sensor RENAULT TWINGO 2009 2.G Chasiss User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 281

Page 140 of 281

33A-42

REAR AXLE COMPONENTS

Complete rear axle system: Removal - Refitting

33A

2 - Refitting

aLower the lift.

aPosition the bearing centring devices (12) opposite

the centring holes.

aRefit the rear axle bearing bolts.

aTorque tighten the rear axle bearing bolts (62 Nm).

aRemove the safety strap(s).

aRaise the lift.

aRefit:

-the rear suspension springs (see 33A, Rear axle

components, Rear suspension spring: Remov-

al - Refitting, page 33A-28) ,

-the brake hose lower unions.

aTorque tighten the brake hose lower unions (17

Nm).

aConnect the ABS sensor connectors.

aClose the ABS sensor connector protective unit.

aClip the parking brake cables onto the reservoir.

aPosition the parking brake cables on the parking

brake compensator.

aCheck that the parking brake cable stops are proper-ly inserted in their housings.

III - FINAL OPERATION.

aAdjust the parking brake cables (see 37A, Mechan-

ical component controls, Parking brake lever:

Removal - Refitting, page 37A-46) .

aRefit the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

aRemove the pedal press.

aBleed the braking circuit (see 30A, General infor-

mation, Braking circuit: Bleed, page 30A-4) .

119651

Page 180 of 281

37A-1

MECHANICAL COMPONENT CONTROLS

Master cylinder: Removal - Refitting

JB1 or JH1 or JH3 or JR5

37A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the battery (see Battery: Removal - Refitting)

(80A, Battery)

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the injection computer (see Petrol injection com-

puter: Removal - Refitting) (17B, Petrol injection),

-the injection computer support.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the fuel filler cap from the brake fluid reser-

voir (1) .

aDisconnect the brake fluid level sensor connector (2)

.

aDrain the brake fluid reservoir with a syringe. Tightening torquesm

brake fluid reservoir bolt4 Nm

master cylinder nuts on

the brake servo25 Nm

rigid brake pipe unions

on the master cylinder15 Nm

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

K4M

121344

Page 182 of 281

37A-3

MECHANICAL COMPONENT CONTROLS

Master cylinder: Removal - Refitting

JB1 or JH1 or JH3 or JR5

37A

aUsing the workbench, remove:

-the brake fluid reservoir bolt (7) ,

-the brake fluid reservoir.

aFit blanking plugs on the master cylinder.

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace the master cylinder seals (8) .

aRemove the blanking plugs from the master cylin-

der.

aCarefully pre-fill the master cylinder with the recom-

mended brake fluid (see 30A, General information,

Brake fluid: Specifications, page 30A-18) .II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the brake fluid reservoir,

-the master cylinder making sure that the brake ser-

vo shaft is correctly aligned with the master cylin-

der shaft,

-the rigid brake pipe unions on the master cylinder.

aTighten to torque:

-the brake fluid reservoir bolt (4 Nm),

-the master cylinder nuts on the brake servo (25

Nm),

-the rigid brake pipe unions on the master cylin-

der (15 Nm).

aRemove the blanking plugs from the brake fluid res-

ervoir supply pipe and the clutch master cylinder.

aRefit the clutch master cylinder supply pipe.

aConnect the brake fluid level sensor connector.

III - FINAL OPERATION.

aRefit:

-the injection computer mounting,

-the injection computer (see Petrol injection com-

puter: Removal - Refitting) (17B, Petrol injection).

aFill up the brake fluid reservoir.

aBleed the braking circuit (see 30A, General infor-

mation, Braking circuit: Bleed, page 30A-4) .

aBleed the clutch circuit (see 37A, Mechanical com-

ponent controls, Clutch circuit: Bleed, page 37A-

54) .

aRefit:

-the filler cap of the brake fluid reservoir.

