torque RENAULT TWINGO 2009 2.G Chasiss - Power Assisted Steering Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 54

Page 7 of 54

36B-7

MR-413-X44-36B000$134.mif

V2

36B

POWER – ASSISTED STEERING

Fault finding – List and location of components

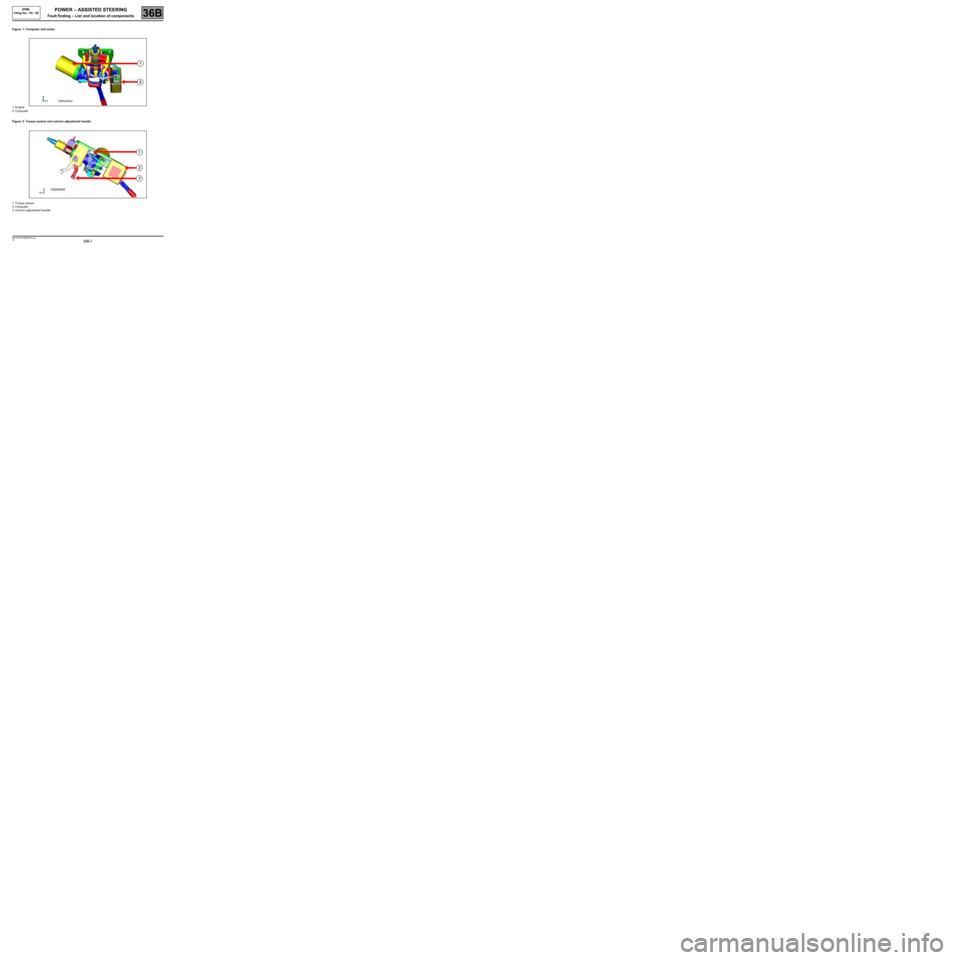

Figure 1: Computer and motor

1Engine

2Computer

Figure 2: Torque sensor and column adjustment handle

1Torque sensor

2Computer

3Column adjustment handle

1

2

3 1

2

EPAS

Vdiag No.: 04 - 08

MR-413-X44-36B000$134.mif

Page 9 of 54

36B-9

MR-413-X44-36B000$201.mif

V2

36B

POWER – ASSISTED STEERING

Fault finding – Role of components

Angle sensor:

This sensor indicates the position of the steering wheel in real time (only for Vdiag 04).

Torque sensor:

This sensor enables the assistance torque to be controlled according to the force applied to the steering wheel by

the driver.

Computer:

This computer calculates the level of steering assistance required according to various parameters, including the

vehicle speed and the steering wheel torque.

