light RENAULT TWINGO 2009 2.G Chasiss ABS User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 76

Page 50 of 76

38C-50

MR-413-X44-38C000$517_eng.mif

V1

ANTI-LOCK BRAKING SYSTEM

Fault finding - Interpretation of faults

MK70 ABS

Vdiag No: 04

38C

DF311

PRESENT

OR

STOREDNO BVR MULTIPLEX SIGNAL

NOTESSpecial notes:

Even though it is stored in the computer, this fault does not cause the warning lights to

come on or a fault message, because the ABS system is not faulty.

Perform fault finding on the BVR (sequential gearbox) using the diagnostic tool.

Note:

After repairing the fault in the BVR (sequential gearbox), clear the fault memory

in the ABS system.

Priority in the event of a number of faults:

Deal with fault DF152 Multiplex network first if it is present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present when the engine is started up.

Check the gearbox type configuration with the diagnostic tool, using command LC008 Gearbox type.

If the configuration is not correct, configure the gearbox type present on the vehicle using configuration command

CF079 Gearbox type.

Check the BVR (sequential gearbox) using the diagnostic tool.

Run a multiplex network test (see 88B, Multiplex).

If the fault is still present, contact the Techline.

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS_V04_DF311

Page 53 of 76

38C-53

MR-413-X44-38C000$658_eng.mif

V1

38C

ANTI-LOCK BRAKING SYSTEM

Fault finding - Interpretation of statuses

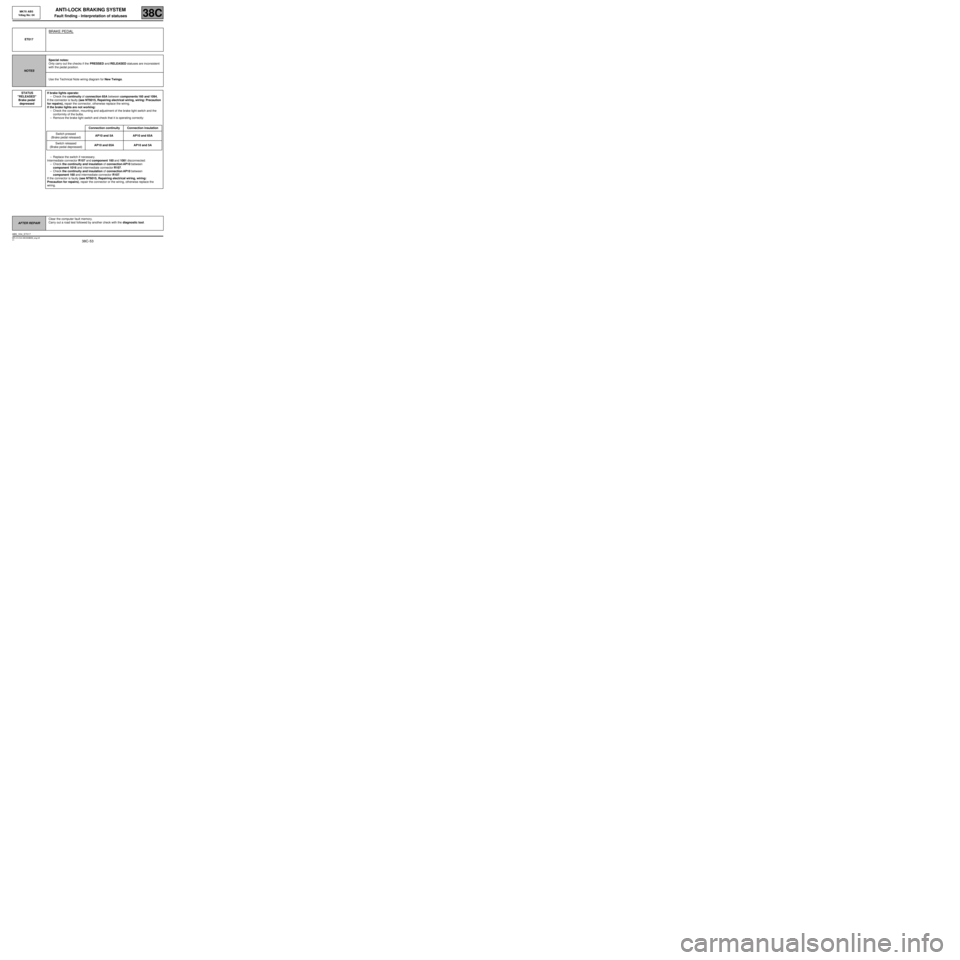

ET017

BRAKE PEDAL

NOTESSpecial notes:

Only carry out the checks if the PRESSED and RELEASED statuses are inconsistent

with the pedal position.

