wheel RENAULT TWINGO 2009 2.G Chasiss Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 281

Page 1 of 281

© Renault s.a.s 2007 "The repair procedures given by the manufacturer in this document are based on the

technical specifications current when it was prepared.

The procedures may be modified as a result of changes introduced by the manufacturer in

the production of the various component units and accessories from which the vehicles are

constructed".All rights reserved by Renault.

Copying or translating, in part or in full, of this document or use of the service part reference

numbering system is forbidden without the prior written authority of Renault.

NOVEMBER 2009 EDITION ANGLAISE

X44

3Chassis

30AGENERAL INFORMATION

31AFRONT AXLE COMPONENTS

33AREAR AXLE COMPONENTS

35AWHEELS AND TYRES

36ASTEERING ASSEMBLY

36BPOWER ASSISTED STEERING

37AMECHANICAL COMPONENT CONTROLS

38CANTI-LOCK BRAKING SYSTEM

Page 3 of 281

Contents

Radiator mounting cross

member: Removal - Refitting 31A-51

Front anti-roll bar: Removal -

Refitting 31A-52

33A REAR AXLE COMPONENTS

Rear brake pads: Removal -

Refitting 33A-1

Rear brake hose: Removal -

Refitting 33A-4

Rear brake calliper: Removal

- Refitting 33A-7

Rear brake calliper

mounting: Removal -

Refitting 33A-9

Rear brake disc: Removal -

Refitting 33A-11

Rear brake disc: Description 33A-13

Rear brake lining: Removal -

Refitting 33A-14

Rear brake cylinder:

Removal - Refitting 33A-17

Rear brake drum: Removal -

Refitting 33A-19

Rear brake drum:

Description 33A-21

Rigid brake pipe: Removal -

Refitting 33A-22

Shock absorber: Removal -

Refitting 33A-24

Rear suspension spring:

Removal - Refitting 33A-28

Rear drum bear ing: Removal

- Refitting 33A-30

Rear stub axle carr ier:

Removal - Refitting 33A-32

Complete rear axle system:

Removal - Refitting 33A-37 31A FRONT AXLE COMPONENTS

35A WHEELS AND TYRES

Wheel: Removal - Refitting 35A-1

Wheel: Balancing 35A-4

Tyres: Identification 35A-7

Tyres: Removal - Refi tting 35A-8

Tyre pressure: Identification 35A-10

Wheel r im: Identifi cation 35A-11

36A STEERING ASSEMBLY

Steering box: Removal -

Refitting 36A-1

Track rod: Removal -

Refitting 36A-2

Axial ball joint linkage:

Removal - Refitting 36A-4

Steering column: List and

location of components 36A-6

Steering column: Removal -

Refitting 36A-7

Steering box gaiter: Removal

- Refitting 36A-16

Bulkhead seal: Removal -

Refitting 36A-17

Intermediate shaft: Removal

- Refitting 36A-18

Steering column adjustment

handle: Removal - Refitting 36A-21

Steering wheel: Removal -

Refitting 36A-23

36B POWER ASSISTED STEERING

Power-assisted steering

computer: Removal -

Refitting 36B-1

Page 4 of 281

Contents

37A MECHANICAL COMPONENT CONTROLS

Master cylinder: Removal -

Refitting 37A-1

Brake servo non-return

valve: Removal - Refitting 37A-11

Brake servo: Remo val -

Refitting 37A-14

Vacuum pump: Removal -

Refitting 37A-25

Pedal assembly: List and

location of components 37A-27

Accelerator pedal: Removal -

Refitting 37A-29

Brake pedal: Removal -

Refitting 37A-31

Brake pedal switch: Removal

- Refitting 37A-42

Parking br ake lever: Removal

- Refitting 37A-46

Parking brake lever:

Adjustment 37A-48

Clutch control: List and

location of components 37A-49

Clutch cable: Removal -

Refitting 37A-51

Clutch pedal switch:

Removal - Refitting 37A-52

Clutch circuit: Bleed 37A-54

Clutch master cylinder:

Removal - Refitting 37A-61

Clutch circuit: Removal -

Refitting 37A-63

Manual gear control: List and

location of components 37A-65

Gear control unit: Removal -

Refitting 37A-67

Gear control unit: Adjustment 37A-71

Parking brake cables:

Removal - Refitting 37A-74

Brake servo: Check 37A-7838C ANTI-LOCK BRAKING SYSTEM

Hydraulic brake unit: List and

location of components 38C-1

Hydraulic brake unit:

Removal - Refitting 38C-2

Front wheel speed sensor:

Removal - Refitting 38C-15

Rear wheel speed sensor :

Removal - Refitting 38C-17

Lateral acceleration and yaw

sensor: Removal - Refitting 38C-19

Braking computer: Removal -

Refitting 38C-21

Page 6 of 281

30A-2

GENERAL INFORMATION

Brake circuit: Precautions for the repair

30A

I - SAFETY

1 - Advice to be followed before any operation

For an operation requiring the use of a lift, follow the

safety advice (see Vehicle: Towing and lifting) (02A,

Lifting equipment).