121345

112622

JH3 or JR5

K4M

JH3 or JR5

Page 185 of 281

37A-6

MECHANICAL COMPONENT CONTROLS

Master cylinder: Removal - Refitting

RIGHT-HAND DRIVE

37A

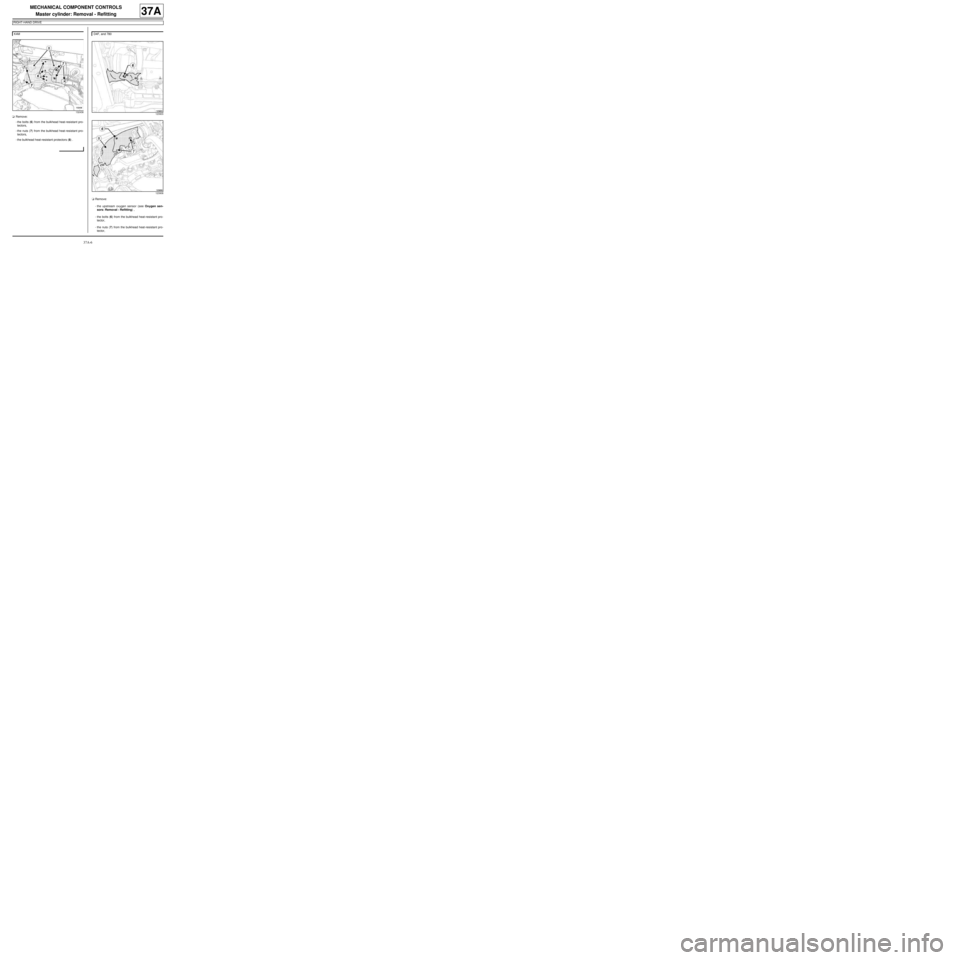

aRemove:

-the bolts (6) from the bulkhead heat-resistant pro-

tectors,

-the nuts (7) from the bulkhead heat-resistant pro-

tectors,

-the bulkhead heat-resistant protectors (8) .

aRemove:

-the upstream oxygen sensor (see Oxygen sen-

sors: Removal - Refitting) ,

-the bolts (6) from the bulkhead heat-resistant pro-

tector,

-the nuts (7) from the bulkhead heat-resistant pro-

tector, K4M

132436

D4F, and 780

123903

123908

Page 190 of 281

37A-11

MECHANICAL COMPONENT CONTROLS

Brake servo non-return valve: Removal - Refitting

RIGHT-HAND DRIVE

37A

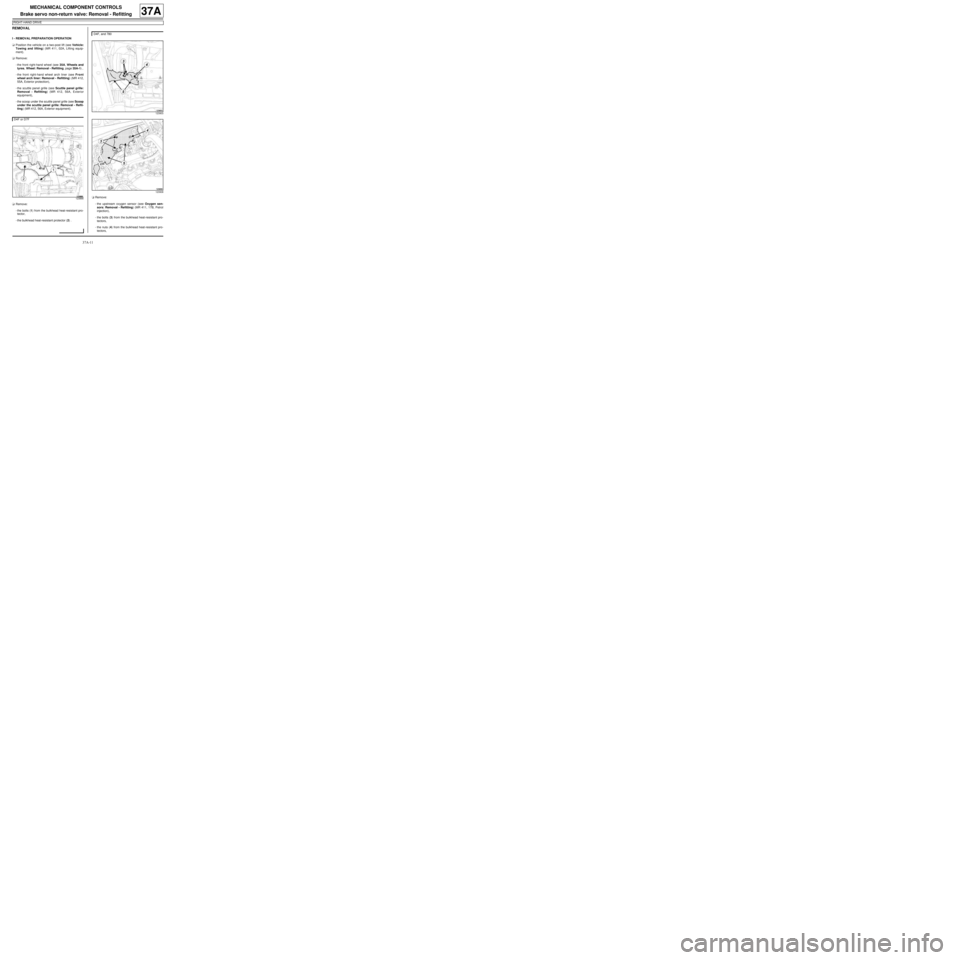

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove:

