sensor RENAULT TWINGO 2009 2.G Air Conditioning Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 122

Page 2 of 122

TWINGO - Chapitre 6

Contents

Pages

TWINGO - Chapitre 6ContentsPages

61A HEATING

Heating: List and location of

components 61A-1

Cabin filter: Removal -

Refitting 61A-6

Front side air distribution

duct: Removal - Refitting 61A-7

Front centre air distribution

duct: Removal - Refitting 61A-9

Front footwell air distribution

duct: Removal - Refitting 61A-11

Recirculation control cable:

Removal - Refitting 61A-14

Air distribution cable:

Removal - Refitting 61A-19

Air mixing cable: Removal -

Refitting 61A-23

Distribution unit: Removal -

Refitting 61A-27

Heater matrix: Removal -

Refitting 61A-44

Fan assembly: Removal -

Refitting 61A-53

Heating resistors: Removal -

Refitting 61A-57

Passenger compartment fan

assembly control unit:

Removal - Refitting 61A-58

Control panel: Removal -

Refitting 61A-65

Recirculation motor:

Removal - Refitting 61A-68

Mixing motor : Removal -

Refitting 61A-71

Distribution motor: Removal -

Refitting 61A-75

Passenger compartment

temperature sensor:

Removal - Refitting 61A-78

62A AIR CONDITIONING

Air conditioning: Precautions

for the repair 62A-1

Air conditioning: Parts and

consumables for the repair 62A-2

Air conditioning: List and

location of components 62A-3

Air conditioning: Check 62A-4

Refrigerant circuit: Check 62A-7

Refrigerant circuit: Draining -

Filling 62A-8

Condenser: Removal -

Refitting 62A-11

Dehydrator reservoir:

Removal - Refitting 62A-15

Compressor : Removal -

Refitting 62A-18 61A HEATING

Page 3 of 122

Contents

Expansion valve: Removal -

Refitting 62A-21

Evaporator: Removal -

Refitting 62A-25

Evaporator: Cleaning 62A-26

Expansion valve -

inter mediate pipe connecting

pipe at the expansion valve

outlet: Removal - Refitting 62A-27

Dehydrator reservoir -

expansion valve connecting

pipe: Removal - Refitting 62A-28

Compressor - condenser

connecting pipe: Removal -

Refitting 62A-33

Compressor - intermediate

pipe connecting pipe:

Removal - Refitting 62A-37

Pressure sensor: Removal -

Refitting 62A-40

Exter ior air temperature

sensor: Removal - Refitting 62A-41 62A AIR CONDITIONING

Page 81 of 122

61A-78

HEATING

Passenger compartment temperature sensor: Removal - Refitting

CLIMATE CONTROL

61A

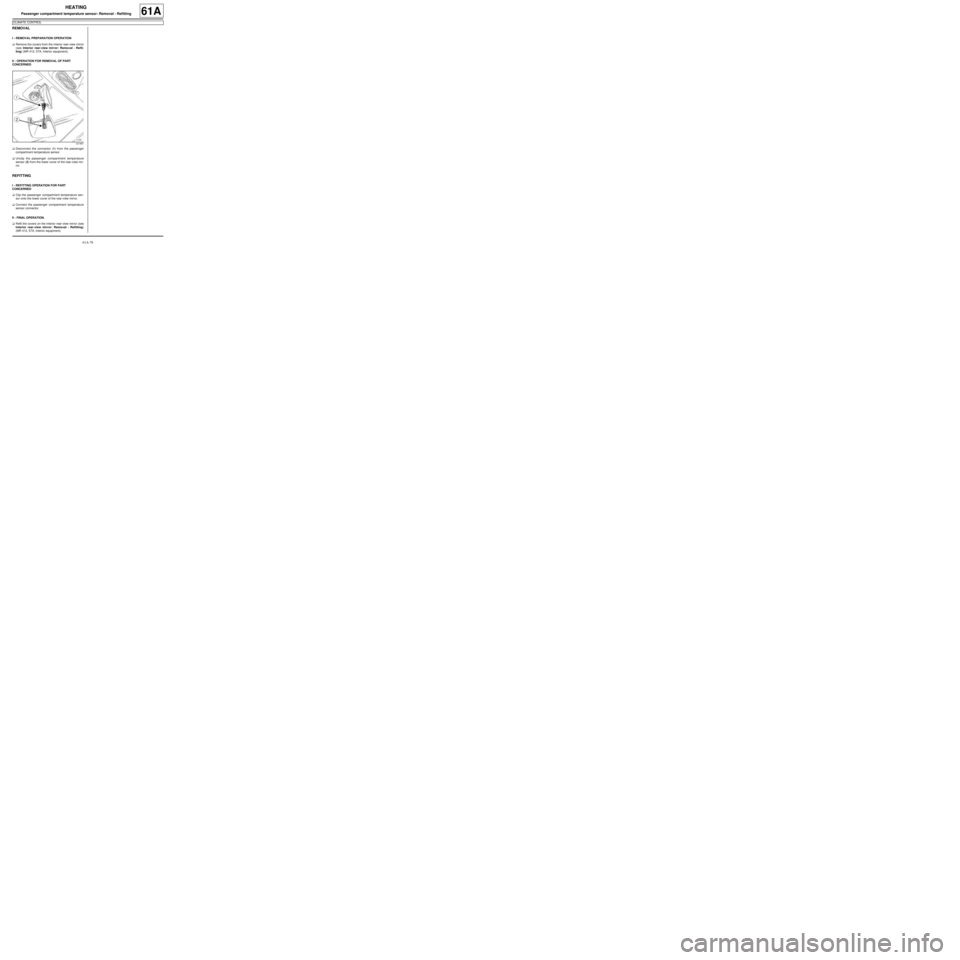

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the covers from the interior rear-view mirror

(see Interior rear-view mirror: Removal - Refit-

ting) (MR 412, 57A, Interior equipment).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the connector (1) from the passenger

compartment temperature sensor.

aUnclip the passenger compartment temperature

sensor (2) from the lower cover of the rear-view mir-

ror.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aClip the passenger compartment temperature sen-

sor onto the lower cover of the rear-view mirror.

aConnect the passenger compartment temperature

sensor connector.

II - FINAL OPERATION.

aRefit the covers on the interior rear-view mirror (see

Interior rear-view mirror: Removal - Refitting)

(MR 412, 57A, Interior equipment).