Use the Technical Note wiring diagram for New Twingo.

STATUS

"RELEASED"

Brake pedal

depressed

If brake lights operate:

–Check the continuity of connection 65A between components 160 and 1094.

If the connector is faulty (see NT6015, Repairing electrical wiring, wiring: Precaution

for repairs), repair the connector, otherwise replace the wiring.

If the brake lights are not working:

–Check the condition, mounting and adjustment of the brake light switch and the

conformity of the bulbs.

–Remove the brake light switch and check that it is operating correctly:

Connection continuity Connection insulation

Switch pressed

(Brake pedal released)AP10 and 5A AP10 and 65A

Switch released

(Brake pedal depressed)AP10 and 65A AP10 and 5A

–Replace the switch if necessary.

Intermediate connector R107 and component 160 and 1081 disconnected:

–Check the continuity and insulation of connection AP10 between

component 1016 and intermediate connector R107.

–Check the continuity and insulation of connection AP10 between

component 160 and intermediate connector R107.

If the connector is faulty (see NT6015, Repairing electrical wiring, wiring:

Precaution for repairs), repair the connector or the wiring, otherwise replace the

wiring.

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS_V04_ET017

MK70 ABS

Vdiag No: 04

MR-413-X44-38C000$658_eng.mif

Page 54 of 76

38C-54

MR-413-X44-38C000$658_eng.mif

V1

MK70 ABS

Vdiag No: 04ANTI-LOCK BRAKING SYSTEM

Fault finding - Interpretation of statuses38C

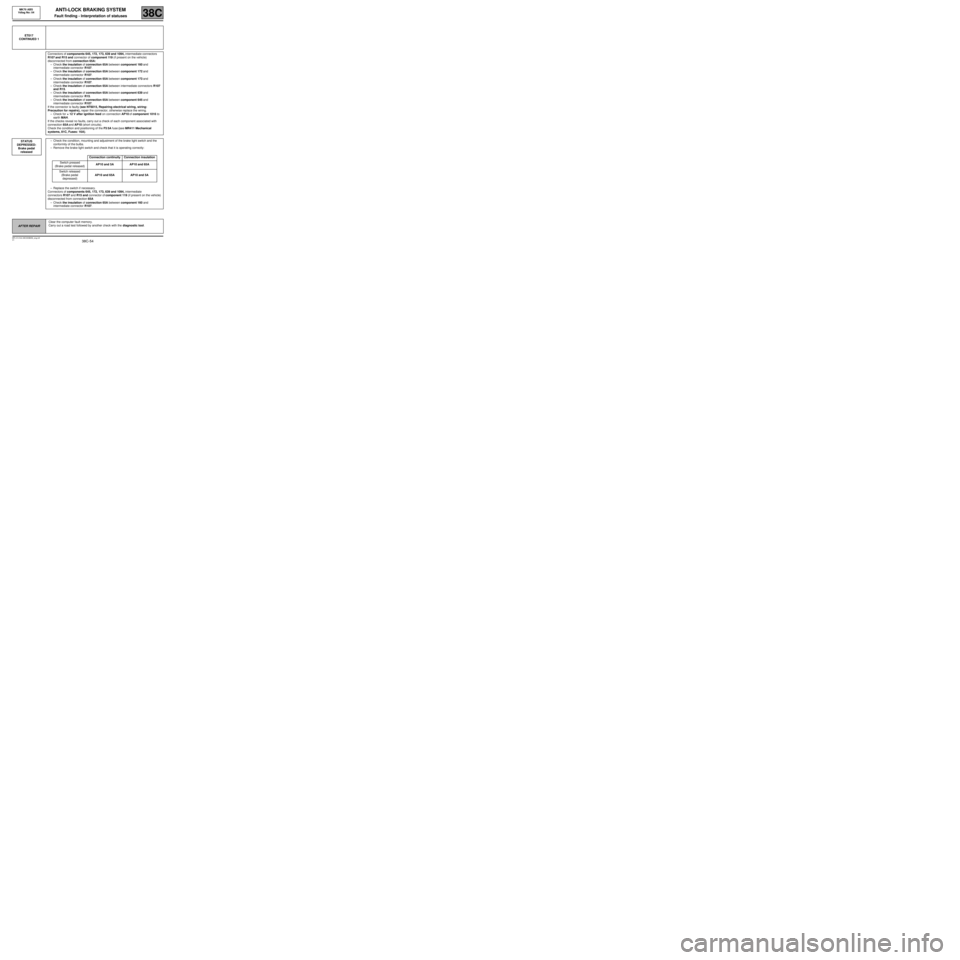

ET017

CONTINUED 1

Connectors of components 645, 172, 173, 639 and 1094, intermediate connectors

R107 and R15 and connector of component 119 (if present on the vehicle)

disconnected from connection 65A:

–Check the insulation of connection 65A between component 160 and

intermediate connector R107.

–Check the insulation of connection 65A between component 172 and

intermediate connector R107.

–Check the insulation of connection 65A between component 173 and

intermediate connector R107.

–Check the insulation of connection 65A between intermediate connectors R107

and R15.

–Check the insulation of connection 65A between component 639 and

intermediate connector R15.

–Check the insulation of connection 65A between component 645 and

intermediate connector R107.

If the connector is faulty (see NT6015, Repairing electrical wiring, wiring:

Precaution for repairs), repair the connector, otherwise replace the wiring.

–Check for + 12 V after ignition feed on connection AP10 of component 1016 to

earth MAH.

If the checks reveal no faults, carry out a check of each component associated with

connection 65A and AP10 (short circuits).

Check the condition and positioning of the F5 5A fuse (see MR411 Mechanical

systems, 81C, Fuses: 16A).

–Check the condition, mounting and adjustment of the brake light switch and the

conformity of the bulbs.

–Remove the brake light switch and check that it is operating correctly:

Connection continuity Connection insulation

Switch pressed

(Brake pedal released)AP10 and 5A AP10 and 65A

Switch released

(Brake pedal

depressed)AP10 and 65A AP10 and 5A

–Replace the switch if necessary.

Connectors of components 645, 172, 173, 639 and 1094, intermediate

connectors R107 and R15 and connector of component 119 (if present on the vehicle)

disconnected from connection 65A

–Check the insulation of connection 65A between component 160 and

intermediate connector R107.

STATUS

DEPRESSED:

Brake pedal

released

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

Page 58 of 76

38C-58

MR-413-X44-38C000$799_eng.mif

V1

38C

ANTI-LOCK BRAKING SYSTEM

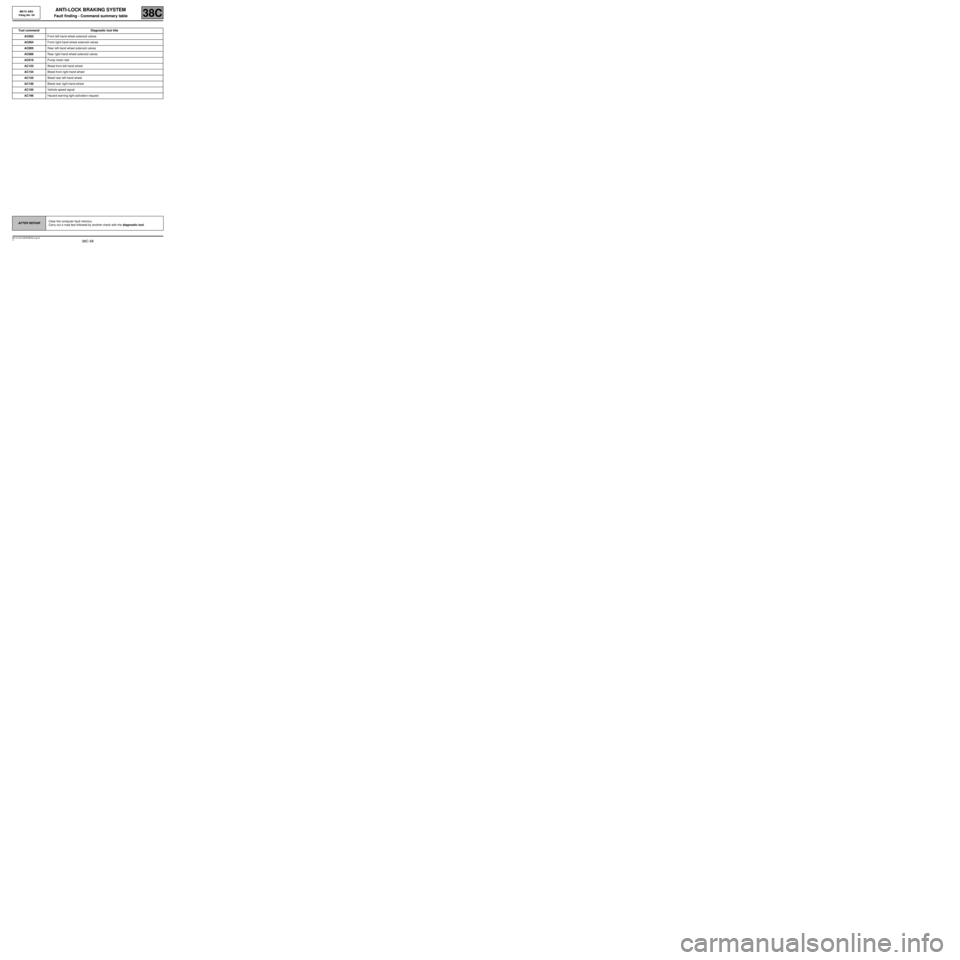

Fault finding - Command summary table

Tool command Diagnostic tool title

AC003Front left-hand wheel solenoid valves

AC004Front right-hand wheel solenoid valves

AC005Rear left-hand wheel solenoid valves

AC006Rear right-hand wheel solenoid valves

AC016Pump motor test

AC153Bleed front left-hand wheel

AC154Bleed front right-hand wheel

AC155Bleed rear left-hand wheel

AC156Bleed rear right-hand wheel

AC195Vehicle speed signal

AC196Hazard warning light activation request

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

MK70 ABS

Vdiag No: 04

MR-413-X44-38C000$799_eng.mif

Page 63 of 76

38C-63

MR-413-X44-38C000$846_eng.mif

V1

ANTI-LOCK BRAKING SYSTEM

Fault finding - Dealing with command modes

MK70 ABS

Vdiag No: 04

38C

AC196

HAZARD WARNING LIGHT ACTIVATION REQUEST

NOTESConditions of use of the command.

Ignition on, engine stopped and vehicle speed zero.

Before using the command, check that the battery is fully charged.

This command sends a hazard warning light activation request to the UCH (Passenger compartment connection

unit) to test their operation in the event of emergency braking (depending on UCH, Passenger Compartment

Connection Unit configuration).