Motor:

The motor provides the necessary steering torque assistance according to driver requirements. EPAS

Vdiag No.: 04 - 08

MR-413-X44-36B000$201.mif

Page 10 of 54

36B-10

MR-413-X44-36B000$268.mif

V2

36B

POWER – ASSISTED STEERING

Fault finding – Function

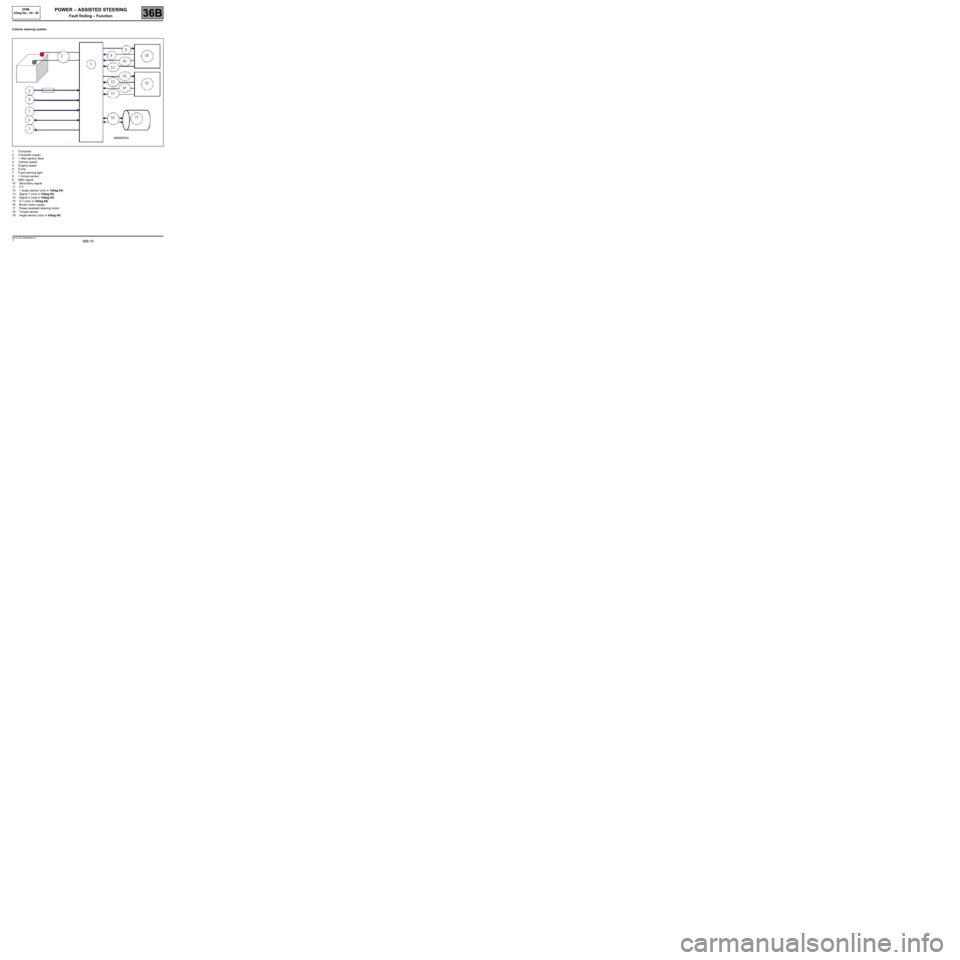

Column steering system

1Computer

2Computer supply

3+ after ignition feed

4Vehicle speed

5Engine speed

6K line

7Fault warning light

8+ torque sensor

9Main signal

10 Secondary signal

11 0 V

12 + angle sensor (only in Vdiag 04)

13 Signal 1 (only in Vdiag 04)

14 Signal 2 (only in Vdiag 04)

15 0 V (only in Vdiag 04)

16 Brush motor supply

17 Power-assisted steering motor

18 Torque sensor

19 Angle sensor (only in Vdiag 04)

EPAS

Vdiag No.: 04 - 08

MR-413-X44-36B000$268.mif

Page 11 of 54

36B-11

MR-413-X44-36B000$268.mif

V2

POWER – ASSISTED STEERING

Fault finding – Function

EPAS

Vdiag No.: 04 - 08

36B

GENERAL OPERATION

On this vehicle, the steering system is power-assisted by an electric motor attached to the steering column.