121467

Page 84 of 122

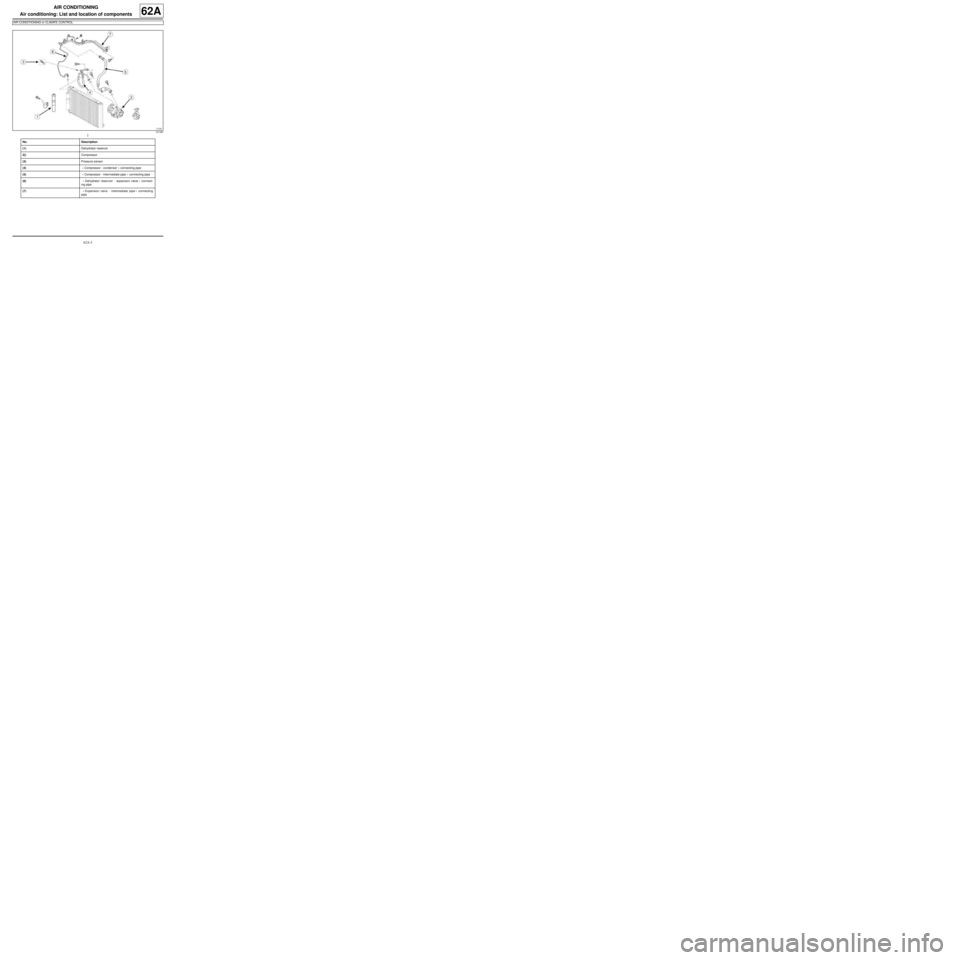

62A-3

AIR CONDITIONING

Air conditioning: List and location of components

AIR CONDITIONING or CLIMATE CONTROL

62A

121397

No. Description

(1)Dehydrator reservoir

2()Compressor

(3)Pressure sensor

(4) « Compressor - condenser » connecting pipe

(5) « Compressor - intermediate pipe » connecting pipe

(6) « Dehydrator reservoir - expansion valve » connect-

ing pipe

(7) « Expansion valve - intermediate pipe » connecting

pipe

Page 85 of 122

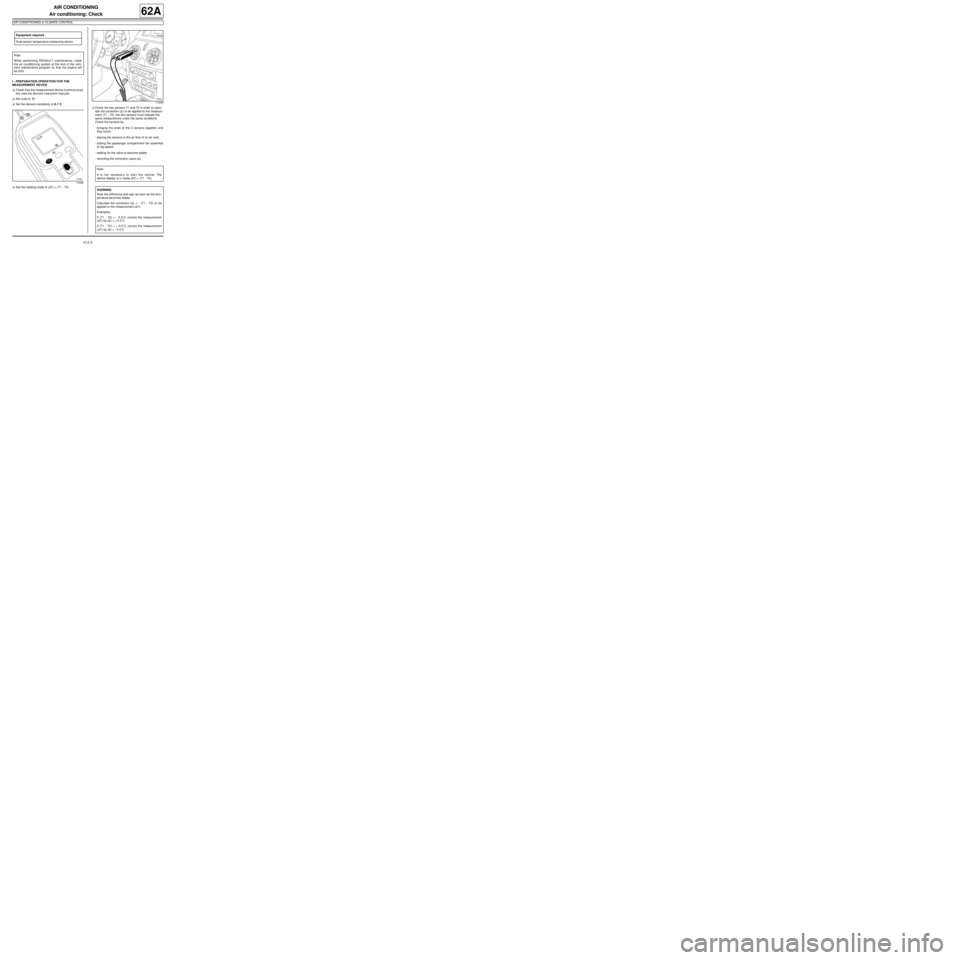

62A-4

AIR CONDITIONING

Air conditioning: Check

AIR CONDITIONING or CLIMATE CONTROL

62A

I - PREPARATION OPERATION FOR THE

MEASUREMENT DEVICE

aCheck that the measurement device functions prop-

erly (see the device's instruction manual).

aSet units to ˚C.

aSet the device's sensitivity to 0.1˚C.

aSet the reading mode to (∆T) = (T1 - T2)aCheck the two sensors T1 and T2 in order to calcu-

late the correction (∆) to be applied to the measure-

ment (T1 - T2). the two sensors must indicate the

same measurement under the same conditions.

Check the sensors by:

-bringing the ends of the 2 sensors together until

they touch,

-placing the sensors in the air flow of an air vent,

-setting the passenger compartment fan assembly

to top speed.

-waiting for the value to become stable.

-recording the correction value (∆). Equipment required

Dual-sensor temperature measuring device

Note:

When performing RENAULT maintenance, check

the air conditioning system at the end of the vehi-

cle's maintenance program so that the engine will

be cold.

119360

119358

Note:

It is not necessary to start the vehicle. The

device display is in mode (∆T) = (T1 - T2).

WARNING

Note the diff erence and sign as soon as the tem-

per ature becomes stable.

Calculate the correction (∆) = - (T1 - T2) to be

applied to the measurement (∆T).

Examples:

If (T1 - T2) = - 0.3˚C, correct the measurement

(∆T) by (∆) = + 0.3˚C

If (T1 - T2) = + 0.3˚C, correct the measurement

(∆T) by (∆) = - 0.3˚C

Page 86 of 122

62A-5

AIR CONDITIONING

Air conditioning: Check

AIR CONDITIONING or CLIMATE CONTROL

62A