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS_V04_AC196

Page 64 of 76

38C-64

MR-413-X44-38C000$893_eng.mif

V1

38C

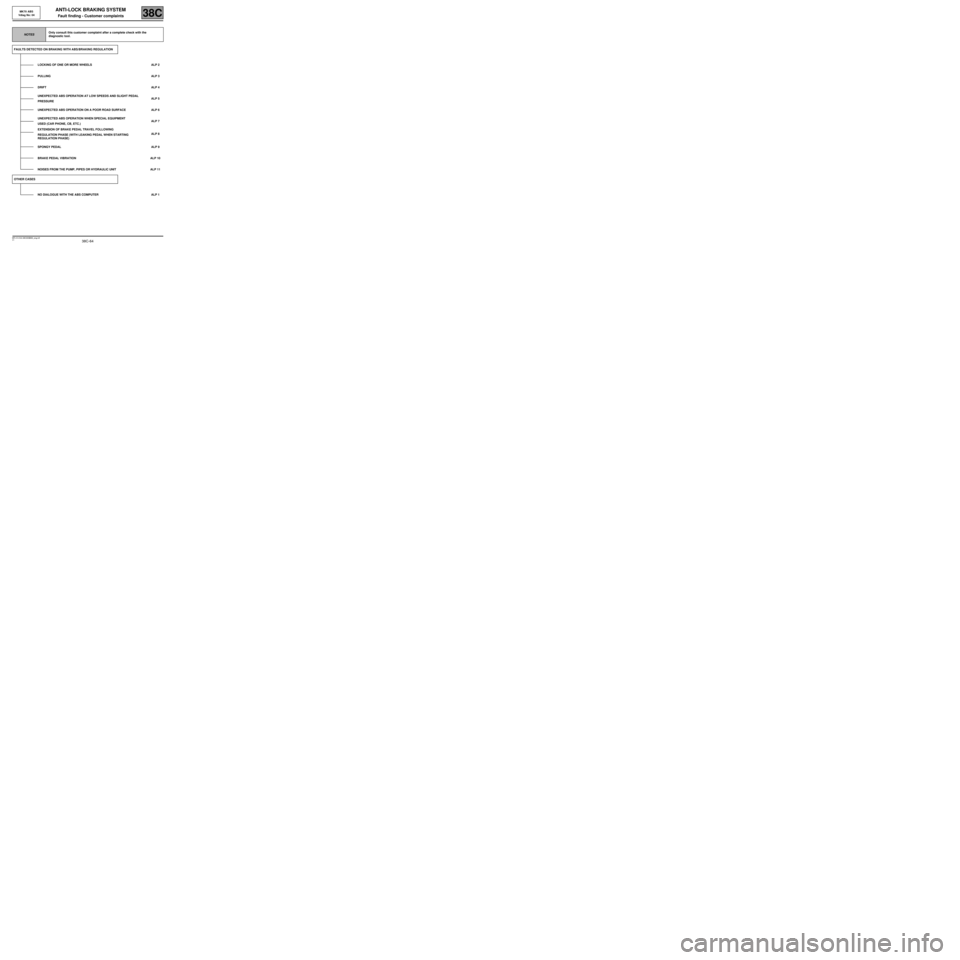

ANTI-LOCK BRAKING SYSTEM

Fault finding - Customer complaints

NOTESOnly consult this customer complaint after a complete check with the

diagnostic tool.