The torque sensor and steering column angle sensor interpret any movement of the steering wheel as it is turned.

Assistance is provided by an electric motor which applies more or less torque to the steering column, in one direction

or the other.

A computer controls this assistance according to several vehicle environment parameters, including the vehicle

speed.

EPAS ALSO OFFERS THE FOLLOWING:

Active recall:

This function is made necessary by the design of the front axle of vehicles with electric power-assisted steering.

It returns the steering wheel to the centre point when driving at low speeds (5 to 20 mph / 8 to 32 km/h) but not when

the vehicle is stationary. This function is normal on hydraulic power-assisted steering vehicles or vehicles without

assistance.

This function cannot be deactivated by the diagnostic tool.

Depending on the operating conditions and the operations performed on the vehicle before switching on the ignition,

the assistance system may take a certain amount of time to be activated after engine starting, for instance after

battery cut-off or switching off the ignition (see Configurations and programming).Note:

When the computer detects a fault, the level of assistance can be modified depending on how serious the fault is.

An incorrect or absent vehicle speed signal results in assistance equal to that provided at 72 mph (120 km/h)

without active return. The EPAS sends a "Steering wheel angle signal" to the ABS/ESP computer.

Page 12 of 54

36B-12

MR-413-X44-36B000$268.mif

V2

POWER – ASSISTED STEERING

Fault finding – Function

EPAS

Vdiag No.: 04 - 08

36B

SIGNALS RECEIVED AND SENT

1Vehicle speed

2Engine speed

3Power supply (permanent +)

4Supply (+ after ignition feed)

5Earth

6Steering wheel angle (Vdiag 04 only)