II - VEHICLE PREPARATION OPERATION

aPut the vehicle in the shade, where the temperature

is greater than or equal to 15˚C minimum.

aClose the bonnet.

aOpen the front windows.

aStart the engine and let it idle.

aSet the air conditioning controls with:

-recirculation mode in the external position,

-the ventilation distribution in "face" mode,

-the temperature control to coldest temperature set-

ting in front (and at the back, if it exists),

-the speed of the passenger compartment fan as-

sembly set to maximum (switch off the rear control

if it exists),

-the front side and centre air vents open with the

vanes in a neutral position,

-the air conditioning system must be turned on (indi-

cator light illuminated).

aWait 5 minutes with the engine idling before tak-

ing any measurements.

III - MEASUREMENTS

aRecord the air temperature at the scuttle panel grille

(T3).

-open the bonnet, depending on the vehicle, to ac-

cess the scuttle panel grille.

-place the sensor where air is drawn through the

scuttle panel grille.-wait for the value to become stable.

-record the T3 temperature value.

-close the bonnet if it was opened.

aRecord the air temperature at the left air vent (T1),

and at the right air vent (T2).

-fit sensor T1 in the left air vent (1) .

-fit sensor T2 in the right air vent (2) .

aRecord the differences in temperature once the (∆T)

value has stabilised:

-between T3 and the higher of values T1 or T2, (T3

- highest value).

-record this difference in temperature.

-between T1 and T2 (read the (∆T) value (T1-T2)

display mode).

-record the difference in temperature (∆T) accord-

ing to the correction (∆) to be applied to the mea-

surement.

aIf the (∆T)=(T1-T2) measurement is unstable, follow

the procedure below:

119359

119357

Note:

Depending on the vehicle's air conditioning sys-

tem programming, this check method may not be

applicable because the engine cooling fan

assembly has been activated. Its operation ren-

ders the (∆Τ) value between T1 and T2 unstable.

To eliminate this error, the fan assembly must be

activated for the entire period over which temper-

ature T1 and T2 measurements are recorded.