FAULTS DETECTED ON BRAKING WITH ABS/BRAKING REGULATION

LOCKING OF ONE OR MORE WHEELS ALP 2

PULLING ALP 3

DRIFT ALP 4

UNEXPECTED ABS OPERATION AT LOW SPEEDS AND SLIGHT PEDAL

PRESSURE ALP 5

UNEXPECTED ABS OPERATION ON A POOR ROAD SURFACE ALP 6

UNEXPECTED ABS OPERATION WHEN SPECIAL EQUIPMENT

USED (CAR PHONE, CB, ETC.) ALP 7

EXTENSION OF BRAKE PEDAL TRAVEL FOLLOWING

REGULATION PHASE (WITH LEAKING PEDAL WHEN STARTING

REGULATION PHASE)ALP 8

SPONGY PEDAL ALP 9

BRAKE PEDAL VIBRATION ALP 10

NOISES FROM THE PUMP, PIPES OR HYDRAULIC UNIT ALP 11

OTHER CASES

NO DIALOGUE WITH THE ABS COMPUTER ALP 1

MK70 ABS

Vdiag No: 04

MR-413-X44-38C000$893_eng.mif

Page 68 of 76

38C-68

MR-413-X44-38C000$940_eng.mif

V1

MK70 ABS

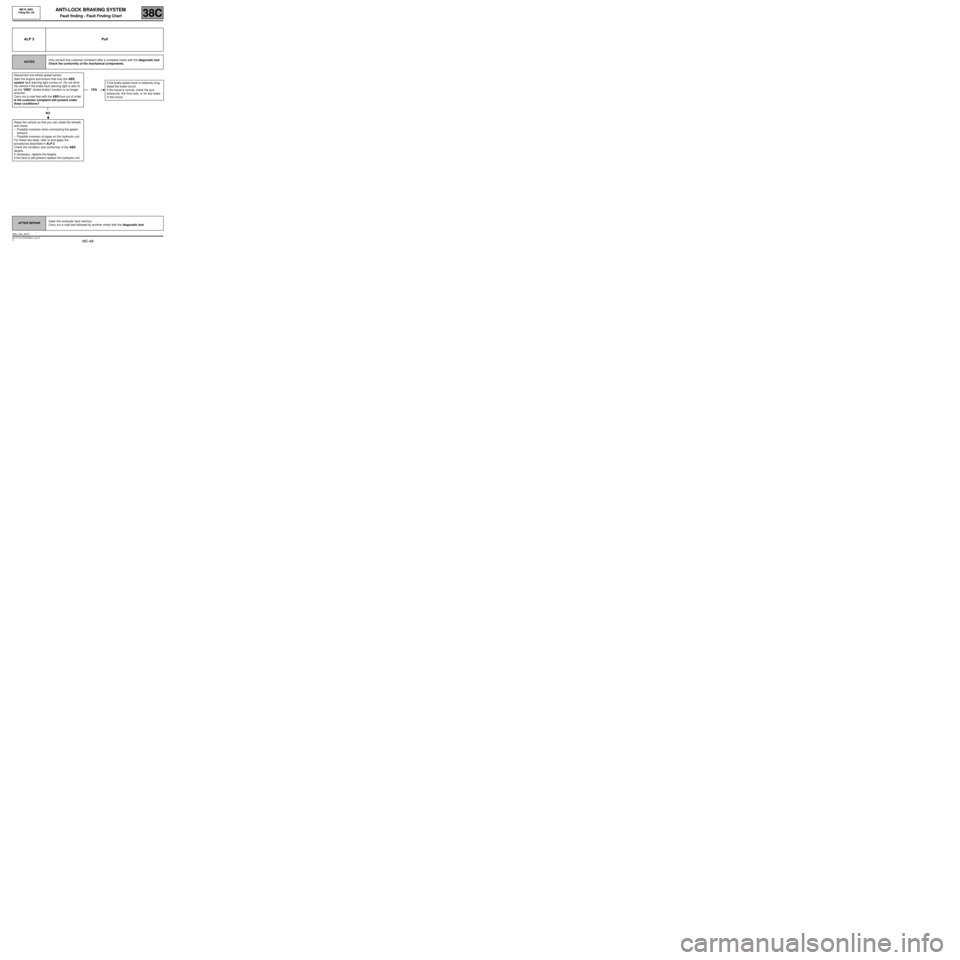

Vdiag No: 04ANTI-LOCK BRAKING SYSTEM

Fault finding - Fault Finding Chart38C

ALP 3 Pull

NOTESOnly consult this customer complaint after a complete check with the diagnostic tool.

Check the conformity of the mechanical components.

Disconnect one wheel speed sensor.

Start the engine and ensure that only the ABS

system fault warning light comes on. Do not drive

the vehicle if the brake fault warning light is also lit,

as the "EBD" (brake limiter) function is no longer

ensured.

Carry out a road test with the ABS thus out of order.

Is the customer complaint still present under

these conditions?

NO

Raise the vehicle so that you can rotate the wheels

and check:

–Possible inversion when connecting the speed

sensors.

–Possible inversion of pipes on the hydraulic unit.

For these two tests, refer to and apply the

procedures described in ALP 2.

Check the condition and conformity of the ABS

targets.

If necessary, replace the targets.

If the fault is still present replace the hydraulic unit.

YESIf the brake pedal travel is relatively long,

bleed the brake circuit.

If the travel is normal, check the tyre

pressures, the front axle, or for any leaks

in the circuit.

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS_V04_ALP3

Page 69 of 76

38C-69

MR-413-X44-38C000$940_eng.mif

V1

MK70 ABS

Vdiag No: 04ANTI-LOCK BRAKING SYSTEM

Fault finding - Fault Finding Chart38C

ALP 4 Drift

NOTESOnly consult this customer complaint after a complete check with the diagnostic tool.

Disconnect one wheel speed sensor.

Start the engine and ensure that only the ABS

system fault warning light comes on. Do not drive

the vehicle if the brake fault warning light is also lit,

as the "EBD" (brake limiter) function is no longer

ensured.

Carry out a road test with the ABS thus out of order.

Is the customer complaint still present under

these conditions?

NO

Normal behaviour linked to the system operation

during the regulation phase, mainly on surfaces with

uneven grip or which are poorly laid.