7Steering wheel torque

8Instrument panel indicator light on

9Diagnostic socket

10 Power-assisted steering computer

Page 15 of 54

36B-15

MR-413-X44-36B000$469.mif

V2

36B

POWER – ASSISTED STEERING

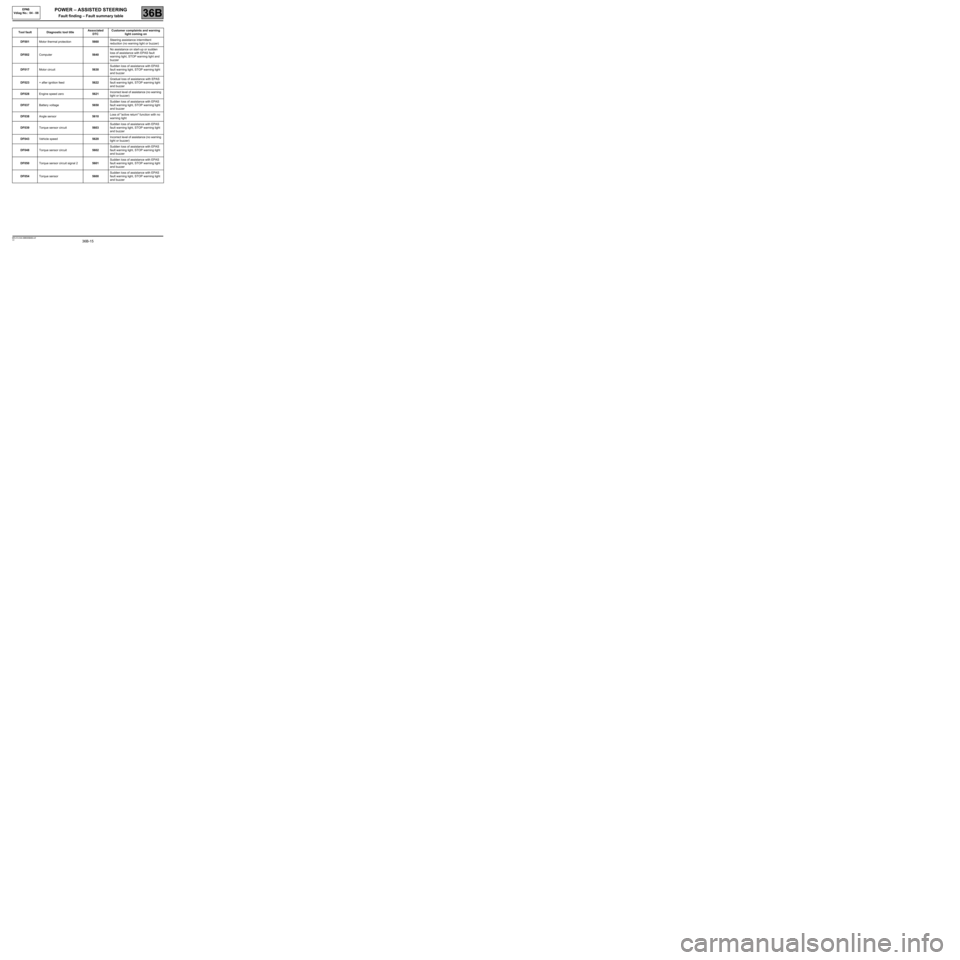

Fault finding – Fault summary table

Tool fault Diagnostic tool titleAssociated

DTCCustomer complaints and warning

light coming on

DF001Motor thermal protection5660Steering assistance intermittent

reduction (no warning light or buzzer)

DF002Computer5640No assistance on start-up or sudden

loss of assistance with EPAS fault

warning light, STOP warning light and

buzzer

DF017Motor circuit5630Sudden loss of assistance with EPAS

fault warning light, STOP warning light

and buzzer

DF023+ after ignition feed5622Gradual loss of assistance with EPAS

fault warning light, STOP warning light

and buzzer

DF028Engine speed zero5621Incorrect level of assistance (no warning

light or buzzer)

DF037Battery voltage5650Sudden loss of assistance with EPAS

fault warning light, STOP warning light

and buzzer

DF038Angle sensor5610Loss of "active return" function with no

warning light

DF039Torque sensor circuit5603Sudden loss of assistance with EPAS

fault warning light, STOP warning light

and buzzer

DF043Vehicle speed5620Incorrect level of assistance (no warning

light or buzzer)