Page 102 of 122

62A-21

AIR CONDITIONING

Expansion valve: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

REMOVAL

I - REMOVAL PREPARATION OPERATION

a

aDrain the refrigerant circuit using a refrigerant

charging station (see 62A, Air conditioning, Re-

frigerant circuit: Draining - Filling, page 62A-8) .

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the wiper arms (see Windscreen wiper arm: Re-

moval - Refitting) (85A, Wiping - Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).

aRemove:

-the air filter unit (see Air filter unit: Removal - Re-

fitting) (12A, Fuel mixture),

-the upstream oxygen sensor (see Oxygen sen-

sors: Removal - Refitting) (17B, Petrol injection). Equipment requiredrefrigerant charging station

compressed air nozzle

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see 62A, Air conditioning, Air conditioning:

Precautions for the repair, page 62A-1) ,

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

Note:

Use blanking plugs for the fuel circuits with part

numbers 77 01 208 229 or 77 01 476 857 to plug

any openings exposed to the open air. They must

be clean. Do not use any which have already been

used to plug a fuel circuit.

WARNING

To prevent moisture from entering the system,

place plugs on the cold loop components which are

open to the air.

WARNING

In order to avoid any refrigerant leaks, do not dam-

age (deform, twist, etc.) the pipe.

WARNING

To prevent the surrounding components from over-

heating, do not damage (tear, pierce, bend, etc.) a

heat shield.

Any damaged heat shields must be replaced.WARNING

Consult the device's operating manual to avoid

incorrect use.

D4F, and 780 – K4M, and 854

Page 104 of 122

62A-23

AIR CONDITIONING

Expansion valve: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

REFITTING

I - REFITTING PREPARATION OPERATION

a

aClean the surface and seal of the pipe using EN-

GINE CLEANER (see Vehicle: Parts and con-

sumables for the repair) (04B, Consumables -

Products).aUse a compressed air nozzle to blow on the sur-

face and the seal of the connecting pipe.

aLubricate the surface of the connecting pipe and the

seal with air conditioning oil (see 62A, Air condi-

tioning, Air conditioning: Parts and consum-

ables for the repair, page 62A-2) .

aRemove the blanking plugs.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the expansion valve.

aFit the expansion valve connecting pipes.

aRefit the bolts of the connecting pipes on the expan-

sion valve.

III - FINAL OPERATION

aRefit:

-the bulkhead heat-resistant protectors,

-the upstream oxygen sensor (see Oxygen sen-

sors: Removal - Refitting) (17B, Petrol injection), WARNING

Do not remove the blanking plugs from each

component until the last moment.

Also, do not remove the components from their

packaging until they are to be fitted to the vehi-

cle.

143880

143882

Note:

Gradually tighten the bolts of the expansion valve

so that the expansion valve is positioned evenly

on the distr ibution unit.

D4F, and 780 – K4M, and 854

Page 110 of 122

62A-29

AIR CONDITIONING

Dehydrator reservoir - expansion valve connecting pipe: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