-the front right-hand wheel (see 35A, Wheels and

tyres, Wheel: Removal - Refitting, page 35A-1) ,

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (MR 412,

55A, Exterior protection),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (MR 412, 56A, Exterior

equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (MR 412, 56A, Exterior equipment).

aRemove:

-the bolts (1) from the bulkhead heat-resistant pro-

tector,

-the bulkhead heat-resistant protector (2) .aRemove:

-the upstream oxygen sensor (see Oxygen sen-

sors: Removal - Refitting) (MR 411, 17B, Petrol

injection),

-the bolts (3) from the bulkhead heat-resistant pro-

tectors,

-the nuts (4) from the bulkhead heat-resistant pro-

tectors, D4F or D7F

123866

D4F, and 780

123903

123908

Page 192 of 281

37A-13

MECHANICAL COMPONENT CONTROLS

Brake servo non-return valve: Removal - Refitting

RIGHT-HAND DRIVE

37A

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit the non-return valve.

aClip on the non-return valve.

aConnect the non-return valve pipe:

-to the brake servo,

-to the intake distributor.

II - FINAL OPERATION.

aRefit:

-the bulkhead heat-resistant protectors,

-the bulkhead heat-resistant protector nuts,

-the bulkhead heat-resistant protector bolts,

-the upstream oxygen sensor (see Oxygen sen-

sors: Removal - Refitting) .

aRefit:

-the bulkhead heat-resistant protector,

-the bulkhead heat-resistant protector bolts.

aRefit:

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (MR 412, 56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (MR 412, 56A, Exterior

equipment),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (MR 412,

55A, Exterior protection),

-the front right-hand wheel (see 35A, Wheels and

tyres, Wheel: Removal - Refitting, page 35A-1) . D4F, and 780

D4F or D7F

Page 274 of 281

38C-15

ANTI-LOCK BRAKING SYSTEM

Front wheel speed sensor: Removal - Refitting

38C

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove the front wheel (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .

aRemove the clip (1) .

aLift part of the front wheel arch liner (2) .

aUnclip the pin (3) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the front wheel speed sensor cable con-

nector (4) .

aUnclip the front wheel speed sensor cable at (5) and

(6) . Tightening torquesm

front wheel speed sen-

sor bolt8 Nm

121479

121478

121477

Page 275 of 281

38C-16

ANTI-LOCK BRAKING SYSTEM

Front wheel speed sensor: Removal - Refitting

38C

aRemove:

-the front wheel speed sensor bolt (7) ,

-the front wheel speed sensor.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the front wheel speed sensor,

-the front wheel speed sensor bolt.

aTorque tighten the front wheel speed sensor bolt

(8 Nm).

aConnect the front wheel speed sensor cable con-

nector.

aClip on the front wheel speed sensor cable.II - FINAL OPERATION.

aRefit the front wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

121477

WARNING

To avoid damaging the wheel speed sensor

cable:

-Do not tension the cable,

-Do not twist the cable,

-Check that there is no contact with the sur-

rounding components,

-Do not use tools that may damage the cable.

Page 276 of 281

38C-17

ANTI-LOCK BRAKING SYSTEM

Rear wheel speed sensor: Removal - Refitting

38C

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove the rear wheel (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aOpen the rear wheel speed sensor connector pro-

tection unit flap (1) .

aDisconnect the rear wheel speed sensor cable con-

nector (2) .aUnclip the rear wheel speed sensor cable at (3) and

(4) . Tightening torquesm

rear wheel speed sen-

sor bolt8 Nm

121476

121476

Page 277 of 281

38C-18

ANTI-LOCK BRAKING SYSTEM

Rear wheel speed sensor: Removal - Refitting

38C

aRemove:

-the rear wheel speed sensor bolt (5) ,

-the rear wheel speed sensor.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the rear wheel speed sensor,

-the rear wheel speed sensor bolt.

aTorque tighten the rear wheel speed sensor bolt (8

Nm).

aClip on the rear wheel speed sensor cable.

aConnect the rear wheel speed sensor cable connec-

tor.II - FINAL OPERATION.

aClose the rear wheel speed sensor connector pro-

tection unit flap.

aRefit the rear wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

121476

WARNING

To avoid damaging the wheel speed sensor

cable:

-Do not tension the cable,

-Do not twist the cable,

-Check that there is no contact with the sur-

rounding components,

-Do not use tools that may damage the cable.