DF048Torque sensor circuit5602Sudden loss of assistance with EPAS

fault warning light, STOP warning light

and buzzer

DF050Torque sensor circuit signal 25601Sudden loss of assistance with EPAS

fault warning light, STOP warning light

and buzzer

DF054Torque sensor5600Sudden loss of assistance with EPAS

fault warning light, STOP warning light

and buzzer

EPAS

Vdiag No.: 04 - 08

MR-413-X44-36B000$469.mif

Page 16 of 54

36B-16

MR-413-X44-36B000$469.mif

V2

EPAS

Vdiag No.: 04 - 08

36B

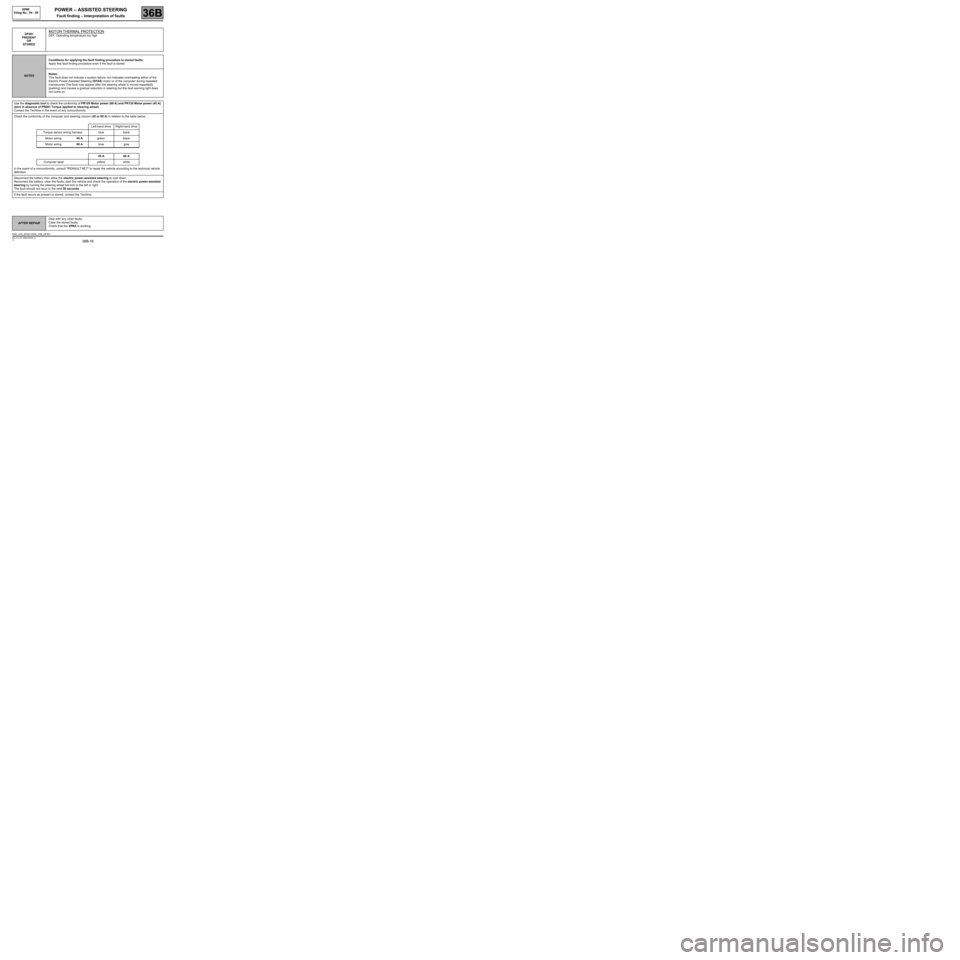

DF001

PRESENT

OR

STOREDMOTOR THERMAL PROTECTION

DEF: Operating temperature too high

NOTESConditions for applying the fault finding procedure to stored faults:

Apply this fault finding procedure even if the fault is stored.

Notes:

This fault does not indicate a system failure, but indicates overheating either of the

Electric Power-Assisted Steering (EPAS) motor or of the computer during repeated

manoeuvres.This fault may appear after the steering wheel is moved repeatedly

(parking) and causes a gradual reduction in steering but the fault warning light does

not come on.

Use the diagnostic tool to check the conformity of PR129 Motor power (60 A) and PR130 Motor power (45 A)

(zero in absence of PR001 Torque applied to steering wheel).

Contact the Techline in the event of any nonconformity.

Check the conformity of the computer and steering column (45 or 60 A) in relation to the table below:

Left-hand drive Right-hand drive

Torque sensor wiring harness blue black

Motor wiring45 Agreen black

Motor wiring60 Ablue grey

45 A 60 A

Computer label yellow white

In the event of a nonconformity, consult "RENAULT NET" to repair the vehicle according to the technical vehicle

definition.

Disconnect the battery then allow the electric power-assisted steering to cool down.

Reconnect the battery, clear the faults, start the vehicle and check the operation of the electric power-assisted

steering by turning the steering wheel full lock to the left or right.

The fault should not recur in the next 30 seconds.

If the fault recurs as present or stored, contact the Techline.

AFTER REPAIRDeal with any other faults.

Clear the stored faults.

Check that the EPAS is working.