The brake regulation circuit must be free of all hydrau-

lic and electrical faults.

In case of incorrect handling, the brake fluid can cause

serious injury and damage. Follow the manufacturer's

instructions for brake fluid.

To prevent dust from entering the master cylinder res-

ervoir and the brake circuit, the plug must be removed

just before filling and closed immediately afterwards,

2 - Instructions to be followed during the operation

Do not press on the brake pedal during work on the

brake system.

If, during work on the brake system, any damage on

any part is observed, it must be repaired before driving

the vehicle again.

Brake fluid is highly corrosive. Ensure any brake fluid

spilt on parts of the vehicle is cleaned off.

Use brake fluids that comply with the Renault standard

(see Vehicle: Parts and consumables for the repair)

.

Check the brake fluid levels in the braking circuit and

the bleeding device.

Check that the pressure of the bleeding device is be-

tween 1.5 bar and 2 bar.

II - CLEANLINESS

1 - Advice to be followed before any operation

Protect any bodywork components that risk being dam-

aged by brake fluid with a cover.

2 - Instructions to be followed during the operation

Fit blanking plugs recommended for the Siemens K9K

injection system at the end of each pipe and in all the

openings of the disconnected components of the brake

circuit.

Clean around the braking system with BRAKE

CLEANER (see Vehicle: Parts and consumables

for the repair) (04B, Consumables - Products).Do not allow friction materials to come into contact with

grease, oil or other lubricants and cleaning products

which are mineral oil based.

III - GENERAL RECOMMENDATIONS

When replacing brake pads, always replace the pads

on the other side as well.

When replacing a disc, always replace the disc on the

opposite side.

When replacing brake discs, you must replace the

brake pads.

Always replace the rigid brake pipe clips.

Reminder:

-The pipes between the master cylinder, callipers and

the hydraulic assembly are connected using threaded

unions with a metric thread.

-Therefore, only parts specified in the Parts Catalogue

for this vehicle should be used. WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

WARNING

In order not to damage the brake hose:

-do not tension the hose,

-do not twist the hose,

-check that there is no contact with the surrounding

components, regardless of the position of the

wheels.

IMPORTANT

To avoid any accident, br ing the pistons, brake pads

and brake discs into contact by depressing the

brake pad several times.

Page 22 of 281

30A-18

GENERAL INFORMATION

Brake fluid: Specifications

30A

BRAKE FLUID REPLACEMENT INTERVAL

Our braking technology, and in particular the disc

brakes (hollow pistons which conduct little heat, have a

low volume of fluid in the cylinder, sliding callipers

avoiding the need for a fluid reserve in the least cooled

area of the wheel), has allowed us to prevent the risk of

« vapour lock » as far as possible, even with heavy

braking (mountainous area). However, current brake

fluids are subject to minor deterioration during the first

months of use due to slight humidity intake. This is why

it is recommended that you change the brake fluid: see

maintenance booklet for the vehicle.

1 - Topping up the level

Wear of the brake pads will result in a gradual drop in

the fluid level in the reservoir.

Do not top up the fluid, as the level will rise again when

the pads are next changed. The brake fluid level must

not fall below the minimum mark.

2 - Approved brake fluid

Mixing two incompatible brake fluids in the brake circuit

may lead to:

-serious risk of leakage due mainly to deterioration of

the cups,

-deterioration in the operation of the ESP system.

To prevent such risks, it is essential to use only brake

fluids that comply with the RENAULT standard (see

Vehicle: Parts and consumables for the repair) .