YESRoad holding fault not related to the ABS.

Check the condition of the brake linings

and that they are to specification and

check the tyre pressures, the front axle,

etc.

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS_V04_ALP4

Page 70 of 76

38C-70

MR-413-X44-38C000$940_eng.mif

V1

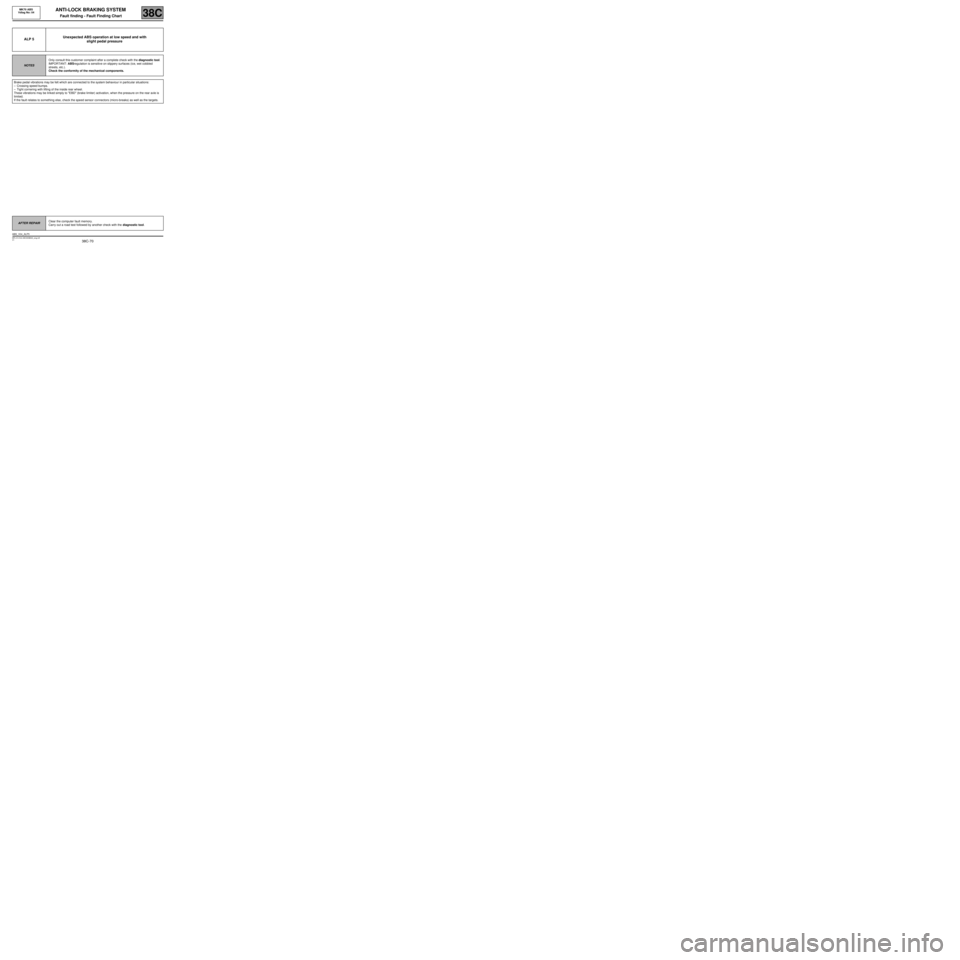

ANTI-LOCK BRAKING SYSTEM

Fault finding - Fault Finding Chart

MK70 ABS

Vdiag No: 04

38C

ALP 5Unexpected ABS operation at low speed and with

slight pedal pressure

NOTESOnly consult this customer complaint after a complete check with the diagnostic tool.

IMPORTANT: ABS regulation is sensitive on slippery surfaces (ice, wet cobbled

streets, etc.).

Check the conformity of the mechanical components.

Brake pedal vibrations may be felt which are connected to the system behaviour in particular situations:

–Crossing speed bumps.

–Tight cornering with lifting of the inside rear wheel.

These vibrations may be linked simply to "EBD" (brake limiter) activation, when the pressure on the rear axle is

limited.

If the fault relates to something else, check the speed sensor connectors (micro-breaks) as well as the targets.

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS_V04_ALP5