DAE_V04_DF001 /DAE_V08_DF001

POWER – ASSISTED STEERING

Fault finding – Interpretation of faults

Page 23 of 54

36B-23

MR-413-X44-36B000$469.mif

V2

POWER – ASSISTED STEERING

Fault finding – Interpretation of faults

EPAS

Vdiag No.: 04 - 08

36B

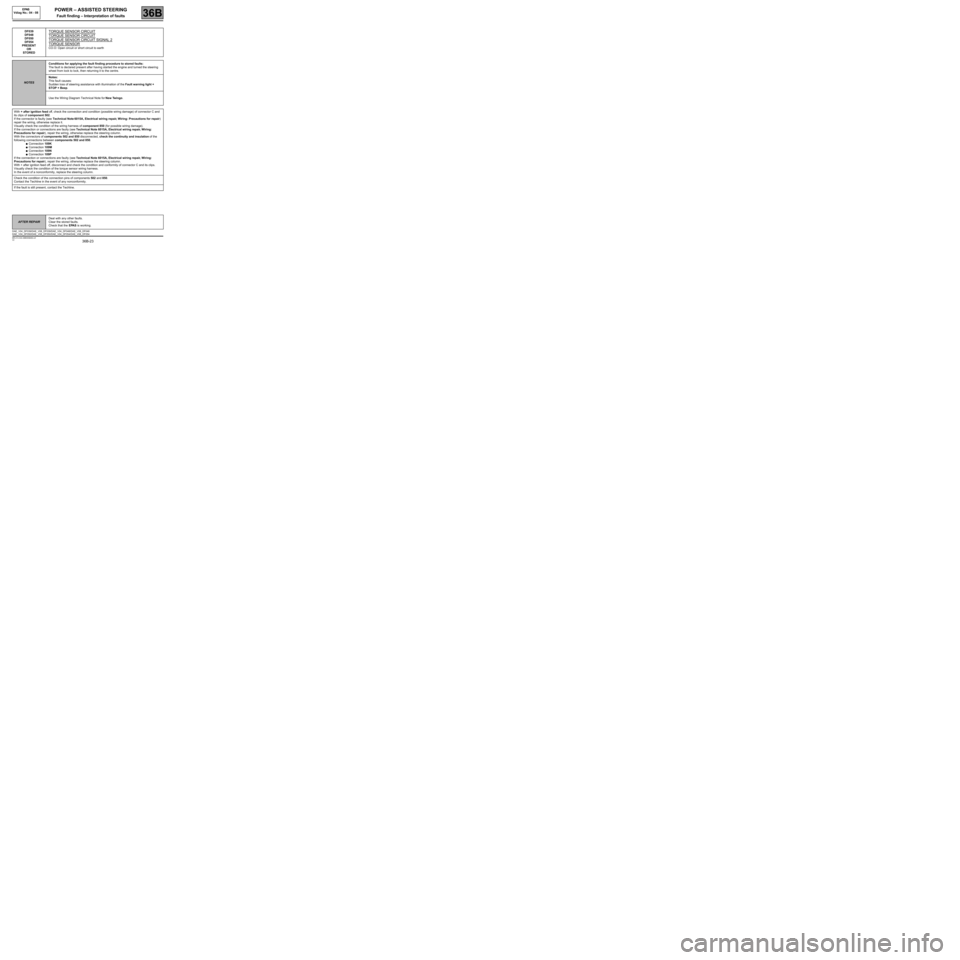

DF039

DF048

DF050

DF054

PRESENT

OR

STOREDTORQUE SENSOR CIRCUIT

TORQUE SENSOR CIRCUIT

TORQUE SENSOR CIRCUIT SIGNAL 2

TORQUE SENSOR

CO.O: Open circuit or short circuit to earth

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present after having started the engine and turned the steering

wheel from lock to lock, then returning it to the centre.

Notes:

This fault causes:

Sudden loss of steering assistance with illumination of the Fault warning light +

STOP + Beep.

Use the Wiring Diagram Technical Note for New Twingo.

With + after ignition feed off, check the connection and condition (possible wiring damage) of connector C and

its clips of component 502.

If the connector is faulty (see Technical Note 6015A, Electrical wiring repair, Wiring: Precautions for repair)

repair the wiring, otherwise replace it.

Visually check the condition of the wiring harness of component 850 (for possible wiring damage).

If the connection or connections are faulty (see Technical Note 6015A, Electrical wiring repair, Wiring:

Precautions for repair), repair the wiring, otherwise replace the steering column.

With the connectors of components 502 and 850 disconnected, check the continuity and insulation of the

following connections between components 502 and 850.

●Connection 109K

●Connection 109M

●Connection 109N

●Connection 109P

If the connection or connections are faulty (see Technical Note 6015A, Electrical wiring repair, Wiring:

Precautions for repair), repair the wiring, otherwise replace the steering column.

With + after ignition feed off, disconnect and check the condition and conformity of connector C and its clips.

Visually check the condition of the torque sensor wiring harness.

In the event of a nonconformity, replace the steering column.

Check the condition of the connection pins of components 502 and 850.

Contact the Techline in the event of any nonconformity.

If the fault is still present, contact the Techline.

AFTER REPAIRDeal with any other faults.

Clear the stored faults.

Check that the EPAS is working.

