigerant

charging station (see 62A, Air conditioning, Re-

frigerant circuit: Draining - Filling, page 62A-8) .

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection).

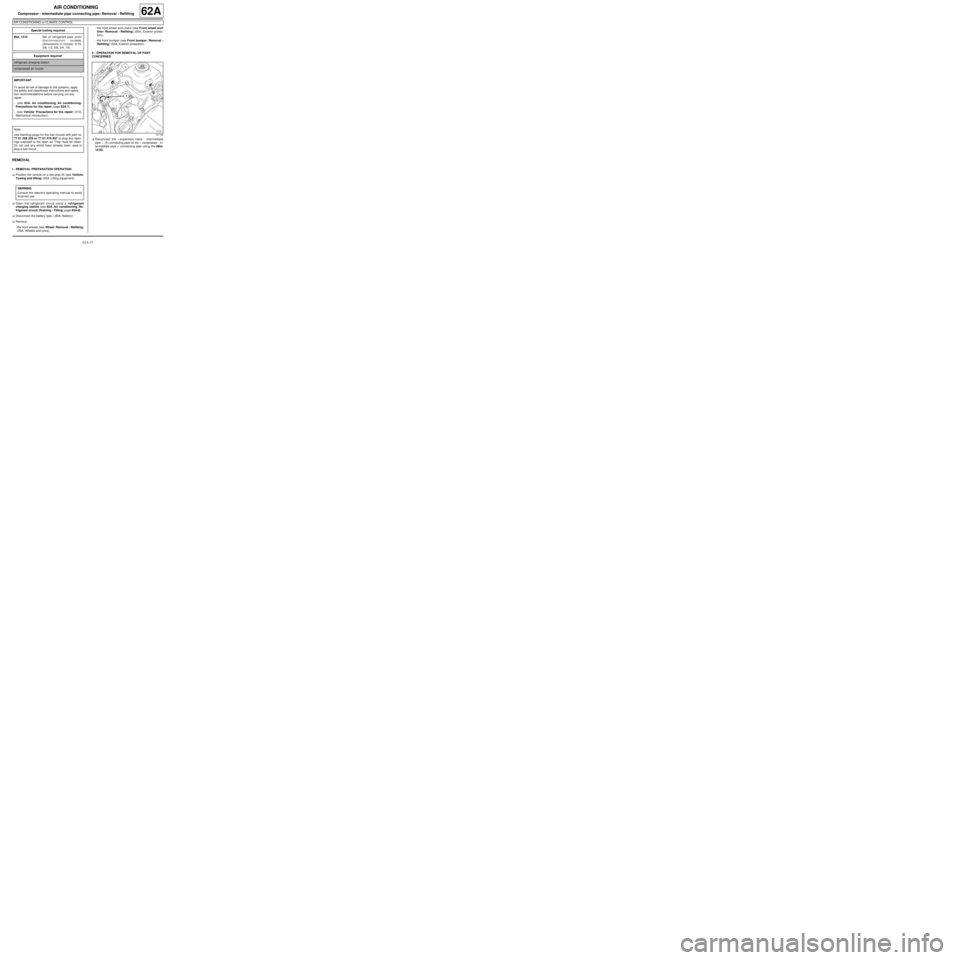

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the « expansion valve - intermediate

pipe » (1) connecting pipe on the « compressor - in-

termediate pipe » connecting pipe using the (Mot.

1410). Special tooling required

Mot. 1410Set of refrigerant pipe union

disconnection sockets.

(dimensions in inches): 5/16,

3/8, 1/2, 5/8, 3/4, 7/8.

Equipment required

refrigerant charging station

compressed air nozzle

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see 62A, Air conditioning, Air conditioning:

Precautions for the repair, page 62A-1) ,

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

Note:

Use blanking plugs for the fuel circuits with part no.

77 01 208 229 or 77 01 476 857 to plug any open-

ings exposed to the open air. They must be clean.

Do not use any which have already been used to

plug a fuel circuit.

WARNING

Consult the device's operating manual to avoid

incorrect use.

121180