Page 25 of 281

30A-21

GENERAL INFORMATION

Steering: Tightening torque

30A

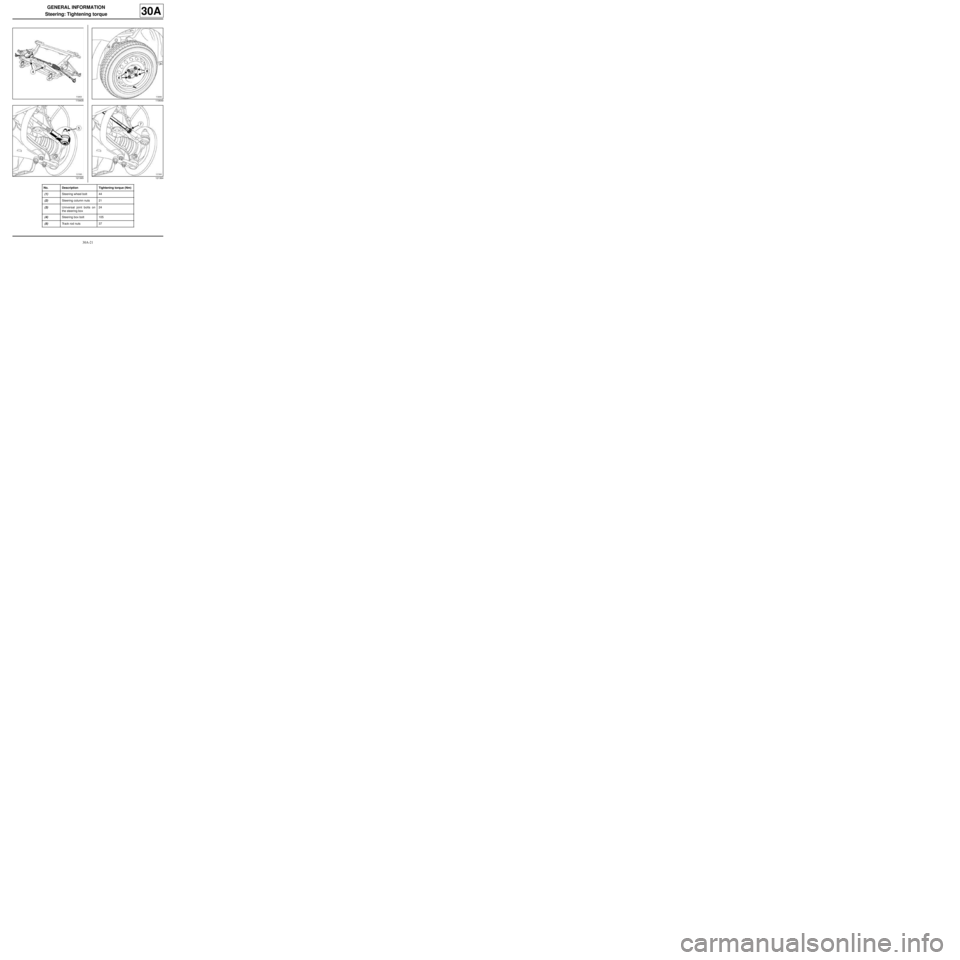

119405

121365119649

121364

No. Description Tightening torque (Nm)

(1) Steering wheel bolt 44

(2) Steering column nuts 21

(3) Universal joint bolts on

the steering box24

(4) Steering box bolt 105

(5) Track rod nuts 37

Page 26 of 281

30A-22

GENERAL INFORMATION

Steering: Tightening torque

30A

(6) Wheel bolt 105

(7) Wheel alignment lock nut 53 No. Description Tightening torque (Nm)

Page 27 of 281

30A-23

GENERAL INFORMATION

Axle assemblies: Check

30A

aLock the slip plates of the lift.

aPosition the vehicle on a lift (see Vehicle: Towing

and lifting) .

aCheck the condition of the following components:

-track rods,

-axial ball joint linkages,

-subframe,

-lower arm rubber bushes,

-lower arm ball joints (see Front driveshaft lower

arm ball joint: Check) ,

-shock absorbers,

-tyres,

aCheck:

-the tyre size (see 35A, Wheels and tyres, Tyres:

Identification, page 35A-7) ,

-the tyre inflation pressure (see 35A, Wheels and

tyres, Tyre pressure: Identification, page 35A-

10) .

aPut the vehicle in the VODM position (vehicle in run-

ning order) (see 30A, General information, Under-

body heights: Adjustment value, page 30A-24) :

-tank full,

-vehicle empty (without luggage, etc.).

aConsult:

-the front axle geometry values (see 30A, General

information, Front axle assembly: Adjustment

values, page 30A-31) ,

-the rear axle geometry values (see 30A, General

information, Rear axle assembly: Adjustment

values, page 30A-38) .

aRefer to the user manual for the geometry tester.

aCheck the geometry using the geometry tester.

aIf there is an inconsistency between the manufactur-

er's values and the measured values:

aAdjust the front axle (see 30A, General informa-

tion, Front axle system: Adjustment, page 30A-

36)