DAE_V04_DF039/DAE_V08_DF039/DAE_V04_DF048/DAE_V08_DF048

DAE_V04_DF050/DAE_V08_DF050/DAE_V04_DF054/DAE_V08_DF054

Page 25 of 54

36B-25

MR-413-X44-36B000$536.mif

V2

36B

POWER – ASSISTED STEERING

Fault finding – Conformity check

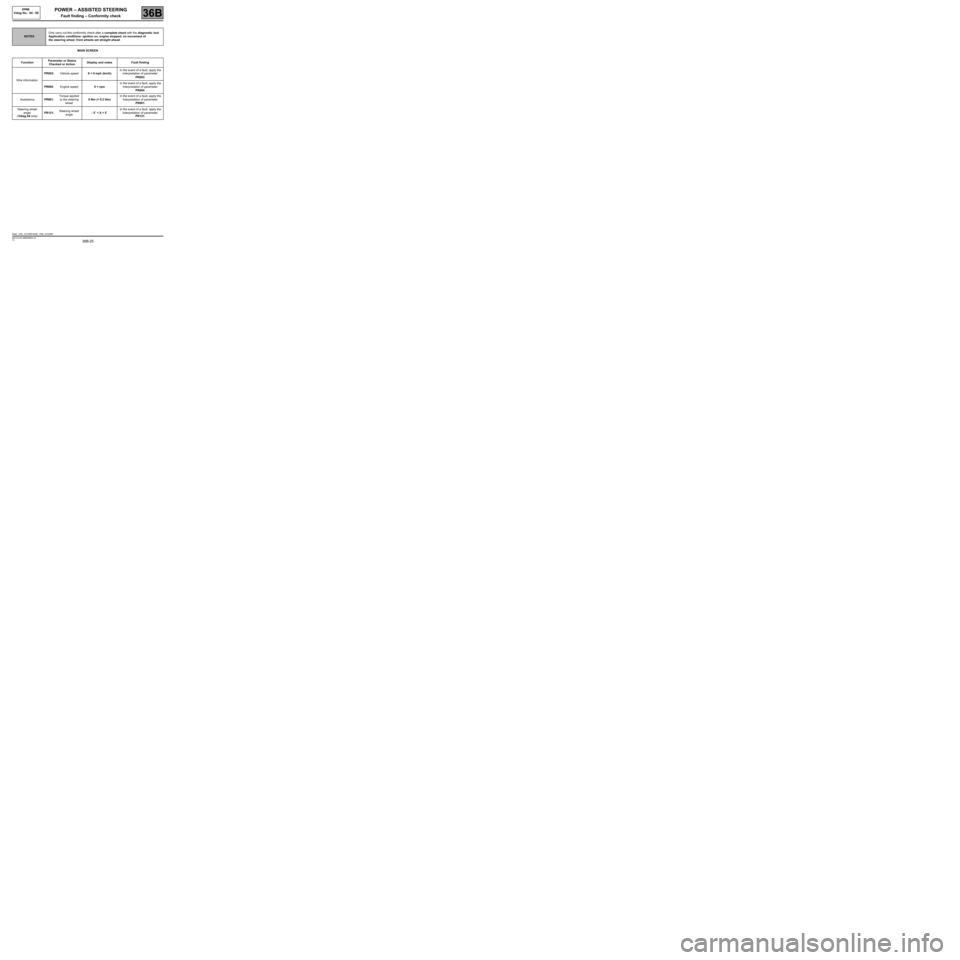

MAIN SCREEN

NOTESOnly carry out this conformity check after a complete check with the diagnostic tool.

Application conditions: ignition on, engine stopped, no movement of

the steering wheel, front wheels set straight ahead.

FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

Wire informationPR003:Vehicle speedX = 0 mph (km/h)In the event of a fault, apply the

interpretation of parameter

PR003.

PR004: Engine speed0 = rpmIn the event of a fault, apply the

interpretation of parameter

PR004.

AssistancePR001: Torque applied

to the steering

wheel0 Nm (+ 0.2 Nm)In the event of a fault, apply the

interpretation of parameter

PR001.

Steering wheel

angle

(Vdiag 04 only)PR121:Steering wheel

angle- 5˚ < X < 5˚In the event of a fault, apply the

interpretation of parameter

PR121.