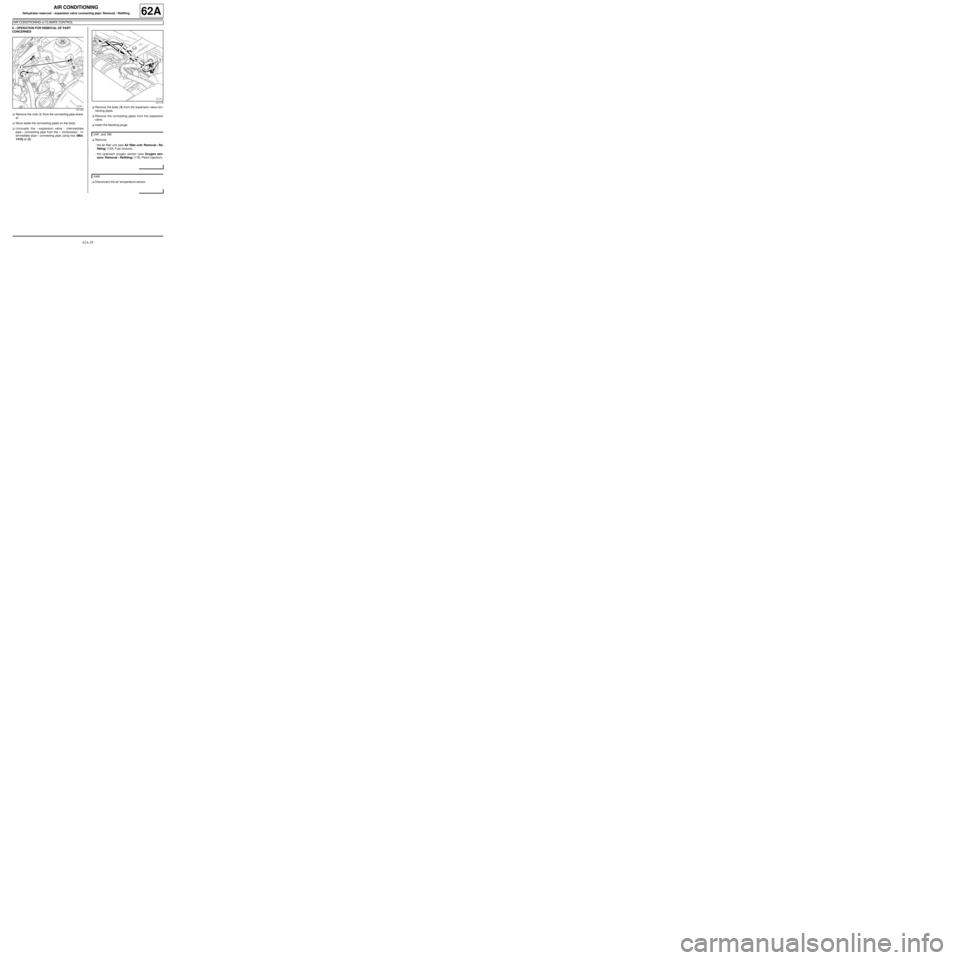

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the nuts (1) from the connecting pipe brack-

et.

aMove aside the connecting pipes on the body.

aUncouple the « expansion valve - intermediate

pipe » connecting pipe from the « compressor - in-

termediate pipe » connecting pipe using tool (Mot.

1410) at (2) .aRemove the bolts (3) from the expansion valve con-

necting pipes.

aRemove the connecting pipes from the expansion

valve.

aInsert the blanking plugs.

aRemove:

-the air filter unit (see Air filter unit: Removal - Re-

fitting) (12A, Fuel mixture),

-the upstream oxygen sensor (see Oxygen sen-

sors: Removal - Refitting) (17B, Petrol injection).

aDisconnect the air temperature sensor.

121180

121178

D4F, and 780

K4M

Page 112 of 122

62A-31

AIR CONDITIONING

Dehydrator reservoir - expansion valve connecting pipe: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

aClean the surface and seal of the pipe using EN-

GINE CLEANER (see Vehicle: Parts and con-

sumables for the repair) (04B, Consumables -

Products).

aUse a compressed air nozzle to blow on the sur-

face and the seal of the connecting pipe.

aLubricate the surface of the connecting pipe and the

seal with air conditioning oil (see 62A, Air condi-

tioning, Air conditioning: Parts and consum-

ables for the repair, page 62A-2) .

aRemove the blanking plugs.II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the assembly of the « dehydrator reservoir - ex-

pansion valve » and « expansion valve - intermedi-

ate pipe » connecting pipes.

aFit:

-the « dehydrator reservoir - expansion valve » con-

necting pipe on the dehydrator reservoir,

-the connecting pipes on the expansion valve.

aCouple the « expansion valve - intermediate pipe »

connecting pipe to the « compressor - intermediate

pipe » connecting pipe.

aRefit:

-the bolts of the connecting pipes on the expansion

valve,

-the bolt of the « dehydrator reservoir - expansion

valve » connecting pipe on the dehydrator reser-

voir.

aFit the connecting pipes on the body.

aRefit the connecting pipe bracket nuts on the body.

III - FINAL OPERATION

aRefit the bulkhead heat-resistant protectors.

aRefit:

-the upstream oxygen sensor (see Oxygen sen-

sors: Removal - Refitting) (17B, Petrol injection),

-the air filter box (see Air filter unit: Removal - Re-

fitting) (12A, Fuel mixture).

aConnect the air temperature sensor.

aRefit:

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

143880

143882

D4F, and 780 – K4M

D4F, and 780

K4M