Page 28 of 281

30A-24

GENERAL INFORMATION

Underbody heights: Adjustment value

30A

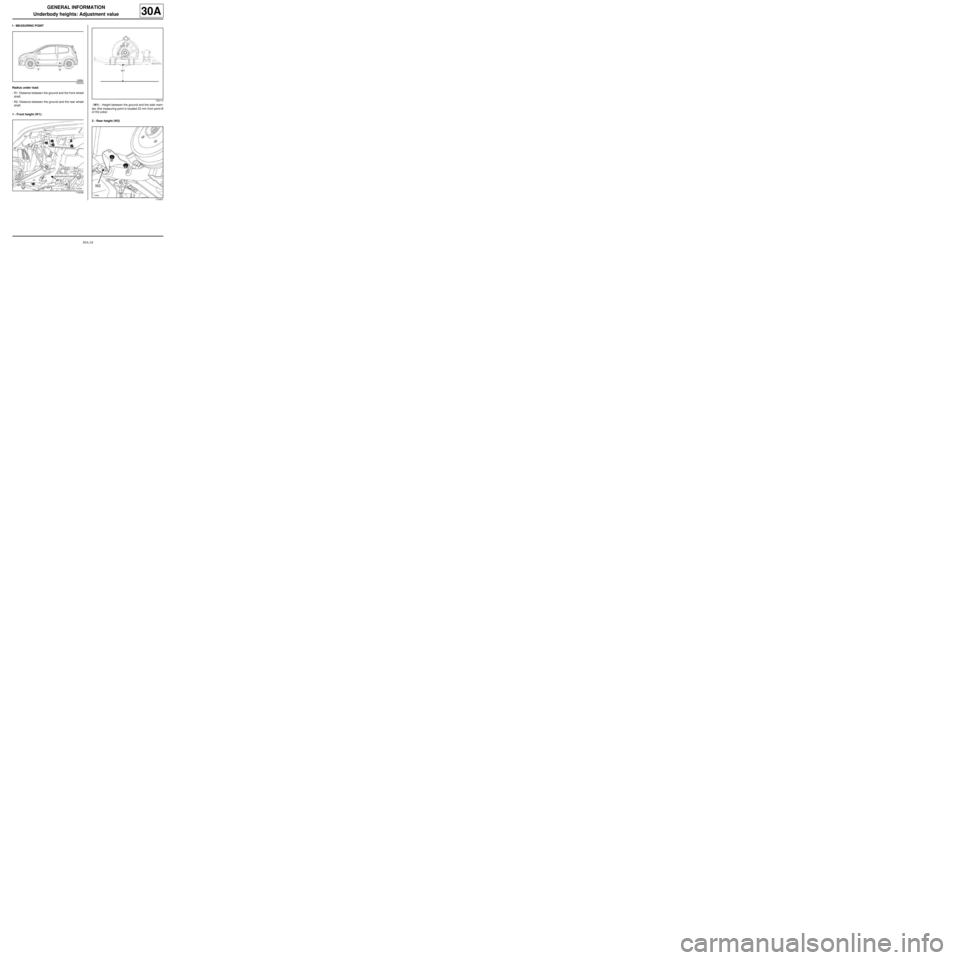

I - MEASURING POINT

Radius under load:

-R1: Distance between the ground and the front wheel

shaft.

-R2: Distance between the ground and the rear wheel

shaft.

1 - Front height (W1): (W1) : Height between the ground and the side mem-

ber (the measuring point is located 23 mm from point B

of the yoke)

2 - Rear height (W2)

132534

119336

139113

119401

Page 30 of 281

30A-26

GENERAL INFORMATION

Underbody heights: Adjustment value

30A

W1 = 158 mm ±± ± ±

8 mm

W2 = 270.7 mm ±± ± ±

12 mm

W1 = 163.5 mm ±± ± ±

8 mm

W2 = 275.1 mm ±± ± ±

12 mm

W1 = 157.7 mm ±± ± ±

8 mm

W2 = 270.3 mm ±± ± ±

12 mm EQUIPMENT LEVEL SPORT, and 16" ALUMIN-

IUM WHEELS

EQUIPMENT LEVEL SPORT, and 17" ALUMIN-

IUM WHEELS, and WITHOUT ADDITIONAL

SPORT PACK

EQUIPMENT LEVEL SPORT, and 17" ALUMIN-

IUM WHEELS, and ADDITIONAL EXTREME PACK

Note:

The position of the vehicle varies according to:

-the weight of the engine,

-the springs and shock absorbers,

-the tyres,

-the amount of fuel in the tank.