EPAS

Vdiag No.: 04 - 08

MR-413-X44-36B000$536.mif

DAE_V04_CCONF/DAE_V08_CCONF

Page 27 of 54

36B-27

MR-413-X44-36B000$536.mif

V2

POWER – ASSISTED STEERING

Fault finding – Conformity check

EPAS

Vdiag No.: 04 - 08

36B

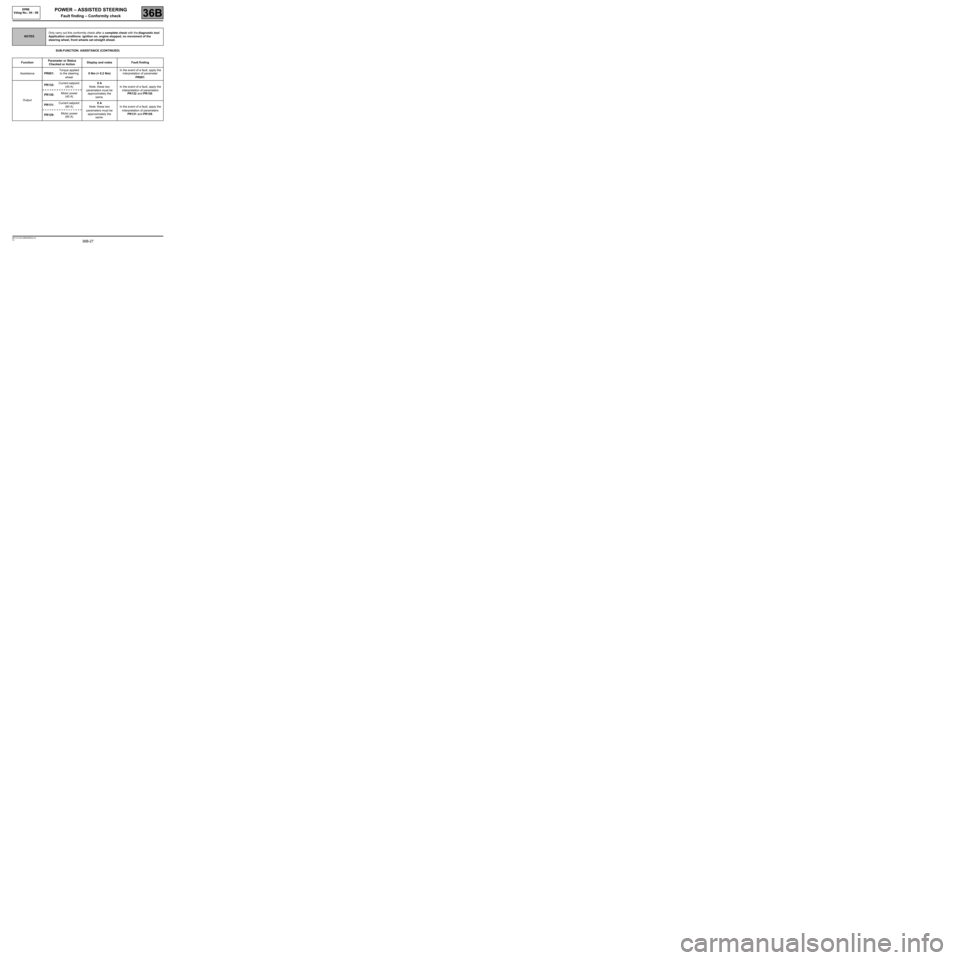

SUB-FUNCTION: ASSISTANCE (CONTINUED)

NOTESOnly carry out this conformity check after a complete check with the diagnostic tool.

Application conditions: ignition on, engine stopped, no movement of the

steering wheel, front wheels set straight ahead.

FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

AssistancePR001:Torque applied

to the steering

wheel0 Nm (+ 0.2 Nm)In the event of a fault, apply the

interpretation of parameter

PR001.

OutputPR132:Current setpoint

(45 A)0 A

Note: these two

parameters must be

approximately the

same.In the event of a fault, apply the

interpretation of parameters

PR132 and PR130.

PR130:Motor power

(45 A)

PR131:Current setpoint

(60 A)0 A

Note: these two

parameters must be

approximately the

same.In the event of a fault, apply the

interpretation of parameters

PR131 and PR129.

PR129:Motor power

(60 A)